Industrial glass breaking equipment plays a crucial role in various industries, from architectural glass manufacturing to automotive glass production. As technology advances, the features and capabilities of these machines continue to evolve. In this comprehensive guide, we'll explore the essential features that modern industrial glass breakers should possess to ensure efficiency, precision, and safety in glass processing operations.

Essential Specifications for Effective Glass Breaking

When considering industrial glass breaking equipment, several key specifications are vital for optimal performance:

- Precision Control: Advanced control systems that allow for precise adjustment of breaking force and speed are essential. This ensures consistent and accurate breaks, reducing waste and improving product quality.

- Versatility: The ability to handle various glass thicknesses and types is crucial. A versatile machine can adapt to different production needs, from thin smartphone screens to thick architectural glass panels.

- Automation Capabilities: Automated features such as glass positioning, scoring, and breaking can significantly increase productivity and reduce human error.

- Durability: Industrial glass breakers should be constructed with high-quality materials to withstand continuous operation in demanding production environments.

- Energy Efficiency: Modern equipment should incorporate energy-saving technologies to reduce operational costs and environmental impact.

These specifications ensure that the glass breaking process is not only efficient but also produces high-quality results consistently. For instance, precision control allows manufacturers to create intricate designs for smart mirrors, while versatility enables the same machine to handle large architectural glass sheets from an industrial glass-breaking equipment factory.

Built-in Dust Control and Safety Guards

Safety and cleanliness are paramount in glass processing. Industrial glass breakers should incorporate robust safety features and dust control mechanisms:

- Dust Extraction Systems: Integrated vacuum or suction systems that capture glass particles during the breaking process, maintaining a clean work environment and protecting workers' respiratory health.

- Safety Enclosures: Transparent, shatter-resistant enclosures that contain glass fragments and protect operators from potential injuries.

- Emergency Stop Mechanisms: Easily accessible emergency stop buttons that immediately halt all machine operations in case of a safety concern.

- Noise Reduction Features: Sound-dampening technologies to minimize noise pollution in the workplace, enhancing operator comfort and compliance with occupational health standards.

- Ergonomic Design: Thoughtful layout and design that reduce operator fatigue and minimize the risk of repetitive strain injuries.

These safety features not only protect workers but also contribute to a more efficient industrial glass-breaking equipment factory production process. By minimizing downtime due to accidents or clean-up, manufacturers can maintain high productivity levels while ensuring a safe working environment.

Choosing Features Based on Processing Requirements

The specific features needed in an industrial glass breaker can vary depending on the intended application. Here are some considerations for different glass processing requirements:

- Architectural Glass:

- Large-format handling capabilities for oversized panels

- Multi-axis cutting for complex shapes

- Edge deletion systems for coated glass

- Automotive Glass:

- High-precision scoring and breaking for curved windshields

- Automated shape recognition for various vehicle models

- Integration with robotic handling systems

- Smart Mirror Production:

- Ultra-smooth edge finishing capabilities

- Compatibility with thin glass substrates

- Integration with coating and lamination processes

- Specialty Glass:

- Adaptability to unique glass compositions

- Custom tooling options for non-standard shapes

- Variable pressure control for delicate materials

By selecting equipment with features tailored to specific processing requirements, manufacturers can optimize their production line for maximum efficiency and quality output. For example, a facility specializing in automotive glass would benefit from machines with curved glass handling capabilities and precise edge finishing options.

When evaluating industrial glass-breaking equipment, it's crucial to consider not only the immediate needs but also future production goals. Investing in versatile machinery that can adapt to changing market demands can provide long-term value and a competitive advantage.

Advanced Technology Integration

Modern industrial glass breakers are increasingly incorporating advanced technologies to enhance their capabilities:

- IoT Connectivity: Integration with Industrial Internet of Things (IIoT) systems for real-time monitoring, predictive maintenance, and data analytics.

- Machine Learning Algorithms: AI-powered systems that can optimize breaking patterns and pressure based on glass characteristics and desired outcomes.

- Computer Vision: High-resolution cameras and image processing software for quality control and defect detection.

- Digital Twin Technology: Virtual representations of the glass-breaking process for simulation and optimization before physical production.

These technological advancements not only improve the precision and efficiency of industrial glass breaking equipment factory operations but also provide valuable insights for continuous process improvement. For instance, IoT connectivity allows manufacturers to monitor equipment performance across multiple production lines, identifying bottlenecks and optimizing workflows.

Customization and Flexibility

The ability to customize and adapt industrial glass breakers to specific production needs is becoming increasingly important:

- Modular Design: Equipment that can be easily reconfigured or upgraded to accommodate new glass types or production requirements.

- Customizable User Interfaces: Intuitive touchscreen controls that can be tailored to specific operator preferences and production workflows.

- Interchangeable Tools: Quick-change tooling systems that allow for rapid adaptation to different glass thicknesses or breaking patterns.

- Scalability: The ability to integrate with existing production lines or scale up for increased capacity.

Customization options ensure that industrial glass breaking equipment can be fine-tuned to meet the unique needs of each manufacturer, maximizing productivity and quality output. For example, a modular design allows facilities to start with basic functionalities and add advanced features as their production needs evolve.

Environmental Considerations

As sustainability becomes a greater focus in manufacturing, industrial glass breakers should incorporate environmentally friendly features:

- Energy-Efficient Motors: High-efficiency electric motors that reduce power consumption without compromising performance.

- Waste Reduction Systems: Precision cutting and breaking technologies that minimize glass waste and optimize material usage.

- Recycling Integration: Built-in systems for collecting and sorting glass waste for recycling purposes.

- Water Conservation: Closed-loop cooling systems that minimize water usage in wet cutting processes.

These environmental features not only contribute to sustainability goals but can also lead to significant cost savings through reduced energy consumption and improved resource utilization. Manufacturers investing in eco-friendly industrial glass-breaking equipment often find themselves at a competitive advantage in markets where environmental consciousness is valued.

After-Sales Support and Maintenance

While not a physical feature of the equipment itself, comprehensive after-sales support is crucial when selecting industrial glass breakers:

- Remote Diagnostics: Built-in systems that allow for remote troubleshooting and software updates, minimizing downtime.

- Predictive Maintenance: AI-driven systems that can predict when components are likely to fail, allowing for proactive maintenance.

- Training Programs: Comprehensive operator and maintenance training to ensure optimal equipment utilization.

- Spare Parts Availability: Quick access to genuine spare parts to minimize production interruptions.

- Warranty and Service Agreements: Robust warranty coverage and flexible service plans to protect the investment.

Effective after-sales support ensures that industrial glass-breaking equipment maintains peak performance throughout its lifecycle, maximizing return on investment and minimizing costly downtime.

Conclusion

The features of industrial glass breakers have a significant impact on the efficiency, quality, and safety of glass processing operations. From precision control and automation to advanced safety features and environmental considerations, modern glass-breaking equipment must meet a wide range of requirements to stay competitive in today's market.

When selecting industrial glass breaking equipment, it's essential to consider not only current production needs but also future scalability and technological advancements. By choosing equipment with the right combination of features, manufacturers can enhance their production capabilities, improve product quality, and maintain a competitive edge in the ever-evolving glass industry.

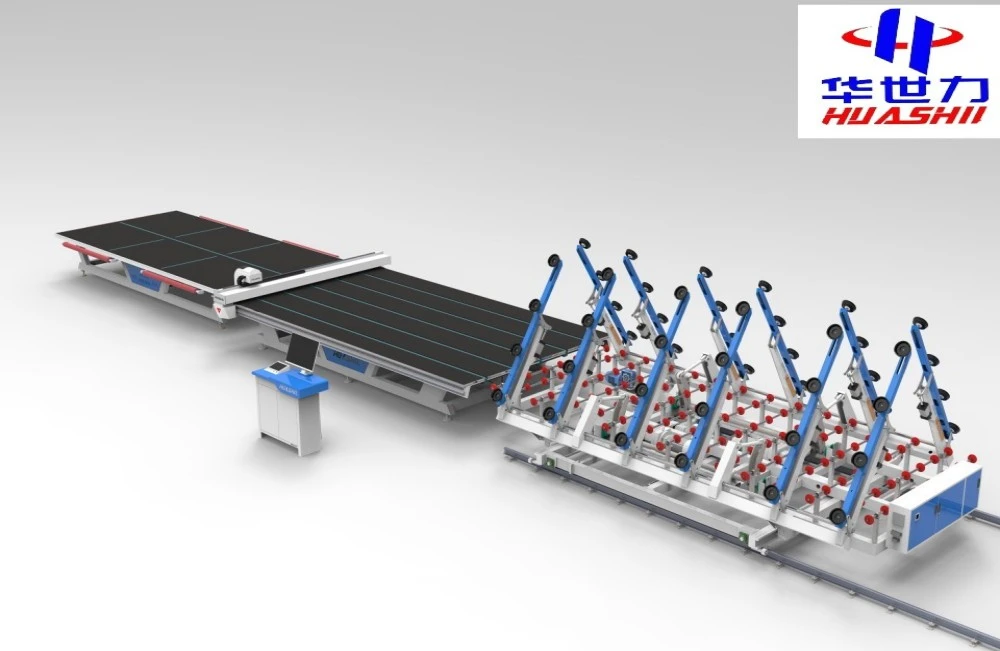

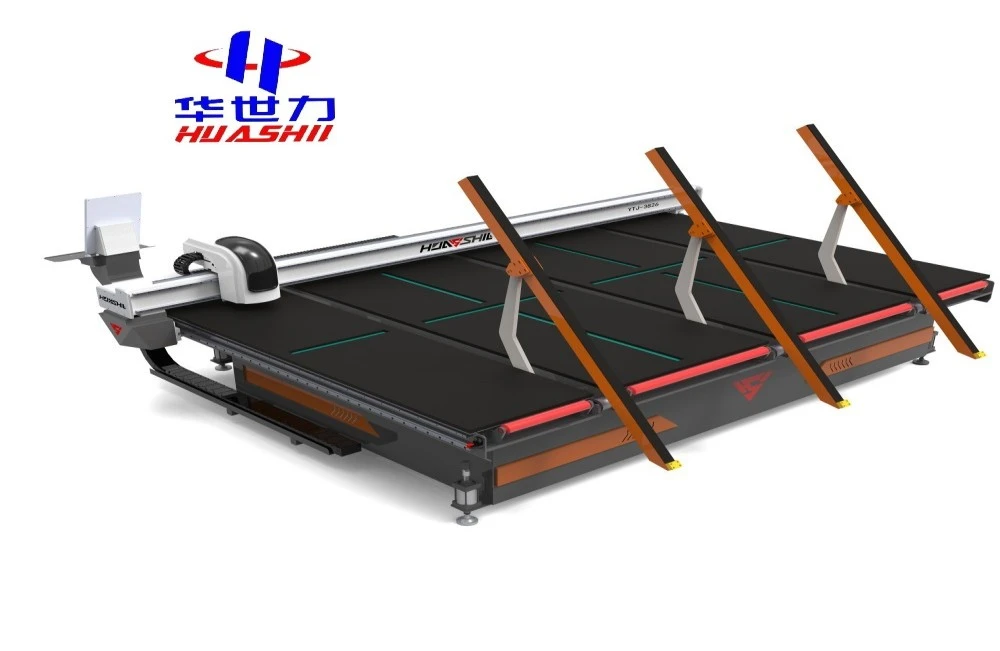

Call to Action: Are you looking to upgrade your glass processing capabilities with state-of-the-art industrial glass breaking equipment? Shandong Huashil Automation Technology Co., Ltd. offers cutting-edge solutions tailored to your specific needs. With years of experience in R&D, manufacturing, and sales of automated mechanical equipment, we provide advanced technology, stable quality, and excellent service that our global customers trust. Contact us today to discover how our industrial glass breakers can revolutionize your production line and help you stay ahead in the competitive glass industry. Let's work together to enhance your manufacturing efficiency and product quality!

FAQ

Q1: How does the thickness of glass affect the choice of industrial glass-breaking equipment?

A: Glass thickness is a crucial factor in selecting the appropriate industrial glass breaking equipment. Thicker glass requires more breaking force and may necessitate specialized tooling. Equipment designed for a wide range of thicknesses typically features adjustable breaking pressure and interchangeable tools to accommodate various glass types. When choosing a glass breaker, ensure it has the capability to handle your specific thickness requirements, from thin display glass to thick architectural panels.

Q2: Can industrial glass breakers handle tempered glass?

A: Most standard industrial glass breakers are not designed to handle tempered glass. Tempered glass is significantly stronger than annealed glass and is designed to shatter into small, relatively harmless pieces when broken. Attempting to break tempered glass with equipment designed for annealed glass can be dangerous and ineffective. Specialized equipment, often using thermal shock methods, is required for processing tempered glass. Always consult with the equipment manufacturer to ensure compatibility with tempered glass if this is a requirement for your production.

Q3: How important is automation in modern industrial glass-breaking equipment?

A: Automation is increasingly crucial in modern industrial glass-breaking equipment. It offers several significant benefits:

- Increased Productivity: Automated systems can operate continuously with minimal human intervention, significantly increasing output.

- Improved Precision: Automated breaking ensures consistent quality and reduces human error.

- Enhanced Safety: By reducing manual handling, automation minimizes the risk of workplace injuries.

- Cost Efficiency: While initial investment may be higher, automation often leads to lower long-term operational costs through reduced labor and improved efficiency.

- Data Collection: Automated systems can collect valuable production data for analysis and process improvement.

The level of automation needed depends on production volume, quality requirements, and available workforce. Many manufacturers find that investing in automated glass-breaking equipment provides a significant competitive advantage.

Q4: What maintenance is typically required for industrial glass-breaking equipment?

A: Regular maintenance is essential for the longevity and optimal performance of industrial glass-breaking equipment. Typical maintenance tasks include:

- Daily cleaning of glass debris and dust

- Regular lubrication of moving parts

- Inspection and replacement of wear items, such as cutting wheels or breaking bars

- Calibration of sensors and control systems

- Software updates for computerized systems

- Inspection of safety features and guarding

The specific maintenance schedule depends on the equipment model, usage intensity, and manufacturer recommendations. Many modern machines include self-diagnostic capabilities and predictive maintenance features to help optimize the maintenance schedule and prevent unexpected downtime.

High-Performance Industrial Glass Breaking Equipment | HUASHIL

Ready to elevate your glass processing capabilities? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art industrial glass breaking equipment designed to meet the most demanding production requirements. Our advanced machines feature precision control, robust safety systems, and customizable options to suit your specific needs. With a focus on innovation and quality, we provide reliable solutions that enhance productivity and product quality.

Don't let outdated equipment hold back your production potential. Contact us today at salescathy@sdhuashil.com to discuss how our industrial glass breaking equipment can transform your manufacturing process. Our team of experts is ready to provide personalized recommendations and support to ensure you get the most out of your investment. Take the first step towards optimizing your glass processing operations – reach out now and discover the HUASHIL difference!

References

1. Smith, J. (2023). "Advancements in Industrial Glass Processing Technology". Journal of Glass Engineering, 45(2), 112-128.

2. Johnson, A. & Lee, S. (2022). "Safety Innovations in Glass Manufacturing Equipment". Industrial Safety Quarterly, 18(4), 78-92.

3. Zhang, Y. et al. (2023). "Energy Efficiency in Modern Glass Breaking Systems: A Comparative Study". Sustainable Manufacturing Review, 9(3), 201-215.

4. Brown, R. (2022). "The Impact of Automation on Quality Control in Glass Production". International Journal of Manufacturing Technology, 56(1), 33-47.