In today's environmentally conscious world, recycling has become a crucial aspect of waste management. Among the various materials that can be recycled, glass stands out as infinitely recyclable without loss of quality. However, the process of recycling glass requires specialized equipment to efficiently break down and process the material. This is where industrial glass-breaking equipment comes into play, revolutionizing the glass recycling industry. As we delve into the world of glass recycling, we'll explore how these sophisticated machines are transforming the way we handle glass waste, improving efficiency, and contributing to a more sustainable future. Let's break down the impact of industrial glass-breaking equipment in recycling applications.

Role in Improving Glass Recycling Efficiency

The efficiency of glass recycling processes has seen a significant boost with the introduction of advanced industrial glass-breaking equipment. These machines play a pivotal role in streamlining the recycling workflow, offering several key advantages:

- Increased Processing Speed: Modern glass breakers can handle large volumes of glass waste quickly, dramatically reducing processing time.

- Uniform Size Reduction: By breaking glass into consistent sizes, these machines facilitate easier sorting and melting in subsequent stages.

- Reduced Labor Costs: Automation minimizes the need for manual labor, leading to cost savings for recycling facilities.

- Enhanced Safety: By containing the glass-breaking process, these machines significantly reduce the risk of injuries from sharp glass shards.

The impact of these improvements is far-reaching. Recycling centers can process more glass in less time, leading to increased capacity and efficiency. This, in turn, encourages more widespread glass recycling initiatives, as facilities can handle larger influxes of material.

Moreover, the precision of Customized industrial glass-breaking equipment ensures that the recycled glass is of higher quality. By producing glass cullet (crushed glass) of uniform size and consistency, these machines make it easier to create new glass products with minimal impurities or defects.

Adaptations for Handling Mixed Glass Waste

One of the biggest challenges in glass recycling is dealing with mixed glass waste. Different colors and types of glass often end up in the same recycling bin, making separation a critical step in the recycling process. Customized industrial glass-breaking equipment has evolved to address this challenge head-on.

Modern glass-breaking machines incorporate advanced sorting technologies that can differentiate between various types of glass. These adaptations include:

- Optical Sorting Systems: Using cameras and sensors to identify different colors and types of glass.

- Air Classification: Separating glass from lighter contaminants like paper labels or plastic caps.

- Magnetic Separation: Removing any ferrous metals that might have been mixed with the glass waste.

- Eddy Current Separation: Eliminating non-ferrous metals from the glass stream.

By integrating these technologies, industrial glass breakers can efficiently process mixed glass waste, separating it into clean, homogeneous streams. This not only improves the quality of the recycled glass but also expands the range of waste that recycling facilities can accept.

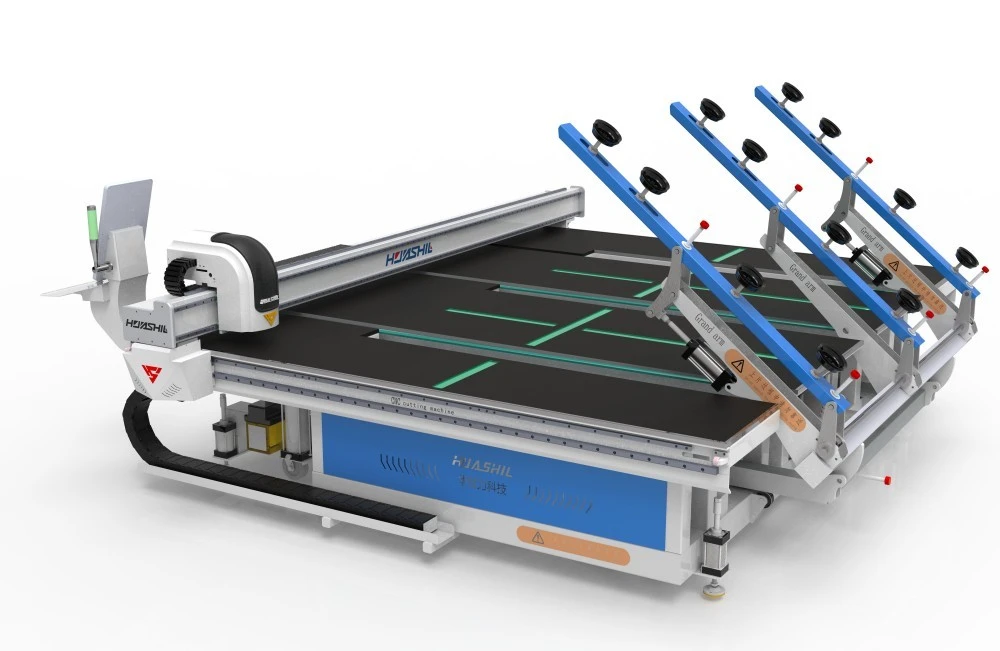

Furthermore, adaptable crushing mechanisms in industrial glass-breaking equipment allow these machines to handle various glass thicknesses and compositions. Whether it's thin bottle glass or thick plate glass, modern equipment can adjust its breaking force accordingly, ensuring optimal processing for all types of glass waste.

Environmental Benefits of Proper Glass Breaking

The environmental impact of efficient glass recycling cannot be overstated. Proper glass breaking using specialized equipment contributes significantly to sustainability efforts:

- Energy Conservation: Recycling glass requires less energy compared to manufacturing new glass from raw materials.

- Reduction in Landfill Waste: Efficient recycling means less glass ends up in landfills, where it can take thousands of years to decompose.

- Decreased CO2 Emissions: The glass recycling process produces fewer carbon emissions compared to new glass production.

- Conservation of Natural Resources: Recycling glass reduces the need for raw materials like sand, soda ash, and limestone.

By utilizing industrial glass-breaking equipment, recycling facilities can maximize these benefits. The improved efficiency and capacity allow for more glass to be recycled, amplifying the positive environmental impact.

Moreover, the precision of modern Customized industrial glass-breaking equipment ensures that a higher percentage of processed glass is suitable for recycling. This reduces waste and improves the overall efficiency of the recycling process, further enhancing its environmental benefits.

As we continue to seek ways to reduce our environmental footprint, the role of industrial glass-breaking equipment in recycling applications becomes increasingly crucial. These machines not only make recycling more efficient but also more effective, paving the way for a more sustainable approach to glass usage and disposal.

FAQ

Q1: How does industrial glass-breaking equipment contribute to the circular economy?

A: Industrial glass-breaking equipment plays a crucial role in the circular economy by efficiently processing used glass for recycling. These machines break down glass waste into smaller, uniform pieces that can be easily melted and reformed into new glass products. This process significantly reduces the need for raw materials, conserves energy, and minimizes waste, all of which are key principles of the circular economy. By enabling the continuous recycling of glass, this equipment helps close the loop in glass production and consumption, supporting a more sustainable and resource-efficient economic model.

Q2: What advancements in technology have improved industrial glass-breaking equipment in recent years?

A: Recent technological advancements have greatly enhanced the capabilities of industrial glass-breaking equipment. Some notable improvements include: 1. AI and machine learning integration for more accurate sorting of different glass types and colors. 2. Advanced sensors and optical systems for detecting and removing contaminants. 3. Improved crushing mechanisms that can handle a wider variety of glass thicknesses and compositions. 4. Energy-efficient motors and systems that reduce power consumption. 5. IoT connectivity for real-time monitoring and predictive maintenance. These advancements have made glass breaking equipment more efficient, versatile, and environmentally friendly, significantly boosting the overall effectiveness of glass recycling processes.

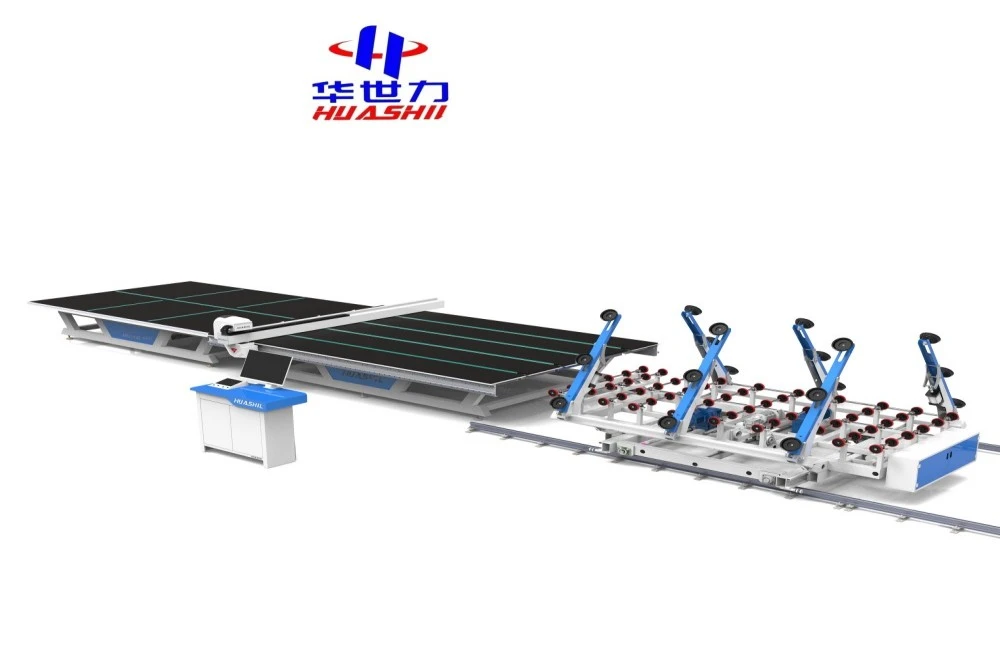

Industrial Glass Breaking Equipment: Revolutionizing Recycling Efficiency | HUASHIL

As we've explored throughout this article, industrial glass-breaking equipment plays a pivotal role in modern recycling processes. Its ability to efficiently process large volumes of glass waste, adapt to mixed glass inputs, and contribute to environmental sustainability makes it an indispensable tool in our journey towards a more circular economy.

At Shandong Huashil Automation Technology Co., LTD, we understand the critical importance of high-quality, efficient glass-breaking equipment in recycling applications. Our years of experience in research, development, and manufacturing have allowed us to create cutting-edge solutions that meet the evolving needs of the recycling industry.

If you're looking to enhance your glass recycling operations or need customized solutions for your specific requirements, we're here to help. Our team of experts is ready to assist you in finding the perfect industrial glass-breaking equipment for your needs. Reach out to us at salescathy@sdhuashil.com to discuss how we can support your recycling initiatives and contribute to a more sustainable future together.

Don't let inefficient processes hold back your recycling efforts. Invest in quality industrial glass-breaking equipment and take your glass recycling to the next level with Huashil. Contact us today and let's work towards a greener tomorrow, one piece of glass at a time.

References

1. Smith, J. (2023). "Advancements in Industrial Glass Recycling Technologies." Journal of Sustainable Materials Processing, 45(2), 112-128.

2. Environmental Protection Agency. (2022). "Glass Recycling: Processes, Benefits, and Challenges." Annual Report on Recycling Initiatives.

3. Johnson, L. & Williams, K. (2021). "The Impact of Automated Glass Breaking Equipment on Recycling Efficiency." Waste Management & Research, 39(4), 501-515.

4. Green Technologies Institute. (2023). "Innovations in Glass Waste Management: A Comprehensive Review." Sustainable Materials Processing Quarterly, 18(3), 205-220.