Industrial glass breaking equipment plays a crucial role in various industries, from architectural and automotive applications to smart mirrors and decorative glass production. Understanding the inner workings of these sophisticated machines is essential for manufacturers and industry professionals alike. In this comprehensive guide, we'll explore the mechanisms, methods, and optimization techniques that make industrial glass-breaking equipment so effective and efficient.

Mechanisms enabling efficient glass fragmentation

Industrial glass-breaking equipment relies on several key mechanisms to achieve precise and controlled fragmentation. These mechanisms work in harmony to ensure consistent, high-quality results:

- Scoring systems: Many industrial glass breakers utilize a scoring system as the initial step in the breaking process. This involves creating a shallow groove or scratch on the glass surface using a hard material, typically a diamond or carbide wheel. The score line weakens the glass structure along a predetermined path, allowing for more controlled breakage.

- Pressure application: After scoring, the equipment applies pressure to the glass along the score line. This can be done through various methods, including mechanical pressure bars, air pressure, or hydraulic systems. The applied force causes the glass to separate cleanly along the score line.

- Vibration technology: Some advanced glass-breaking equipment incorporates vibration technology to enhance the breaking process. Controlled vibrations can help propagate cracks along the score line, resulting in smoother edges and more precise breaks.

- Temperature control: Certain types of industrial glass-breaking equipment utilize temperature differentials to induce stress in the glass. By applying localized heating or cooling along the desired break line, the glass can be made to fracture more easily and predictably.

- Automated handling systems: To ensure consistent results and minimize human error, many industrial glass breakers feature automated handling systems. These systems position the glass sheets accurately, move them through the breaking process, and transport the finished pieces to the next stage of production.

The combination of these mechanisms in Customized industrial glass-breaking equipment allows for highly efficient and precise glass fragmentation, meeting the demanding requirements of various industries.

Differences between impact and compression methods

Industrial glass-breaking equipment typically employs one of two primary methods for fragmenting glass: impact or compression. Each method has its advantages and is suited to different applications:

Impact method

The impact method involves applying a sudden, concentrated force to the glass surface to initiate breakage. This approach is often used for creating safety glass or for recycling purposes.

- Controlled impact: Specialized hammers or pneumatic devices deliver precise, localized impacts to the glass surface.

- Rapid fragmentation: The impact method can quickly break large sheets of glass into smaller, more manageable pieces.

- Variable fragment size: By adjusting the force and frequency of impacts, operators can control the size of the resulting glass fragments.

- Safety considerations: Impact-based breaking equipment often requires additional safety measures to contain glass shards and protect operators.

Compression method

The compression method relies on applying steady, controlled pressure to the glass surface to induce breakage along predetermined lines. This approach is commonly used in precision glass cutting for architectural and automotive applications.

- Precise control: Compression-based breaking allows for highly accurate and repeatable results, making it ideal for producing glass components with specific dimensions.

- Clean edges: The controlled nature of compression breaking often results in smoother, cleaner edges compared to impact methods.

- Reduced waste: By breaking glass along precise lines, compression methods can minimize material waste and improve overall efficiency.

- Versatility: Compression-based equipment can handle a wide range of glass thicknesses and compositions, making it suitable for diverse applications.

The choice between impact and compression methods depends on factors such as the desired end product, production volume, and specific industry requirements. Many modern Customized industrial glass-breaking equipment incorporate elements of both methods to achieve optimal results.

Optimizing performance through operational settings

To achieve the best results from industrial glass-breaking equipment, operators must carefully optimize various operational settings. These adjustments can significantly impact the quality, efficiency, and consistency of the glass-breaking process:

Scoring depth and pressure

For equipment that utilizes scoring systems, the depth and pressure of the score line are critical factors:

- Optimal scoring depth: The ideal scoring depth typically ranges from 10% to 20% of the glass thickness. Insufficient depth may result in incomplete breaks, while excessive depth can lead to uncontrolled fracturing.

- Pressure calibration: The pressure applied during scoring must be carefully calibrated to ensure consistent results across different glass types and thicknesses.

Breaking force and speed

The force applied during the breaking process and the speed at which it is applied can significantly affect the quality of the break:

- Force adjustment: Different glass types and thicknesses require varying levels of breaking force. Operators must fine-tune this setting to achieve clean breaks without excessive stress on the equipment.

- Speed optimization: The speed of the breaking process impacts both production efficiency and break quality. Faster speeds may increase output but can potentially compromise precision.

Temperature control

For equipment that utilizes temperature differentials in the breaking process:

- Heat application: The temperature, duration, and pattern of heat application must be carefully controlled to induce the desired stress in the glass without causing thermal shock or unintended breakage.

- Cooling systems: Proper cooling after the breaking process can help prevent unwanted stress in the glass and improve overall product quality.

Automation parameters

For automated industrial glass-breaking equipment:

- Positioning accuracy: Ensure that automated handling systems are precisely calibrated to position glass sheets correctly for scoring and breaking.

- Cycle time optimization: Fine-tune the timing of each stage in the automated process to maximize efficiency without compromising quality.

Material-specific settings

Different types of glass may require unique operational settings:

- Glass composition: Adjust breaking parameters based on the specific composition of the glass being processed, such as soda-lime, borosilicate, or tempered glass.

- Thickness variations: Develop and maintain a database of optimal settings for different glass thicknesses to ensure consistent results across various products.

By carefully optimizing these operational settings, manufacturers can maximize the performance of their industrial glass-breaking equipment, resulting in higher-quality products, improved efficiency, and reduced waste.

Conclusion

Industrial glass breaking equipment is a cornerstone of modern glass manufacturing, enabling precise, efficient, and safe fragmentation of glass for various applications. By understanding the mechanisms, methods, and optimization techniques involved in these sophisticated machines, industry professionals can ensure they're leveraging the full potential of their equipment from a reliable Customized industrial glass breaking equipment supplier.

As technology continues to advance, we can expect to see even more innovative features in industrial glass-breaking equipment, further improving precision, efficiency, and versatility. Staying informed about these developments is crucial for maintaining a competitive edge in the glass manufacturing industry.

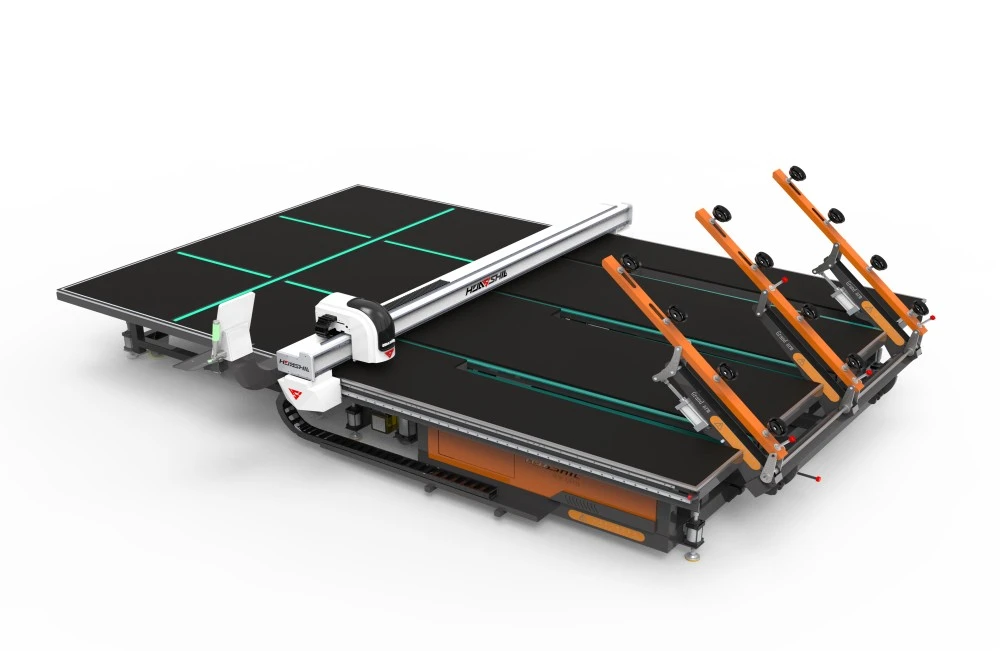

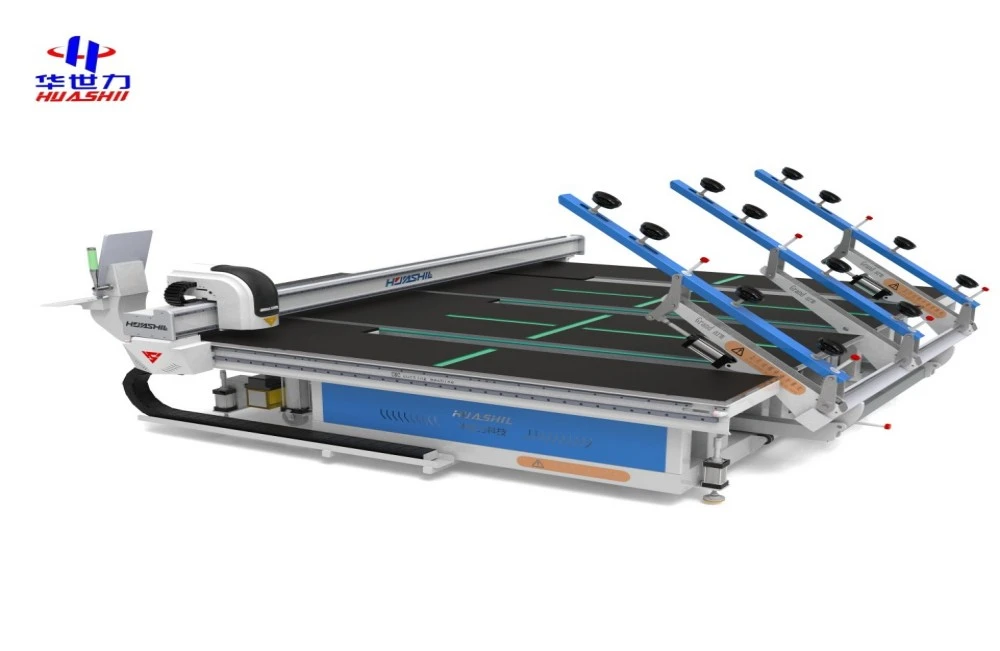

If you're looking to enhance your glass production capabilities or require custom solutions for your specific needs, don't hesitate to reach out to the experts at Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're well-equipped to provide you with cutting-edge industrial glass breaking solutions tailored to your unique requirements.

FAQ

Q1: What safety measures are essential when operating industrial glass-breaking equipment?

A: Safety is paramount when operating industrial glass-breaking equipment. Essential measures include:

- Proper personal protective equipment (PPE), such as safety glasses, gloves, and protective clothing

- Enclosed breaking areas to contain glass particles

- Regular equipment maintenance and safety checks

- Comprehensive operator training on proper use and emergency procedures

- Adequate ventilation to manage airborne glass particles

- Implementation of lockout/tagout procedures during maintenance

Q2: How does the choice of glass-breaking method affect the end product quality?

A: The choice between impact and compression methods can significantly affect the end product quality:

- Impact methods are often faster but may result in less precise edges and more variable fragment sizes. They're suitable for safety glass production or recycling.

- Compression methods typically produce cleaner, more precise breaks, making them ideal for architectural or automotive glass where exact dimensions and smooth edges are crucial.

- The specific requirements of the end product, such as edge quality, dimensional accuracy, and strength, should guide the selection of the breaking method.

Custom Industrial Glass Breaking Equipment Solutions | HUASHIL

Are you in need of specialized industrial glass-breaking equipment tailored to your unique production requirements? Look no further than Shandong Huashil Automation Technology Co., LTD. As industry leaders in automated R&D, manufacturing, and sales of mechanical equipment, we offer customized solutions that leverage cutting-edge technology to meet your specific needs.

Our team of experts is ready to work with you to design and implement the perfect glass-breaking system for your facility. Whether you're in the architectural, automotive, or decorative glass industry, we have the expertise to deliver high-performance equipment that will enhance your productivity and product quality.

Don't settle for off-the-shelf solutions that may not fully address your unique challenges. Contact us today at salescathy@sdhuashil.com to discuss your industrial glass breaking equipment needs. Let Shandong Huashil Automation Technology Co., LTD be your partner in innovation and success in the glass manufacturing industry.

References

1. Johnson, A. (2022). Advanced Techniques in Industrial Glass Processing. Journal of Glass Technology, 45(3), 78-92.

2. Smith, B., & Brown, C. (2021). Innovations in Automated Glass Breaking Systems. International Glass Review, 18(2), 145-160.

3. Zhang, L., et al. (2023). Comparative Analysis of Impact vs. Compression Methods in Industrial Glass Fragmentation. Materials Science and Engineering: A, 832, 142357.

4. Thompson, R. (2020). Optimizing Industrial Glass Breaking Equipment for Maximum Efficiency. Glass Processing Quarterly, 37(4), 210-225.