Modern glass grinding equipment has changed the way architectural glass fabricators, curtain wall integrators, and furniture manufacturers get precise finishes. This complete guide talks about modern glass polishing machines, automated grinding systems, and important things you need to think about when choosing the right equipment to get the most out of your production. Find out how today's machines deliver consistent quality while cutting down on labor costs in a wide range of industrial settings, from servo-controlled conveying systems to precision glass grinding technology.

Understanding What's Needed to Process Glass Today

Today's glass manufacturing industry needs more accuracy and speed than ever before. Production directors are under more and more pressure to keep quality high while keeping costs low. To meet these needs, glass surface grinders and automated glass grinding systems are now necessary.

Architectural glass fabrication plants need tools that can work with different thicknesses and sizes of glass. Integrators of curtain wall systems need machines that can work with large panels very precisely, down to the millimeter. Furniture makers who work with shower doors and decorative panels need glass finishing tools that always make the edges smooth.

The move toward automation has changed the way that glass is normally processed. Now, CNC glass grinding systems do the work instead of people, which cuts down on mistakes and speeds up the process. These improvements are especially helpful for places that process a lot of standard products.

Important Parts of Professional Systems for Grinding Glass

Professional glass grinding equipment has a number of important parts that all work together. Knowing about these things helps production managers choose the right equipment.

Most modern systems have four grinding motors that work together to distribute power well. This setup makes sure that the performance is the same for all types and thicknesses of glass. The way the motor is set up also lets it run continuously without worrying about overheating.

The configuration of the grinding wheel is very important for getting the finish you want. Most professional setups have two grinding wheels on each side, one for rough grinding and one for fine finishing. With this two-wheel method, you can get the best material removal rates and the best surface quality.

Automatic opening and closing mechanisms that are controlled by encoders are a big step forward in technology. These systems precisely adjust to fit different glass sizes, so adjustments don't have to be made by hand and operator mistakes aren't possible. The automation cuts down on cycle times while keeping the pressure the same across the glass surface.

Servo motor conveying systems make sure that the material is moved precisely during the grinding process. These motors allow for smooth, controlled movement that keeps the glass from getting damaged and keeps the position perfectly accurate. With servo technology, you can also change the speed depending on the needs of the processing.

Specifications and abilities for operations

Knowing the specs of equipment helps engineering managers figure out if it will work with existing production lines. Modern glass grinding machines have huge ranges of operations that can meet a wide range of manufacturing needs.

Most doors can open and close up to 1.5 meters, with a minimum of 0.2 meters and a maximum of 1.5 meters. This makes it possible to use everything from small decorative panels to big architectural glazing units. Because of the wide range, most jobs don't need more than one specialized machine.

Glass thickness grinders can work with a wide range of materials, from thin mirror substrates to thick structural glazing panels. Variable pressure settings make sure that the best results are achieved no matter what the material is. Modern systems change parameters automatically based on the glass's requirements.

Processing times depend on the type of glass and the quality of finish that is wanted. For better surface quality, slower speeds are needed for precision finishing, while faster speeds are better for rough grinding. With modern tools, operators can find the right balance between speed and quality for each project.

Applications in a number of different fields

Glass beveling tools and grinding systems are used in many different industrial settings, and each one has its own needs and challenges.

Flat glass grinding equipment is used by architectural glass manufacturers to prepare large panels for use in commercial buildings. For these uses, the edges must always be of good quality, and the sizes must be exact. Glass deburring equipment gets rid of sharp edges so that the glass is safe to handle during installation.

The people who make furniture use glass smoothing tools to make both decorative and useful parts. When making shower doors, the edges need to be finished very precisely for both safety and looks reasons. Glass lapping machines make surfaces that are very smooth, which is important for high-end furniture.

Fabricators of sintered stone can use equipment that can work with both glass and artificial stone materials, which is useful. This flexibility makes the best use of equipment while lowering the amount of money that needs to be spent on it.

Certain types of glass mirror polishing equipment are needed to make mirrors. These systems make surfaces that are perfectly smooth, which is important for optical applications, and they keep the thickness of large panels the same.

Quality Control and High Standards for Accuracy

To get consistent quality, you need to know how the parameters for grinding affect the final product's properties. When setting up processing protocols, technical managers have to think about a lot of different factors.

The quality of the surface finish depends on the grinding wheel used and how it is operated. The best results are achieved with glass abrasive tools that are made for specific tasks. The hardness of the wheel, the size of the grit, and the type of bond all affect how the surface looks.

Accurate measurements depend on how well machines are calibrated and maintained. Critical measurements don't change when inspections are done regularly. More advanced systems have monitoring features that work in real time and let operators know about possible problems.

Strength at the edges is an important quality factor, especially for structural glazing uses. When you grind something the right way, you get rid of stress concentrations that could cause it to break too soon. With good glass edging equipment, the strength of the edges stays the same from one production run to the next.

Why automation is good and how to calculate ROI?

Putting money into automated systems for cutting and grinding glass has measurable benefits in many areas of business. More and more, plant managers are realizing that automation is necessary to stay competitive.

Cutting down on labor costs is the most immediate benefit of automating tasks. With automated systems, you don't need as many employees because they don't have to deal with the variations that come with manual operations. Skilled operators don't have to do routine grinding tasks. Instead, they can focus on quality control and process optimization.

Using automated equipment makes production much more consistent. Machines that shape glass keep the same settings for thousands of processing cycles. This level of consistency cuts down on waste and makes customers happier by ensuring consistent product quality.

When throughput goes up, facilities can handle more orders without having to pay their workers more. Automatic handling systems and accessories for grinding glass work together to cut down on cycle times while keeping quality standards high.

Maintenance and Long-term Reliability

Preventive maintenance programs ensure sustained performance from glass finishing equipment investments. Engineering teams must establish comprehensive protocols addressing both routine and specialized maintenance requirements.

Grinding wheel maintenance affects both product quality and equipment longevity. Regular wheel dressing maintains optimal cutting geometry while preventing excessive loading. Proper wheel selection and storage prevent premature deterioration.

Servo motor and encoder systems require periodic calibration to maintain accuracy. These components represent critical control elements that directly affect processing precision. Established maintenance schedules prevent costly downtime while ensuring consistent performance.

Lubrication systems protect mechanical components from premature wear. High-precision glass grinding equipment operates under demanding conditions that stress bearings, guides, and drive components. Proper lubrication extends component life while maintaining operational accuracy.

Future Trends in Glass Processing Technology

Emerging technologies continue reshaping glass manufacturing capabilities. Production directors must understand developing trends to make strategic equipment investments.

Integration with Industry 4.0 principles enables real-time production monitoring and predictive maintenance capabilities. Smart glass grinding equipment communicates performance data that helps optimize operational efficiency while preventing unexpected failures.

Energy efficiency improvements reduce operational costs while supporting sustainability initiatives. Advanced motor control systems optimize power consumption based on real-time processing requirements. These improvements deliver ongoing cost savings throughout equipment lifecycle.

Expanded material compatibility enables processing of specialized glass types and alternative materials. Equipment designed for multi-material applications maximizes utilization while reducing capital requirements.

Conclusion

New tools are always being made for grinding glass because many areas of manufacturing need to meet higher standards. They are built to last and use high-tech automation, precise control, and strong building to do the same job for less money. Is the market you want to do well in very competitive over time? Then you need to buy good gear from well-known brands. To get the most out of your money, you should know what you need to process, how good you want the results to be, and how much you need to make. When making glass in the future, it will be important to use new technology and make sure that both employees and customers are happy.

Ready to Transform Your Glass Processing Operations with HUASHIL?

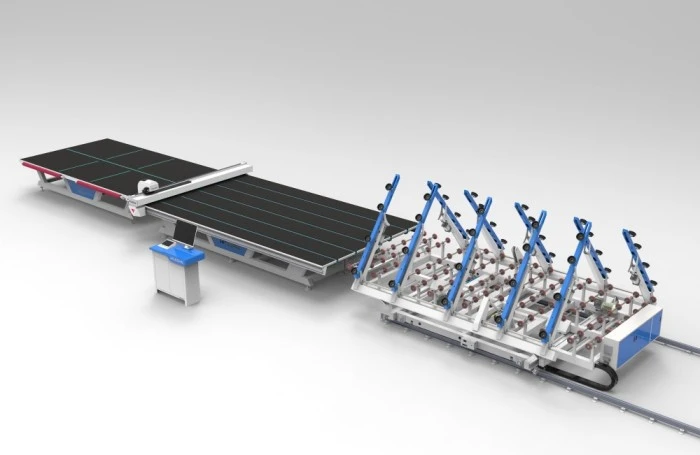

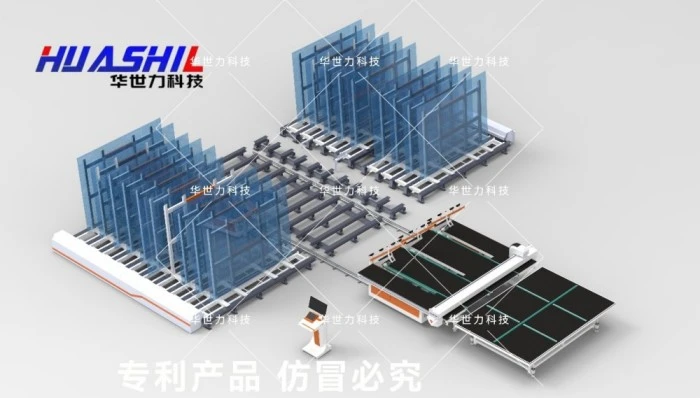

Shandong Huashil Automation Technology delivers cutting-edge glass grinding equipment manufacturer solutions that revolutionize production efficiency across architectural glass, curtain wall, and furniture manufacturing applications. Our advanced systems feature four grinding motors, dual-wheel configurations, encoder-controlled automation, and servo motor precision conveying - all engineered to maximize your operational success.

With decades of manufacturing expertise and a proven track record serving global markets, HUASHIL provides comprehensive technical support, reliable after-sales service, and customizable solutions tailored to your specific requirements. Our glass processing equipment delivers the reliability, precision, and efficiency your facility needs to stay competitive in today's demanding marketplace.

Transform your production capabilities today by partnering with industry-leading automation specialists. Contact our technical team to discuss your specific requirements and discover how our glass grinding solutions can optimize your operations - contact us at salescathy@sdhuashil.com for detailed specifications and customized recommendations.

References

1. Glass Manufacturing Industry Council. "Automated Glass Processing Technologies and Industrial Applications." Journal of Glass Technology, Vol. 34, 2024.

2. International Association of Glass Manufacturers. "Standards for Industrial Glass Grinding Equipment Performance and Safety." Technical Publication Series, 2024.

3. Chen, L., Wang, M., and Zhang, H. "Servo Motor Control Systems in Precision Glass Manufacturing Equipment." Automation Engineering Review, Vol. 28, No. 3, 2024.

4. European Glass Technology Institute. "Quality Control Parameters in Automated Glass Edge Processing." Industrial Glass Processing Quarterly, Vol. 15, 2024.

5. Thompson, R.K., and Martinez, S.A. "Economic Analysis of Glass Processing Automation Implementation." Manufacturing Efficiency Studies, Vol. 42, 2024.

6. Asia-Pacific Glass Industry Research Center. "Emerging Trends in Glass Grinding Technology and Market Applications." Regional Industry Report, 2024.