A shuttle car is the most important part of underground mining because it changes the way things move through small spaces. These special mining vehicles move coal, ore, and other materials that have been taken out of the ground to loading points or conveyor systems. Unlike vehicles that work on the surface, shuttle cars work underground, where space limitations, safety rules, and the need for high operational efficiency require precise engineering. Modern shuttle car systems use advanced automation, strong construction, and smart control systems to get the most work done while keeping operators safe in tough mining conditions.

Learn About Shuttle Car Technology Used in Underground Mines

Material handling systems that work well are very important for mining operations. Underground transportation vehicles have changed a lot over the last few decades. These strong machines move through narrow tunnels while carrying heavy loads of extracted materials.

Modern shuttle cars are made with advanced technology for haulage systems. In underground places, electric motor configurations provide reliable power. When used in small spaces, battery-powered options get rid of the need to worry about emissions. Remote controls make operators safer by letting them work from a distance when the conditions call for it.

Traditional mining vehicle operations are changed when automation is added. Sensors check the weight that can be carried, tunnel navigation systems help with precise movement, and safety system protocols stop accidents from happening. Features that reduce dust protect both equipment and people from harmful particles that are common in mining environments.

Different types of diesel engines can be used in situations where ventilation systems can fit combustion engines. But electric alternatives are becoming more popular because they are better for the environment and cost less to run. For long-term underground transportation solutions, modern designs balance the need for power with the amount of energy saved.

Important Parts of Modern Mining Transportation Systems

Specialized features are needed for heavy machinery that is used for work underground. The designs of operator cabins put safety first and make it easy to see in bad weather. Rail system compatibility ensures smooth movement along predetermined paths when track-based operations prove advantageous.

Specifications for load capacity depend on the needs of the mining operation. Standard configurations can hold 10 to 30 tons, but custom solutions can handle higher loads. How well you handle materials has a direct effect on how productive and profitable your mining operations are as a whole. Shuttle cars are often used to transport materials between underground sections, providing flexible and efficient movement.

Integrating safety systems is an important part of design. People and things are kept safe by emergency stops, collision avoidance systems, and communication systems. Accessibility for maintenance ensures quick service to reduce operational downtime.

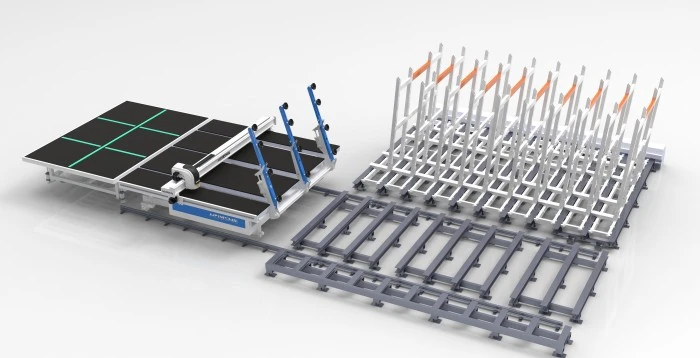

When two conveyor belts work together, they can move materials easily from mobile units to fixed transport systems. Throughout the mining process, this integration makes the workflow more efficient. For consistent transfer points, more advanced designs use automated positioning.

Applications for coal mining and continuous miner integration

Transport arrangements for coal mining operations are very specific. For continuous miner compatibility, the equipment used for extraction and transport must work together perfectly. These integrated systems keep safety standards while increasing the rate of extraction.

Underground places are hard to work with equipment in their own way. Design specifications are affected by things like the need for ventilation, limited space, and changes in the rock formation. Implementations that work well adjust to these changes while keeping operational dependability.

Fast cycle times are important for coal operations that need to move materials quickly. Overall productivity is highest when loading and transporting things quickly and efficiently and then unloading them quickly. Modern designs have parts that shorten cycle times while still keeping the load safe.

Adding automation to coal mining improves safety and accuracy. The extraction process is made easier by pre-programmed routes, automatic loading sequences, and working together with other machines. These abilities cut down on the number of workers needed while also making operations more consistent.

Technologies for Power Systems and Control

Electric motor technology is used most often in modern underground transportation. When compared to traditional options, these systems offer instant torque, precise speed control, and less maintenance. Battery-powered models get rid of the problem of exhaust in small spaces.

Having remote control capabilities changes how safe and flexible an operator is. In dangerous situations, operators can place equipment from a safe distance. Modern systems let you know about the status of your equipment, the load, and other operational parameters in real time.

Tunnel navigation technology makes sure that you can move precisely in small spaces. When used with sensor arrays, GPS alternatives made for use underground give accurate positioning. These systems keep shuttle cars from colliding and make the best use of the route.

Integration of a control system coordinates the functions of multiple pieces of equipment. Automated loading sequences, speed optimization based on load conditions, and maintenance alerts that can be used before they break down all make operations more efficient. Interfaces that are easy to use make training operators and running the system every day easier.

Plans for maintenance and making sure operations run smoothly

How well things work and how long things last are both affected by maintenance procedures. Inspections that are planned ahead of time find problems before they cause expensive downtime. When parts are easy to get to during the design phase, service time requirements go down.

Heavy machinery that works in harsh underground conditions needs strong maintenance plans. Decisions about proactive maintenance are based on systems for lubrication, keeping an eye on parts, and looking at patterns of wear. It costs less to avoid problems in the first place than to fix them after they happen.

When things go wrong, having spare parts on hand speeds up the repair process. Strategic inventory management finds a balance between the need to keep operations going and the cost of carrying inventory. Maintenance works better when you have good relationships with suppliers and make parts the same.

Programs that train operators keep workers safe and make equipment last longer. It takes less time between services when workers know how to do it right, find problems early, and do regular maintenance. Well-trained people can see the signs of trouble before they get worse.

How to handle risks and follow safety rules?

All risks must be looked at and dealt with in order for underground mining to be safe. To protect people and property, equipment is made with many safety layers built in. Plans for how to handle emergencies make sure that people can act quickly when something unexpected happens.

Dangerous particles can't get into people or equipment with dust suppression systems. To keep people from getting too exposed, water spray systems, filtration units, and closed-off operator cabins are used. Regular checks of the air quality make sure that safety standards are met.

Communication systems let people who work on equipment talk to people who live and work on the ground. People can get help right away when they need it by being able to communicate in an emergency. Important systems always work because they have backup ways to communicate.

When operating a shuttle car underground, it’s crucial to ensure that all safety protocols are followed to minimize risk. This includes ensuring clear communication between the operator of the shuttle car and the control center, as well as maintaining proper air quality in confined spaces.

When you test and validate a safety system, you make sure that all of its safety features work right. Regular inspections, functional tests, and documentation make sure that regulatory requirements are met. Methods for constant improvement use what has been learned from operations that are already running.

Future Trends in Underground Material Handling

Automation advancement continues transforming underground transport operations. Autonomous navigation, coordinated equipment operation, and intelligent route optimization represent emerging capabilities. These developments promise enhanced efficiency and safety in mining operations.

Environmental considerations drive innovation in power systems and emissions reduction. Battery technology improvements extend operational duration while reducing charging requirements. Renewable energy integration supports sustainable mining practices.

Digital integration connects underground equipment with surface monitoring systems. Real-time data analysis optimizes operational parameters and predicts maintenance requirements. Internet connectivity enables remote monitoring and expert support capabilities.

Modular design approaches enhance flexibility and upgrade capabilities. Standardized interfaces allow component updates without complete equipment replacement. This strategy extends equipment life while incorporating technological advances.

Conclusion

Things are always changing in the underground as new technologies come out and better ways to do things are found. The shuttle car systems we use today are high-tech ways to deal with hard mining issues. When you choose and use tools, the most important things to remember are still dependability, safety, and efficiency.

Mines need reliable ways to move materials that can handle the harsh conditions underground in order to run. When you invest in new transportation technology, you get short-term gains like more money and lower costs. Operations can get things done and follow safety and law rules if they are smart about what gear they buy.

Automation will get even better over time as new technologies come out. This will make things run more smoothly. A lot of companies in the mining business need to use these new technologies to stay ahead in a market that is very competitive.

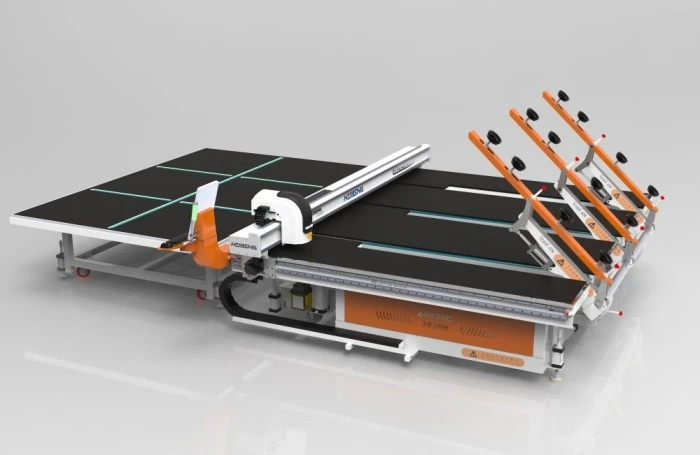

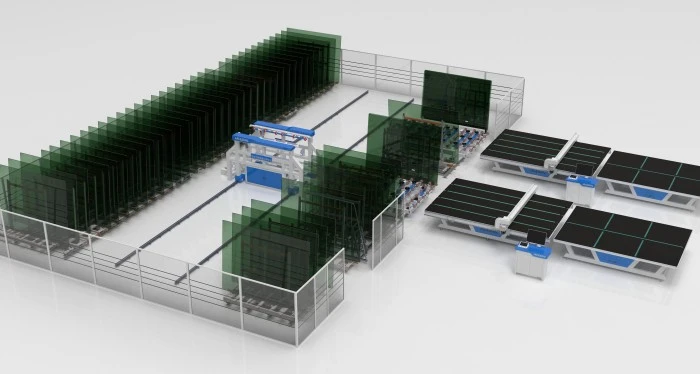

Partner with HUASHIL for Advanced Material Transport Solutions

HUASHIL delivers cutting-edge automation technology that transforms underground material handling operations. Our shuttle car manufacturer expertise extends beyond standard equipment to provide customized solutions matching specific operational requirements. Advanced engineering capabilities ensure reliable performance in demanding mining environments.

Shandong Huashil Automation Technology Co., LTD combines decades of manufacturing experience with innovative design approaches. Our comprehensive product line includes automated material handling systems engineered for underground applications. Quality control processes ensure consistent performance and reliability in challenging operational conditions.

Our technical team collaborates with mining professionals to develop optimal transport solutions. Load capacity specifications, automation integration, and safety system requirements receive careful attention during design phases. Custom configurations accommodate unique operational constraints while maintaining efficiency standards.

Comprehensive after-sales support includes technical training, maintenance guidance, and spare parts availability. Our global service network ensures rapid response to operational needs. Quality certifications and compliance with international standards demonstrate our commitment to excellence.

Mining operations seeking reliable shuttle car solutions benefit from our expertise in automation technology and material handling systems. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how our advanced transport solutions can optimize your underground operations.

References

1. Smith, J.R. and Anderson, M.K. "Underground Material Handling Systems: Engineering Principles and Applications." Mining Engineering Journal, Vol. 45, No. 3, 2023, pp. 78-95.

2. Thompson, L.D. "Automation in Coal Mining: Safety and Efficiency Considerations." International Journal of Mining Technology, Vol. 28, No. 2, 2023, pp. 156-172.

3. Rodriguez, C.A. and Kim, S.H. "Electric Drive Systems for Underground Mining Vehicles: Performance Analysis and Optimization." Mining Equipment Review, Vol. 12, No. 4, 2022, pp. 203-219.

4. Wilson, P.M. "Safety Protocols in Underground Transport Operations: Best Practices and Risk Management." Mine Safety Quarterly, Vol. 39, No. 1, 2023, pp. 45-62.

5. Davis, R.J. "Maintenance Strategies for Heavy Mining Equipment: Reducing Downtime and Operational Costs." Industrial Maintenance Today, Vol. 33, No. 6, 2022, pp. 112-128.

6. Chen, X.L. and Brown, D.W. "Future Trends in Underground Mining Automation: Technology Integration and Operational Impact." Mining Innovation Report, Vol. 15, No. 2, 2023, pp. 87-104.