Some small businesses in the glass production industry have a hard time competing with bigger companies while still keeping costs low and quality high. The answer is in the cheap CNC glass machine technology that has changed how glass processing works. These computer-controlled systems can change the way you make things without costing too much. They cut with perfect accuracy, make sure that processes are automated, and guarantee that the quality of the output is always the same. New glass cutting tools are the best way for businesses to improve their manufacturing methods while keeping their prices low.

Understanding CNC Glass Machines

CNC is a complex industrial method that uses very advanced machinery to do tasks with high levels of accuracy. These machines use computer-controlled systems to follow exact cutting patterns. This avoids mistakes that people might make and makes sure that every production run has the same outcome.

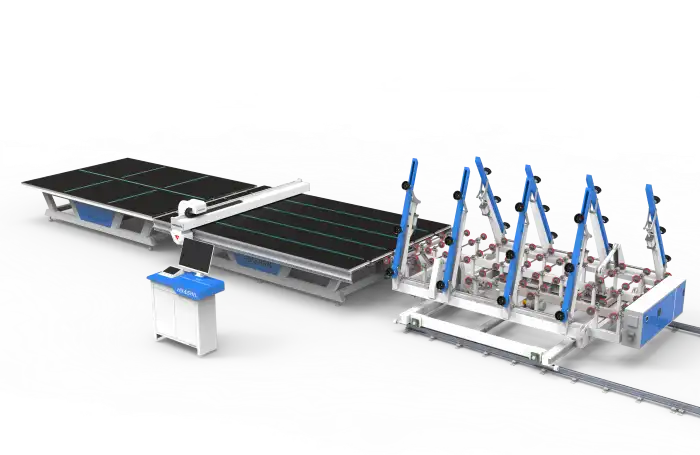

The most important feature of current glass cutting systems is that they can automatically position and scan. When the machine is started, robotic arms instantly use advanced suction technology to get glass sheets from storage shelves. Then, sensor-controlled systems help the glass find the right edge position in both the X and Y directions, making sure that everything is lined up perfectly before the cutting starts.

One important piece of technology in a CNC glass machine is CAD software that is built into the system. This lets workers plan and change cutting patterns right from their computers. The system figures out the best ways to cut things so that there is as little waste as possible and all of the materials are used up. Industrial-grade electrical and pneumatic parts make sure that cutting accuracy is kept up across different forms and thicknesses of glass.

Carbon steel is used in the frame of the machine, and normal welding and annealing methods are used so that it doesn't bend or break even after long periods of use. The strong base holds up the gantry milling system, which works on parts that are single molded units with no splicing or welding of joints. This avoids places of failure and guarantees long-term stability.

Benefits of Using CNC Glass Machines

The change from cutting glass by hand to automatic CNC systems brings big benefits that directly affect your bottom line. Knowing these benefits helps explain why the money should be spent and shows the long-term value it can bring to your business.

Automated CNC glass machine tools' most important benefit is that they can cut very precisely. Traditional hands-on methods often lead to mistakes and inconsistent measurements that waste materials and cost money to fix. CNC systems cut with the help of tolerances that are within millimeter accuracy. This makes sure that every part meets the exact requirements and there are not too many rejections.

It is also amazing that production has become more efficient. Here are the main things that these tools can do for your business:

- Automated workflow management: The integrated system positions the glass, scans it, and cuts it all on its own, so operators can focus on quality control and system monitoring instead of doing the same tasks by hand over and over.

- Better material use: Compared to doing it by hand, smart software figures out the best ways to cut glass sheets so that no more than 15% of the material is wasted.

- Consistent high quality: Computer-controlled cutting gets rid of differences in method and pressure, so all production runs have the same edge quality.

- Better safety rules: Automated handling keeps workers away from sharp glass edges and repeated motions, which makes the workplace safer and lowers liability and insurance costs.

These changes make things run more smoothly, which lowers costs and increases productivity. For most small business uses, this usually means that the cost of the tools is paid back in 18 to 24 months.

Choosing the Right CNC Glass Machine

Choosing the right glass cutting tools takes a close look at your space, budget, and production needs. The process of making a choice includes looking at many things that affect the long-term success of the business.

You need to make sure that the specs of the CNC glass machine are right for the amount of glass and the kinds of glass that you make. Think about the maximum glass thickness, the size of the cutting table, and how fast you need to handle things. Small businesses usually get more value out of small models that are flexible and don't need a lot of changes to be made to the floor space.

Software capabilities play a crucial role in operational efficiency. Automatic typesetting, shape recognition, and optimization methods that cut down on programming time and material waste are all features of modern systems. Find easy-to-use platforms that don't require a lot of training and offer advanced features for complicated cutting patterns.

Automatic oil filling systems that keep cutting performance steady, laser pointing technology for exact alignment, and closed-loop feedback systems that make sure accuracy is maintained over long production runs are all important features to consider. These features have a direct effect on the quality of cutting and the dependability of the process.

Reputation and part quality have a big impact on long-term success. Established makers' reliable electrical and pneumatic parts ensure the system always works and needs less maintenance. Industrial-grade building materials, like treated steel frames and parts made with precise machining, are strong enough to be used in places where production never stops.

Purchasing and Maintaining CNC Glass Machines

Getting the right tools isn't just about looking at the prices. The total cost of ownership covers the installation, training, upkeep, and supply of spare parts for the duration of the machine's working life.

Working with trustworthy sources ensures you can get a lot of help and real replacement parts for your CNC glass machine. Installation help, training programs for operators, and technical support are services that the most well-known makers offer. These services are very helpful when first setting things up and during day-to-day operations.

Automated glass cutting systems are usually easy to keep in good shape, but it is important for them to keep working well. Regular repair should include:

- Daily cleaning and checking: Clear off the glass cutting tables, and make sure that the air tools are properly sealed and pressurized.

- Weekly plans for lubrication: As long as you follow the manufacturer's instructions for maintaining moving parts, they won't wear out too quickly and will work smoothly.

- Every month, tuning checks: Make sure the cuts are straight and accurate by practicing on a sample piece. If needed, change the settings to make sure you meet the standard for precision.

- Every three months, part inspection: Before they affect output, look at software updates, electrical connections, and mechanical parts for signs of wear or problems that could happen.

These preventive maintenance practices keep tools working well and for longer, which makes the money you spent on them worth it.

About Our Company

Shandong Huashil Automation Technology Co., Ltd. is a top maker of automatic glass processing tools. Our company focuses on making and selling advanced CNC glass machine cutting tools that are designed especially to help small and medium-sized businesses improve their production.

We know how hard it is for small businesses in today's competitive manufacturing world because we've worked in robotic technology for years. Our tech team works on making affordable fixes that get the job done like high-end gear, but without the hassle and cost that usually come with industrial automation tools.

Our products include complete glass cutting systems with automatic positioning, smart software integration, and dependable construction. Every machine is tested many times to make sure it meets our quality standards and works well in real-world industrial settings.

Helping customers is still at the heart of how we do business. We offer full help with installation, training programs for operators, and ongoing technical support to make sure you get the most out of your CNC glass machine equipment investment. During the entire operational lifetime of your machine, our service network and spare parts inventory guarantee minimal downtime and steady output capability.

Conclusion

Affordable CNC glass machines are a smart way for small businesses to invest in making their glass production business more competitive. These automated systems keep the cost-effectiveness that is vital for small business success while providing clear gains in precision, efficiency, and operational consistency. Cutting-edge technology, easy-to-understand operation, and great support all together make a strong case for buying the equipment because it will help people be more productive and lower the cost of running a business. Working with manufacturers who know what they're doing will get you reliable equipment and help for the long-term success of your business.

FAQ

Q1: What is the typical return on investment for small CNC glass cutting machines?

A: Most small businesses have payback periods of 18 to 24 months by lowering labor costs, making better use of materials, and increasing their production capability. The exact time will rely on how much you are currently making and how much more efficiently you are able to operate.

Q2: How much training is required to operate automated glass cutting equipment?

A: For glass workers who have done it before, basic operation training usually takes 2–3 days. The intuitive software interface and automated functions reduce the amount of time that people need to learn how to use the system. This lets operators quickly get used to it while working on quality control and system optimization.

Q3: What ongoing maintenance costs should I budget for CNC glass machines?

A: The cost of maintenance each year is usually about 3% to 5% of what the tools originally cost. This includes things that are used up every day, parts that are replaced every once in a while, and tools for preventive repair. A proper upkeep schedule avoids most surprise repair costs.

Partner with HUASHIL for Advanced Glass Processing Solutions

Change the way you make glass with CNC glass machine technology from HUASHIL, which is proven to work for small businesses. Our automated cutting systems provide the accuracy, speed, and dependability your business needs to succeed in today's tough market.

As a well-known producer of CNC glass machines, we offer a full range of services, such as installing the equipment, teaching operators, and giving ongoing technical support. Our machines have smart software, automatic tracking systems, and a build quality suitable for heavy-duty use. This guarantees that they always work the same way and can be relied on to last a long time.

Our experienced team knows that small businesses have different needs, and we work directly with each customer to figure out the best way to set up their equipment for their individual needs. Our automated systems can be used to process building glass, furniture parts, or decorative elements. They will adapt to your production needs while still being cost-effective.

Ready to discover how advanced glass cutting technology can transform your production capabilities? Contact us at salescathy@sdhuashil.com to discuss your specific requirements and learn about our current CNC glass machine for sale options. Visit our website at huashil.com for detailed product information and case studies demonstrating real-world performance improvements achieved by businesses similar to yours.

References

1. Manufacturing Technology Review. "Automation in Small Glass Manufacturing: Trends and Applications." Industrial Manufacturing Quarterly, 2023.

2. Glass Industry Association. "Cost-Benefit Analysis of CNC Technology in Glass Processing." Glass Manufacturing Today, 2023.

3. Smith, J. and Anderson, K. "Small Business Manufacturing: Technology Adoption and ROI Analysis." Business Technology Journal, 2023.

4. International Glass Manufacturing Council. "Safety and Efficiency Standards in Automated Glass Processing." Industrial Safety Review, 2023.

5. Chen, L. "Precision Manufacturing Technologies for Glass Industry Applications." Manufacturing Engineering Perspectives, 2023.

6. Roberts, M. "Maintenance Strategies for CNC Glass Cutting Equipment." Equipment Management Professional, 2023.