Selecting the right industrial glass breaking equipment is crucial for optimizing your facility's glass processing capabilities. Whether you're in the architectural, automotive, or smart mirror industry, the right equipment can significantly impact your productivity, quality, and bottom line. This comprehensive guide will walk you through the essential factors to consider when choosing glass breaking equipment, helping you make an informed decision that aligns with your facility's needs and goals.

Key Criteria for Selecting Suitable Equipment

When evaluating industrial glass breaking equipment, several critical factors come into play. Understanding these criteria will help you narrow down your options and find the perfect fit for your facility:

Precision and Accuracy

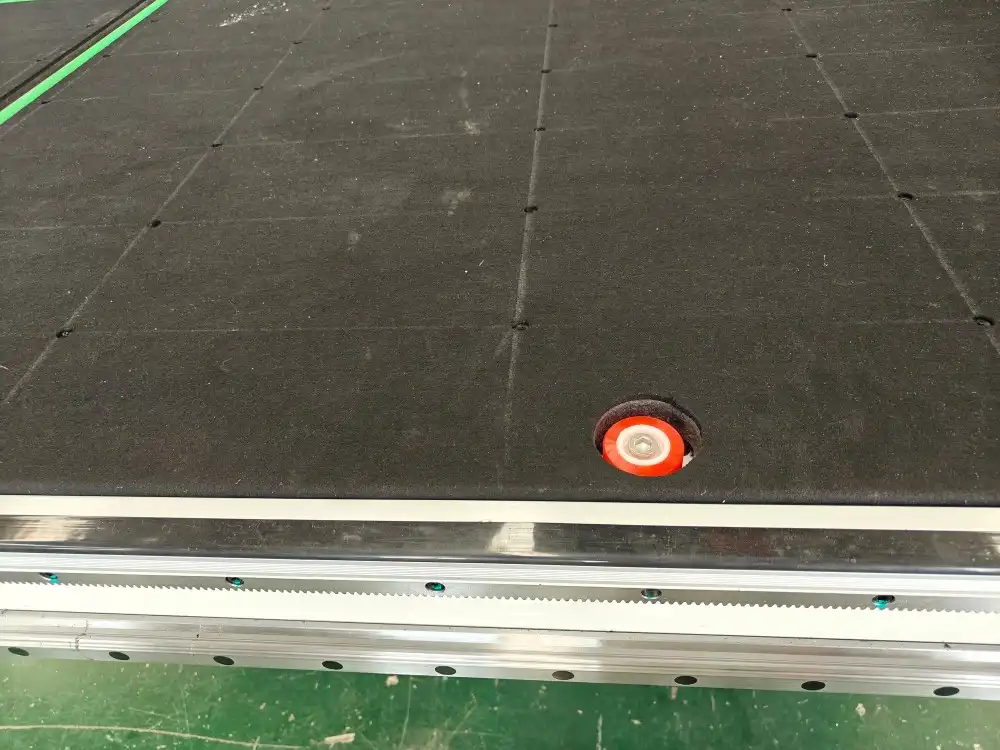

The hallmark of high-quality glass breaking equipment is its ability to maintain consistent precision throughout the cutting process. Look for machines that offer:

- Advanced positioning systems for accurate glass placement

- High-resolution cutting heads for clean, precise breaks

- Adjustable cutting parameters to accommodate different glass types and thicknesses

Speed and Efficiency

To maximize your facility's output, consider equipment that offers:

- Rapid cutting speeds without compromising accuracy

- Quick setup and changeover times between different glass types

- Automated loading and unloading systems to reduce manual handling

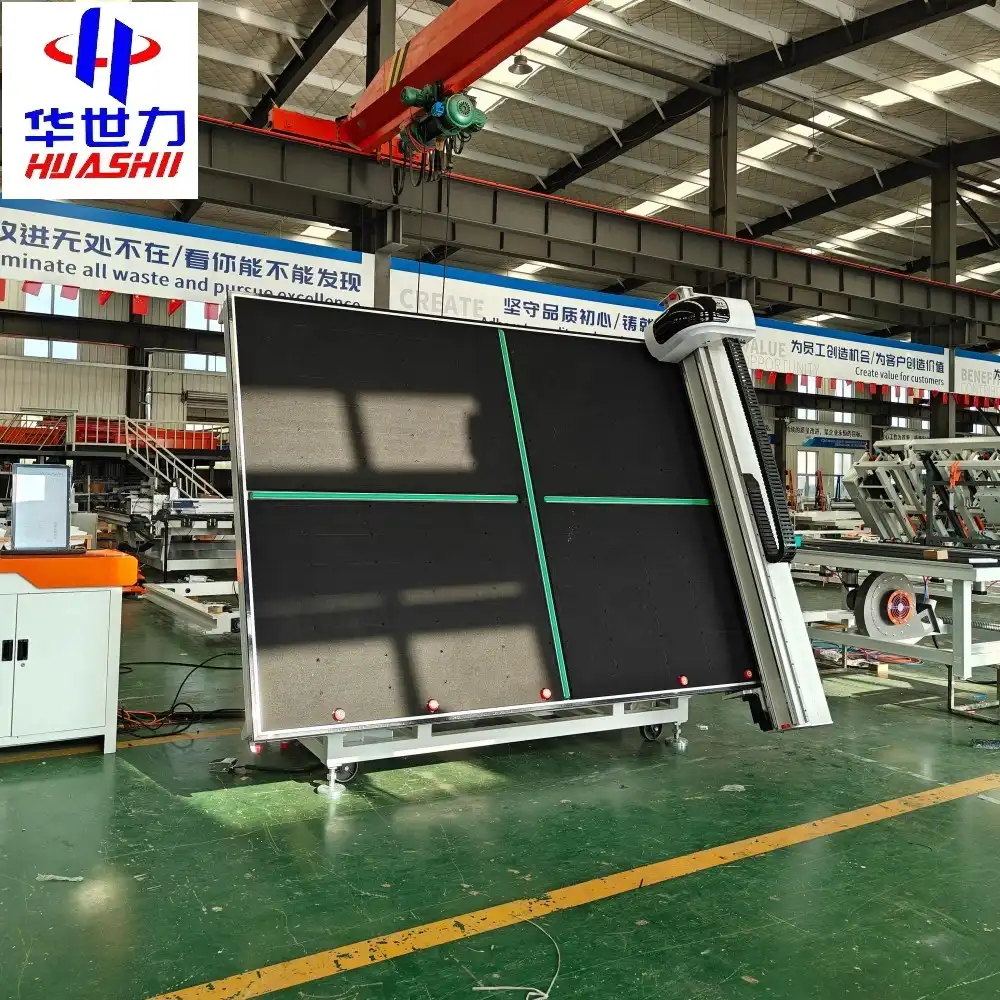

Versatility and Flexibility

The ability to handle various glass types and sizes is crucial for facilities with diverse production needs. Look for:

- Adjustable cutting tables to accommodate different glass dimensions

- Multi-axis cutting capabilities for complex shapes and patterns

- Compatibility with different glass thicknesses and compositions

Durability and Reliability

Investing in robust equipment ensures long-term performance and minimizes downtime. Consider:

- High-quality materials and construction for extended equipment lifespan

- Reliable mechanical and electrical components from reputable manufacturers

- Comprehensive warranty and after-sales support

Safety Features

Prioritize equipment from a Customized industrial glass breaking equipment factory that incorporates advanced safety measures to protect your operators and maintain a secure working environment:

- Emergency stop buttons and safety interlocks

- Enclosed cutting areas to contain glass particles and debris

- Ergonomic design to reduce operator fatigue and potential injuries

Matching Equipment to Facility Size and Output

Selecting the right size and capacity of industrial glass breaking equipment is crucial for optimizing your facility's productivity and efficiency. Here's how to align your equipment choice with your facility's needs:

Assess Your Production Volume

Start by analyzing your current and projected production volumes:

- Calculate your daily, weekly, and monthly glass processing requirements

- Factor in potential growth and seasonal fluctuations in demand

- Consider peak production periods and how equipment capacity affects your ability to meet deadlines

Evaluate Available Space

Consider the physical constraints of your facility:

- Measure the available floor space for new equipment installation

- Account for additional space needed for material handling and operator movement

- Assess ceiling height limitations, especially for vertical glass breaking systems

Analyze Workflow Integration

Ensure the new equipment seamlessly integrates into your existing production line:

- Map out your current glass processing workflow

- Identify potential bottlenecks that new equipment could alleviate

- Consider how the equipment's input and output will affect upstream and downstream processes

Consider Scalability

Invest in equipment that can grow with your business:

- Look for modular systems that allow for future expansion

- Choose equipment with upgradeable software and hardware components

- Assess the potential for integrating automation and smart manufacturing technologies

Balance Automation and Manual Operations

Determine the right mix of automated and manual processes for your industrial glass breaking equipment facility:

- Evaluate the skill level of your workforce and their ability to operate complex machinery

- Consider the impact of automation on labor costs and productivity

- Assess the potential for retraining or upskilling existing staff to work with new equipment

Evaluating Cost-Effectiveness and ROI Factors

Investing in industrial glass breaking equipment is a significant decision that requires careful financial consideration. Here's how to evaluate the cost-effectiveness and return on investment (ROI) of your equipment choices:

Initial Investment Costs

Consider all upfront expenses associated with acquiring and installing the equipment:

- Purchase price of the machinery

- Shipping and installation costs

- Facility modifications or upgrades required to accommodate the new equipment

- Initial training costs for operators and maintenance staff

Operational Costs

Calculate the ongoing expenses associated with running and maintaining the equipment:

- Energy consumption and utility costs

- Consumables and replacement parts

- Regular maintenance and servicing expenses

- Labor costs for equipment operation and maintenance

Productivity Improvements

Estimate the potential increase in output and efficiency:

- Projected increase in production capacity

- Reduction in processing time per unit

- Improved quality and reduced waste

- Potential for new product lines or capabilities

Quality and Waste Reduction

Assess the impact on product quality and material waste:

- Improved precision leading to fewer defects and reworks

- Reduction in material waste due to more accurate cutting

- Potential for higher-value products or premium pricing

Long-Term Cost Savings

Consider potential savings over the equipment's lifespan:

- Reduced labor costs through automation

- Lower maintenance costs compared to older equipment

- Energy efficiency improvements

- Potential tax incentives or rebates for investing in advanced manufacturing equipment

Financing Options

Explore different ways to finance your equipment purchase:

- Leasing vs. purchasing options

- Availability of low-interest loans or equipment financing programs

- Potential for phased implementation to spread out costs

ROI Calculation

Perform a comprehensive ROI analysis:

- Estimate the payback period for the investment

- Calculate the net present value (NPV) of the investment over its expected lifespan

- Consider both tangible and intangible benefits, such as improved workplace safety and employee satisfaction

By thoroughly evaluating these cost-effectiveness and ROI factors, you can make a well-informed decision on the Customized industrial glass breaking equipment factory that best suits your facility's needs and financial goals.

Conclusion

Choosing the right industrial glass breaking equipment is a critical decision that can significantly impact your facility's productivity, quality, and profitability. By carefully considering factors such as precision, efficiency, versatility, and cost-effectiveness, you can select equipment that not only meets your current needs but also positions your business for future growth and success.

Remember to assess your facility's specific requirements, production volumes, and available space when making your decision. Additionally, don't overlook the importance of after-sales support, training, and ongoing maintenance in ensuring the long-term success of your investment.

At Shandong Huashil Automation Technology Co., LTD, we're committed to helping you navigate this important decision. Our team of experts is ready to provide personalized guidance and support to ensure you find the perfect glass breaking solution for your facility. With our advanced technology, years of experience, and dedication to customer satisfaction, we're confident that we can help you achieve your glass processing goals.

Don't let outdated or inefficient equipment hold your business back. Upgrade to cutting-edge industrial glass breaking equipment and unlock new levels of productivity and quality. Contact us today at salescathy@sdhuashil.com to explore how our customized solutions can transform your glass processing operations. Let's work together to elevate your facility's capabilities and drive your success in the competitive glass industry landscape.

FAQ

Q1: What are the main types of industrial glass breaking equipment available?

A: The main types of industrial glass breaking equipment include:

- CNC cutting tables for the precision cutting of large glass sheets

- Vertical cutting lines for efficient processing of architectural glass

- Water jet cutting systems for complex shapes and patterns

- Laser cutting equipment for ultra-precise cuts and specialized applications

- Manual scoring and breaking tables for smaller operations or custom work

Each type has its own advantages and is suited to different production needs and glass types.

Q2: How often should industrial glass breaking equipment be maintained?

A: The maintenance frequency for industrial glass breaking equipment depends on several factors, including usage intensity, environmental conditions, and manufacturer recommendations. Generally, daily inspections and cleaning are essential, while more comprehensive maintenance should be performed weekly or monthly. Critical components like cutting heads, bearings, and positioning systems may require quarterly or bi-annual servicing. Always refer to the manufacturer's maintenance schedule and consider implementing a preventive maintenance program to ensure optimal performance and longevity of your equipment.

Q3: Can industrial glass breaking equipment handle tempered glass?

A: Most industrial glass breaking equipment is designed to cut and shape annealed glass before the tempering process. Tempered glass, due to its internal stress patterns, cannot be cut or drilled after the tempering process without shattering. However, some specialized equipment can perform controlled fracturing of tempered glass for specific applications. If you need to process tempered glass, it's crucial to cut and shape the glass to its final dimensions before tempering. Always consult with equipment manufacturers to ensure compatibility with your specific glass processing needs.

Q4: What safety measures should be in place when operating industrial glass breaking equipment?

A: Safety is paramount when operating industrial glass breaking equipment. Key safety measures include:

- Proper operator training and certification

- Use of personal protective equipment (PPE) such as safety glasses, gloves, and appropriate footwear

- Installation of emergency stop buttons and safety interlocks

- Adequate ventilation and dust collection systems

- Regular equipment inspections and maintenance

- Clear workspace organization and material handling procedures

- Implementation of lockout/tagout procedures during maintenance

- Compliance with all relevant OSHA and industry-specific safety regulations

Always prioritize safety and follow manufacturer guidelines and local regulations to create a secure working environment.

Top-Quality Industrial Glass Breaking Equipment | HUASHIL

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that high-performance industrial glass breaking equipment plays in your facility's success. Our state-of-the-art machines are designed to meet the diverse needs of the glass processing industry, from architectural applications to automotive and smart mirror production.

With years of experience in R&D, manufacturing, and export, we pride ourselves on delivering advanced technology, stable quality, and excellent service. Our commitment to innovation and customer satisfaction has made us a trusted partner for glass manufacturers worldwide.

Ready to elevate your glass processing capabilities? Contact our expert team today to discuss how our customized solutions can optimize your facility's performance and drive your business forward. Send your inquiry to salescathy@sdhuashil.com and take the first step towards transforming your glass breaking operations.

References

1. Johnson, M. (2022). Advancements in Industrial Glass Processing Equipment: A Comprehensive Review. Journal of Glass Technology, 45(3), 112-128.

2. Smith, A., & Brown, R. (2021). Optimizing Efficiency in Glass Manufacturing: Equipment Selection and Implementation Strategies. International Glass Review, 18(2), 67-82.

3. Glass Processing Safety Institute. (2023). Best Practices for Industrial Glass Breaking Equipment Safety. Annual Safety Report, 12-15.

4. Zhang, L., et al. (2020). Cost-Benefit Analysis of Automated Glass Processing Systems in Medium-Scale Facilities. Journal of Industrial Automation, 33(4), 201-215.