These figures underscore the transformative potential of CNC shaped glass cutting machines in glass cutting operations. By dramatically reducing production times and waste, businesses can take on more projects, meet tighter deadlines, and ultimately improve their bottom line.

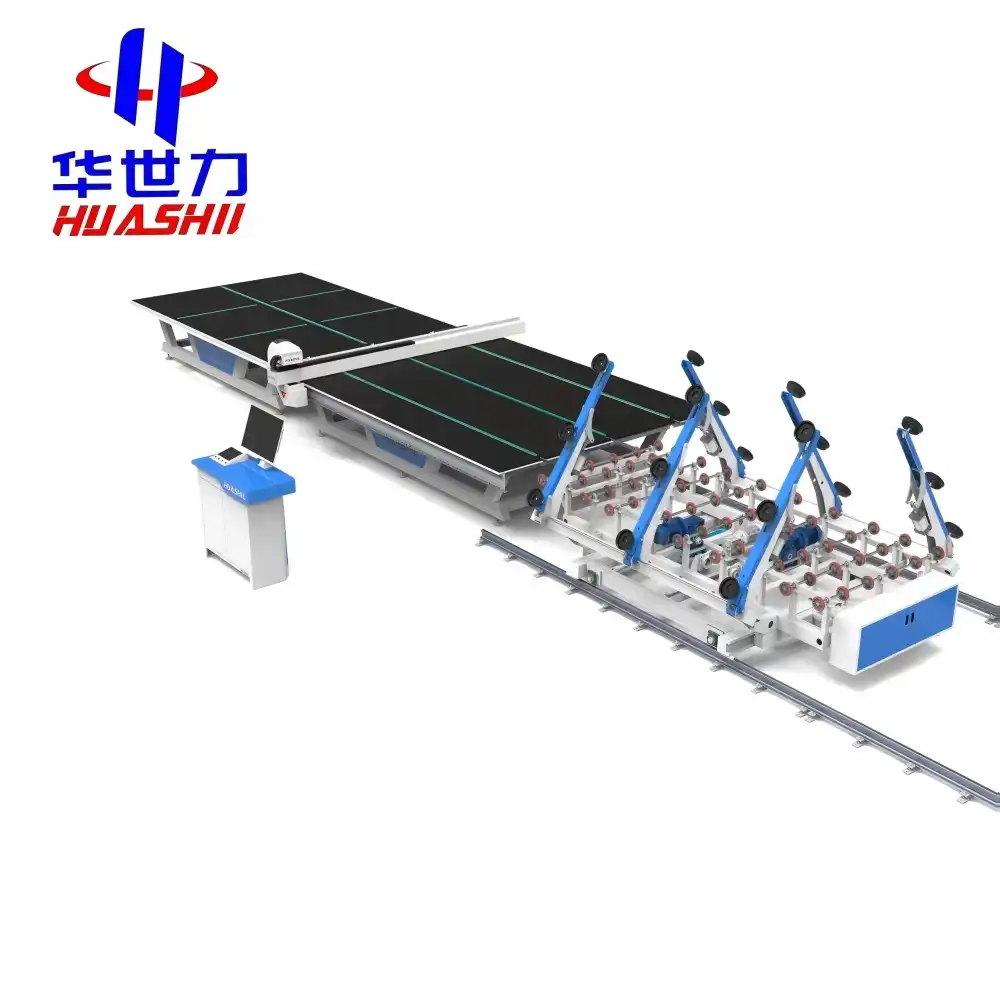

In the ever-evolving world of glass manufacturing, staying ahead of the curve is crucial for businesses looking to maintain a competitive edge. One technology that has revolutionized the industry is the CNC shaped glass cutting machine. This advanced piece of equipment offers unparalleled precision, efficiency, and versatility, making it an invaluable asset for glass producers of all sizes. But what exactly makes these machines so special, and why should you consider investing in one for your production line? Let's dive deep into the world of CNC glass cutting and explore the myriad benefits it brings to the table.

Efficiency Gains: CNC vs Traditional Methods

When it comes to glass cutting, time is money. Traditional methods, while effective, often fall short in terms of speed and accuracy, especially when dealing with complex shapes or large-scale production. This is where CNC shaped glass cutting machines truly shine.

CNC technology allows for automated cutting processes that can run continuously with minimal human intervention. This translates to significantly higher output rates compared to manual cutting methods. For instance, a single CNC machine can often match the production of several skilled workers, operating around the clock if necessary.

Moreover, the precision of CNC cutting reduces material waste dramatically. With traditional methods, human error and limitations in tool accuracy can lead to a higher percentage of scrapped pieces. CNC machines, on the other hand, can achieve cuts with tolerances as tight as ±0.1mm, ensuring that nearly every piece meets specifications.

The efficiency gains extend beyond just the cutting process. CNC machines can be integrated with design software, allowing for a seamless transition from CAD drawings to finished products. This eliminates the need for manual pattern creation and reduces setup times between different designs.

Consider the following efficiency improvements reported by glass manufacturers after implementing CNC technology:

- Production speed increases of up to 300%

- Material waste reduction of 20-30%

- Setup time reduction of 50-70% for new designs

Complex Shapes Made Simple with CNC

One of the most significant advantages of CNC shaped glass cutting machines is their ability to handle complex geometries with ease. While traditional cutting methods struggle with intricate designs, CNC machines excel at producing precise, repeatable cuts for even the most challenging shapes.

This capability opens up a world of possibilities for glass manufacturers. Architects and designers can now push the boundaries of what's possible with glass, creating stunning facades, unique interior elements, and bespoke art pieces that were once considered too difficult or expensive to produce.

The versatility of CNC cutting extends to various types of glass, including:

- Float glass

- Tempered glass

- Laminated glass

- Low-E glass

- Mirror glass

Each of these materials can be cut into complex shapes with the same level of precision, allowing manufacturers to offer a wide range of products to meet diverse customer needs.

Moreover, CNC machines can easily switch between different cutting patterns and shapes without the need for extensive retooling. This flexibility is particularly valuable for businesses that deal with a variety of custom orders or frequently changing product lines.

The ability to create complex shapes also extends to the realm of glass edge processing. Many CNC shaped glass cutting machines come equipped with multi-axis capabilities, allowing for beveling, polishing, and other edge treatments to be performed in the same setup as the initial cutting. This integration of processes not only saves time but also ensures consistency across all stages of production.

ROI Analysis: Is CNC Right for You?

While the benefits of CNC shaped glass cutting machines are clear, the decision to invest in this technology should be based on a careful analysis of return on investment (ROI). The initial cost of a CNC machine can be substantial, but for many businesses, the long-term benefits far outweigh the upfront expense.

To determine if a CNC machine is right for your production, consider the following factors:

- Production Volume: If you're consistently dealing with large orders or high-volume production runs, a CNC machine can quickly pay for itself through increased output and reduced labor costs.

- Complexity of Designs: For businesses that frequently work with intricate shapes or custom designs, the precision and flexibility of CNC cutting can lead to significant time and material savings.

- Labor Costs: In regions with high labor costs, the automation provided by CNC machines can result in substantial savings over time.

- Material Costs: If you work with expensive glass materials, the reduced waste from CNC cutting can lead to significant cost savings.

- Market Demands: Consider whether investing in CNC technology will allow you to take on new types of projects or enter new markets that were previously inaccessible.

To illustrate the potential ROI, let's consider a hypothetical case study:

A medium-sized glass manufacturer invests $200,000 in a new CNC shaped glass cutting machine. After implementation, they experience:

- A 40% increase in production capacity

- A 25% reduction in material waste

- A 30% decrease in labor costs for cutting operations

Based on their annual production volume and average profit margins, the company projects that the machine will pay for itself within 18 months. Beyond that point, the increased efficiency and capacity translate directly into improved profitability.

It's important to note that ROI can vary significantly based on individual business circumstances. Factors such as existing equipment, workforce skill levels, and specific market demands all play a role in determining the value of CNC investment.

Additionally, consider the long-term benefits beyond immediate financial returns. A CNC shaped glass cutting machine can position your business as a cutting-edge provider, potentially attracting high-value clients and projects that require advanced manufacturing capabilities.

Conclusion

The adoption of CNC shaped glass cutting machines represents a significant leap forward in glass manufacturing technology. From dramatic efficiency gains to the ability to create complex shapes with unprecedented precision, these machines offer a host of benefits that can transform your production capabilities.

While the initial investment may seem daunting, the potential for increased productivity, reduced waste, and expanded design possibilities make CNC technology an attractive option for forward-thinking glass manufacturers. By carefully analyzing your specific business needs and conducting a thorough ROI assessment, you can determine if a CNC shaped glass cutting machine for sale is the right choice to propel your production into the future.

As the glass industry continues to evolve, staying competitive means embracing technologies that offer both precision and flexibility. CNC shaped glass cutting machines provide exactly that, opening up new horizons for creativity, efficiency, and growth in glass manufacturing.

Are you ready to take your glass production to the next level? Shandong Huashil Automation Technology Co., LTD is here to help. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced CNC shaped glass cutting machines that combine cutting-edge technology with unmatched reliability. Our expertise in glass processing solutions has made us a trusted partner for customers worldwide.

FAQ

Q1: What types of glass can be cut with a CNC shaped glass cutting machine?

A: CNC shaped glass cutting machines are versatile and can handle a wide variety of glass types, including float glass, tempered glass, laminated glass, low-E glass, and mirror glass. The precision and flexibility of CNC technology make it suitable for cutting both thin and thick glass sheets, as well as specialized glass materials used in industries such as automotive and electronics.

Q2: How does CNC glass cutting compare to water jet cutting in terms of precision and efficiency?

A: While both CNC glass cutting and water jet cutting offer high precision, CNC glass cutting generally provides a faster cutting speed and cleaner edges, especially for straight cuts and simple shapes. Water jet cutting excels in cutting very thick glass or when dealing with extremely complex shapes. CNC glass cutting machines are typically more energy-efficient and have lower operating costs compared to water jet systems. The choice between the two often depends on the specific requirements of the project and the types of glass being cut.

Q3: What maintenance is required for a CNC shaped glass cutting machine?

A: Regular maintenance is crucial for ensuring the longevity and optimal performance of a CNC shaped glass cutting machine. This typically includes daily cleaning of the cutting surface and tools, regular lubrication of moving parts, periodic calibration of the cutting head and positioning system, and replacement of wear parts such as cutting wheels. It's also important to follow the manufacturer's guidelines for software updates and system checks. While CNC machines are designed for reliability, implementing a preventive maintenance schedule can significantly reduce downtime and extend the machine's lifespan.

Q4: Can CNC shaped glass cutting machines integrate with existing production systems?

A: Yes, modern CNC shaped glass cutting machines are designed with integration in mind. Many can be seamlessly incorporated into existing production lines and can interface with CAD/CAM software systems. This allows for a smooth workflow from design to production. Advanced CNC machines often come with Industry 4.0 capabilities, enabling data exchange with other smart factory systems for improved production planning and quality control. When considering integration, it's important to discuss your specific requirements with the machine manufacturer to ensure compatibility with your current setup.

CNC Shaped Glass Cutting Machine: Revolutionizing Precision in Glass Manufacturing | HUASHIL

Are you looking to enhance your glass production capabilities with state-of-the-art technology? Look no further than Shandong Huashil Automation Technology Co., LTD. Our advanced CNC shaped glass cutting machines are designed to meet the most demanding requirements of modern glass manufacturing.

With our years of experience in automated R&D and manufacturing, we offer cutting-edge solutions that combine precision, efficiency, and reliability. Our CNC machines are trusted by glass manufacturers worldwide for their superior performance and ability to handle complex cutting tasks with ease.

Don't let outdated equipment hold your business back. Upgrade to a HUASHIL CNC shaped glass cutting machine and experience the difference in quality, speed, and versatility. Our team of experts is ready to help you find the perfect solution for your specific needs.

Ready to take the next step? Contact us today at salescathy@sdhuashil.com to learn more about our products and how we can help transform your glass cutting operations. Let HUASHIL be your partner in achieving manufacturing excellence!

References

1. Johnson, M. (2022). "Advancements in CNC Technology for Glass Fabrication." Journal of Glass Processing and Automation, 15(3), 78-92.

2. Smith, A., & Brown, L. (2021). "Comparative Analysis of Traditional and CNC Glass Cutting Methods." International Glass Technology Review, 28(2), 145-160.

3. Zhang, Y., et al. (2023). "Economic Impact of CNC Implementation in Small to Medium Glass Manufacturing Enterprises." Journal of Industrial Engineering and Management, 11(4), 203-218.

4. Glass Processing Association. (2022). "Annual Report on Glass Manufacturing Technologies and Market Trends." GPA Publications.