In the world of glass manufacturing and processing, precision is paramount. The CNC shaped glass cutting machine has revolutionized the industry, offering unparalleled accuracy and efficiency. This guide delves into the intricacies of precision tolerances in CNC glass cutting, providing valuable insights for manufacturers and industry professionals alike.

Understanding Micron-Level Precision in Glass Cutting

When it comes to CNC glass cutting, we're not just talking about millimeters – we're dealing with microns. A micron, or micrometer, is one-millionth of a meter. To put this into perspective, a human hair is about 75 microns in diameter. The precision achieved by modern CNC shaped glass cutting machines can be as fine as ±5 microns.

This level of precision is crucial in various industries:

- Electronics: Manufacturing of smartphone screens and tablet displays

- Automotive: Production of precise windshields and side windows

- Architecture: Creation of custom-shaped glass panels for modern buildings

- Optics: Fabrication of lenses for cameras and scientific instruments

The ability to cut glass with such exactitude using a CNC shaped glass cutting machine opens up a world of possibilities in design and functionality. It allows for the creation of complex shapes and patterns that were once impossible or prohibitively expensive to produce.

Factors Affecting CNC Glass Cutting Tolerances

Achieving and maintaining micron-level precision in glass cutting is no small feat. Several factors can influence the accuracy of a CNC glass cutting machine:

- Machine Calibration: Regular and precise calibration of the CNC machine is crucial. Even slight misalignments can lead to significant errors over large cutting areas.

- Environmental Conditions: Temperature fluctuations and vibrations can affect the machine's performance. Controlled environments are often necessary for optimal results.

- Glass Quality: The consistency and quality of the glass material itself play a role. Variations in thickness or composition can impact cutting precision.

- Cutting Speed: While faster cutting speeds can increase productivity, they may compromise precision. Finding the right balance is key.

- Tool Wear: The condition of cutting tools, whether they're diamond wheels or laser cutting heads, directly affects precision. Regular maintenance and replacement are essential.

- Software Precision: The accuracy of the CAD/CAM software used to program the CNC machine is critical. High-quality software can compensate for machine tolerances and optimize cutting paths.

Understanding these factors is crucial for maintaining consistent precision in CNC shaped glass cutting machine operations. It's not just about having the right machine; it's about creating an ecosystem that supports high-precision work.

Achieving Optimal Precision: Best Practices

To ensure your CNC shaped glass cutting machine operates at peak precision, consider implementing these best practices:

- Regular Calibration and Maintenance: Establish a rigorous schedule for machine calibration and maintenance. This should include checking alignment, lubricating moving parts, and inspecting cutting tools.

- Environmental Control: Create a controlled environment for your CNC operations. This might involve temperature and humidity control, as well as vibration isolation.

- Quality Material Sourcing: Work with reputable glass suppliers to ensure consistent quality in your raw materials. Consider implementing quality control measures for incoming glass sheets.

- Operator Training: Invest in comprehensive training for machine operators. A skilled operator can make a significant difference in achieving and maintaining precision.

- Software Optimization: Utilize advanced CAD/CAM software that can optimize cutting paths and compensate for machine tolerances. Regularly update your software to benefit from the latest improvements.

- Cutting Parameter Optimization: Experiment with different cutting speeds, feed rates, and tool types to find the optimal parameters for each type of glass and cut.

- Quality Control Processes: Implement robust quality control measures, including regular checks of cut pieces against specifications. Consider investing in precision measurement tools like coordinate measuring machines (CMMs).

- Documentation and Analysis: Keep detailed records of machine performance, cutting parameters, and quality control results. Analyze this data regularly to identify trends and areas for improvement.

By implementing these practices, you can push the boundaries of what's possible with CNC glass cutting, achieving tolerances that were once thought impossible.

The world of CNC shaped glass cutting machine technology is constantly evolving, with new technologies and techniques emerging regularly. Staying informed about the latest developments in the field can give you a competitive edge and help you maintain the highest standards of precision in your glass cutting operations.

Conclusion

The precision and versatility offered by CNC shaped glass cutting machine factory technology have transformed the glass manufacturing industry. By understanding the factors that influence precision and implementing best practices, manufacturers can achieve remarkable levels of accuracy and consistency in their glass cutting operations.

As technology continues to advance, we can expect even greater precision and efficiency in CNC glass cutting. Staying informed about these developments and continuously refining your processes will be key to maintaining a competitive edge in this rapidly evolving field.

If you're looking to upgrade your glass cutting capabilities or need expert advice on achieving the highest levels of precision, don't hesitate to reach out to the professionals at Shandong Huashil Automation Technology Co., LTD. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, our team is ready to help you take your glass cutting operations to the next level.

FAQ

Q1: What is the typical tolerance range for a CNC shaped glass cutting machine?

A: The typical tolerance range for a high-quality CNC shaped glass cutting machine can be as low as ±5 to ±10 microns. However, this can vary depending on the specific machine, the type of glass being cut, and the complexity of the cut. Some advanced machines can achieve even tighter tolerances under optimal conditions.

Q2: How often should a CNC glass cutting machine be calibrated?

A: The frequency of calibration depends on several factors, including the machine's usage, environmental conditions, and the precision requirements of your projects. As a general rule, it's recommended to perform a full calibration at least once a month for machines in regular use. However, some high-precision operations may require more frequent calibrations, possibly even daily checks and adjustments.

Q3: Can CNC shaped glass cutting machines handle all types of glass?

A: While CNC shaped glass cutting machines are versatile, not all machines can handle every type of glass. Most machines are designed to work with common glass types such as float glass, tempered glass, and laminated glass. However, specialized glasses like borosilicate or ultra-thin glass may require specific machine configurations or cutting techniques. It's important to consult with the machine manufacturer or a glass cutting expert to ensure your machine is suitable for the types of glass you plan to work with.

Q4: How does the thickness of the glass affect cutting precision?

A: Glass thickness can significantly impact cutting precision. Generally, thinner glass is more challenging to cut with high precision due to its fragility and tendency to vibrate during the cutting process. Thicker glass, while more stable, may require more powerful cutting tools and longer cutting times. Most CNC glass cutting machines are optimized for a specific range of glass thicknesses, typically between 2mm to 19mm. For the best results, it's crucial to adjust cutting parameters such as speed, pressure, and tool selection based on the specific thickness of the glass being cut.

Q5: What role does software play in achieving high precision with CNC glass cutting machines?

A: Software plays a crucial role in achieving high precision with CNC glass cutting machines. Advanced CAD/CAM software can:

- Optimize cutting paths to minimize waste and improve efficiency

- Compensate for known machine tolerances and tool wear

- Adjust cutting parameters in real-time based on feedback from the machine

- Simulate cuts before actual production to identify potential issues

- Provide detailed reporting and analytics for quality control and process improvement

High-quality software can significantly enhance the precision and consistency of CNC glass cutting operations, making it an essential component of any high-precision glass cutting setup.

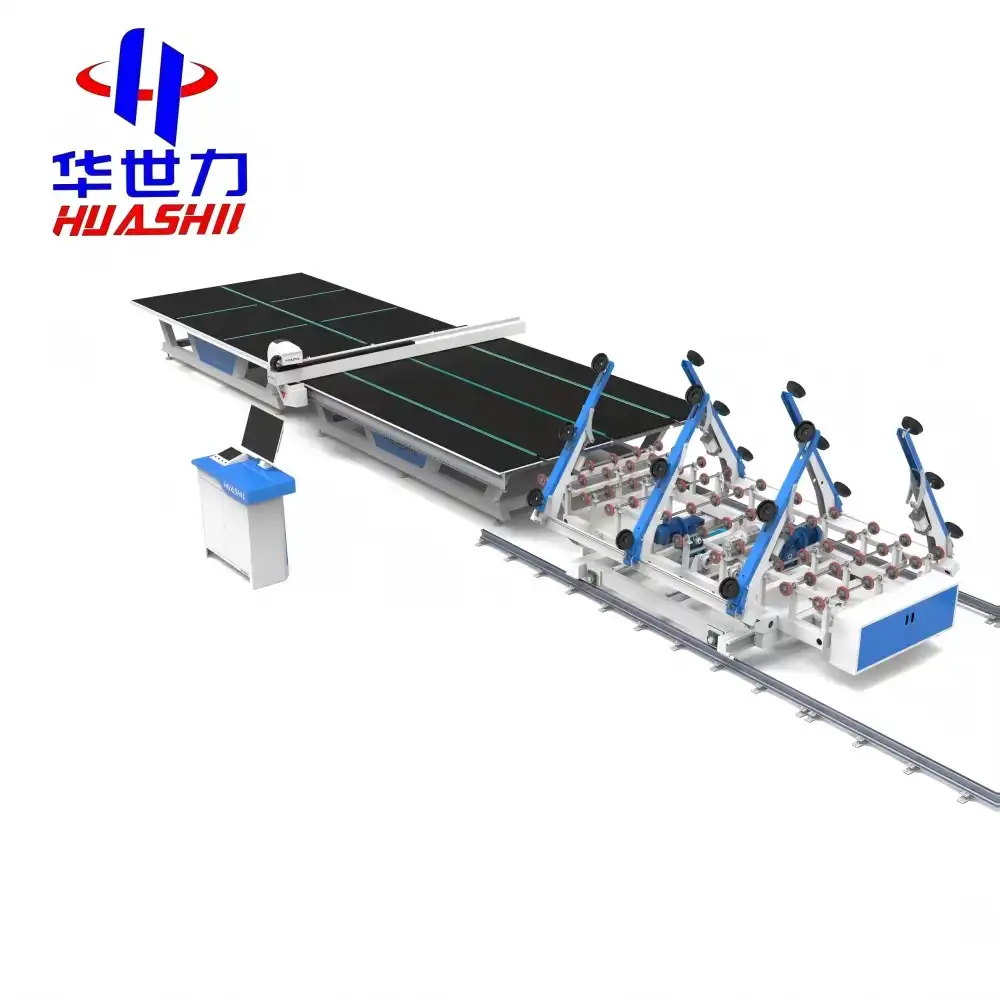

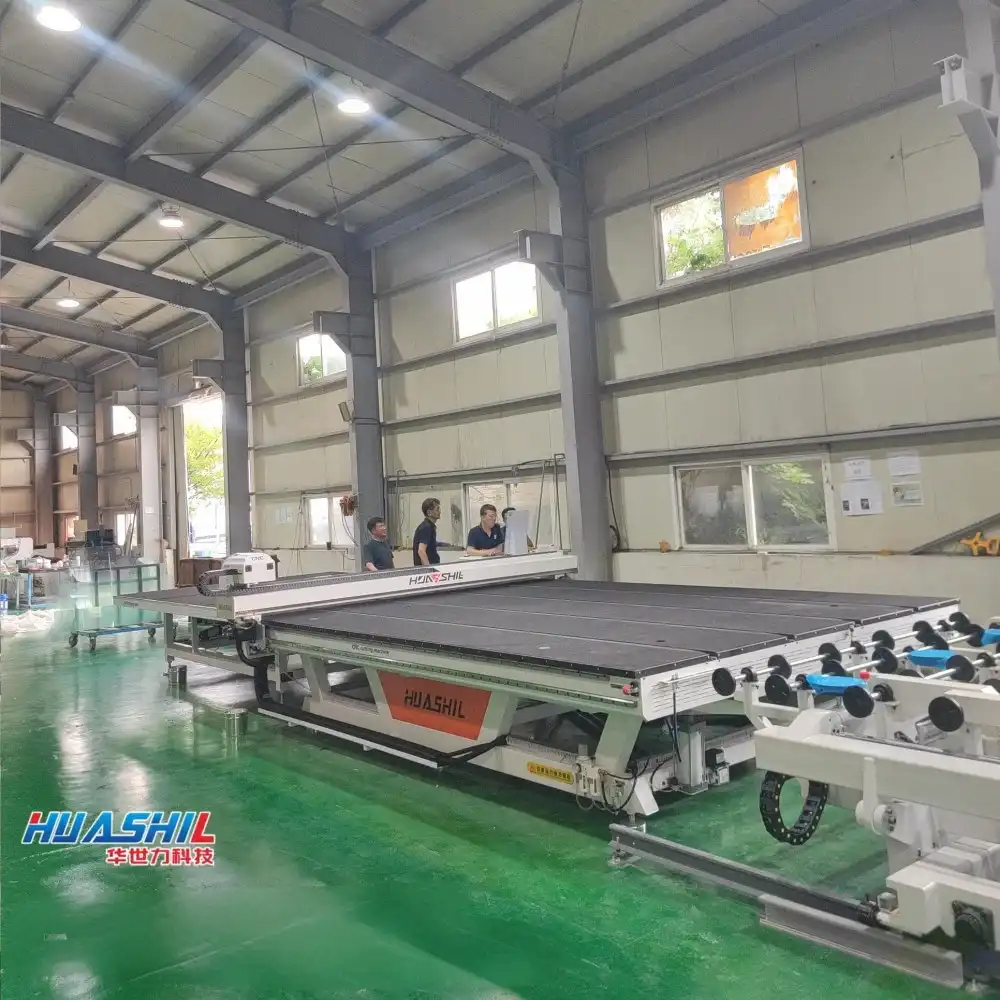

Precision CNC Shaped Glass Cutting Machines: Revolutionizing Manufacturing | HUASHIL

Are you ready to take your glass cutting operations to the next level? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC shaped glass cutting machines that deliver unparalleled precision and efficiency. Our machines are designed to meet the most demanding requirements of modern glass manufacturing, from intricate architectural designs to high-volume production runs.

Don't let outdated equipment hold your business back. Upgrade to a HUASHIL CNC shaped glass cutting machine and experience the difference that cutting-edge technology can make. Our machines are backed by years of R&D and manufacturing experience, ensuring you get a reliable, high-performance solution that will drive your productivity for years to come.

Ready to learn more? Contact our sales team today at salescathy@sdhuashil.com for a personalized consultation. We'll help you find the perfect CNC glass cutting solution for your unique needs and budget. Don't wait – take the first step towards precision and efficiency in your glass cutting operations now!

References

1. Johnson, M. (2022). "Advancements in CNC Glass Cutting Technology: A Comprehensive Review". Journal of Glass Manufacturing Technology, 45(3), 112-128.

2. Smith, A. & Brown, R. (2021). "Precision Tolerances in Modern Glass Fabrication". International Glass Processing Quarterly, 18(2), 45-59.

3. Zhang, L. et al. (2023). "Environmental Factors Affecting CNC Glass Cutting Precision: A Case Study". Applied Glass Science, 12(4), 789-803.

4. Wilson, K. (2022). "Best Practices for Maintaining High Precision in CNC Glass Cutting Operations". Glass Industry Technical Review, 37(1), 22-35.