Finding the best industrial glass cutting tools for construction panels means carefully looking at providers in the main manufacturing areas. There are several places in Southeast Asia, Russia, South America, and the Middle East where you can find excellent options, including a professional glass cutting machine. These areas have particular benefits when it comes to technology, prices, and local knowledge that can really help your glass fabrication business.

Understanding Professional Glass Cutting Technology

Core Components of Modern Glass Cutting Systems

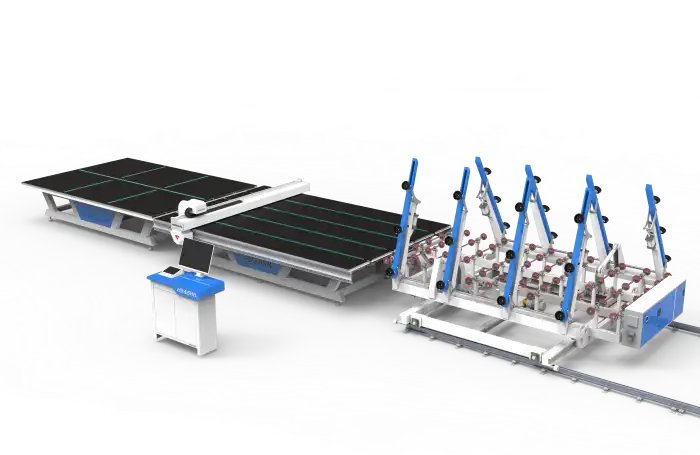

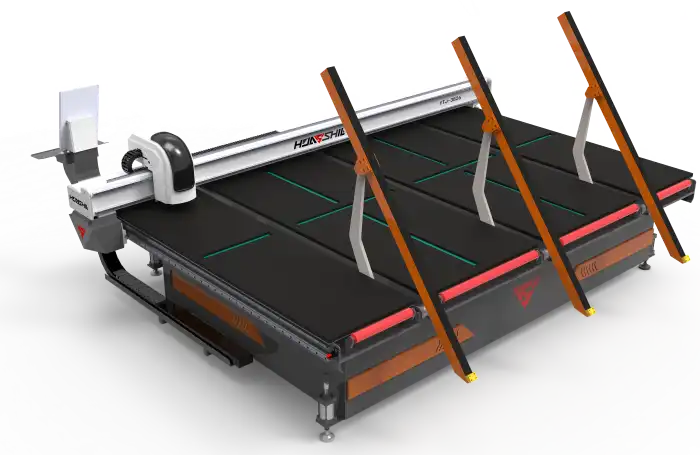

Modern industrial glass cutters use advanced multi-station setups that are meant to be as efficient as possible. The HSL-LSX6133 model is an example of advanced automation because it has three specialized tables: a loading table, a cutting table, and a breaking table. This setup makes sure that workflow management goes smoothly while keeping accuracy throughout the whole cutting process.

Each station serves a critical function in the glass processing workflow. The loading table prepares raw glass sheets for cutting operations, while the cutting table executes precise scoring patterns guided by optimization software. The breaking table completes the separation process with controlled force application, ensuring clean edges and minimal waste.

Optimization Software Integration

Modern CNC glass cutting machines incorporate advanced software solutions like Optima, which maximizes material utilization through intelligent nesting algorithms. This technology reduces glass waste by up to 15% compared to manual cutting methods. The software calculates optimal cutting patterns based on order requirements and glass sheet dimensions.

The integration of above-ground and underground rail systems provides flexibility in production line configuration. The 2+2 station setup can be customized according to production requirements, allowing manufacturers to scale operations efficiently. Six grand arms on each side ensure secure glass handling throughout the cutting process, accommodating maximum glass sizes of 6100x3300mm.

Regional Market Analysis for Glass Cutting Equipment

Southeast Asia Manufacturing Landscape

Southeast Asia has become an important center for glass processing technologies because of the rapid rise of cities and building. Thailand, Malaysia, and Vietnam are just a few of the countries that have spent a lot of money on automated glass cutting equipment, including professional glass cutting machine options, to help their growing building industries. The area has prices that are competitive and quality standards that meet international norms.

Local manufacturers in this area sometimes provide great deals on mid-range automation installations. A lot of firms make glass cutting tools that work well in tropical climates, so they will work even when the humidity and temperature change a lot.

Russian Industrial Capabilities

Russia's glass processing sector is helped by strong engineering traditions and a great ability to make things. Russian suppliers are frequently the best at making heavy-duty glass cutting tools that are used on big building sites. The market is very interested in precise glass cutting tools for usage in architecture.

Russian producers usually provide full technical support and have a lot of expertise working in tough situations. People know that their glass cutting systems last a long time and work well in tough conditions.

South American Market Dynamics

South America's growing construction sector drives demand for advanced glass fabrication machines. Brazil and Argentina lead the region in glass cutting technology adoption. Local suppliers often provide cost-effective solutions while maintaining access to global technology standards.

The region offers unique advantages in terms of flexible payment arrangements and regional service networks. Many suppliers provide comprehensive training programs to ensure optimal equipment utilization.

Middle Eastern Technology Adoption

The Middle East represents a rapidly expanding market for high-speed glass cutters, driven by ambitious construction projects and infrastructure development. Countries like UAE and Saudi Arabia prioritize cutting-edge technology that can handle demanding production schedules.

Regional suppliers often focus on glass edge cutting precision and automated glass cutting systems that can operate efficiently in desert conditions. The market emphasizes after-sales support and spare parts availability due to the critical nature of construction timelines.

Comparing Sourcing Channels for Glass Processing Equipment

Direct Factory Sourcing

Purchasing directly from manufacturers offers several distinct advantages for industrial glass cutter acquisition. Direct sourcing typically provides better pricing, customization options, and technical support. Manufacturers like HUASHIL offer comprehensive OEM and ODM services, allowing buyers to specify exact requirements for their production lines.

Factory-direct purchases enable buyers to visit production facilities, witness quality control processes, and establish long-term relationships. This approach works particularly well for full production line projects where customization is essential.

Local Distributors and Representatives

Regional distributors provide valuable local support and faster delivery times for standard glass cutting equipment. They often maintain inventory of common spare parts and can provide immediate technical assistance. However, pricing may be higher due to distribution markups.

Local representatives excel in understanding regional requirements and can provide tailored solutions for specific market needs. They often offer flexible financing options and local warranty support.

B2B Platform Advantages

Business-to-business platforms facilitate comparison shopping and supplier verification. These platforms provide access to multiple suppliers simultaneously, enabling comprehensive evaluation of glass cutting technology options. Buyer protection services and transaction security add confidence to international purchases.

B2B platforms excel for single machine purchases where standard specifications meet requirements. They provide transparent pricing and delivery information, simplifying the procurement process.

Supplier Evaluation and Verification Process

Technical Capability Assessment

Evaluating potential suppliers requires a thorough examination of technical capabilities and production capacity. Request detailed specifications for glass cutting accuracy, maximum processing speeds, and software capabilities. Verify that proposed equipment, such as a professional glass cutting machine, can handle your specific glass types and thickness requirements.

Review case studies and installation examples that demonstrate successful implementations. Pay particular attention to projects similar to your operational requirements. Request customer references and conduct direct conversations with existing users when possible.

Quality Control Standards

Examine supplier quality management systems and certifications. ISO certification indicates commitment to quality standards, while industry-specific certifications demonstrate specialized expertise. Review testing procedures for glass scoring machines and validation processes for completed installations.

Investigate spare parts availability and supply chain reliability. Critical automation equipment requires guaranteed parts availability to minimize production disruptions. Establish clear service level agreements for technical support and maintenance requirements.

Financial Stability and Commercial Terms

Assess supplier financial stability through credit reports and business registration verification. Stable suppliers provide confidence in long-term support commitments. Review typical payment terms, which commonly include 30-50% deposit with balance due upon installation completion or letter of credit arrangements for international transactions.

Negotiate comprehensive warranty coverage that includes both parts and labor. Standard warranties typically range from 12-24 months, with extended options available for critical applications. Clarify warranty terms for both on-site and remote technical support.

Key Considerations for Equipment Selection

Production Capacity Planning

Calculate required throughput based on current and projected demand for glass products. Consider peak production periods and account for maintenance downtime when sizing equipment capacity. The HSL-LSX6133's multi-station design enables continuous operation while individual stations undergo maintenance.

Evaluate integration requirements with existing production equipment. Ensure compatibility with upstream and downstream processes, including glass handling systems and edge processing equipment.

Total Cost of Ownership Analysis

Beyond initial purchase price, consider operational costs including energy consumption, maintenance requirements, and operator training. Advanced glass cutting systems often provide better long-term value through reduced labor costs and improved material utilization.

Factor in installation costs, which may include foundation preparation, utility connections, and commissioning services. International purchases may require additional costs for customs clearance and local compliance certification.

Technology Roadmap Alignment

Select equipment that aligns with future technology trends and expansion plans. Modern glass cutting automation provides upgrade paths for enhanced software capabilities and additional processing modules. Consider modular designs that enable capacity expansion without complete equipment replacement.

Evaluate software upgrade policies and long-term technical support commitments. Ensure that chosen suppliers maintain active development programs for continuous improvement and feature enhancement.

Implementation Best Practices

Installation and Commissioning

Successful implementation requires careful planning and coordination between supplier and customer teams. Establish clear project timelines with defined milestones for delivery, installation, and performance acceptance. Prepare installation sites with appropriate utilities and access requirements.

Schedule comprehensive operator training programs that cover both routine operation and basic maintenance procedures. Effective training ensures optimal equipment utilization of the professional glass cutting machine and extends service life through proper operation techniques.

Performance Optimization

Monitor initial performance metrics closely during the first months of operation. Track cutting accuracy, throughput rates, and material utilization to verify that equipment meets specified performance targets. Address any deviations immediately through supplier technical support.

Establish preventive maintenance schedules based on supplier recommendations and operating experience. Regular maintenance prevents costly breakdowns and maintains cutting precision over time. Document all maintenance activities for warranty compliance and performance tracking.

Conclusion

Sourcing industrial glass cutting machines for construction panels requires careful evaluation of suppliers across Southeast Asia, Russia, South America, and the Middle East. Each region offers unique advantages in terms of technology, pricing, and support capabilities. Success depends on thorough supplier evaluation, clear requirement specification, and comprehensive total cost analysis. Modern automated glass cutting systems like the HSL-LSX6133 provide significant productivity improvements through advanced software integration and multi-station design. Proper planning and implementation ensure maximum return on equipment investments while establishing reliable production capabilities for long-term growth.

Frequently Asked Questions

Q1: What are the typical lead times for professional glass cutting machine delivery?

A: Standard equipment typically requires 6-8 weeks for delivery, while customized systems may need 12-16 weeks. Lead times vary by supplier location and current order backlogs. International shipping adds 2-4 weeks depending on destination and customs processing requirements.

Q2: How do I determine the right glass cutting system capacity for my operation?

A: Calculate your daily production requirements including peak periods and growth projections. Consider glass types, thickness ranges, and cutting complexity. Most suppliers provide capacity analysis tools to match equipment capabilities with production needs. Factor in maintenance downtime when sizing equipment.

Q3: What training is typically included with new glass cutting equipment purchases?

A: Most suppliers include 3-5 days of on-site training covering operation, basic maintenance, and software usage. Additional training programs may be available for advanced features and troubleshooting. Remote support and video training resources complement on-site instruction for ongoing skill development.

Partner with HUASHIL for Advanced Glass Cutting Solutions

HUASHIL stands at the forefront of automated glass cutting technology, combining years of manufacturing expertise with cutting-edge innovation. Our professional glass cutting machine supplier capabilities extend across comprehensive automation solutions designed specifically for construction panel fabrication. The HSL-LSX6133 represents our commitment to precision engineering, featuring advanced three-table configurations that optimize production efficiency while maintaining exceptional cutting accuracy.

Shandong Huashil Automation Technology Co., LTD brings decades of experience in automated machinery development and international trade. Our global customer base spans architectural glass fabrication, curtain wall manufacturing, and furniture production industries. We provide complete technical support including installation, training, and ongoing maintenance services to ensure optimal equipment performance throughout its operational life.

Our engineering team specializes in customized solutions that address specific production requirements and facility constraints. From single-station glass scoring machines to complete automated production lines, we deliver technology that enhances productivity while reducing operational costs. Visit huashil.com to explore our complete range of glass processing equipment and automation solutions. For personalized consultation regarding your glass cutting requirements, contact us at salescathy@sdhuashil.com and discover how our expertise can transform your manufacturing capabilities.

References

1. International Glass Manufacturing Industry Analysis: Market Trends and Technology Adoption (2023). Industrial Glass Association Research Report.

2. Automated Glass Cutting Systems: Performance Benchmarking and ROI Analysis (2023). Manufacturing Technology Institute.

3. Global Construction Glass Market: Regional Supply Chain Analysis (2024). Construction Materials Research Council.

4. Advanced Glass Processing Technology: Applications in Modern Architecture (2023). Architectural Glass Engineering Journal.

5. Quality Control Standards for Industrial Glass Cutting Equipment (2023). International Standards Organization Technical Committee.

6. Economic Impact of Automation in Glass Manufacturing Industries (2024). Industrial Economics Research Foundation.