The main difference between manual and automated glass cutting tables is how they are used and how advanced their technology is. People who work at manual glass cutting tables have to use traditional tools to do the cutting by hand. Automated systems, on the other hand, have computerized controls, precise cutting mechanisms, and advanced software optimization. Manual glass cutting tables usually have lower start-up costs, but they need skilled workers and take longer to process. Automated glass cutting table solutions offer higher accuracy, faster production rates, and less reliance on manual labor. This makes them perfect for high-volume manufacturing settings that value consistency and efficiency above all else.

How to Use Manual Glass Cutting Tables?

Manual glass cutting systems are old-fashioned ways of working with glass that have been used for many years. Most of the time, these workbenches come with basic safety features like measuring grids, suction cup systems, and places to put hand-operated cutting tools.

Most manual glass cutting tables have height-adjustable mechanisms and surfaces that are made to handle glass well. When operators use handheld cutting tools and measuring devices, they rely on their knowledge to make accurate cuts. Specialized coatings are often built into the material of the cutting table's surface to protect glass from damage during processing.

Some important things about manual systems are:

- Full control over all cutting processes by the operator

- Lower costs to buy the equipment at first

- Needs for minimal power consumption

- Easy maintenance, and replacement parts are easy to find

- Ability to make your own cutting patterns

Manual glass cutting tables are better for your business if you need cost-effective ways to make small amounts of products or do specialized custom work.

Looking into technology for automatic glass cutting

With computerized accuracy and cutting edge engineering, automated glass cutting systems change the way things are made. Modern technology is built into these high-tech machines so they can consistently produce high-quality results for a wide range of glass cutting table sizes and shapes.

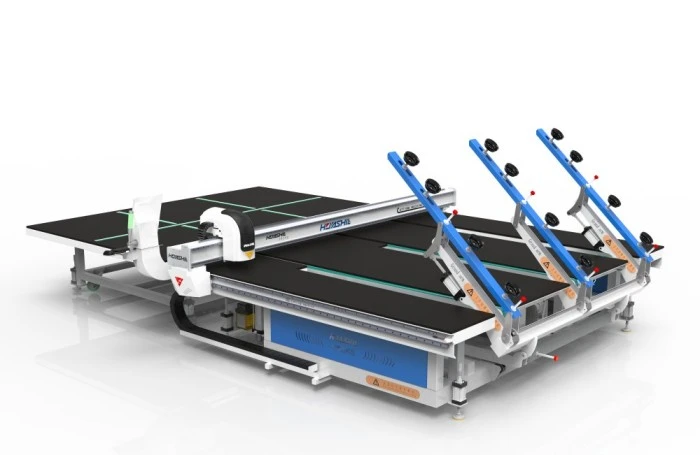

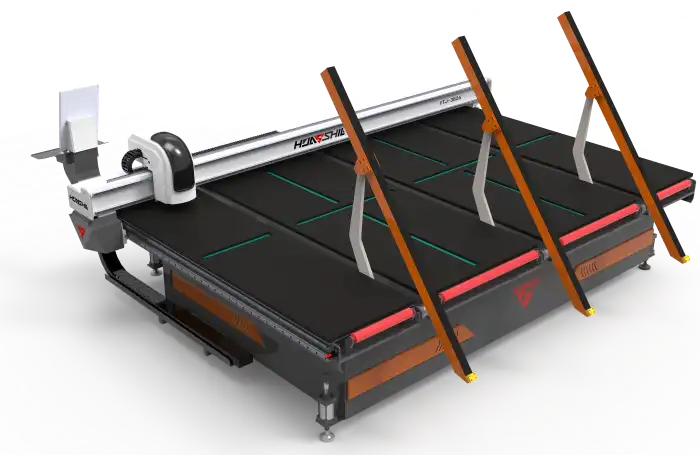

Modern automated systems have optimization software that figures out the best ways to cut materials, which cuts down on waste by a large amount. With a cutting thickness range of 2–19mm and a maximum glass size of 3660x2440mm, the HUASHIL HSL-YTJ3826 is a great example of high-tech automation. This system has edge-finding technology, pressure control systems, and the ability to load automatically.

Advanced features that are common in automatic glass cutting tables are:

- Systems that use air to float glass so it moves smoothly

- 360-degree control ability from a distance

- Ejector rod systems make it easy to move things around.

- Safety systems that work together and have emergency stops

- Monitoring and collecting data on production in real time

Automated glass cutting solutions are better for your manufacturing needs if you want to achieve high quality standards while also increasing production efficiency.

Performance Analysis: Speed and Accuracy Side by Side

Performance metrics show that cutting glass by hand and cutting it automatically are very different. Data from independent tests shows that automated systems always do better than manual methods when it comes to both speed and accuracy.

According to data that compares speeds, automated systems can handle 150 to 200 square meters per hour, while humans can only handle 20 to 30 square meters per hour in ideal conditions. This means that production throughput has increased by about 600% since automation technology was put in place.

Precision measurements show that automated systems consistently keep cutting tolerances within ±0.1mm, while manual cutting usually ends up with tolerances of ±0.5mm. The higher accuracy comes from computerized control systems that get rid of the chance of human error.

| Metrics for Performance | Hand-held Systems | Built-in Computers |

|---|---|---|

| How Fast You Cut | 20 to 30 m³/h | 150 to 200 m³/h |

| Tolerance for Precision | approximately 0.5 mm | about 0.1 mm |

| Throwaway Materials | 8–12% | 2-4 percent |

| Needs an Operator | 1.5 to 2 skilled workers | 1 tech |

Quality consistency is another important thing that sets us apart. When an operator is tired or has different levels of skill, automated systems always give the same results. On the other hand, manual processes depend a lot on the person's level of skill and concentration.

Automated precision cutting technology is better for meeting quality standards when you need to work on large curtain wall projects or meet strict architectural glass specifications.

A comparison of the costs of investing and running a business

To figure out how choosing a glass cutting table will affect your finances, you need to look at both the initial investment and the long-term costs of running the business. The total cost of ownership includes more than just the price of buying the equipment. It also includes the cost of labor, upkeep, and lost productivity.

The cost of the initial investment makes manual systems much more appealing. Setting up a professional glass cutting table by hand usually costs between $3,000 and $8,000. Automated systems, on the other hand, cost between $50,000 and $200,000, depending on their features and how they need to be customized.

But over time, operational expense analysis shows different patterns. For manual operations, the cost of labor includes paying two to three skilled workers each shift. However, for automated systems, only one technician is usually needed for maintenance and oversight.

The breakdown of annual operational costs shows:

- For manual systems, higher labor costs cancel out lower equipment wear and tear.

- Automated systems: lower labor costs but longer equipment wear and tear

- Due to optimization software, the cost of material waste makes automation more appealing.

- Maintenance costs depend on how complicated the system is and how it is used.

For medium to high-volume operations, return on investment calculations usually show that automated systems pay for themselves in 18 to 36 months. Manufacturers who make fewer items may need longer payback periods or decide that manual systems are more cost-effective.

If you want to keep your startup costs low and be able to handle changing production volumes, then manual glass cutting tables are a better choice.

When it's needed in business and other situations

There are different ways to use a glass cutting table for different kinds of work and project needs. You can find the best ways to make things in different situations if you know about these uses.

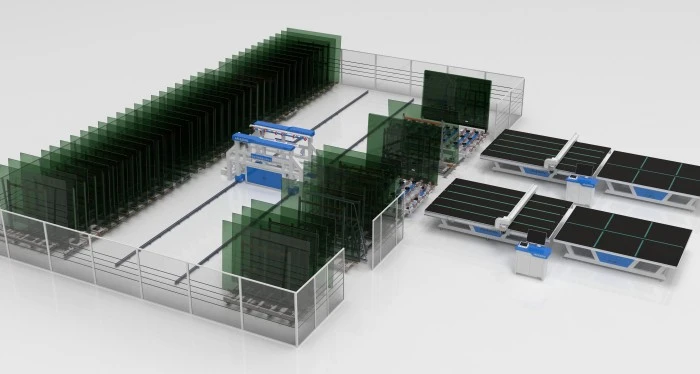

Plants that make a lot of windows and glass for buildings often find that automated systems help them do their jobs better. For curtain wall projects that need uniform quality and close tolerances, the only way to cut is with a machine.

Based on how much money they need to make, companies that make furniture and home decor often use both. For small orders, cutting furniture by hand might be more convenient, but machines are better for making a lot of furniture at once.

People who work with stained glass and other specialized crafts like manual glass cutting tables because they let them be more creative and have more direct control over more complicated designs. When you use these apps, being able to be creative is more important than making things quickly.

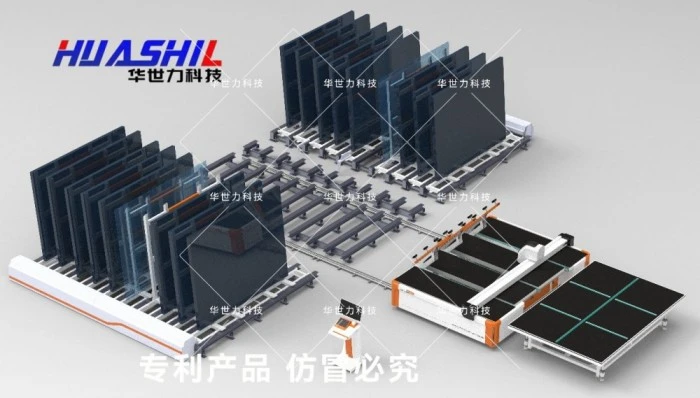

When a factory needs to do a lot of heavy work, they will usually choose well-built automated systems with a lot of room. The HUASHIL HSL-YTJ3826 is 4925x3650mm, which makes it easy to fit big wall panels made of glass.

When people work on do-it-yourself projects or in small workshops, they usually pick manual systems that are easy to move around and have a height that can be changed.

For operational flexibility, hybrid approaches that use both manual and automated tools are best. These work best when you have a lot of different products that are all different levels of complicated.

Technology Features and Capabilities

Modern glass cutting table technology incorporates sophisticated features that enhance precision, safety, and operational efficiency. Understanding these technological capabilities helps evaluate system suitability for specific applications.

Automated systems integrate optimization software like Optima, which calculates cutting patterns to minimize material waste. This software analyzes glass dimensions and required cuts to generate efficient cutting sequences that maximize material utilization.

Air flotation systems facilitate smooth glass movement across cutting table surfaces, reducing friction and potential damage during processing. These systems use controlled air pressure to create cushioning effects that protect glass integrity.

Advanced safety features include emergency stop mechanisms, operator presence detection, and automated shutdown procedures. These systems comply with international safety standards including CE certification requirements for equipment exported globally.

Remote control capabilities enable operators to manage cutting processes from safe distances. The 360-degree wireless control functionality provides complete operational flexibility while maintaining safety protocols.

Automatic pressure control systems adjust cutting force based on glass thickness and type, ensuring optimal cutting quality across different material specifications. This technology eliminates manual adjustments and reduces setup time between different jobs.

If you need advanced technological capabilities with comprehensive safety features, then automated glass cutting systems are more suitable for meeting modern manufacturing standards.

HUASHIL Glass Cutting Table Advantages

HUASHIL automated glass cutting solutions offer compelling advantages that address modern manufacturing challenges while delivering superior performance and reliability:

- Advanced Engineering Excellence: Our HSL-YTJ3826 model incorporates cutting-edge technology with maximum glass processing capacity of 3660×2440mm, accommodating large architectural panels and curtain wall components efficiently.

- Comprehensive Automation Features: Integrated automatic loading systems, pressure control mechanisms, and edge-finding technology streamline operations while maintaining consistent quality standards across all production runs.

- Precision Cutting Capabilities: Advanced optimization software (Optima) calculates optimal cutting patterns, reducing material waste to 2-4% compared to traditional methods, significantly improving material utilization and cost efficiency.

- Enhanced Safety Systems: Complete safety integration includes air flotation systems, ejector rod mechanisms, and 360-degree remote control operation, minimizing operator exposure to hazards while maintaining full operational control.

- Versatile Processing Range: Accommodates glass cutting thickness from 2-19mm, suitable for diverse applications from architectural glazing to furniture manufacturing and specialty glass processing requirements.

- International Certification Standards: CE and ISO9001 certifications ensure compliance with global quality and safety requirements, facilitating international installations and meeting stringent regulatory standards.

- Robust Construction Design: Heavy duty construction with dimensions of 4925×3650mm provides stable processing platform capable of handling demanding production schedules and maintaining precision over extended operation periods.

- Complete Technical Support: Comprehensive after-sales service includes installation assistance, operator training, maintenance guidance, and readily available replacement parts to ensure continuous production capability.

- Customization Capabilities: OEM and ODM support enables tailored solutions for specific production requirements, integrating seamlessly with existing manufacturing lines and specialized processing needs.

- Proven Industry Experience: Years of manufacturing expertise and global export experience ensure reliable equipment delivery and long-term partnership support for glass processing operations worldwide.

- Cost-Effective Operation: Reduced labor requirements and improved production efficiency typically recover initial investment within 18-36 months, providing substantial long-term operational savings and competitive advantages.

- Quality Assurance: Advanced technique implementation and stable quality control processes deliver consistent cutting results, meeting demanding specifications for architectural glass and precision manufacturing applications.

Conclusion

The choice between manual and automated glass cutting tables fundamentally depends on production requirements, quality standards, and operational objectives. Manual systems provide cost-effective solutions for smaller operations with flexibility needs, while automated technology delivers superior precision, efficiency, and consistency for high-volume manufacturing environments. Understanding performance differences, cost implications, and technological capabilities enables informed decision-making that aligns equipment selection with business goals. HUASHIL's advanced automation solutions offer comprehensive features and reliable support to help manufacturers achieve enhanced productivity and competitive advantages in today's demanding glass processing market.

Get cutting-edge glass projects done with HUASHIL.

You can change the way you work with glass with the help of cutting edge automated solutions from Shandong Huashil (China). When it comes to making things, we have a lot of different glass cutting table tools that can be used for everything from small projects to big industrial installations.

Our engineers can help you choose the best equipment setups by giving you clear technical advice. This is because they have a lot of experience. We help with every part of the project, from figuring out how to install the equipment and finding the right people to run it. We also offer technical support all the time to make sure the job is done right.

One of the best companies that makes glass cutting tables is HUASHIL. They use both cutting edge technology and reliable ways to check the quality of their work. Their goods are loved by people all over the world. We care about meeting international quality standards and making sure our customers are happy because we have ISO9001 and CE certifications.

No matter if you need help with a single machine or a whole production line, we can make sure that everything we do meets your exact needs. Because we offer OEM and ODM support, we can make solutions that work well for your business and don't cause any problems.

Check out HUASHIL's cutting edge glass technology to take your work to the next level and get more work. There are technical experts on our team who are ready to listen to your needs and give you specific tips that will help you reach your manufacturing goals.

Are you ready to change how you cut glass? HUASHIL automation technology can help your business make more things and compete better. Talk to our tech experts right away to find out how. Send our sales team an email at salescathy@sdhuashil.com to set up a meeting and get full equipment specs.

References

1. Glass Manufacturing Industry Association. "Automation Trends in Glass Processing Technology." Industrial Glass Manufacturing Report, 2023.

2. International Organization for Standardization. "Safety Requirements for Glass Cutting Equipment - ISO 12100 Guidelines." Safety Standards Publication, 2022.

3. European Glass Technology Conference. "Comparative Analysis of Manual vs Automated Glass Processing Systems." Annual Technical Proceedings, 2023.

4. American Architectural Manufacturers Association. "Quality Standards for Curtain Wall Glass Processing." Technical Bulletin Series, 2023.

5. Glass Processing Equipment Research Institute. "Economic Impact Analysis of Automation in Glass Manufacturing." Industry Economics Report, 2022.

6. World Glass Manufacturing Council. "Best Practices for Glass Cutting Table Selection and Implementation." Technical Guidelines Manual, 2023.