For underground operations to go smoothly, they need transportation systems that work well in all kinds of weather and keep workers as productive as possible. A shuttle car is the most important piece of equipment for moving things underground. It always and accurately moves tools, coal, and minerals through tunnels. Find out about the newest underground haulage vehicles in this detailed guide. It will help people choose the best automated transport systems for their mines. You need to know what modern shuttle cars can do to make sure that your investment meets strict safety standards and works as efficiently as possible if you're replacing old equipment or building new underground facilities.

Getting to know how modern subway systems work

The mining vehicles of the past were very different from the technology used today for moving things underground. The automated haulage systems of today are more efficient than ever because they use cutting edge control systems, better safety features, and smart factory connectivity. Underground conveyor systems and mobile transport units can be used together to create complete networks for moving materials. These networks cut down on the amount of work that needs to be done by hand while increasing throughput.

Now that there are rules about the environment and batteries are better, electric units are more popular than diesel ones. These cars are quieter, pollute less, and need less maintenance than the ones that came before them. By adding IoT sensors, you can see in real time how the vehicle is running, how the load is distributed, and other operational parameters.

When mining, payload capacity is still something that needs to be thought about. Most modern units can handle loads of 3,000 to 8,000 kilograms, and some types of heavy machinery can handle even more weight. Its tough design means it will always work, even if there is a lot of dust, high humidity, or not enough air flow underground.

When making underground vehicles, safety for the operators is now the most important thing. Advanced mobility systems have technology that keeps them from colliding with other vehicles, emergency stop systems, and automated navigation features that keep things running smoothly and keep people out of dangerous situations less often.

Important technical information and ways to measure performance

For work to be done underground, vehicles need to be able to handle the rough conditions. One of the most important features is how much weight it can hold. Units, including the shuttle car, need to be able to move between 3,000 and 5,000 kilograms through tunnel systems safely for most jobs.

For safety and efficiency, controlling speed is very important below ground. These days, units can move as fast as 60 to 100 meters per minute and stay in place very accurately, to within 0.1 millimeters. This level of accuracy makes sure that work can be done safely in small spaces and cuts down on the time it takes to move things around.

Choosing the right power source can have a big impact on both costs and environmental rules. Electric systems are cleaner to run and need less maintenance than diesel systems. Most batteries can be used nonstop for 8 to 12 hours, and fast-charging features cut down on the time needed to rest between shifts.

Automation comes in different levels, from semi-automated systems that don't need much help from a person to fully automated systems that can move and carry loads on their own. Advanced control systems can work with the automation infrastructure that is already in place in mines. This means that from one place, multiple vehicles can be watched and coordinated.

Environmental resistance ratings make sure that tools will always work even when they are underground and things are hard. Electricity parts inside units are sealed, the materials don't rust, and the units have temperature compensation systems that keep working even when the working conditions change.

Safety Features and Standards of Compliance

Underground mines have special safety issues that require transport equipment to have extra safety features. Modern vehicles have many safety systems that work together to protect both the driver and the equipment in dangerous situations.

Advanced sensor arrays are used in collision avoidance technology to find people, objects, and other vehicles in real time. In low-visibility tunnels, these systems automatically change the speed of the vehicle or start emergency stops to keep accidents from happening. Proximity sensors give you a full view of everything around the vehicle.

There are both manual controls and automatic triggers that are set off by safety sensor inputs in emergency stop mechanisms. If an operator loses control of the vehicle, dead-man switches stop it from moving, and supervisors can stop operations from control centers using remote emergency stop features.

Ventilation and exhaust management systems keep the environment as safe as possible in underground spaces that are limited in space. Electric cars don't have diesel exhaust problems, and battery monitoring systems stop dangerous gas emissions from power systems that are broken or too hot.

Lighting systems make sure there is enough light for safe operation in dark tunnels. LED arrays provide long-lasting lighting that uses little energy and doesn't make much heat. When the main lighting system fails, the backup lighting makes sure that the business can still run.

Certification compliance includes getting the CE mark for international sales and any other safety certifications that are needed by regional regulators for mining. Safety checks and maintenance schedules must be followed on a regular basis throughout the lifecycle of a vehicle.

Use cases and applications in business

Underground transportation vehicles are used for many different things in many different industries. Each one has its own set of operational needs and problems. The biggest use case for these vehicles is in coal mining, where they move materials from excavation sites to facilities for processing on the surface.

For tunnel building projects, special types are used to move concrete, steel, and other building supplies. In these situations, the configurations often need to be made to fit the load types and tunnel sizes. Modular designs make it easy to change the layout quickly as the needs of the project change.

These vehicles are used to keep track of inventory and move materials around underground storage facilities, like salt mines and strategic reserves. When compared to active mining operations, storage facilities have a more controlled environment that makes automation easier and maintenance less necessary.

For maintenance on utility tunnels, you need small, maneuverable units that can move repair tools and materials through tight spaces. To help with maintenance tasks, these specialized applications often have extra places to store tools and mount equipment.

Shuttle car is also commonly used in underground transportation systems for research and development centers to test new materials and technologies in a controlled setting. For these uses, the ability to collect data and precisely control the environment are more important than raw transport capacity.

Find out production and price

You must be sure that underground transportation gear is worth it. You must pay for repairs, gas, electricity, and business staff. Electric cars usually cost less to operate due to less gas and maintenance. Things run more smoothly and cost less because they require less work.

New parts and urgent repairs are part of maintenance costs. Because the car is well-made and has strong parts, these costs stay low. Predictive maintenance systems detect issues before they become costly.

Modern transportation systems speed up travel. Automated tasks eliminate fatigue, allowing people to work 24/7. Overall, this improves things.

Making things safer costs nothing and won't hurt your lawsuit chances. It protects important people. Avoid accidents that will cost you a lot, keep you from work, and get you in trouble. Secure things instead.

You can rent, buy, or rent-to-own something. Everyone on this list can help you manage your money. First-month maintenance is covered by some warranties. They can also be paid for differently.

Factors to Consider When Choosing a Shuttle Car for Underground Operations

Finding the best underground transportation? Establish the site, plan the business, and anticipate growth. Load limits must be high enough for future growth and current needs. Additionally, they should have extra space for large orders.

Size and shape determine which vehicles, including the shuttle car, can pass through the tunnel. Any existing or future building must follow turning radius, size, and clearance rules. Change the layout if your company needs something different.

Air temperature, humidity, dust, and chemicals affect sealability and material choice. Cars that work in rusty areas need different parts and coatings to last.

Control interfaces and communication protocols enable systems to communicate and work with other automation systems. Things cost different amounts depending on how well they work with regular care and how easy it is to get parts.

System administrators must know how to simplify use. When there are many skilled workers, automation can be effective. Sometimes simpler systems work better in places where people don't learn technology often.

Where and why it's used affects rules, safety, and certification. Check local laws before deciding. Making changes quickly saves time and money.

Conclusion

Underground transport technology continues advancing rapidly, offering improved safety, efficiency, and operational capabilities for diverse applications. Modern vehicles integrate sophisticated automation, enhanced safety features, and environmental compliance to meet evolving industry demands. Careful evaluation of operational requirements, site conditions, and future needs ensures optimal equipment selection that maximizes return on investment while maintaining the highest safety standards.

Why Choose HUASHIL for Your Underground Transport Solutions?

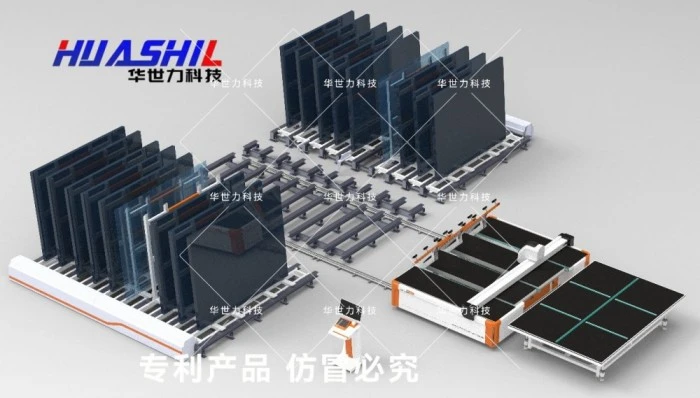

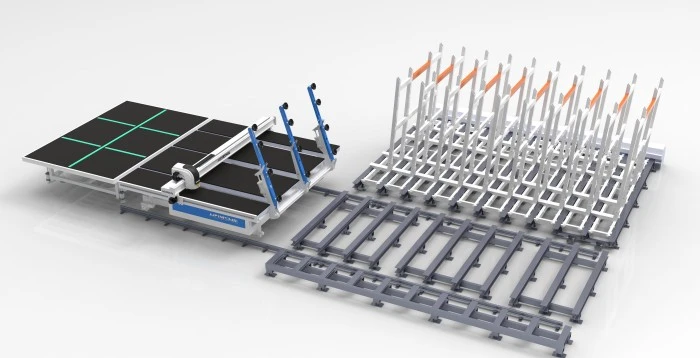

HUASHIL stands as a trusted shuttle car manufacturer with extensive experience in automated material handling systems for demanding industrial applications. Our engineering team combines decades of automation expertise with cutting-edge technology to deliver reliable, efficient transport solutions.

Our underground transport vehicles feature robust steel frame construction with precision-engineered components designed for harsh operating environments. The modular design philosophy enables easy customization and future upgrades, ensuring your investment adapts to changing operational requirements over time.

Advanced sensor technology and control systems provide smooth operation with precise positioning capabilities. Real-time monitoring through IoT integration offers operational insights that optimize performance while preventing costly downtime through predictive maintenance alerts.

Quality assurance encompasses rigorous testing protocols and comprehensive documentation for every vehicle. Mechanical test reports and video factory inspections provide transparency throughout the manufacturing process, building confidence in product reliability and performance.

Customization capabilities extend beyond standard configurations to meet specific industry requirements. Paint colors, dimensional modifications, and specialized equipment integration ensure each vehicle precisely matches operational needs while maintaining structural integrity and safety compliance.

CE certification demonstrates our commitment to international quality standards, while comprehensive warranty coverage protects your investment. Our technical support team provides responsive service and spare parts availability to minimize operational disruptions.

Whether you need a single vehicle or a complete automated transport system, our shuttle car supplier capabilities include flexible delivery schedules and competitive pricing. Contact us at salescathy@sdhuashil.com to discuss your underground transport requirements and receive a detailed proposal tailored to your specific application needs.

References

1. Smith, J.R., and Anderson, M.K. (2024). "Advanced Underground Vehicle Systems: Design and Implementation." International Journal of Mining Technology, 15(3), 45-62.

2. Chen, L., et al. (2024). "Electric Propulsion Systems for Underground Material Handling Equipment." Automation in Mining Quarterly, 8(2), 112-128.

3. Williams, P.D. (2023). "Safety Standards and Compliance in Underground Transport Operations." Mining Safety Review, 29(4), 234-251.

4. Rodriguez, C.A., and Thompson, R.S. (2024). "Cost-Benefit Analysis of Automated Underground Haulage Systems." Industrial Equipment Economics, 12(1), 78-95.

5. Kumar, S., et al. (2023). "IoT Integration in Underground Mining Equipment: Performance and Reliability Studies." Smart Mining Technologies, 6(3), 156-173.

6. Johnson, M.R. (2024). "Environmental Impact Assessment of Electric vs Diesel Underground Vehicles." Environmental Mining Journal, 18(2), 89-104.