A round glass grinding machine is a specialized piece of automated machinery made to exactly grind, polish, and shape round pieces of glass for use in many industrial settings. This high-tech glass polishing equipment uses precise servo motors and several grinding wheels to make sure the edges are always smooth and the surface is of the highest quality. In industries like making architectural glass, car glass, and furniture, where perfectly rounded and polished glass edges are needed for safety and aesthetic reasons, these machines are very important.

Understanding Round Glass Grinding Equipment

The most advanced automatic glass edge grinding technology is a round glass grinding machine. These high-tech systems have several grinding stations that are placed precisely by a computer. This allows for accurate circle glass processing. Modern round glass grinding equipment, on the other hand, has advanced servo motor controls and encoder-based automation that make sure consistent results even during high-volume production cycles.

The main function is to precisely grind glass using grinding wheels that are placed in a certain way. One side of most expert systems has three grinding wheels, usually set up as one rough grinding wheel, one fine grinding wheel, and one polishing wheel. One rough grinding wheel paired with two fine grinding wheels is another possible arrangement, but it depends on the needs of the application.

These tools are great at working with different kinds of glass, from regular architectural glass to specialized optical glass grinding jobs. The automatic glass grinder technology gets rid of mistakes made by people and makes production much more efficient. Modern units can fit glass pieces with openings ranging from 0.2 meters at the smallest to 1.5 meters at the largest. This makes them very flexible for a wide range of project sizes.

Adding encoder controls for automatic opening and closing mechanisms makes sure that the glass grinder stays in the exact right place during the whole process. This automation cuts down on the cost of labor while keeping quality standards that can't be met by manual work. These kinds of high-tech glass shaping tools are essential in today's competitive manufacturing world.

Manufacturing Challenges These Machines Address

In today's tough market, glass producers have to deal with a lot of problems. Traditional ways of finishing the edges of glass often have trouble being consistent, which can cause quality differences that can ruin whole production batches. Manual glass grinding takes a lot of work, a lot of time, and mistakes are common, especially when precise glass needs to be used in building applications.

Safety concerns are another big problem in the round glass grinding machine process. If the sides of the glass aren't finished properly, they can seriously hurt people during installation or use. Round glass grinding tools take care of this important problem by making sure that the edges are smooth and polished, so there are no sharp edges or other possible danger points.

Demands for production efficiency keep going up in all manufacturing areas. Businesses need ways to cut and grind glass that can keep up with high output while maintaining quality. Traditional ways of making things just can't keep up with the needs of modern production, especially when it comes to big building projects or making glass for cars.

As exact tolerances are needed for architectural glass and curtain walls, quality consistency becomes more and more important. Some things can go wrong with manual grinding that can't happen with automatic systems. These problems can be solved by modern CNC glass grinder technology, which is computer-controlled and keeps the exact specifications even after thousands of production runs.

Cost pressures drive manufacturers to look for ways to cut down on labor needs while also improving the quality of their products. Round glass grinding automation is the answer because it replaces many human tasks with tasks that can be done by a single machine. This consolidation cuts down on the need for floor space, lowers the amount of material handling, and greatly improves the efficiency of production processes.

Advanced Features and Technical Capabilities

Modern round glass grinding machines incorporate sophisticated technical features that set them apart from conventional glass processing equipment. The heart of these systems lies in their precision servo motor controls, which manage both conveying mechanisms and grinding wheel positioning with exceptional accuracy. These servo systems enable repeatable positioning within micron tolerances, essential for high-precision optical glass grinding applications.

The grinding motor configuration typically features six dedicated grinding motors, providing the power and torque necessary for efficient material removal across different glass types. This multi-motor approach ensures consistent grinding pressure while accommodating varying glass hardness levels and thicknesses. The distributed motor design also provides redundancy, minimizing production disruptions due to individual component failures.

Encoder-controlled automatic opening and closing mechanisms represent another breakthrough in glass grinding automation. These systems continuously monitor glass position and automatically adjust grinding wheel positioning to maintain optimal contact pressure throughout the entire grinding cycle. This real-time adjustment capability ensures consistent edge quality regardless of glass size variations or material irregularities.

The three-wheel grinding configuration offers exceptional versatility for different finishing requirements. The initial rough grinding stage removes excess material and establishes the basic edge profile. The fine grinding stage refines surface texture and eliminates scratches from the rough grinding process. The final polishing stage achieves the mirror-like finish required for premium glass applications.

Customization capabilities allow manufacturers to tailor machines for specific production requirements. Variable speed controls, adjustable grinding pressures, and programmable grinding cycles enable optimization for different glass types and thickness ranges. This flexibility proves invaluable for manufacturers serving diverse market segments with varying quality specifications.

Cutting-Edge Technology Behind Glass Grinding Automation

Mechanical, electrical, and software systems are very carefully combined in current round glass grinding machines to make them work. Modern encoder technology gives you real-time input on your position, so you can precisely control where the grinding wheel goes and how it moves. Industrial controllers talk to these encoders and process positioning data hundreds of times per second. This makes sure that grinding activities go smoothly and accurately.

Servo motor technology is another important step forward in automating the grinding of glass. Servo systems are different from standard AC motors because they can precisely control speed and torque while keeping the same performance even when the load changes. This feature is very useful when working with different kinds of glass that need different grinding settings to get the best results.

Computer numerical control (CNC) integration lets workers set up complicated cutting paths and save them for later use. This programmability lets you switch between different types of glass quickly, without having to make any changes by hand or go through a long setup process. The CNC glass grinder method also makes it easier to track quality by keeping thorough records of production and parameters.

Multiple sensors and tracking devices are built into safety systems so that they are always checking the conditions of operation. Overload protection, emergency stop circuits, and automatic shutdown sequences keep both the technology and the people who use it safe. These safety features meet international safety standards for manufacturing while keeping up with production levels.

Modern automation systems for grinding glass can also be monitored from afar, which lets production managers keep an eye on how the equipment is working and see if it needs any repair before problems happen. This method of predictive maintenance cuts down on unplanned downtime and increases the life and consistency of equipment performance.

Key Advantages of Automated Glass Grinding Systems

Fully automated glass cutting systems have huge advantages that change the way glass is made. Improving production productivity is the most obvious benefit. For example, modern machines can process glass pieces much faster than people could by hand. These efficiency improvements directly lead to higher throughput and lower prices per unit of production.

Another big benefit of automated glass edge grinding technology is that it makes quality stability possible. Computer-controlled systems get rid of human error, so every piece of glass meets the same standards, no matter how skilled or tired the user is. This stability is especially helpful for big building projects where uniformity in the glass is important for both looks and strength.

For manufacturers who use automated solutions, lowering the cost of labor is a big long-term gain. Round glass grinding machines usually only need one operator to handle multiple production rounds. This is different from manual processes, which need a person to be in charge of each grinding station. This improvement in labor efficiency has a direct effect on how profitable manufacturing is, and it also helps markets that are short on trained workers.

As technology is put in place, safety standards are raised, protecting workers from grinding hazards and injuries caused by doing the same thing over and over again. Autonomous systems keep grinding operations inside, and they provide constant edge quality that lowers the risk of handling problems in later steps.

Manufacturers can quickly adapt to changing market needs thanks to the benefits of flexibility. Programmable grinding patterns make it easy to switch quickly between different types of glass without having to retool or set up the machine in a lot of different ways. This flexibility is very helpful for businesses that want to serve a wide range of customers with different needs and requirements for volume.

Investment Considerations and Operational Requirements

Implementing round glass grinding automation requires careful consideration of various operational and financial factors. Initial capital investment represents the most significant consideration, as automated systems typically require substantially higher upfront costs compared to manual alternatives. However, a comprehensive total cost of ownership analysis usually demonstrates positive returns within reasonable payback periods.

Floor space requirements differ significantly from manual grinding setups. While automated systems may require larger individual footprints, they typically eliminate multiple manual stations, often resulting in net space savings. Proper facility planning must account for material handling requirements, maintenance access, and safety clearances around automated equipment.

Skilled technician requirements represent another important consideration for manufacturers evaluating automation investments. While automated systems reduce overall labor requirements, they demand higher-skilled personnel for setup, programming, and maintenance activities. Companies must invest in training programs or recruit qualified technicians to maximize automation benefits.

Power infrastructure requirements may necessitate electrical system upgrades to support multiple grinding motors and servo control systems. Adequate compressed air supply and coolant circulation systems also require consideration during installation planning. These infrastructure investments add to overall project costs but provide long-term operational benefits.

Maintenance scheduling becomes more critical with automated systems, as unplanned downtime affects production more severely than manual operations. Preventive maintenance programs must address mechanical components, electrical systems, and software updates to maintain optimal performance levels. Spare parts inventory management also requires more sophisticated planning compared to simpler manual equipment.

Comparative Analysis with Alternative Solutions

In the market for processing glass, round glass grinding tools compete with a number of other technologies. The old-fashioned way is to use a manual glass grinder, which has lower starting costs but requires a lot more work and produces inconsistent results. For small-batch tasks, manual systems are flexible, but when it comes to high-volume production, automated systems are more efficient.

Half-automated glass beveling tools are between fully automated and fully manual options. When compared to manual operations, these systems take less work and cost less to set up than full automation. However, semi-automated solutions still need a lot of help from a person and can't be as consistent as fully automated systems.

Optical glass grinding machines are designed to handle very precise tasks with very small margins. Most of the time, these tools cost a lot more than regular round glass grinding systems, but they can do more than most architectural glass needs. The spending justification depends a lot on the quality standards and target market groups.

Among other ways to finish the surface of glass, flame polishing and acid etching are also used. Even though these methods can make surfaces look a certain way, they can't compare to mechanical grinding systems when it comes to precise edge control and flexibility. Each of the other technologies has its own special uses, but none of them is as useful as round glass grinding automation.

Different makers make competitive automated systems that can do similar things but have different price structures and feature sets. Some things that should be looked at when judging a machine are how accurate it is, how fast it works, how customizable it is, how much help is available after the sale, and the total cost of ownership. For long-term business success, these things are often more important than the original purchase price.

Target Industries and Application Scenarios

Round glass grinding machines serve diverse industries with varying requirements and production volumes. Architectural glass manufacturers represent the largest market segment, utilizing these machines for curtain wall systems, window fabrication, and decorative glass applications. The precision edge finishing capabilities prove essential for modern building designs that emphasize glass aesthetics and structural integrity.

Automotive glass production requires specialized grinding capabilities to achieve the curved profiles and safety standards demanded by vehicle applications. Round glass grinding automation enables consistent quality while meeting the high-volume requirements of automotive manufacturing schedules. The ability to program specific grinding profiles accommodates the diverse shapes required for different vehicle models.

Furniture and interior decoration manufacturers increasingly rely on precision glass grinding for products ranging from glass tabletops to decorative panels. The automation capabilities enable these manufacturers to achieve consistent quality while maintaining competitive pricing for consumer markets. Custom programming features accommodate the diverse shapes and sizes required for furniture applications.

Smart mirrors and electronic display applications demand extremely precise edge finishing to ensure proper fit within electronic assemblies. Round glass grinding machines provide the accuracy and repeatability required for these high-tech applications while maintaining production efficiency levels necessary for consumer electronics manufacturing.

Shower door and bathroom fixture manufacturers utilize these machines for safety glass processing, where edge quality directly impacts user safety and product liability concerns. The consistent polishing capabilities ensure smooth edges that eliminate injury risks while meeting building code requirements for bathroom installations.

Conclusion

Round glass grinding tools are an important piece of technology for modern glass factories that want to be more efficient, make better glass, and stay ahead of the competition. These high-tech systems use advanced automation, precise engineering, and variable programming to get the same results in a wide range of situations. While the original investment needs to be carefully thought through, the long-term benefits of better quality, lower labor costs, and more production capacity usually make automation investments worth it. Automated grinding technology is becoming more and more important for industrial success as the use of glass continues to grow in the architectural, automotive, and specialty markets. In a competitive manufacturing environment, the future of glass processing definitely lies with automated solutions that offer accuracy, speed, and dependability.

FAQ

Q1: What glass thickness ranges can round glass grinding machines handle?

A: Most professional round glass grinding machines can process glass ranging from 3mm to 25mm in thickness. Advanced models with customizable configurations can accommodate even thicker glass panels up to 40mm. The specific thickness capability depends on motor power, grinding wheel specifications, and machine frame design. Always verify thickness requirements with equipment specifications before making purchasing decisions.

Q2: How long does the typical grinding cycle take for a standard glass piece?

A: Grinding cycle times vary based on glass size, thickness, and finishing requirements. Standard architectural glass pieces typically require 3-8 minutes per cycle, including loading, grinding, and unloading operations. Complex profiles or high-precision optical glass may require longer processing times. Automated systems significantly reduce total processing time compared to manual alternatives while delivering superior consistency.

Q3: What maintenance requirements should manufacturers expect for automated glass grinding equipment?

A: Regular maintenance includes daily cleaning, weekly lubrication of moving parts, and monthly inspection of grinding wheels and servo systems. Grinding wheels typically require replacement every 2-4 weeks, depending on usage intensity and glass types processed. Annual preventive maintenance should include electrical system inspection, encoder calibration, and software updates. Proper maintenance scheduling maximizes equipment lifespan and maintains optimal performance levels.

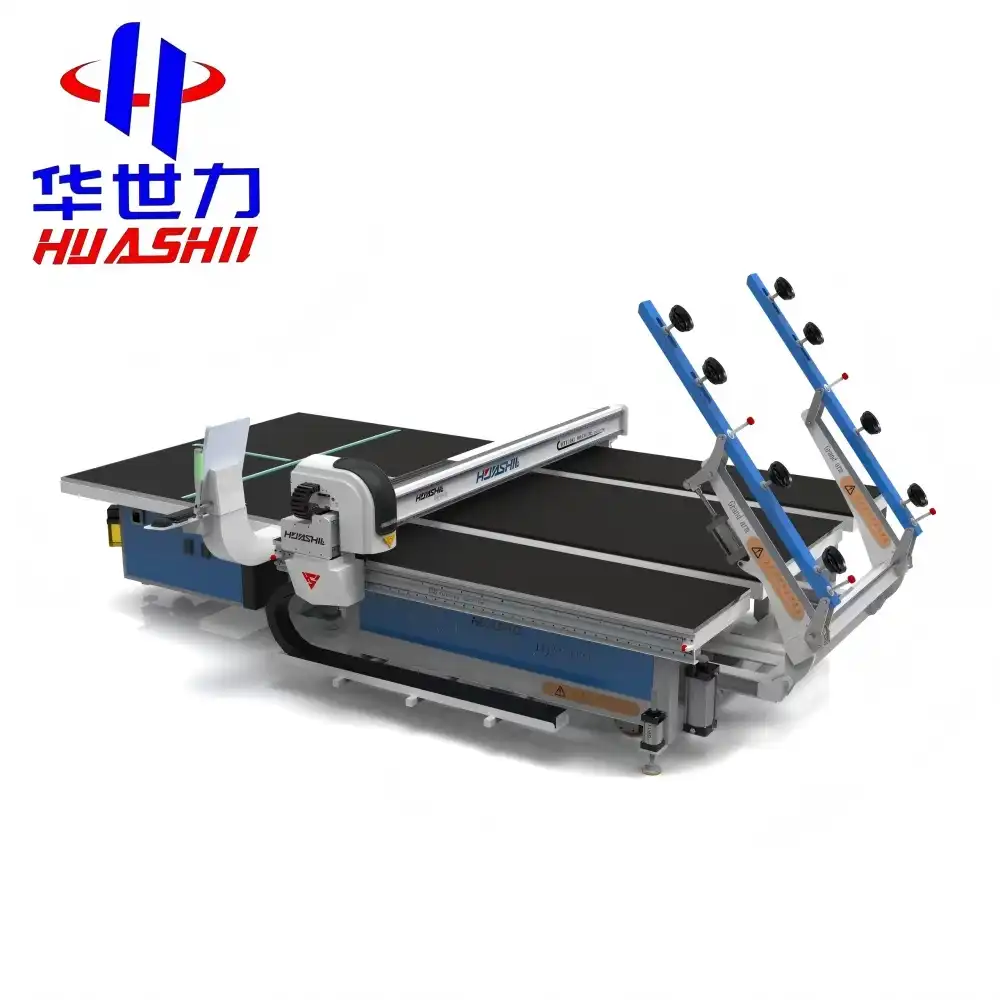

Partner with HUASHIL for Premium Round Glass Grinding Solutions

HUASHIL delivers cutting-edge round glass grinding machine technology backed by decades of manufacturing expertise and comprehensive customer support. Our automated systems feature advanced servo controls, precision grinding capabilities, and customizable configurations designed specifically for your production requirements. With proven reliability across architectural glass, automotive applications, and specialty manufacturing sectors, HUASHIL equipment maximizes your operational efficiency while ensuring consistent quality standards. Contact us at salescathy@sdhuashil.com to discuss how our round glass grinding machine solutions can transform your manufacturing capabilities.

References

1. Glass Manufacturing International Association. "Automated Glass Processing: Industry Standards and Best Practices." Glass Technology Journal, Vol. 45, 2023.

2. Peterson, Michael R. "Precision Glass Grinding: Advances in Automation Technology." Industrial Glass Processing Review, 2023.

3. Chen, Wei-Ming and Roberts, Sarah J. "Servo Motor Applications in Glass Manufacturing Equipment." Automation in Glass Production, 2022.

4. International Glass Processing Institute. "Safety Standards for Automated Glass Grinding Systems." Technical Publication Series, 2023.

5. Thompson, David K. "Economic Analysis of Glass Processing Automation Implementation." Manufacturing Economics Quarterly, Vol. 28, 2023.

6. European Glass Technology Association. "Round Glass Processing: Technical Specifications and Quality Standards." Industry Guidelines, 2022.