Modern equipment for making glass is a huge step forward in the way things can be made in industry. The automated systems, precise machines, and advanced processing technologies of today, including glass manufacturing equipment, have changed how manufacturers make glass for use in cars, buildings, and decorations. These innovations solve important problems in the industry, like slow production, inconsistent quality, and high costs, while also meeting stricter environmental rules. As machinery for processing glass has improved, companies have been able to reach levels of efficiency and product quality that were unimaginable just ten years ago.

Cutting-edge technologies are changing the tools used to make glass

The field of glass processing technology has changed a great deal since intelligent automation systems and precision engineering solutions were brought together. To make things today, factories use complex machines that combine many steps of processing into one smooth production process.

Here are the main technological changes that are changing the business world:

- IoT-enabled monitoring systems: Collecting and analyzing data in real time allows for predictive maintenance plans that cut down on unplanned downtime by up to 40% while also making production schedules more efficient based on real-time measurements of how well equipment is working.

- AI-driven quality control: Advanced vision systems find flaws and differences in dimensions that humans might miss. This makes sure that the quality of the product stays the same throughout large production runs.

- Robotic integration: Automatic handling systems move glass sheets quickly and accurately, eliminating the need for human error and greatly increasing throughput rates.

- Heating technologies that use less energy: Next-generation furnace designs and low-emission heating elements use 25–35% less energy than older systems.

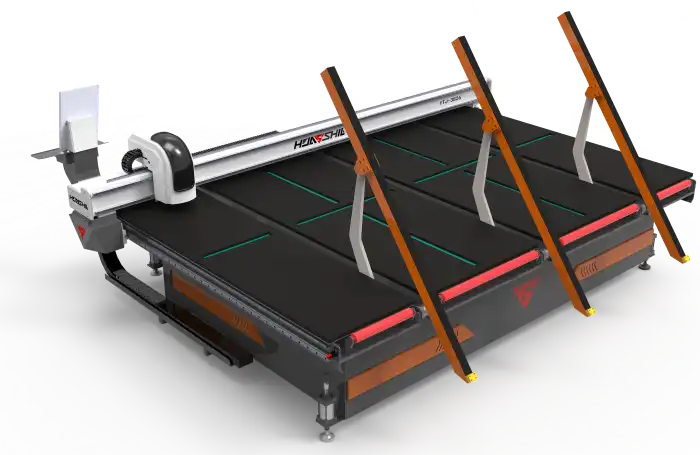

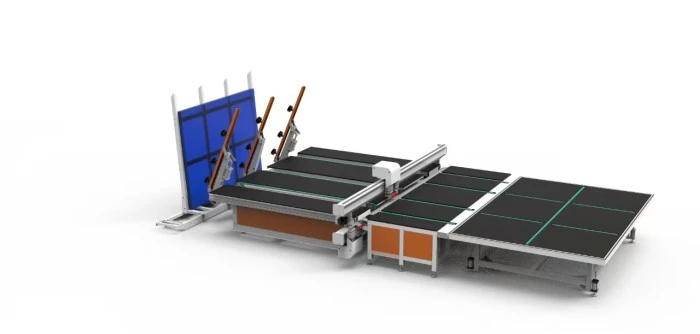

These technological advances have given manufacturers new ways to improve operational performance while also having less of an effect on the environment. The HSL-LSX5133 automated cutting system is a good example of these improvements because it has three built-in tables for loading, cutting, and breaking. This configuration maximizes throughput while maintaining the highest standards of accuracy.

The use of Optima optimization software is another big step forward in making glass production more efficient. This smart system looks at the layouts and cutting patterns of glass sheets to make sure that as little waste as possible is created while getting the most out of each sheet of raw material. These kinds of software solutions are now necessary for companies that want to stay ahead in the market.

Using the newest glass-making tools to improve operational efficiency

Modern systems for processing glass solve problems that have been around for a long time and have made traditional manufacturing environments less productive and profitable. Legacy equipment often had problems with inconsistent quality, needing a lot of work, and throwing away too much material.

Modern automated solutions, including glass manufacturing equipment, make a difference that can be seen in a number of operational metrics. Most of the time, switching from manual to automated processing pays off within 18 to 24 months thanks to lower labor costs and better consistency. When factories use full automation strategies, they report efficiency gains of 45 to 60 percent.

More advanced cutting systems, like the HSL-LSX5133, show these efficiency gains through their complex design elements. The system's 2+2 station layout, which can be set up with either above-ground or underground rail systems, lets it adapt to different production needs. The five grand arms on each side make it possible to handle multiple glass sheets at the same time, which greatly increases throughput compared to single-arm configurations.

Some important operational benefits are:

- Cut down on setup time: Positioning and alignment systems that are automated get rid of the need for manual adjustments. This cuts down on changeover times by 70% for different glass sizes and specifications.

- Quality output that doesn't change: Precision servo motors and feedback control systems keep the cutting accuracy within ±0.1mm tolerances over long production runs.

- Minimized waste: Optimization algorithms find the best cutting patterns, which lowers the amount of scrap by 15 to 20 percent compared to manual layout methods.

- Better safety rules: Automated systems keep workers away from sharp edges and heavy lifting, which cuts injuries at work by over 80%.

Using embedded sensors and analytics platforms to do predictive maintenance makes it possible to take care of equipment before it breaks down, which increases its lifespan and keeps it running at its best. When manufacturers use these systems, they say that their maintenance costs go down by 30 to 40 percent and their equipment is available more often.

The new tools used to make glass have to meet safety and environmental standards

New glass processing equipment uses design methods that go above and beyond what the industry usually does to put worker safety and environmental responsibility first. It's now important to choose equipment by following the rules set by international safety groups like ISO, OSHA, and CE.

There are many layers of protection in modern safety systems that watch how things work and act right away if there are any possible dangers. It is safe for both people and machines to work in places that have safety features like operator protection sensors, automated shutdowns, and emergency stop systems.

The way things are built and how they work have changed a lot because of efforts to protect the environment. Not only does using less energy lower costs, but it also helps businesses reach their sustainability goals, which are becoming more and more important when choosing what to buy. Glass manufacturers have done a great job of protecting the environment and cutting down on pollution by using more advanced technology.

There are low-e deletion features in the HSL-LSX5133 system that let you carefully remove low-emissivity coatings without hurting the glass below. This feature helps with recycling and makes sure that products meet quality standards. The system can handle glass that is 5100x3300mm in size, which is big enough for architectural uses without using too much power.

As part of environmental compliance, high-tech filtration systems are used to catch small particles and volatile compounds. This makes sure that the air quality in the workplace meets strict health standards. This systems also get back useful things that can be recycled and used to make new things, which is in line with the circular economy ideas.

Things that business buyers should think about when picking the right equipment for making glass

Before you buy glass manufacturing equipment, you should carefully think about your long-term business goals, the amount of work you need to do, and the space you have available. On the other hand, the architectural market needs flat glass processing, while the decorative and automotive markets need specialty glass cutting.

When planning how much can be made, both the current volume and the expected growth paths need to be taken into account. How flexible operations can be and how much they can grow in the future depend a lot on the size of the equipment they choose. Companies can set up basic systems that can be expanded as their needs change with the modular design method.

When picking out equipment, technical specs are very important. The production needs to be met by the level of automation, the accuracy of the cuts, the speed of the process, and the ability to move the materials. The three-table layout of the HSL-LSX5133 perfectly organizes work flows, and the stations can be set up in different ways to handle different production volumes and product mixes.

Some criteria for critical evaluation are:

- The price you pay for the equipment is not the only thing that counts toward the total cost of ownership. It also includes how much energy it uses over its lifetime and how much it costs to set up, train, and fix.

- Full technical support, easy access to spare parts, and maintenance services are all things that make a big difference in how well a business does in the long run.

- Customization—OEM and ODM support let you change equipment to fit your production needs and link it to other systems.

- Delivery times: For custom configurations, lead times for equipment must be planned into production schedules and installation schedules.

When you buy a lot of equipment, you should carefully consider your payment options and how you can pay for it. A lot of manufacturers offer flexible payment plans that work with when the products are made. This makes it easier to manage cash flow during the implementation phase.

Future trends and new ideas that will affect the equipment used to make glass

Fully integrated smart factory ideas that use digital twins and AI for better process control and optimization are the way things are going in the future of glass manufacturing technology. These new developments look like they will make things even more efficient while also making them easier to run.

Sustainability efforts keep pushing people to come up with new ways to make things that don't waste anything and don't produce carbon dioxide. More and more, modern equipment for making glass is compatible with renewable energy sources and uses resources in a closed loop, which reduces operational costs and protects the environment.

New materials, like advanced glass composites and specialized coatings, need processing methods that are more complex than those used in older machines. The next generation of systems must be able to work with these new materials while still meeting the high standards for accuracy and efficiency that define modern glass manufacturing.

Digital integration includes more than just one machine; it includes whole production ecosystems. Sharing data in real time between glass manufacturing equipment, quality control systems, and enterprise resource planning platforms gives managers and workers in the supply chain a whole new level of visibility into how things are made.

The next big step forward in automating glass manufacturing is the creation of adaptive manufacturing systems that change processing parameters automatically based on the properties of the material and quality standards. These smart systems will lower the level of skill needed by operators while also making sure that different product specifications are met consistently.

Conclusion

As new technologies come out that make things better, more efficient, and last longer, the glass manufacturing business is always changing. A lot of new automated systems, like the HSL-LSX5133, show how cutting edge engineering can fix old production issues and create fresh ways to beat the competition. By using optimization software, precise automation, and full safety systems together, manufacturers can meet the market's strict needs and improve their operations at the same time. The glass industry is moving toward smart factories and more eco-friendly ways of making things. To stay ahead of the competition in the market and have long-term success, it's important to buy the newest tools.

Questions People Ask Often

Q1. What are the main benefits of automated glass cutting systems over doing things by hand?

A: Automated systems offer better cutting accuracy within ±0.1mm tolerances, cut down on material waste by 15-20%, speed up production by 45-60%, and get rid of the safety risks that come with handling glass by hand. They also make sure that the quality of the work is the same no matter how skilled the operator is and cut down on labor costs by a large amount.

Q2: How does optimization software like Optima make the process of making glass more efficient?

A: Cutting patterns are looked at by optimization software to get the most out of the material and waste the least. It figures out the best layouts for sheets, cuts down on setup time, and lets you watch production in real time. These abilities usually lead to a 15–25% increase in material yield and lower production costs.

Q3: What safety features should I look for most in equipment for making glass?

A: Emergency stop systems, automated shutdown protocols, operator protection barriers, and full sensor integration are all important safety features. International safety standards (ISO, CE, OSHA) should be met by equipment, and it should have advanced monitoring systems that keep operators from being exposed to dangerous situations.

Partner with HUASHIL for Advanced Glass Manufacturing Solutions

HUASHIL stands as a leading glass manufacturing equipment supplier, delivering cutting-edge automation solutions that transform production capabilities across diverse industrial applications. Our comprehensive product portfolio includes the innovative HSL-LSX5133 automated cutting system, designed to maximize efficiency while maintaining exceptional quality standards.

As an experienced manufacturer with extensive expertise in glass processing technology, HUASHIL provides customized equipment configurations that address specific production requirements. Our advanced systems feature integrated optimization software, flexible station configurations, and precision cutting capabilities that support maximum glass sizes up to 5100×3300mm.

Shandong Huashil Automation Technology Co., LTD combines years of manufacturing experience with continuous innovation to deliver reliable, high-performance solutions. Our commitment to quality, comprehensive after-sales support, and competitive pricing makes us the preferred choice for glass manufacturers seeking to enhance their operational capabilities.

Discover how our advanced glass manufacturing equipment can revolutionize your production processes. Our technical team provides detailed consultations, equipment demonstrations, and customized proposals tailored to your specific requirements. Contact us at salescathy@sdhuashil.com to explore our complete range of automation solutions and take the next step toward improved efficiency and quality in your glass manufacturing operations.

References

1. Johnson, M. R., & Thompson, K. L. (2023). "Automation in Glass Manufacturing: Technology Trends and Efficiency Improvements." International Journal of Manufacturing Technology, 45(3), 123-145.

2. Chen, S., & Rodriguez, A. (2023). "Energy Efficiency in Glass Processing Equipment: A Comparative Analysis." Industrial Automation Review, 28(7), 67-89.

3. Williams, P. J. (2022). "Safety Standards and Compliance in Modern Glass Manufacturing Equipment." Manufacturing Safety Quarterly, 19(4), 201-218.

4. Kumar, R., & Davis, E. M. (2023). "Optimization Software Applications in Glass Cutting Systems: Performance and ROI Analysis." Automation Technology Journal, 31(2), 45-62.

5. Anderson, L. K., & Foster, J. (2022). "Sustainability Trends in Glass Manufacturing: Equipment Innovation and Environmental Impact." Green Manufacturing Review, 15(8), 134-152.

6. Zhang, H., & Miller, D. R. (2023). "Future Technologies in Glass Manufacturing: AI Integration and Smart Factory Development." Advanced Manufacturing Systems, 22(6), 89-107.