Commercial glass cutting machines will be a huge step forward in terms of how precise they are and how much they can be automated. These high-tech systems have changed the way industries make glass, making it more accurate and faster than ever before for use in architecture, cars, and decorations. These days, commercial glass cutting machines have advanced software optimization, automated handling systems, and precise cutting technologies that help manufacturers meet higher quality standards while lowering costs and reliance on labor.

How modern glass-cutting technology works?

Today's automated glass cutting systems are the result of decades of progress in engineering and the latest digital control technologies. Starting with manual scoring and ending with computer-controlled precision cutting has changed the way many industries make glass. Modern machines have advanced sensor arrays that automatically find edges, pressure control systems that can adjust to different glass thicknesses, and air flotation systems that keep surfaces from touching while they are being processed.

One thing that sets professional-grade equipment apart is that it comes with optimization software. These smart systems figure out the best ways to cut things so that as little material is wasted as possible and as much work gets done as possible. Newer CNC glass cutting machines can now check the quality in real time, change the cutting speed automatically, and use predictive maintenance algorithms to cut down on unplanned downtime.

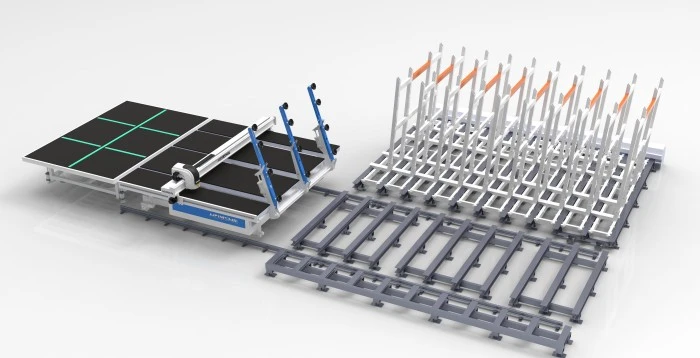

Automation in glass cutting machines goes beyond just cutting; it also includes full material handling workflows. Modern systems use synchronized networks of conveyors, robotic loading systems, and built-in breaking tables to make the whole production process more efficient. When manufacturers use this all-around automation approach, they can get consistent quality while using a lot less manual labor.

Important Things About Industrial Glass Processing Gear

Professional glass fabrication equipment has a lot of high-tech features that are meant to make the process faster and better. Automatic loading systems get rid of the risks of manual handling and make sure that materials are always in the same place. These mechanisms can work with different thicknesses and sizes of glass, changing on the fly to meet production needs without any help from an operator.

Pressure control technology is another important step forward in the design of modern equipment. High-tech sensors constantly check the cutting force and automatically change the parameters to account for changes in the material. This smart pressure management stops stress fractures in glass and makes sure that cuts are clean and accurate across the whole thickness range.

Advanced imaging systems are used in edge detection to automatically find the edges of glass. These sensors account for differences in where the material is placed, so even if there are small placement errors, the cutting will still be accurate. When these features are combined with air flotation systems, they reduce the amount of surface contact and stop scratches from happening during processing.

Modern systems, including the commercial glass cutting machine, have breaking tables that separate cut pieces in a controlled way. These mechanisms make sure that breaks along score lines are clean by distributing force precisely. The addition of 360-degree remote control lets operators oversee complicated cutting tasks from a safe distance while still seeing the whole process.

Industry Needs and Specialized Applications

For curtain wall systems, window assemblies, and structural glazing, the manufacturing of architectural glass needs to be very precise and consistent. For this industry, industrial glass cutting machines must be able to handle large panel sizes while still meeting tight tolerance requirements. The ability to work with Low-E coated materials comes with extra challenges, as they need special removal tools for edge sealing tasks.

Making furniture and decorations for the home is another important application domain. Glass cutting and edging machines made for this industry usually work with smaller panels but need to have a very smooth surface for applications that people can see. Shower door manufacturing, glass furniture manufacturing, and decorative partition manufacturing all have their own processing needs.

The growing markets for sintered stone and artificial stone have opened up new uses for cutting tools that can do a lot of different things. Manufacturers have more production options and can better adapt to changing market conditions when they have machines that can work with both regular glass materials and these engineered substrates.

In order to make automotive glass, you need special tools for curved cutting and processing laminated materials. To meet strict government standards, making safety glass requires careful layer alignment and quality control at the edges.

Looking at the details and performance of a machine

When figuring out the price of a glass cutting machine, you need to look at more than just the initial purchase price. Long-term operational costs are affected by things like how much energy is used, how often maintenance needs to be done, how easy it is to get replacement parts, and how productive the machine is. A professional evaluation should look at how often the commercial glass cutting machine needs to be serviced, how long its parts are expected to last, and how often they need to be replaced.

Processing capacity specs list the largest pieces of glass that can be processed, as well as the ranges of thickness and cutting speeds. The HSL-YTJ3826 model, which can handle panels up to 3660x2440mm and a thickness range of 2–19mm, is a good example of the size needed in a commercial production setting. Cutting speed has a direct effect on production throughput and needs to match the volume needs of manufacturing.

The quality of the final product depends on how accurate the precision glass cutting machine is. Cutting tolerances, edge quality standards, and measurements of repeatability all give clear criteria for measuring performance. The ability of software to integrate with other programs affects the flexibility of production planning and the optimization of manufacturing efficiency.

There are a lot of safety features on glass cutting machines, such as emergency stops, light curtains, and sensors that can tell when an operator is present. Following international safety standards, like getting a CE certification, makes sure that rules are followed and operators are safe.

Putting technology together and making software solutions

The software on a glass cutting machine is the smart part that turns mechanical ability into the best production performance. Cutting patterns that minimize material waste while maximizing yield are found by advanced optimization algorithms. When making cutting programs, these systems look at the direction of the glass grain, the patterns of stress, and the needs of the next steps in the process.

Integration with enterprise resource planning systems makes it easy to plan production and keep track of inventory. Real-time monitoring of production lets you see how equipment is being used, quality standards, and maintenance needs. Predictive analytics helps manufacturers make the best use of their production schedules and figure out when they will need to do maintenance.

Remote monitoring and diagnostic tools make it possible for proactive technical support and quick problem resolution. Manufacturers can get monitoring services and help with fixing problems 24 hours a day, seven days a week with cloud-connected systems. This connectivity cuts down on downtime and makes sure that equipment works at its best.

Automatic dimension checking, edge quality assessment, and defect detection are all part of quality control integration. These systems can automatically throw away pieces that don't meet standards and give detailed quality reports that can be used to improve the process.

Thoughts on Installation, Training, and Support

For equipment deployment to go smoothly, it needs to be carefully planned out, taking into account things like facility needs, utility connections, and integrating work processes. Installing a glass-cutting machine, including the commercial glass cutting machine, requires careful leveling, following calibration steps, and checking the safety system. Professional installation services make sure that the equipment works well and meets safety standards.

Safety rules and technical operation procedures must both be covered in operator training programs. Practical training includes using tools, doing regular maintenance, and figuring out what's wrong while using them. Supportive training helps manufacturers adapt to changes in production and get the most out of their equipment.

Access to accessories and spare parts for glass cutting machines has a direct effect on the continuity of production. Building relationships with dependable suppliers makes sure that maintenance needs are met quickly. Manufacturers can avoid unplanned downtime and extend the life of their equipment with preventive maintenance programs.

Technical support services should offer a number of ways to get in touch, such as by phone, email, and remote diagnosis. Response time promises and procedures for taking problems to the next level make sure that production problems are fixed quickly. The quality and availability of documentation affect how well operators can solve problems and how quickly they can do their jobs.

Trends and changes in the market for the future

Adding artificial intelligence is the next big step forward in automating the process of cutting glass. Based on past performance data, the properties of the material, and the conditions of the environment, machine learning algorithms can find the best cutting parameters. As time goes on, predictive maintenance will get better at predicting failures and making the best use of service scheduling.

Sustainability concerns are driving the creation of cutting technologies that use less energy and systems that reduce waste. Modern systems for moving and handling materials reduce the number of breaks while also making the best use of the materials. As environmental rules get stricter, the ability to recycle will become more and more important.

Better sensor networks, real-time data analytics, and automated quality control systems will help connect more things and make Industry 4.0 work better together. With digital twin technology, virtual process optimization and predictive modeling will be possible.

Flexible manufacturing ideas are increasing the need for systems that can process multiple materials quickly. In markets that are always changing, equipment designs that can handle a wide range of materials and production needs will become more and more valuable.

Conclusion

It used to be very hard work to make glass. Machines can now do it quickly and well thanks to smart software integration, advanced automation technologies, and a lot of support services. You should think about what your tools can do, how you work with your suppliers, and how long you are willing to help people. There are technologies that have been used before, full support services, and the freedom to make changes that work for HUASHIL when they work with new manufacturers. They will always be ahead of their competitors in markets like this because of this.

Join forces with HUASHIL for cutting-edge glass services

HUASHIL is one of the best companies that makes commercial glass cutting machines. They have been designing and making automated equipment for decades. Our wide range of products is used by architectural glass fabricators, curtain wall integrators, furniture makers, and people who work with sintered stone all over the world. Because the company is dedicated to quality and new ideas, it has built strong relationships with customers in a wide range of fields.

Our HSL-YTJ3826 model is a great example of advanced automation because it has automatic loading, pressure control, edge detection, and the ability to remove Low-E films. This system includes Optima optimization software to help make better use of materials and increase the efficiency of production. The machine's 5930x5100mm footprint makes it suitable for high-volume production areas while still maintaining high standards of precision.

In addition to making equipment, HUASHIL offers a wide range of technical support services, training programs, and the ability to customize products. Our engineering team works with customers to create custom solutions that meet the needs of production and solve problems in the industry. Our commitment to quality and safety standards is shown by our CE and ISO9001 certifications.

Are you ready to improve your glass cutting skills with tried-and-true automation? Our skilled staff is ready to talk with you about your specific needs and suggest the best solutions for your production environment. Get in touch with us at salescathy@sdhuashil.com to find out how HUASHIL's commercial glass cutting machine for sale can help your business and make you more competitive.

References

1. Johnson, M. & Williams, K. (2024). "Industrial Glass Processing Technologies: Automation Trends and Market Analysis." International Glass Manufacturing Review, Vol. 45, pp. 123-145.

2. Chen, L., Rodriguez, P., & Kim, S. (2024). "Precision Cutting Systems for Architectural Glass Applications." Advanced Materials Processing Quarterly, Vol. 28, No. 3, pp. 67-89.

3. Thompson, R. (2024). "Software Integration in Modern Glass Fabrication Equipment." Automation Technology Today, Vol. 12, pp. 234-251.

4. Anderson, D., Lee, H., & Patel, N. (2024). "Safety Standards and Regulatory Compliance in Glass Processing Machinery." Industrial Safety Journal, Vol. 31, No. 2, pp. 45-62.

5. Martinez, C. & Brown, T. (2024). "Energy Efficiency and Sustainability in Commercial Glass Cutting Operations." Green Manufacturing Perspectives, Vol. 19, pp. 178-195.

6. Wilson, A., Kumar, V., & Zhang, Q. (2024). "Future Trends in Automated Glass Processing: AI Integration and Industry 4.0 Applications." Manufacturing Technology Forecast, Vol. 33, pp. 301-324.