Glass Double Edging Machine technology has revolutionized modern glass processing, delivering unprecedented precision and efficiency for manufacturers worldwide. These sophisticated machines perform simultaneous edge grinding on both sides of glass panels, significantly reducing processing time while maintaining exceptional quality standards. As the glass industry evolves in 2025, understanding the capabilities, applications, and selection criteria for double edging equipment becomes crucial for production directors, engineering managers, and procurement specialists seeking to optimize their manufacturing operations and maintain competitive advantages in architectural glass, curtain wall systems, and furniture fabrication sectors.

Understanding Glass Double Edging Technology

Glass double edging represents a pivotal advancement in glass processing methodology. Unlike traditional single-edge machines, these systems process both glass edges simultaneously, creating perfectly parallel surfaces with remarkable consistency. The technology employs multiple grinding wheels, each designed for specific functions ranging from rough grinding to final polishing.

Modern double edging equipment integrates CNC glass machine capabilities, enabling operators to program complex edge profiles and geometries. This automation reduces manual intervention while ensuring repeatable results across production batches. The precision achieved through computerized control systems meets stringent architectural specifications required for curtain wall applications and high-end furniture manufacturing.

Advanced glass machinery incorporates servo-driven mechanisms that adjust grinding pressure dynamically. This feature prevents stress fractures while maintaining optimal material removal rates. Temperature control systems manage heat generation during the grinding process, protecting glass integrity and extending tool life significantly.

Types and Classifications of Double Edging Systems

Glass fabrication facilities utilize various double edging configurations depending on their specific production requirements. Straight-line double edgers handle rectangular glass sheets with remarkable efficiency, making them ideal for architectural glass applications and window manufacturing.

Shape edging machines accommodate curved and irregular glass profiles commonly found in automotive and decorative applications. These versatile systems combine traditional edge finishing techniques with modern automation, enabling manufacturers to process complex geometries previously requiring multiple machine setups.

Industrial glass production often demands heavy-duty double edging systems capable of processing thick architectural panels. These robust machines feature reinforced frames and powerful grinding spindles designed to handle substantial glass weights while maintaining micron-level accuracy.

Compact double edging units serve smaller glass processing operations focusing on custom work and specialty applications. Despite their reduced footprint, these machines deliver professional-grade results suitable for shower door fabrication and decorative glass projects.

In addition to these systems, the Glass Double Edging Machine is also used for a variety of precise applications in the glass industry. This machine excels at providing clean, accurate edges for both straight and curved glass, making it a versatile tool for high-quality glass processing.

Key Applications Across Industries

Architectural glass processing represents the largest application segment for double edging technology. Curtain wall manufacturers rely on these machines to produce perfectly parallel glass panels that meet strict building codes and aesthetic requirements. The precision achieved through automated glass machinery ensures proper sealing and structural integrity in high-rise construction projects.

Furniture manufacturing has embraced double edging systems for producing glass tabletops, shelving, and cabinet inserts. The ability to create smooth, polished edges eliminates safety hazards while enhancing visual appeal. Glass surface treatment achieved through quality double edging machines meets furniture industry standards for durability and finish quality.

Automotive glass production utilizes specialized double edging equipment for processing windshields and window glass. These applications demand exceptional edge quality to ensure proper seal integrity and passenger safety. The consistency provided by automated systems proves essential for meeting automotive industry quality standards.

Electronics and appliance manufacturers increasingly specify double-edged glass for display panels and protective covers. The precision edging process eliminates micro-fractures that could compromise product reliability while creating aesthetically pleasing finished products.

Essential Features and Technical Specifications

Modern glass equipment incorporates multiple grinding stations, each serving distinct functions in the edge finishing process. Initial rough grinding removes excess material quickly, while subsequent stations progressively refine the edge surface. Final polishing stations achieve mirror-like finishes suitable for high-end applications.

Automated glass machinery features sophisticated control systems that monitor grinding pressure, spindle speed, and coolant flow continuously. These parameters adjust automatically based on glass thickness and material properties, ensuring optimal processing conditions throughout production runs.

Precision edging capabilities depend heavily on machine rigidity and vibration control. Quality manufacturers engineer their systems with heavy-duty frames and precision linear guides that maintain accuracy even during extended production cycles. Anti-vibration mounting systems isolate grinding operations from external disturbances.

Glass handling systems integrated into Glass Double Edging Machine minimize manual labor while preventing damage during processing. Conveyor systems, suction cups, and automated positioning mechanisms work together to move glass safely through multiple processing stations.

Selection Criteria for Production Managers

Production capacity requirements drive initial equipment selection decisions. Plant managers must evaluate their current and projected glass processing volumes to determine appropriate machine size and speed capabilities. Oversized equipment increases operational costs, while undersized systems create production bottlenecks.

Glass thickness ranges vary significantly across applications. Architectural projects may require processing thick structural glass, while furniture applications often involve thinner decorative panels. Selecting equipment with appropriate thickness capabilities prevents future limitations as product mix evolves.

Edge quality specifications differ between industries and applications. Architectural glass demands different finish standards compared to furniture or automotive applications. Understanding these requirements helps procurement managers select equipment with appropriate grinding and polishing capabilities.

Facility constraints including available floor space, power requirements, and utility connections influence equipment selection. Compact designs may sacrifice some capabilities but enable installation in space-limited facilities. Conversely, high-volume operations benefit from larger systems despite increased space requirements.

Installation and Setup Considerations

Successful glass machinery installation requires careful planning and coordination between facility management and equipment suppliers. Foundation requirements vary based on machine weight and vibration characteristics. Proper foundations prevent accuracy degradation while extending equipment life.

Power infrastructure must accommodate high-amperage requirements typical of glass grinding equipment. Electrical systems should include appropriate protective devices and emergency stops meeting safety regulations. Backup power considerations become important for facilities requiring continuous operation.

Coolant systems play crucial roles in glass processing operations. Adequate water supply, filtration, and disposal systems ensure consistent performance while meeting environmental regulations. Recirculation systems reduce water consumption while maintaining coolant quality throughout extended production runs.

Glass Double Edging Machine installation requires specific attention to coolant and power system integration. Ensuring that these systems are properly set up will allow the Glass Double Edging Machine to function efficiently and with high precision.

Operator training programs ensure safe and efficient equipment utilization from installation day forward. Comprehensive training covers machine operation, maintenance procedures, and troubleshooting techniques. Ongoing support helps operators maximize productivity while maintaining safety standards.

Maintenance and Operational Excellence

Preventive maintenance schedules maximize glass production line reliability while minimizing unexpected downtime. Regular inspection of grinding wheels, coolant systems, and mechanical components identifies potential issues before they impact production schedules.

Grinding wheel management significantly affects both product quality and operational costs. Proper wheel selection, dressing procedures, and replacement timing optimize glass surface treatment while controlling consumable expenses. Automated monitoring systems track wheel condition and recommend replacement intervals.

Coolant system maintenance prevents contamination that could damage glass surfaces or grinding components. Regular filtration system cleaning, coolant replacement, and system flushing maintain optimal processing conditions while extending equipment life.

Documentation systems track production parameters, maintenance activities, and quality metrics. This data enables continuous improvement initiatives while providing valuable insights for optimizing glass technology applications.

Cost Analysis and Return on Investment

Total cost of ownership encompasses initial equipment investment, installation expenses, ongoing operational costs, and maintenance requirements. Comprehensive cost analysis helps finance managers evaluate different equipment options objectively while considering long-term financial implications.

Labor cost reductions through automation often justify equipment investments within reasonable payback periods. Double edging systems typically reduce manual handling requirements while improving processing consistency and speed. These benefits translate directly into improved profitability for glass manufacturing operations.

Quality improvements achieved through precision edging reduce rework costs and customer complaints. Consistent edge quality eliminates manual finishing operations while improving overall product appearance. These factors contribute significantly to return on investment calculations.

Energy efficiency considerations become increasingly important as utility costs rise. Modern glass equipment incorporates energy-saving features including variable-speed drives and efficient cooling systems. These improvements reduce operational expenses while supporting sustainability initiatives.

Future Trends and Technology Developments

Artificial intelligence integration promises to revolutionize glass industry operations through predictive maintenance and adaptive process control. Smart systems will analyze production data continuously, optimizing parameters automatically while identifying potential issues before they impact quality or productivity.

Industry 4.0 connectivity enables remote monitoring and support capabilities that reduce service response times while improving troubleshooting effectiveness. Cloud-based systems provide manufacturers with real-time performance insights and predictive analytics capabilities.

Environmental considerations drive development of more efficient processing methods and reduced waste generation. Next-generation equipment will incorporate advanced recycling systems and energy recovery mechanisms that minimize environmental impact while reducing operational costs.

Customization capabilities continue expanding as manufacturers demand greater flexibility in glass sheet processing. Modular machine designs enable easy reconfiguration for different applications while maintaining the precision and reliability expected from professional glass equipment.

Conclusion

Glass Double Edging Machine technology continues evolving rapidly, offering manufacturers unprecedented opportunities to improve productivity, quality, and profitability. Understanding the technical capabilities, application requirements, and selection criteria enables informed decisions that optimize long-term operational success. Modern automated glass machinery delivers remarkable precision while reducing labor costs and improving consistency across diverse glass processing applications. As the industry advances toward greater automation and connectivity, investing in quality double edging equipment positions manufacturers for sustained competitive advantages in rapidly evolving markets.

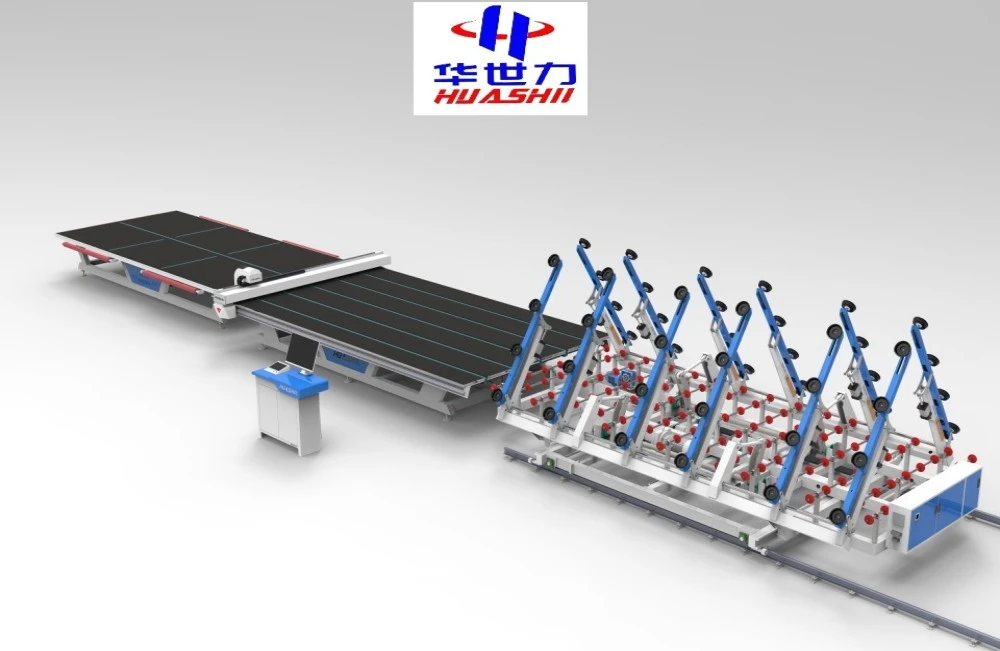

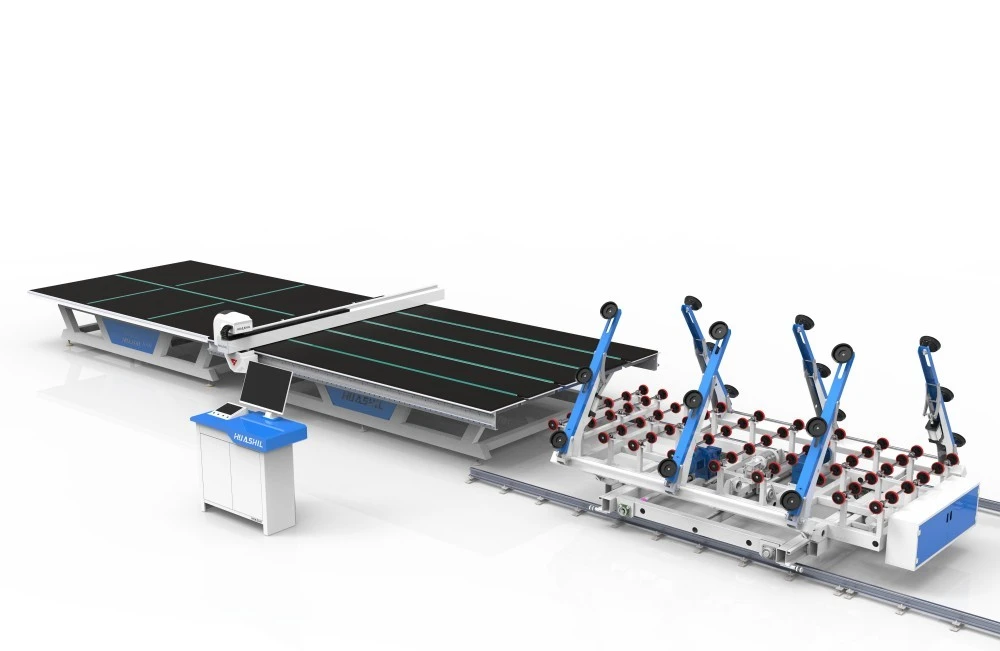

Partner with HUASHIL for Superior Glass Double Edging Solutions

Choosing the right Glass Double Edging Machine manufacturer determines your production success for years to come. HUASHIL stands as a leading glass equipment supplier with decades of experience delivering automated glass machinery solutions to manufacturers worldwide. Our comprehensive product line addresses diverse applications from architectural glass processing to specialized furniture manufacturing requirements.

HUASHIL's engineering expertise enables custom machine configurations that match your specific production needs perfectly. Whether you require standard double edging capabilities or specialized glass technology solutions, our team develops equipment that maximizes your operational efficiency while maintaining exceptional quality standards. Our advanced manufacturing facilities employ rigorous quality control processes ensuring every machine meets demanding performance specifications.

Technical support and after-sales service distinguish HUASHIL from other glass machinery suppliers. Our global service network provides rapid response times for maintenance support and spare parts delivery. Comprehensive training programs ensure your operators achieve maximum productivity while maintaining safety standards. When you need reliable glass processing equipment backed by proven expertise, contact us at salescathy@sdhuashil.com to discuss your requirements with our application specialists.

References

1. Glass Manufacturing Industry Association. "Advanced Glass Processing Technologies and Equipment Standards." Glass Industry Technical Manual, 2024 Edition.

2. International Journal of Glass Science. "Precision Edging Techniques in Modern Glass Fabrication." Volume 15, Issue 3, 2024.

3. Architectural Glass Council. "Quality Standards for Curtain Wall Glass Processing and Edge Finishing." Building Industry Guidelines, 2024.

4. Glass Technology International. "Automation Trends in Glass Manufacturing Equipment." Industrial Processing Review, March 2024.

5. Society of Glass Engineers. "Comparative Analysis of Double Edging Systems in Industrial Applications." Technical Research Report, 2024.

6. Global Glass Manufacturing Report. "Market Analysis and Technology Developments in Glass Processing Machinery." Industry Research Publication, 2024.