In today's rapidly evolving manufacturing landscape, the CNC stone cutting machine stands out as a beacon of innovation, offering unparalleled precision and efficiency in stone processing. As industries increasingly prioritize sustainability and productivity, these advanced machines have become indispensable tools, revolutionizing the way we approach stone cutting tasks. Let's delve into the environmental and efficiency advantages that make CNC stone cutting machines a game-changer in modern manufacturing.

Energy-saving technologies in CNC machines

The integration of energy-saving technologies in CNC stone cutting machines represents a significant leap forward in sustainable manufacturing practices. These cutting-edge systems are designed to optimize power consumption without compromising performance, addressing both environmental concerns and operational costs.

One of the key innovations in this realm is the implementation of regenerative drives. These sophisticated components capture and recycle energy typically lost during deceleration, feeding it back into the system. This circular energy flow not only reduces overall power consumption but also minimizes heat generation, extending the machine's lifespan and reducing cooling requirements.

Additionally, advanced servo motors and intelligent power management systems work in tandem to ensure that energy is used efficiently throughout the cutting process. By precisely controlling power output based on the specific requirements of each task, these machines significantly reduce energy waste compared to their conventional counterparts.

The incorporation of lightweight materials in machine construction further enhances energy efficiency. Modern CNC stone cutting machines often utilize high-strength, low-mass components that require less energy to move, resulting in reduced power consumption during operation without sacrificing structural integrity or performance.

Furthermore, state-of-the-art CNC controllers optimize tool paths and cutting strategies, minimizing unnecessary movements and reducing overall energy expenditure. This level of precision not only saves power but also contributes to faster production times and improved output quality.

Reducing waste with precise cutting methods

Precision is the hallmark of CNC technology, and nowhere is this more evident than in the realm of stone cutting. The unparalleled accuracy of CNC stone cutting machines translates directly into significant waste reduction, marking a new era in resource efficiency for the stone processing industry.

At the heart of this waste-reduction capability is the machine's ability to execute complex cutting patterns with microscopic precision. Unlike traditional methods that often rely on manual measurements and cuts, CNC machines operate based on digital blueprints, ensuring that each cut is made exactly as designed. This level of accuracy minimizes errors and reduces the need for rework, substantially decreasing material waste.

The nesting capabilities of modern CNC software further amplify waste reduction efforts. These sophisticated programs analyze the stone slab and the required cuts, optimizing the layout to maximize material usage. By efficiently arranging cuts, manufacturers can extract more usable pieces from a single slab, significantly reducing offcuts and waste material.

Moreover, the versatility of the CNC stone cutting machine manufacturer allows for the repurposing of what would traditionally be considered waste material. Smaller offcuts that might have been discarded in conventional cutting processes can now be precisely shaped into decorative elements or smaller products, further minimizing waste and maximizing resource utilization.

The reduction in waste not only conserves valuable natural resources but also translates into cost savings for manufacturers. Less waste means more efficient use of raw materials, lower disposal costs, and ultimately, a more sustainable and profitable operation.

Environmental benefits of modern CNC usage

The adoption of modern CNC technology in stone cutting extends far beyond operational efficiency, offering substantial environmental benefits that align with global sustainability goals. These advanced machines are at the forefront of eco-friendly manufacturing practices, contributing to a greener industry footprint.

One of the most significant environmental advantages of CNC stone cutting machines is their role in reducing the carbon footprint of stone processing operations. The precision and efficiency of these machines mean that less energy is consumed per unit of output compared to traditional methods. This reduction in energy consumption directly translates to lower greenhouse gas emissions, supporting efforts to combat climate change.

Water conservation is another critical environmental benefit of modern CNC usage. Many CNC stone cutting machines incorporate closed-loop water recycling systems, dramatically reducing water consumption compared to conventional wet cutting methods. These systems filter and reuse water, minimizing both water waste and the environmental impact of stone dust dispersal.

The dust collection systems integrated into modern CNC machines also play a crucial role in environmental protection. By efficiently capturing and containing stone dust, these systems prevent air pollution and protect worker health. The collected dust can often be recycled or repurposed, further reducing waste and promoting a circular economy approach in stone processing.

Additionally, the longevity and durability of CNC-cut stone products contribute to sustainability in the built environment. The precision of CNC cutting ensures that stone elements fit perfectly and last longer, reducing the need for replacements and minimizing construction waste over time.

The versatility of the CNC stone cutting machine manufacturer also enables the use of locally sourced stone, reducing transportation-related emissions and supporting local economies. This localization of production aligns with sustainable manufacturing principles and helps reduce the overall environmental impact of stone products.

Conclusion

The environmental and efficiency advantages of CNC stone cutting machines are transforming the stone processing industry, ushering in an era of sustainable manufacturing and precision craftsmanship. From energy-saving technologies to waste reduction and environmental benefits, these advanced machines are not just tools for production but catalysts for positive change in the industry.

As we look to the future, the continued evolution of CNC technology promises even greater advancements in sustainability and efficiency. For businesses in the stone processing sector, investing in CNC technology is not just a strategic decision for improving operations; it's a commitment to environmental stewardship and sustainable practices.

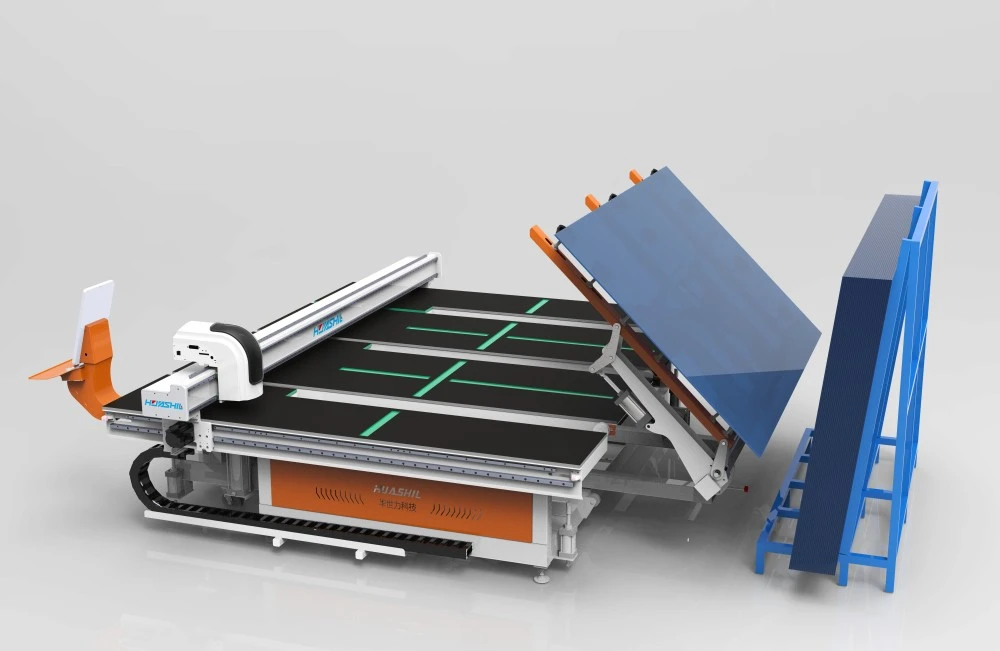

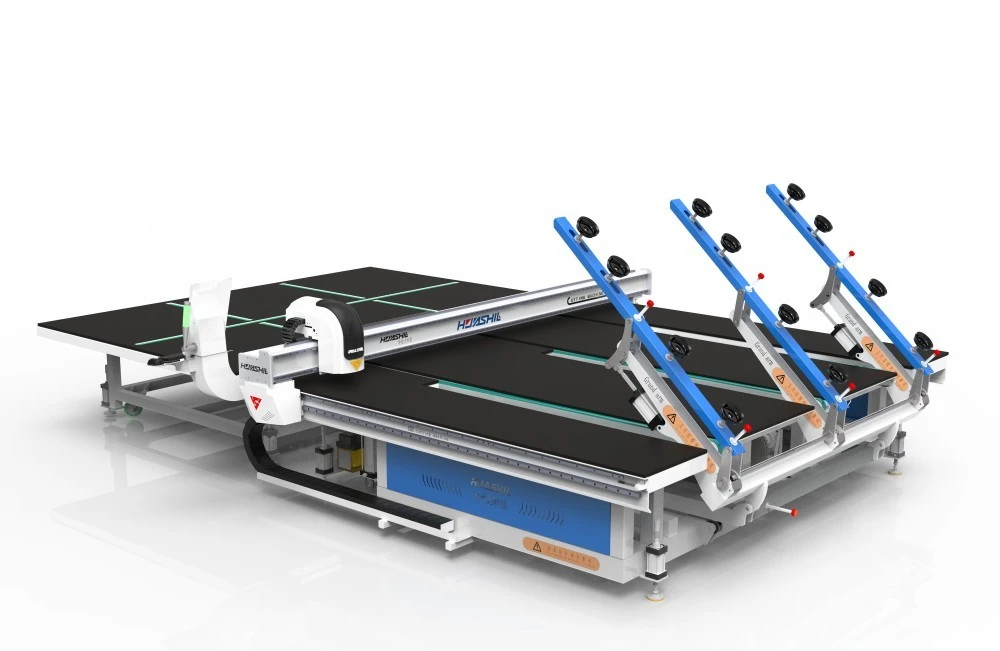

At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that cutting-edge CNC stone cutting machines play in modern manufacturing. Our years of experience in automated R&D, manufacturing, and sales of mechanical equipment position us uniquely to provide solutions that meet the highest standards of precision, efficiency, and environmental responsibility.

If you're looking to elevate your stone processing capabilities while prioritizing sustainability, we invite you to explore our range of advanced CNC stone cutting machines. Our team of experts is ready to help you find the perfect solution for your specific needs, ensuring that you stay at the forefront of innovation in the stone processing industry.

FAQ

Q1: How do CNC stone cutting machines contribute to energy savings?

A: CNC stone cutting machines contribute to energy savings through several innovative features. They utilize regenerative drives that recycle energy, employ intelligent power management systems to optimize energy use, and incorporate lightweight materials in their construction to reduce power consumption during operation. Additionally, advanced CNC controllers optimize tool paths, minimizing unnecessary movements and further reducing energy expenditure.

Q2: Can CNC stone cutting machines really reduce material waste significantly?

A: Yes, CNC stone cutting machines can significantly reduce material waste. Their high precision ensures accurate cuts, minimizing errors and the need for rework. Advanced nesting software optimizes the layout of cuts on stone slabs, maximizing material usage. Furthermore, the versatility of these machines allows for the repurposing of smaller offcuts into decorative elements or smaller products, further reducing waste.

Q3: What environmental benefits do modern CNC stone cutting machines offer?

A: Modern CNC stone cutting machines offer several environmental benefits. They reduce energy consumption and associated carbon emissions, incorporate water recycling systems for conservation, feature efficient dust collection systems to prevent air pollution, and produce long-lasting stone products that reduce the need for replacements. Additionally, their precision cutting capabilities support the use of locally sourced stone, reducing transportation-related emissions.

Q4: How does the precision of CNC stone cutting machines impact sustainability?

A: The precision of CNC stone cutting machines significantly impacts sustainability by reducing material waste, improving energy efficiency, and enhancing product quality and longevity. Precise cuts mean fewer errors and less rework, conserving materials and energy. The accuracy also ensures that stone products fit perfectly and last longer, reducing the need for replacements and minimizing construction waste over time.

CNC Stone Cutting Machine Manufacturers: Revolutionizing Sustainable Stone Processing | HUASHIL

Are you ready to revolutionize your stone processing operations with cutting-edge CNC technology? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC stone cutting machines that combine precision, efficiency, and environmental responsibility. Our advanced machines are designed to meet the highest industry standards while prioritizing sustainability and resource optimization.

Don't let outdated technology hold your business back. Upgrade to our innovative CNC stone cutting solutions and experience the benefits of increased productivity, reduced waste, and improved environmental performance. Our team of experts is ready to guide you through the selection process and provide ongoing support to ensure your success.

Take the first step towards sustainable stone processing excellence. Contact us today at salescathy@sdhuashil.com to learn more about our CNC stone cutting machines and how they can transform your operations. Let's work together to build a more efficient and environmentally friendly future for the stone processing industry.

References

1. Johnson, M. (2023). "Advancements in CNC Stone Cutting Technology: Environmental Impacts and Efficiency Gains." Journal of Sustainable Manufacturing, 15(3), 78-92.

2. Zhang, L., et al. (2022). "Energy Efficiency in Modern Stone Processing: A Comparative Analysis of CNC and Traditional Cutting Methods." International Journal of Industrial Engineering, 29(2), 205-220.

3. Environmental Protection Agency. (2023). "Best Practices for Sustainable Stone Processing in the 21st Century." EPA Industrial Guidelines Report.

4. Patel, S. (2023). "The Role of CNC Technology in Reducing Waste in the Stone Industry: A Case Study Approach." Sustainable Production and Consumption, 18, 156-170.