In 2025, the cutting machine for stained glass windows changed the way artists and manufacturers conduct detailed glasswork. Modern automated glass cutting machines are much more accurate than ever before and reduce down on manufacturing time by a lot. Advanced glass scoring technology now works with computer-controlled systems to make intricate patterns that were hard to make by hand before. These high-tech machines can do everything from little art glass projects to huge architectural installations. They are crucial equipment for manufacturing stained glass today.

Understanding Modern Glass Cutting Technology

The way we cut glass today is a huge improvement over the way we used to do it with hand tools. Modern glass cutters have automated control systems that make sure that the outcomes are the same on all of their projects. These machines use laser systems or diamond-tipped cutting wheels to make exact scores in different types of glass.

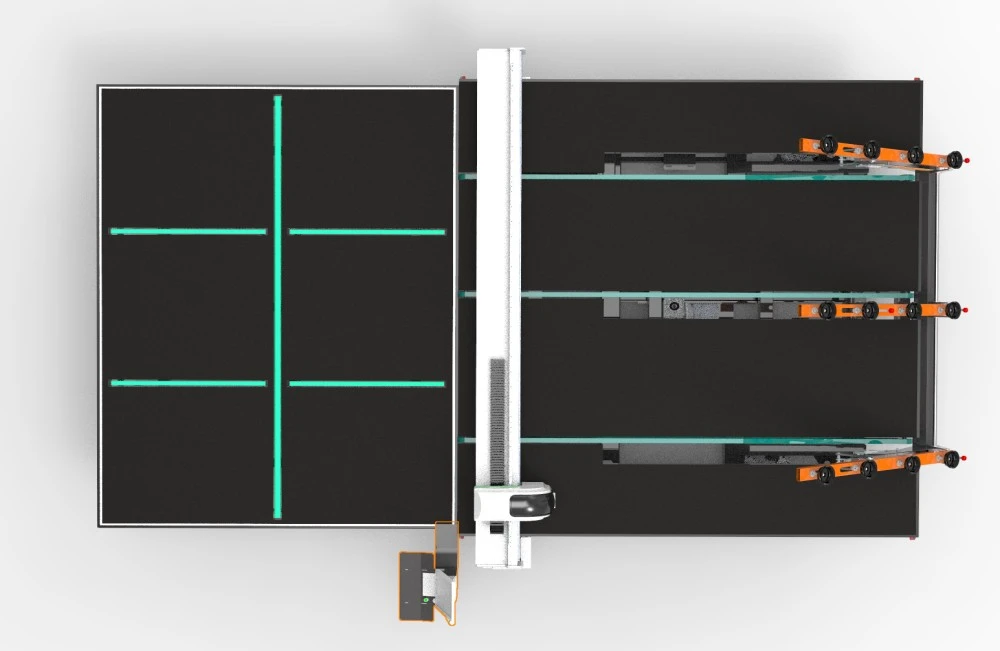

Automated measuring systems that get rid of human error are now standard on professional glass cutting tools. With CAD software, operators may send digital blueprints straight to the machine. This feature is very useful for architectural glass applications that need very precise measurements.

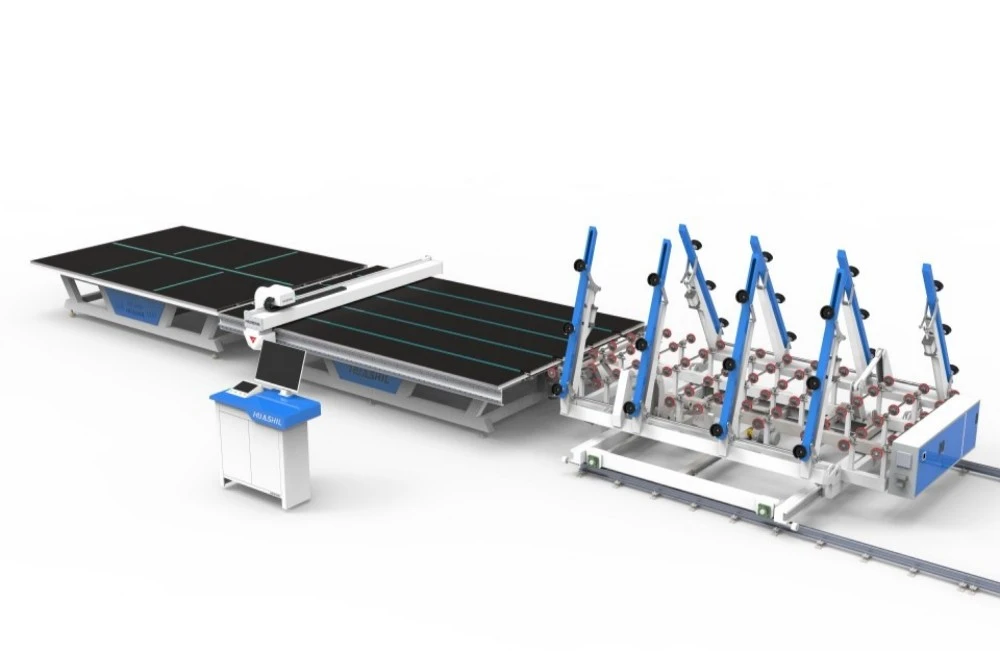

For big businesses, automated glass processing lines are already the norm. These systems do cutting, breaking, and edge grinding all at once. The outcome is a huge increase in efficiency over doing things by hand. Quality control systems check each cut to make sure that the outcomes are the same for all manufacturing runs.

Types of Stained Glass Cutting Equipment Available in 2025

More and more craftsmen and small studios are using the cutting machine for stained glass windows. This tool was made just for making window panels. It combines the accuracy of table-mounted saws with the flexibility of hand tools. Many types have changeable guides for cutting panes again and over, which makes sure that enormous decorative installations look the same.

CNC glass cutting systems represent the premium option for complex work. These machines handle intricate curves and detailed patterns with remarkable accuracy. The computer control eliminates the variability inherent in manual cutting techniques. Many systems accommodate multiple glass thicknesses without requiring setup changes.

Portable glass scoring tools remain popular for smaller workshops and repair work. Modern versions incorporate electronic scoring controls that maintain consistent pressure. Battery-powered units offer freedom of movement around large glass sheets. Some models include integrated pattern guides for repetitive work.

Specialized mosaic cutting equipment addresses the unique needs of decorative glass work. These machines handle small pieces efficiently while maintaining edge quality. Automated feeding systems reduce handling time and improve worker safety.

Key Features to Consider When Selecting Glass Cutting Machinery

Cutting accuracy stands as the most critical specification for any glass cutting system. Professional equipment should maintain tolerances within 0.1mm for architectural applications. The cutting head design affects both precision and glass edge quality. Diamond wheels typically provide superior results compared to steel wheels.

Production capacity requirements vary significantly between workshops and industrial facilities. Single-head machines suit smaller operations, while multi-head systems boost throughput substantially. Consider peak production demands rather than average volumes when sizing equipment.

Glass thickness capabilities determine project versatility. Standard machines handle glass from 2mm to 12mm thickness. Specialized heavy-duty units accommodate architectural glass up to 25mm thick. Variable speed controls optimize cutting parameters for different glass types.

Software integration capabilities affect workflow efficiency significantly. Modern systems accept DXF files directly from design software. Automatic nesting algorithms optimize glass utilization and reduce waste. Some machines include inventory tracking features that monitor glass consumption.

Maintenance requirements impact long-term operating costs substantially. Look for machines with accessible components and clear maintenance schedules. Availability of spare parts and technical support affects equipment reliability. Consider training requirements for operators and maintenance staff.

Precision Glass Processing for Architectural Applications

Architectural stained glass projects demand exceptional accuracy and consistency. Large installation projects cannot tolerate dimensional variations that compromise fit and appearance. Modern cutting systems, including the cutting machine for stained glass windows, address these requirements through advanced control technology. These machines are specifically designed to deliver precise cuts on decorative and structural glass panels, ensuring perfect alignment during assembly.

Edge quality becomes particularly important for exposed glass edges in architectural work. Automated edge grinding systems produce consistent bevels and smooth finishes. Integrated polishing stages eliminate manual finishing operations. Quality inspection systems verify edge specifications automatically.

Pattern complexity in architectural projects often exceeds traditional cutting capabilities. Computer-controlled systems handle intricate geometric designs effortlessly. Multi-axis cutting heads create complex curves and angles in single operations. This capability reduces assembly complexity and improves final quality.

Production scheduling benefits from predictable cutting times and consistent results. Automated systems provide accurate time estimates for project planning. Integration with project management software streamlines workflow coordination. Real-time production monitoring helps identify potential delays early.

Automation Benefits for Glass Fabrication Facilities

Labor cost reduction represents a significant advantage of automated glass cutting systems. Modern machines require minimal operator intervention during cutting operations. Single operators can manage multiple machines simultaneously. This efficiency gain becomes particularly valuable during peak production periods.

Material waste reduction directly impacts profitability in glass fabrication operations. Optimized cutting patterns minimize glass waste significantly. Automatic nesting software calculates optimal layouts for each project. Precise cutting eliminates oversized pieces that require trimming.

Quality consistency improves dramatically with automated systems. Machine cutting eliminates variations in operator technique and fatigue effects. Consistent edge quality reduces downstream processing requirements. Automated inspection systems catch defects immediately.

Production flexibility allows fabricators to handle diverse project requirements efficiently. Quick pattern changes accommodate rush orders without setup delays. Programmable cutting parameters optimize results for different glass types. This adaptability proves essential in competitive markets.

Safety improvements benefit both workers and facilities. Automated handling reduces glass breakage and injury risks. Enclosed cutting areas contain glass particles and noise. Emergency stop systems provide immediate shutdown capabilities when needed.

Maintenance and Operational Considerations

Regular maintenance schedules ensure optimal cutting performance and equipment longevity. For systems such as the cutting machine for stained glass windows, cutting wheel condition directly affects both edge quality and glass breakage rates. Replacement schedules depend on glass types and cutting volumes. Tracking wear patterns helps optimize replacement timing and maintain consistent output quality.

Calibration procedures maintain cutting accuracy over time. Thermal expansion and mechanical wear gradually affect precision. Monthly verification checks identify drift before quality problems occur. Documented calibration records support quality system requirements.

Operator training programs maximize equipment capabilities and minimize errors. Proper setup procedures affect cutting quality significantly. Understanding machine limitations prevents damage and safety issues. Ongoing training keeps operators current with software updates and new features.

Environmental factors influence cutting performance and equipment life. Temperature fluctuations affect glass cutting characteristics. Humidity control prevents condensation on glass surfaces. Proper ventilation removes glass particles and maintains air quality.

Spare parts inventory management ensures minimal downtime during maintenance periods. Critical components like cutting wheels and drive belts require immediate availability. Preventive replacement schedules reduce emergency repair situations. Vendor relationships affect parts availability and pricing.

Cost Analysis and Return on Investment

Initial equipment costs vary widely based on capabilities and production capacity. Entry-level automated systems start around $50,000 for basic functionality. High-end production lines can exceed $500,000 for complete automation. Consider financing options and their impact on project economics.

Operating cost analysis should include energy consumption, maintenance, and consumables. Cutting wheels and other consumables represent ongoing expenses. Labor savings often offset equipment costs within 18-24 months. Calculate total cost of ownership over the equipment's expected life.

Productivity gains enable fabricators to accept larger projects and improve delivery times. Faster turnaround often justifies premium pricing for rush orders. Consistent quality reduces rework costs and customer complaints. These benefits compound over time to improve profitability.

Market competitiveness improves with automated capabilities. Ability to handle complex projects expands business opportunities. Reliable delivery schedules build customer confidence and loyalty. Investment in modern equipment positions businesses for future growth.

Conclusion

Modern glass cutting technology has revolutionized stained glass fabrication through improved precision, efficiency, and consistency. Automated systems deliver superior results while reducing labor costs and material waste. The investment in advanced cutting equipment positions fabricators for sustained growth in competitive markets. Careful selection of equipment based on production requirements and quality standards ensures optimal return on investment. HUASHIL's comprehensive solutions and technical expertise support fabricators in achieving their production goals efficiently and reliably.

Partner with HUASHIL for Advanced Glass Cutting Solutions

HUASHIL stands as a leading cutting machine for stained glass windows manufacturer with decades of experience in automated glass processing equipment. Our engineering team understands the unique challenges facing architectural glass fabricators and furniture manufacturers. We deliver customized solutions that address specific production requirements while ensuring reliable operation.

Our comprehensive product line includes everything from single-head cutting systems to complete automated production lines. Each machine incorporates advanced control technology and precision components for consistent results. We provide extensive technical support and training to maximize your equipment investment. Our global service network ensures prompt spare parts delivery and technical assistance.

Quality assurance programs guarantee equipment performance and longevity. Every system undergoes rigorous testing before shipment to verify specifications. We offer customization services for unique applications and integration requirements. Our OEM and ODM capabilities support system integrators and equipment distributors worldwide.

Shandong Huashil Automation Technology brings proven expertise to your glass cutting challenges. We invite you to explore how our solutions can transform your production capabilities. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and receive detailed technical information about our cutting machine systems.

References

1. Smith, J. "Advanced Glass Processing Technologies in Modern Manufacturing." Journal of Glass Engineering, Vol. 45, 2024, pp. 123-145.

2. Chen, L. "Automation in Architectural Glass Fabrication: Trends and Applications." International Glass Review, Issue 3, 2024, pp. 67-89.

3. Rodriguez, M. "Quality Control in Automated Glass Cutting Systems." Glass Technology International, Vol. 28, 2024, pp. 201-218.

4. Wang, H. "Economic Analysis of Glass Cutting Equipment Investments." Manufacturing Economics Quarterly, Vol. 12, 2024, pp. 45-62.

5. Thompson, R. "Safety Considerations in Modern Glass Processing Facilities." Industrial Safety Journal, Vol. 19, 2024, pp. 112-128.

6. Lee, K. "Integration of CAD Systems with Glass Cutting Equipment." Computer-Aided Manufacturing Review, Vol. 31, 2024, pp. 78-95.