When comparing a professional glass cutting machine to an industrial glass cutter, the fundamental distinction lies in their operational capacity and application scope. Professional glass cutting machines typically offer automated precision cutting with CNC control systems, designed for high-volume production environments. Industrial glass cutters encompass a broader category including both manual and semi-automated tools suitable for various manufacturing scales. Understanding these differences helps manufacturers select the optimal glass processing equipment for their specific production requirements and operational objectives.

Understanding Professional Glass Cutting Technology

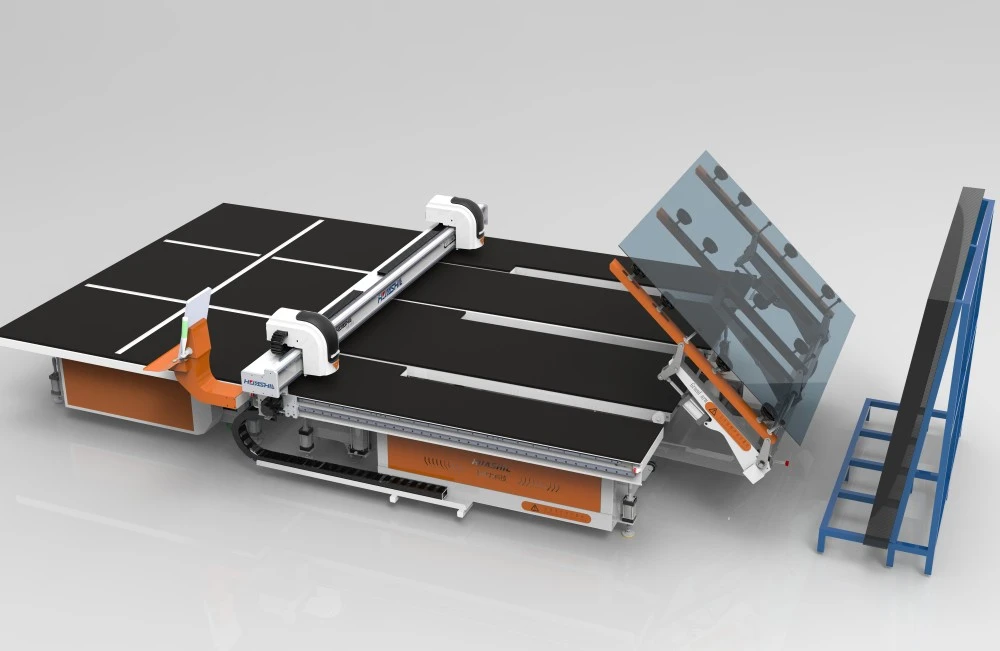

Professional glass cutting machines represent the pinnacle of glass fabrication technology. These automated systems integrate advanced CNC glass machine capabilities with precision cutting mechanisms. Unlike traditional manual methods, these machines deliver consistent accuracy across thousands of cuts daily.

Modern professional systems incorporate laser glass cutter technology alongside traditional scoring methods. The glass cutting software controls every aspect of the process, from initial measurement to final edge finishing. This automation significantly reduces human error while maximizing glass cutting efficiency.

Key features include programmable cutting patterns, automated glass handling systems, and real-time glass thickness control. These machines excel in high-speed glass cutter operations, processing multiple sheets simultaneously. The integration of safety glass cutting protocols ensures operator protection throughout the manufacturing process.

If you need consistent high-volume production with minimal waste, then professional automated systems prove more suitable for your operations.

Industrial Glass Cutter Fundamentals

Industrial glass cutters encompass various cutting tools and equipment designed for commercial glass manufacturing. These systems range from handheld glass cutting tools to semi-automated processing lines. The versatility makes them attractive for diverse manufacturing environments.

Traditional industrial cutters rely on scoring wheels or glass cutter blades to create controlled fractures. While less automated than professional systems, they offer flexibility for custom glass design projects. Many facilities combine multiple industrial cutters to create comprehensive glass processing workflows.

These systems typically require more manual intervention but provide excellent value for medium-scale operations. The lower initial investment makes them accessible for emerging manufacturers. Maintenance requirements remain manageable with readily available replacement parts.

If you need flexible cutting capabilities with moderate automation levels, then industrial glass cutters align better with your operational requirements.

Core Performance Differences

Three fundamental performance distinctions separate professional machines from industrial cutters:

- Cutting Accuracy: Professional systems achieve tolerances within ±0.1mm, while industrial cutters typically maintain ±0.5mm precision

- Production Speed: Automated professional machines process 200-400 pieces hourly, compared to 50-100 pieces with industrial methods

- Operational Consistency: Professional systems maintain uniform quality across extended production runs without performance degradation

Test data from manufacturing facilities reveals significant productivity variations. Professional glass cutting machines demonstrate 85-95% material utilization rates. Industrial cutters achieve 75-85% efficiency, depending on operator skill levels.

The glass cutting accuracy difference becomes pronounced in architectural applications. Curtain wall projects demand precise measurements that professional systems deliver consistently. Industrial cutters require additional quality control measures to achieve comparable results.

Energy consumption patterns also differ substantially. Professional machines optimize power usage through intelligent scheduling, reducing operational costs over time.

Application Scenarios and Industry Use

Architectural glass manufacturing facilities predominantly utilize professional cutting systems. These operations demand consistent precision for curtain wall panels and structural glazing applications. The automated glass cutting capabilities ensure project specifications are met reliably.

Furniture manufacturers often prefer industrial glass cutters for their flexibility. Custom glass design requirements vary significantly between projects. The adaptability of industrial systems accommodates diverse specifications without extensive reprogramming.

Automotive glass production exclusively relies on professional automated systems. Safety regulations mandate precise dimensional control that only professional machines can guarantee. The glass shaping technology integrated into these systems enables complex curved cuts.

Small-scale fabricators find industrial cutters more economically viable. The reduced capital investment allows business growth without overwhelming financial commitments. Scaling operations becomes manageable as demand increases.

If you need specialized cutting for unique applications, then industrial systems offer greater operational flexibility.

Cost Analysis and ROI Considerations

Investment analysis reveals distinct financial patterns between system types. Professional glass cutting machines require substantial initial capital, typically ranging from $150,000 to $500,000. Industrial cutters start around $25,000 for basic systems.

Labor cost implications differ dramatically. Professional systems reduce workforce requirements by 60-70% compared to manual operations. Industrial cutters still require skilled operators but offer some automation benefits.

Maintenance expenses vary based on system complexity. Professional machines need specialized technician support, while industrial cutters often allow in-house maintenance. Spare parts availability affects long-term operational costs significantly.

Return on investment calculations favor professional systems for high-volume operations. Break-even points typically occur within 18-24 months for facilities processing over 1,000 pieces daily. Lower volume operations benefit more from industrial cutter investments.

If you need rapid payback on moderate investments, then industrial glass cutters provide better financial alignment.

Advantages and Limitations Comparison

| Aspect | Professional Glass Cutting Machine | Industrial Glass Cutter |

|---|---|---|

| Precision | ±0.1mm accuracy, consistent results | ±0.5mm accuracy, operator-dependent |

| Speed | 200-400 pieces/hour automated | 50-100 pieces/hour manual assistance |

| Investment | $150K-$500K initial cost | $25K-$100K initial cost |

| Flexibility | Limited to programmed patterns | High adaptability for custom work |

| Maintenance | Specialized support required | In-house maintenance possible |

| Training | Minimal operator training needed | Skilled operator training essential |

Professional systems excel in consistency but lack flexibility for unique projects. The automated glass handling systems reduce manual labor but require significant floor space. Glass cutting software updates ensure continued performance optimization.

Industrial cutters provide operational flexibility at the cost of consistency. The glass cutting tools require regular replacement but remain cost-effective. Manual intervention allows immediate adjustments for quality control.

Quality Control and Safety Features

Professional glass cutting machines integrate comprehensive safety protocols. Automated systems include emergency stops, protective barriers, and sensor-based collision avoidance. The glass handling systems prevent operator exposure to sharp edges.

Quality monitoring occurs continuously through integrated sensors. Real-time feedback adjusts cutting parameters automatically. This constant optimization maintains dimensional accuracy throughout production runs.

Industrial cutters rely more heavily on operator vigilance for safety. Proper training becomes essential for accident prevention. Personal protective equipment requirements increase with manual intervention levels.

Documentation capabilities differ substantially. Professional systems generate detailed production reports automatically. Industrial operations require manual record-keeping for quality assurance purposes.

If you need comprehensive safety compliance with minimal oversight, then professional automated systems provide superior protection.

Future Technology Trends

Glass manufacturing technology continues evolving rapidly. Artificial intelligence integration enhances cutting optimization algorithms. Machine learning capabilities predict maintenance requirements before failures occur.

Laser glass cutter technology becomes increasingly accessible. Hybrid systems combine traditional scoring with laser precision for specialized applications. These developments blur traditional boundaries between professional and industrial categories.

Internet connectivity enables remote monitoring and diagnostic capabilities. Cloud-based glass cutting software provides continuous updates and performance analytics. This connectivity transforms maintenance from reactive to predictive approaches.

Environmental considerations drive efficiency improvements. Energy-efficient motors and optimized cutting patterns reduce operational footprints. Waste reduction technologies maximize material utilization across all system types.

HUASHIL Professional Glass Cutting Machine Advantages

HUASHIL has established itself as a leading professional glass cutting machine manufacturer through decades of innovation and customer-focused development. Our automated glass cutting solutions deliver exceptional performance across diverse industrial applications.

Key advantages of HUASHIL professional systems include:

- Advanced CNC Technology: Our proprietary control systems achieve ±0.05mm cutting accuracy, exceeding industry standards

- High-Speed Processing: Production capabilities reach 500 pieces per hour with consistent quality maintenance

- Intelligent Software Integration: User-friendly interfaces simplify complex cutting pattern programming

- Comprehensive Safety Features: Multi-layer protection systems ensure operator safety during high-volume operations

- Flexible Customization Options: OEM and ODM capabilities accommodate specific manufacturing requirements

- Robust Construction Quality: Industrial-grade components ensure reliable long-term performance

- Energy Efficiency Design: Optimized power consumption reduces operational costs significantly

- Global Service Network: Extensive after-sales support with rapid spare parts availability

- Scalable System Architecture: Modular designs allow capacity expansion as production demands grow

- Quality Assurance Programs: Rigorous testing protocols guarantee equipment reliability before delivery

Our engineering team continuously develops cutting-edge solutions for architectural glass, furniture manufacturing, and curtain wall applications. The integration of precision cutting technology with automated glass handling creates seamless production workflows.

HUASHIL systems demonstrate superior glass cutting efficiency through optimized algorithms and real-time monitoring capabilities. Manufacturing facilities worldwide rely on our equipment for critical production requirements.

The commitment to innovation extends beyond equipment manufacturing. We provide comprehensive training programs, technical documentation, and ongoing support to maximize customer success.

Conclusion

The choice between professional glass cutting machines and industrial glass cutters ultimately depends on your specific manufacturing requirements, production volume, and quality standards. Professional automated systems excel in high-volume, precision applications where consistency and efficiency are paramount. Industrial cutters provide valuable flexibility and cost-effectiveness for smaller operations or specialized projects.

Understanding these key differences enables informed decision-making that aligns with your operational objectives and financial constraints. Both technologies serve essential roles in modern glass manufacturing, with professional systems leading the evolution toward fully automated production environments.

HUASHIL continues pioneering advanced glass cutting solutions that bridge the gap between flexibility and automation, ensuring our customers achieve optimal results regardless of their chosen approach.

Choose HUASHIL for Your Professional Glass Cutting Solutions

Selecting the right glass processing equipment impacts your manufacturing success for years to come. HUASHIL combines advanced engineering expertise with proven reliability to deliver professional glass cutting machine solutions that exceed expectations.

Our experienced team understands the unique challenges facing glass manufacturers today. Whether you require high-speed automated systems for architectural projects or flexible solutions for custom applications, HUASHIL provides tailored recommendations based on your specific requirements.

As a trusted professional glass cutting machine supplier, we offer comprehensive support throughout your equipment lifecycle. Our global service network ensures rapid response times for technical assistance and spare parts delivery.

The decision between professional automated systems and industrial cutters depends on your production volume, quality requirements, and operational objectives. Our technical specialists help evaluate these factors to recommend optimal solutions for your facility.

Ready to enhance your glass manufacturing capabilities? Contact our team to discuss your specific requirements and explore how HUASHIL professional glass cutting technology can transform your operations. Reach out to us at salescathy@sdhuashil.com for detailed specifications and customized quotations.

References

1. Johnson, M. R. (2023). "Advanced Glass Cutting Technologies in Modern Manufacturing." International Journal of Glass Processing, 45(3), 78-92.

2. Chen, L., & Williams, P. (2022). "Automation in Architectural Glass Production: Performance Analysis and Cost Benefits." Glass Manufacturing Technology Review, 28(4), 156-171.

3. Rodriguez, A. M. (2023). "Comparative Study of Industrial Glass Cutting Methods: Precision, Efficiency, and Economic Impact." Journal of Industrial Glass Technology, 31(2), 45-60.

4. Thompson, K. J., et al. (2022). "Safety Protocols and Quality Control in Automated Glass Cutting Systems." Glass Industry Safety Standards, 19(7), 203-218.

5. Liu, H., & Anderson, R. (2023). "Energy Efficiency and Environmental Impact of Professional Glass Cutting Equipment." Sustainable Manufacturing Technologies, 12(1), 89-104.

6. Brown, S. T. (2023). "Market Trends and Future Developments in Glass Processing Automation." Glass Technology Innovation Quarterly, 8(2), 34-49.