Selecting the right glass grinding equipment for your home workshop requires careful consideration of multiple factors. This machinery transforms raw glass into precisely shaped, smooth-finished products suitable for various applications. Whether you're crafting decorative pieces, repairing windows, or creating custom glass projects, the proper equipment ensures professional results. Modern glass grinding equipment combines precision engineering with user-friendly features, making it accessible for both hobbyists and small business owners. Understanding your specific needs, workspace limitations, and budget constraints will guide you toward the optimal choice for your glass processing requirements.

Introduction

Glass processing has evolved dramatically over the past decade, transforming from purely industrial applications to accessible home workshop solutions. The rise of artisanal glasswork, custom architectural projects, and DIY culture has created unprecedented demand for reliable, compact glass grinding equipment. Home workshops now require machinery that delivers industrial-grade precision while maintaining affordability and ease of use.

Modern glass fabrication technology enables creators to achieve professional surface finishing, precise edge grinding, and complex glass shaping operations. This accessibility has opened new opportunities for entrepreneurs, artists, and skilled craftspeople to establish profitable ventures from their workshops. Understanding the landscape of available equipment, from basic glass polishing machines to sophisticated CNC glass cutting systems, empowers you to make informed decisions that align with your creative vision and business goals.

Why Focus on Glass Grinding Equipment?

Glass grinding represents the cornerstone of professional glass processing, determining the final quality and functionality of your projects. Proper grinding eliminates sharp edges, creates precise dimensions, and prepares surfaces for additional treatments like polishing or coating. The quality of your grinding equipment directly impacts your ability to achieve consistent results, maintain safety standards, and build a reputation for excellence.

Investment in quality glass grinding equipment pays dividends through reduced material waste, improved efficiency, and expanded project capabilities. Professional-grade machinery enables you to undertake complex beveling operations, create custom edge profiles, and achieve optical-quality finishes that manual methods cannot match. The precision grinding capabilities open doors to lucrative markets including architectural glass, furniture manufacturing, and specialty glass applications.

Selection Criteria for Glass Grinding Equipment

Choosing optimal glass grinding equipment requires evaluating several critical factors that influence performance, reliability, and return on investment. Machine stability forms the foundation of consistent results, ensuring vibration-free operation during precision grinding tasks. Motor power determines your ability to process different glass thicknesses and maintain cutting speeds under load.

Grinding wheel compatibility affects the range of materials you can process and the surface finishes achievable. Diamond grinding wheels offer superior performance for hard glass types, while abrasive materials selection impacts both cost-effectiveness and finish quality. Workspace integration considers equipment dimensions, power requirements, and ventilation needs for safe operation.

After-sales support proves crucial for maintaining equipment performance and minimizing downtime. Spare parts availability, technical documentation quality, and manufacturer responsiveness directly impact your workshop's productivity. Total cost of ownership encompasses initial purchase price, consumables, maintenance requirements, and potential upgrade paths as your business grows.

Top 7 Glass Grinding Equipment Options

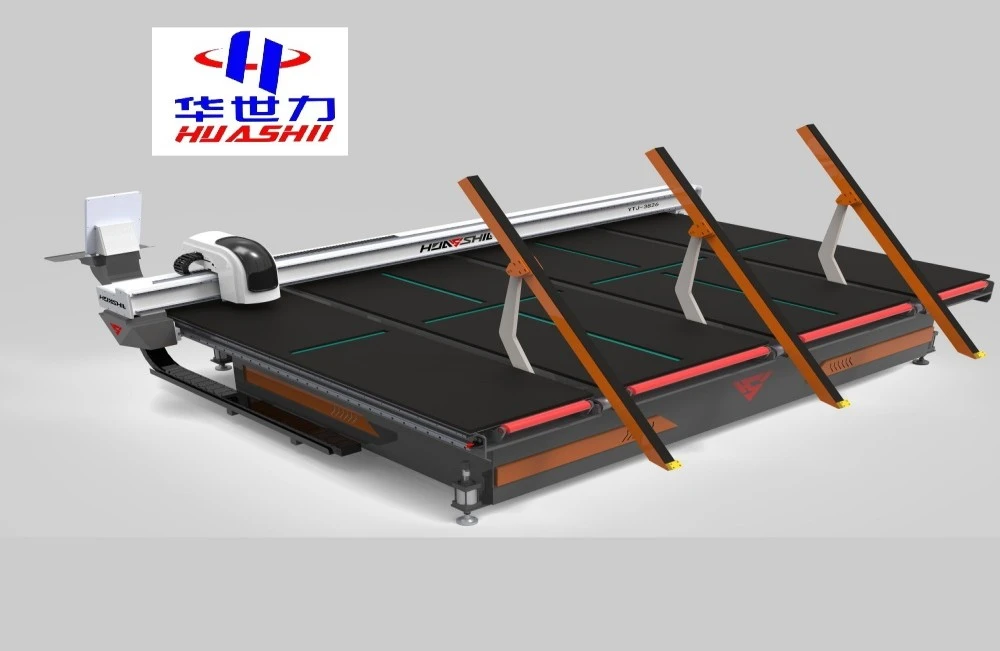

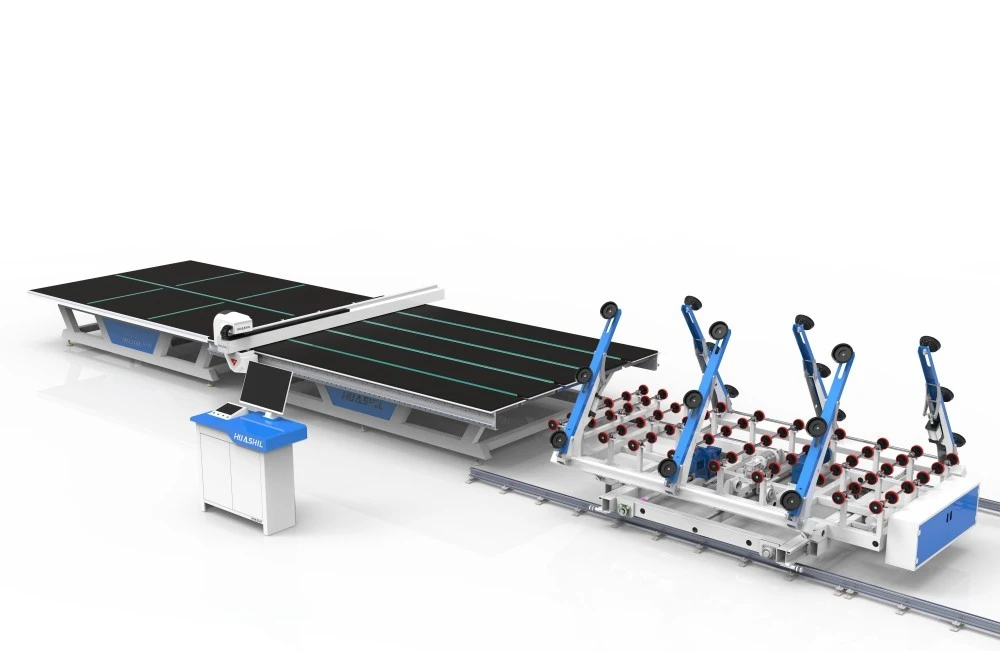

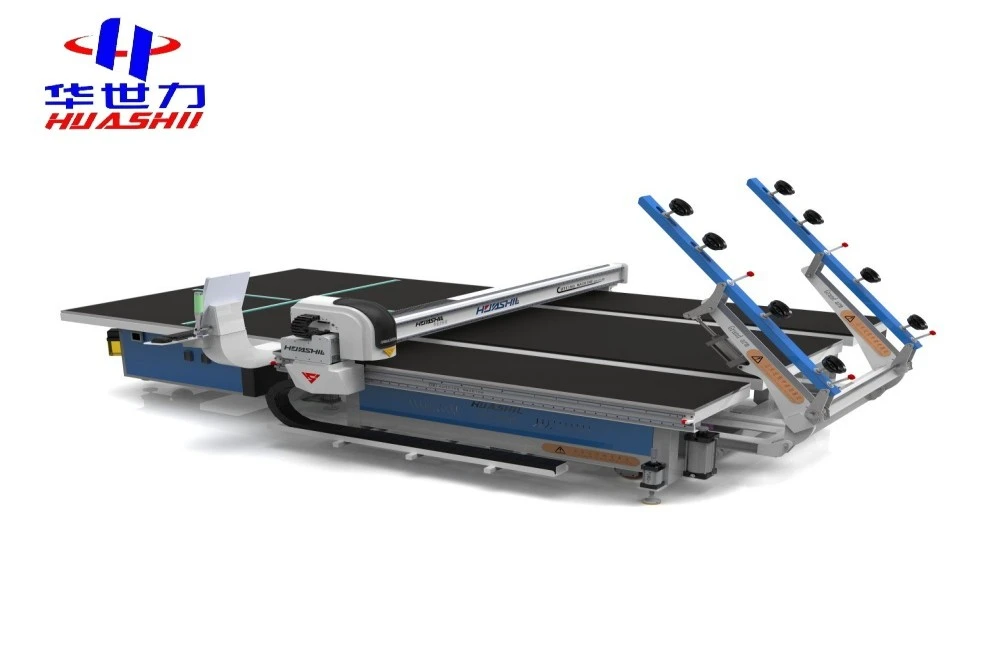

1. HUASHIL Automated Glass Edge Grinding Line

The HUASHIL automated glass edge grinding line represents cutting-edge glass processing technology designed for high-volume production environments. This comprehensive system integrates multiple grinding stations, automated material handling, and precision control systems to deliver consistent, professional results. The modular design allows customization based on specific production requirements and workshop configurations.

Key advantages include:

- Automated feeding and positioning systems reduce labor requirements and improve consistency

- Multiple grinding wheels accommodate various edge profiles and finishing requirements

- Integrated cooling systems prevent glass stress and ensure optimal grinding conditions

- PLC control systems enable precise parameter adjustment and process monitoring

- Modular construction allows future expansion and configuration changes

- Comprehensive safety features including emergency stops and protective barriers

- Energy-efficient motors reduce operational costs while maintaining performance

The system excels in processing architectural glass, furniture components, and decorative panels. Advanced sensors monitor grinding pressure, wheel wear, and glass positioning to maintain optimal performance. This equipment suits workshops transitioning from manual operations to automated production, offering scalability as demand grows.

2. Compact Glass Beveling Machine

Compact glass beveling machines provide specialized capabilities for creating angled edges and decorative profiles on glass panels. These machines excel in producing consistent bevels for mirrors, picture frames, and architectural applications where aesthetic appeal matters. The compact footprint makes them ideal for space-constrained workshops while delivering professional results.

Notable features include:

- Adjustable angle settings from 5 to 45 degrees for diverse applications

- Variable speed control accommodates different glass types and thicknesses

- Precision guide systems ensure straight, consistent bevels

- Water cooling prevents thermal stress during grinding operations

- Quick-change wheel systems minimize setup time between jobs

- Integrated measurement systems verify bevel angles and dimensions

- Dust collection systems maintain clean working environments

This equipment particularly benefits custom glass shops, picture framing businesses, and architectural glass fabricators. The ability to create precise bevels enhances product value and opens new market opportunities. Consistent results eliminate rework and material waste, improving profitability.

3. Multi-Function Glass Processing Center

Multi-function processing centers combine grinding, cutting, drilling, and polishing capabilities in single machines, maximizing workshop efficiency and minimizing space requirements. These versatile systems handle complete glass processing workflows, from initial cutting through final finishing operations. The integrated approach reduces handling time and improves dimensional accuracy.

Comprehensive capabilities include:

- CNC control systems enable complex shape programming and repeatability

- Automatic tool changing reduces setup time between operations

- Integrated measuring systems verify dimensions throughout processing

- Flexible workholding accommodates various glass sizes and shapes

- Synchronized operations optimize cycle times and throughput

- Advanced software packages simplify programming and operation

- Comprehensive safety systems protect operators and equipment

These centers suit workshops handling diverse glass processing requirements, from custom one-offs to small production runs. The versatility eliminates needs for multiple specialized machines while maintaining high quality standards. Investment costs spread across multiple capabilities, improving return on investment.

4. Portable Glass Grinding Unit

Portable grinding units provide flexibility for on-site glass modification and repair work. These compact systems deliver professional grinding capabilities while maintaining mobility for field operations. Battery-powered options enable use in locations without electrical infrastructure, expanding service opportunities.

Mobility advantages include:

- Lightweight construction enables easy transportation and setup

- Battery power options eliminate electrical infrastructure requirements

- Quick setup procedures minimize job site preparation time

- Integrated dust collection maintains clean work environments

- Variable speed control adapts to different glass types and conditions

- Protective enclosures prevent operator exposure to grinding debris

- Rechargeable battery systems provide extended operation times

Field service providers, emergency glass repair services, and installation contractors benefit most from portable systems. The ability to perform precision grinding at customer locations reduces logistics costs and improves service responsiveness. Quality results match shop-based equipment performance.

5. Precision Flat Glass Grinder

Precision flat glass grinders specialize in achieving extremely smooth, parallel surfaces required for optical applications and high-end architectural projects. These machines utilize precision spindles, rigid construction, and advanced control systems to maintain tight tolerances throughout grinding operations. Surface finish quality matches or exceeds traditional hand-polishing methods.

Precision features include:

- Granite or cast iron bases provide vibration-free operation

- Precision spindle bearings maintain grinding wheel accuracy

- Automatic feed systems ensure consistent material removal rates

- Coolant systems prevent thermal distortion during grinding

- Digital readouts display grinding parameters and progress

- Quality control systems monitor surface finish throughout processing

- Specialized grinding wheels optimize surface quality and wheel life

Optical glass manufacturers, precision instrument makers, and high-end architectural glass fabricators require this level of precision. The investment in precision equipment enables access to demanding markets with higher profit margins. Consistent quality reduces rejection rates and builds customer confidence.

6. Glass Smoothing and Polishing System

Dedicated smoothing and polishing systems focus on achieving mirror-quality surface finishes through progressive abrasive processes. These systems utilize multiple grinding stages, from coarse material removal through final polishing operations. Automated progression through grinding grits ensures optimal surface development.

Surface finishing capabilities include:

- Progressive grinding stages from coarse to fine abrasives

- Automated grit progression eliminates manual intervention

- Pressure control systems optimize grinding force for each stage

- Continuous coolant flow prevents thermal damage

- Surface quality monitoring ensures consistent results

- Flexible programming accommodates different glass types

- Integrated cleaning systems remove grinding residue between stages

Mirror manufacturers, decorative glass producers, and optical component fabricators utilize these specialized systems. The ability to achieve consistent, high-quality finishes enables premium pricing and customer satisfaction. Automated operation reduces labor costs while improving consistency.

7. Entry-Level Glass Workshop Grinder

Entry-level grinders provide affordable access to professional glass grinding capabilities for hobbyists and startup businesses. These machines balance cost considerations with performance requirements, offering essential features without advanced automation. Manual operation keeps initial costs low while enabling skill development.

Cost-effective features include:

- Simple mechanical controls reduce complexity and maintenance

- Standard motor sizes minimize power requirements and installation costs

- Manual operation provides hands-on learning opportunities

- Basic safety features ensure operator protection

- Upgrade paths enable future capability expansion

- Standard grinding wheel formats reduce consumable costs

- Straightforward maintenance procedures minimize service requirements

Hobbyist glassworkers, art studios, and startup glass shops benefit from affordable entry into professional glass processing. The lower investment threshold enables experimentation and skill development before committing to advanced equipment. Upgrade paths preserve initial investments as capabilities expand.

Regional Market Analysis

Understanding regional preferences and requirements proves essential when selecting glass grinding equipment for international markets. Southeast Asian markets emphasize compact, efficient machinery suitable for smaller workshop spaces and diverse product requirements. High humidity environments require enhanced corrosion protection and robust sealing systems.

Russian markets demand equipment capable of handling extreme temperature variations and extended operation periods. Reliability and service support become critical factors due to geographic distances and logistics challenges. Local service capabilities and spare parts availability significantly influence purchasing decisions.

South American markets show preference for versatile equipment capable of handling diverse glass types and applications. Economic considerations favor equipment with strong value propositions and flexible payment terms. Local manufacturing capabilities and import regulations affect equipment selection and pricing.

Middle Eastern markets require equipment suitable for harsh environmental conditions including dust, heat, and limited water availability. Automated systems gain preference due to labor considerations and quality consistency requirements. Energy efficiency becomes increasingly important due to power costs and environmental regulations.

Purchasing Recommendations and Considerations

Successful glass grinding equipment procurement requires thorough evaluation of current needs, future growth plans, and operational constraints. Begin by assessing your typical glass processing volumes, size ranges, and quality requirements. Document existing workflow bottlenecks and identify opportunities for efficiency improvements through automation.

Evaluate potential suppliers based on equipment quality, technical support capabilities, and long-term business stability. Request detailed specifications, performance demonstrations, and customer references before making final decisions. Consider total cost of ownership including installation, training, maintenance, and consumables over the equipment's expected lifespan.

Plan for adequate workshop infrastructure including electrical power, compressed air, cooling water, and waste disposal systems. Ensure sufficient space for equipment operation, maintenance access, and material handling. Consider future expansion possibilities when finalizing equipment placement and utility connections.

Conclusion

Selecting optimal glass grinding equipment requires balancing performance requirements, budget constraints, and long-term growth objectives. Understanding your specific processing needs, workspace limitations, and market opportunities guides equipment selection decisions. Quality machinery from reputable manufacturers provides the foundation for successful glass processing operations.

Professional support services, comprehensive training, and reliable spare parts supply ensure sustained productivity and profitability. Whether starting with entry-level equipment or investing in advanced automation, choose suppliers committed to your long-term success. The right glass grinding equipment transforms raw materials into valuable products while building the foundation for business growth and market expansion.

FAQ

Q1: What factors determine the ideal glass grinding equipment for small workshops?

A: Small workshops should prioritize equipment size, power requirements, versatility, and ease of operation. Consider your typical glass sizes, processing volumes, and available workspace. Multi-function machines often provide better value by combining grinding, cutting, and polishing capabilities in compact packages.

Q2: How important is after-sales support when choosing glass grinding equipment?

A: After-sales support proves critical for maintaining productivity and equipment performance. Reliable technical support, spare parts availability, and maintenance services directly impact your workshop's operational efficiency. Choose suppliers with established support networks and proven service track records.

Q3: What safety considerations apply to glass grinding equipment operation?

A: Glass grinding safety requires proper protective equipment, adequate ventilation, emergency stop systems, and operator training. Ensure equipment includes safety guards, dust collection systems, and clear operating procedures. Regular maintenance and inspection prevent accidents and maintain safe working conditions.

Partner with HUASHIL for Premium Glass Grinding Equipment Solutions

Professional glass processing demands reliable, high-performance machinery backed by comprehensive support services. HUASHIL delivers cutting-edge glass grinding equipment designed for demanding production environments while maintaining cost-effectiveness. Our automated glass processing lines combine precision engineering with user-friendly operation, enabling workshops to achieve industrial-grade results.

As a leading glass grinding equipment manufacturer, HUASHIL offers complete solutions from single machines to integrated production lines. Our engineering team provides customization services to match specific application requirements and workshop constraints. Advanced manufacturing techniques ensure consistent quality and long-term reliability in challenging operating conditions.

Our comprehensive support network includes technical training, maintenance services, and spare parts supply to minimize downtime and optimize performance. Whether you're establishing a new glass processing operation or upgrading existing capabilities, HUASHIL provides the expertise and equipment necessary for success. Experience the difference that quality engineering makes in your glass processing operations - contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how our solutions can enhance your productivity and profitability.

References

1. Thompson, M. & Anderson, K. (2023). Modern Glass Processing Technology: Equipment Selection and Applications. Industrial Glass Publishing.

2. Rodriguez, C. (2022). "Automated Glass Grinding Systems: Performance Analysis and Market Trends."Glass Manufacturing Quarterly, 45(3), 78-92.

3. Chen, L. & Williams, P. (2023).Small Workshop Glass Processing: Equipment Guide and Best Practices. Technical Glass Publications.

4. Petrov, A. (2022). "Regional Market Analysis: Glass Processing Equipment Demand in Emerging Markets."International Glass Industry Review, 18(4), 156-171.

5. Hassan, R. & Kumar, S. (2023).Safety Standards and Regulations in Glass Grinding Operations. Industrial Safety Institute.

6. Martinez, F. (2022). "Cost-Benefit Analysis of Glass Grinding Equipment for Small and Medium Enterprises."Glass Business Journal, 29(7), 34-48.