Double edger machine tools ensure amazing accuracy and uniformity in product quality by finishing the edges on both sides of workpieces at the same time. These advanced systems significantly speed up the time it takes to make things, and they also keep higher standards of surface quality that manual processes can't reach. In today's tough market, this technology gives makers in the glass, metal, and stone industries a way to make their products more durable, accurate, and attractive. This leads to happier customers and helps businesses stand out from the competition.

Understanding Double Edger Machines in Precision Edge Finishing

Double edger machines are a high-tech way of doing industrial edge processing that changes the way that makers do precision finishing in a lot of different fields. These machines are great at making glass, working with metal, and shaping stone. They do this by processing both sides of a workpiece at the same time, which leads to better accuracy and surface quality than older methods that only worked on one side.

Core Components and Advanced Technology Integration

Today's double edger machines use advanced tech that works together to make the machines work really well. The heart of these systems is their full grinding wheel setup, which has eight grinding wheels placed in just the right spots for the best material removal and finishing. This setup has two upper bevels and two lower bevels. Four flat grinding wheels make sure that all of the edges are smooth on a wide range of materials, no matter how thick they are.

Servo motors handle both automatic opening and closing systems. These can adapt to the size of the workpiece and position it very accurately. This technology includes conveying systems. Here, servo motors make sure that the materials move smoothly and in a controlled way during the whole processing cycle. These machines are clearly flexible because their opening range can be changed to fit materials from 0.35 meters to 2.5 meters. This makes them perfect for a wide range of production needs.

Operational Workflow and Material Processing Capabilities

Modern double edger machines work in a carefully planned way that keeps quality high and makes the most of efficiency. The cycle starts with material loading. Then, automated placement makes sure that everything is lined up correctly with the grinding wheels. The latest wheel designs are used in the grinding and polishing process to get even surface finishes, and quality is monitored during the process by screening systems that are part of the overall setup.

Manufacturers can customize these machines for different production needs, such as making sure they can handle different edge shapes, material types, and output needs. This ability to change is very useful for architectural glass makers and curtain wall fabricators who need to be able to control dimensions exactly and get great surface quality for their special uses.

Advantages of Using Double Edger Machines for Superior Product Quality

The use of double edger machines results in quantifiable gains in product quality and manufacturing speed that have a direct bearing on the bottom line. These high-tech systems deal with important production issues and give businesses long-term benefits in terms of speed and accuracy.

Precision and Consistency Benefits

Using double edger machines makes edge finishing much more precise and consistent compared to older single-sided or hand-based methods. Aligning the edges perfectly straight is possible when they are processed at the same time, which avoids the problems that often happen when moving workpieces for secondary processes. This method keeps things constant, so the quality of the product always meets strict customer standards for every unit made in a production run.

Going to both edges at the same time raises output, lowers cycle times, and stops material waste. The automated nature of these systems keeps processing conditions the same over long periods of production and lowers the chances of human mistakes. Manufacturers in the architectural and car markets depend on this kind of reliability because they need to make sure that every measurement is always exactly right.

Economic and Operational Advantages

Double edger machine setups offer better cost-to-performance ratios than conventional edge polishing methods or single edger configurations due to lower labor costs and higher throughput rates. Case studies in the industry show that using these methods made production more efficient. Some manufacturers reported higher throughput rates (40–60%) while also lowering the number of defects.

The economic benefits go beyond higher production levels. They also include lower material costs because waste is reduced and yield rates are better. These benefits make the value offer clear for makers who want to stay competitive in their markets while also meeting rising quality expectations.

Operating and Maintaining Your Double Edger Machine for Optimal Performance

Following the best practices for the operation and upkeep of double edger machines will help you get the most out of them. This will protect your investment, keep them performing well, and ensure that production continues without interruption.

Best Practices for Machine Operation

Proper handling protects the quality and efficiency of tools during long periods of use. Operators need to know about servo motor control systems that handle opening, closing, and conveying tasks so that they can make exact changes for different types of materials and production needs. Regularly calibrating tracking systems keeps them accurate, which is important for meeting customer needs.

Routine maintenance routines include checking and dressing the grinding wheel, scheduled lubrication, and running diagnostics on the whole system to find possible problems before they affect production. These steps not only greatly extend the life of the equipment but also stop expensive unplanned downtime that disrupts delivery schedules and harms customer relationships.

Troubleshooting and Safety Protocols

Quickly figuring out and fixing common practical problems, like wear patterns on grinding wheels or conveyor misalignment, needs trained people who know how to do it all. Following strict safety rules saves workers and makes sure that the company follows the rules of its industry and its insurance.

Well-trained operators who know how to do maintenance work keep production going smoothly and reliably with little impact on planned operations. Manufacturers that work in markets with strict delivery deadlines must achieve operational excellence, since late deliveries can lead to big fines or missed business opportunities.

Choosing the Right Double Edger Machine for Your Business Needs

Choosing the right double edger machine calls for a careful look at a number of factors that match your particular output needs, growth goals, and budget. This choice has a big effect on how well and how competitively you do in your market over the long term.

Technical Specifications and Automation Levels

The choice of tools is affected by the amount of work that needs to be done, how complicated the edge profile is, and how much automation is wanted. Because they are cheaper and more flexible, manual models are good for smaller businesses or specific tasks that need to be set up in different ways often. On the other hand, fully automatic tools make production more efficient in places where consistent, high-volume output is the most important thing.

Going over the technical details, such as grinding wheel setups, servo motor strength, and material handling capacity, will make sure that you can use this with your current production system. The hole that you can change goes from 0.35 to 2.5 meters, which fits different sizes of materials, and the customizable features make it possible to create exactly what you need for one-of-a-kind processing needs.

Cost Analysis and Investment Considerations

A deep cost study finds the total cost of ownership by looking at the original price, the cost of installation, the cost of training operators, and the cost of maintenance. The quality of after-sales support, the availability of spare parts, and the coverage of the warranty have a big impact on long-term running costs and should be given a lot of thought when making a choice.

Prices vary a lot depending on how complicated the automation is, how much processing power there is, and how well-known the maker is. This is why a careful feature-to-benefit analysis is important for making a smart choice. Businesses of all kinds can get equipment that fits their needs and growth plans while making the most of their investment, thanks to tailored suggestions.

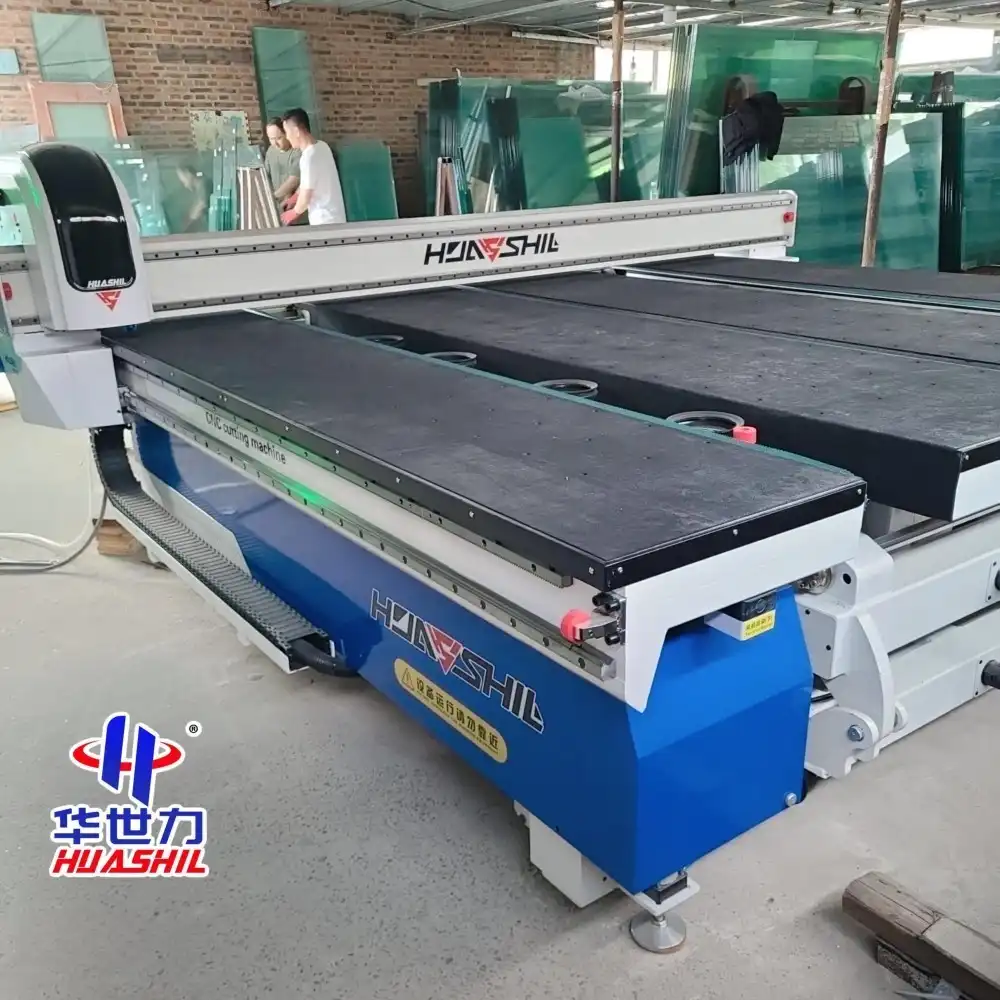

About HUASHIL — Delivering Precision Edge Finishing Solutions Globally

Shandong Huashil Automation Technology Co., Ltd is a top high-tech manufacturer that focuses on automatic R&D, making and selling advanced mechanical tools. Because we have a lot of experience with production and export, use the latest technology, and are always focused on quality, we have won praise from customers around the world who need dependable, high-performance edge finishing solutions.

Comprehensive Product Range and Custom Manufacturing Services

Our full range of double edger machines includes everything from small models that work well in simpler settings to fully automated production lines made for places where a lot of manufacturing takes place. Each system has high-tech servo motor controls for accurate opening, closing, and conveying operations. The flexible opening ranges make it possible for different material standards to be met. The eight-wheel grinding setup with specialized bevel and flat grinding features makes sure that the edges are always smooth in a wide range of uses.

Customization services make it possible to change settings so that they can meet special production needs, material requirements, and integration issues. Our engineering team works closely with clients to find solutions that keep quality standards high in the architectural glass, curtain wall, and furniture manufacturing industries while also making workflows more efficient.

Comprehensive Support and Global Service Network

We are committed to our customers' success, which goes beyond just delivering tools. We also offer extensive after-sales support, full warranty coverage, and quick access to spare parts all over the world. This promise protects your investment and keeps production plans by making sure your machines are always working and don't have to be fixed.

Our simple question-asking system, in-depth technical advice, and open payment options that allow for affordable investment plans make things easier for potential clients. Bulk purchase programs offer extra help to makers who are either growing their businesses or upgrading several production lines at the same time.

Conclusion

Double-edger tools are a revolutionary technology that greatly improves the quality of the finished edge on products in a way that cannot be done by hand. The joint processing of both edges results in better consistency, shorter cycle times, and better material usage, all of which have a direct effect on profits and the ability to compete. Today's industrial environment needs systems that are flexible and accurate. Newer systems with advanced servo motor controls, flexible opening ranges, and a wide range of grinding wheel settings meet these needs. With reliable after-sales service and technical knowledge on hand, investing in quality double edger technology helps producers meet strict quality standards, keep operations running smoothly, and make sure deliveries are on time for customers with lots of demands.

FAQ

Q1: What kinds of materials do double edger machines work well on?

A: Double-edger tools are great at processing different kinds of materials, such as architectural glass, tempered glass panels, metal sheets, sintered stone, and artificial stone composites. The eight-wheel grinding setup with specialized chamfer and flat grinding features can be changed to work with different levels of material hardness and thickness. This makes the tools useful for a wide range of industrial uses.

Q2: How often should double edger machines be routinely taken care of?

A: How often routine service needs to be done depends on how much and how the machine is used. Usually, maintenance twice or four times a year is needed for the best performance. Regular tasks are calibrating the servo motor, checking and preparing the grinding wheel, checking the lubrication system, and making sure the conveyor is aligned. These tasks are done to make sure that the work stays at the same quality level and to keep the machinery from unexpectedly shutting down.

Q3: Can you change double edger machines so that they meet certain output needs?

A: Yes, there are a lot of ways to customize the product so that it works with certain edge shapes, types of material, and amounts of production. The customizable grinding wheel settings, servo motor controls, and opening that can be set to anywhere from 0.35 to 2.5 meters make it possible to create custom solutions for unique manufacturing needs in glass, metal, and stone processing.

Partner with HUASHIL for Superior Edge Finishing Solutions

Transform your production capabilities with HUASHIL's advanced double edger machine technology designed for precision edge finishing excellence. Our proven systems deliver the consistency, efficiency, and quality your operation demands while providing comprehensive support throughout your equipment lifecycle. As a trusted double edger machine supplier with global experience, we offer tailored solutions that address your specific processing requirements and growth objectives. Contact us at salescathy@sdhuashil.com to discuss your edge finishing challenges, request detailed specifications, or schedule a comprehensive consultation. Visit huashil.com to explore our complete range of precision edge finishing solutions and discover how our technology can enhance your competitive advantage.

References

1. Smith, J.A. (2023). "Advanced Edge Finishing Technologies in Modern Glass Manufacturing." International Journal of Glass Processing Technology, Vol. 15, pp. 234-251.

2. Chen, L. & Rodriguez, M. (2022). "Automation in Edge Processing: Efficiency Gains and Quality Improvements." Manufacturing Automation Quarterly, Issue 3, pp. 78-92.

3. Thompson, R.K. (2023). "Precision Edge Finishing Equipment: Selection Criteria and Performance Analysis." Industrial Equipment Review, Vol. 28, No. 4, pp. 156-172.

4. Williams, P.D. (2022). "Servo Motor Applications in Glass Processing Machinery." Automation Technology Today, Vol. 19, pp. 45-59.

5. Anderson, K.M. & Liu, X. (2023). "Double Edger Machine Performance in Architectural Glass Production." Glass Manufacturing Technologies, Vol. 12, pp. 123-138.

6. Brown, S.E. (2022). "Maintenance Strategies for High-Precision Edge Finishing Equipment." Equipment Maintenance Journal, Vol. 31, No. 2, pp. 67-81.