Material Compatibility: UV and CO₂ Compared

Understanding the material compatibility of UV and CO₂ lasers is crucial when choosing the right glass laser marking machine for your application. Let's delve into how each technology interacts with glass and other materials:

UV Laser Marking

UV laser marking machines utilize ultraviolet light to create precise and high-contrast markings on glass surfaces. These machines excel in:

- Marking thin and delicate glass without causing thermal damage

- Creating microscopic engravings with exceptional detail

- Producing high-contrast marks on transparent and translucent glass

- Marking specialized glass types, such as borosilicate and quartz

The UV laser's short wavelength allows for minimal heat generation during the marking process, reducing the risk of micro-cracks or other structural damage to the glass. This makes UV laser marking particularly suitable for applications requiring utmost precision and quality, such as medical devices, scientific instruments, and high-end glassware.

CO₂ Laser Marking

CO₂ laser marking machines employ infrared light to engrave and mark glass surfaces. These versatile machines offer:

- Excellent performance on a wide range of glass thicknesses

- Ability to create deep engravings and 3D effects

- Efficient marking of large surface areas

- Compatibility with various glass types, including soda-lime and borosilicate

CO₂ glass laser marking machines generate more heat during the marking process, which can be advantageous for creating frosted or matte finishes on glass surfaces. This technology is particularly well-suited for applications such as architectural glass, decorative glassware, and large-scale industrial marking projects.

Energy Efficiency: Choosing the Right Laser Type

Energy efficiency is a crucial factor to consider when selecting a glass laser marking machine. Let's examine how UV and CO₂ lasers compare in terms of power consumption and overall efficiency:

UV Laser Energy Efficiency

UV laser marking machines typically offer:

- Lower power consumption for fine detail work

- Reduced heat generation, minimizing energy waste

- Efficient conversion of electrical energy to laser output

- Longer operational lifespan due to lower stress on components

The high photon energy of UV lasers allows for efficient material removal with minimal power input. This makes UV laser marking an energy-efficient choice for applications requiring intricate details and high-precision markings on glass surfaces.

CO₂ Laser Energy Efficiency

CO₂ laser marking machines are known for:

- Higher power output for faster marking of large areas

- Efficient heat generation for creating frosted effects

- Versatility in handling various glass thicknesses

- Lower initial equipment costs compared to UV lasers

While CO₂ glass laser marking machines may consume more power overall, their efficiency shines in applications requiring deep engravings or large-scale markings. The higher power output allows for faster processing times, which can offset the increased energy consumption in high-volume production environments.

Application-Specific Advantages: Making the Right Choice

To determine whether a UV or CO₂ glass laser marking machine is best for your needs, consider the specific advantages each technology offers for different applications:

UV Laser Marking Applications

UV laser marking excels in:

- Medical device marking: Ensuring traceability and sterilization compatibility

- Microelectronics: Marking delicate glass components with high precision

- Luxury glassware: Creating intricate designs and logos without damaging the surface

- Optical components: Engraving precise scales and markings on lenses and prisms

The non-thermal nature of UV laser marking makes it ideal for applications where maintaining the structural integrity of the glass is paramount. Industries that require consistent, high-quality markings on sensitive materials often prefer UV laser technology.

CO₂ Laser Marking Applications

CO₂ laser marking shines in:

- Architectural glass: Creating large-scale designs and patterns

- Beverage industry: Marking bottles and containers with logos and information

- Decorative glassware: Producing frosted effects and 3D engravings

- Industrial glass marking: High-speed labeling of mass-produced glass items

The versatility and speed of CO₂ laser marking make it a popular choice for industries that require efficient processing of large quantities of glass products. The ability to create both surface and subsurface markings adds to its appeal in decorative and functional applications.

Hybrid Solutions: Combining UV and CO₂ Technologies

In some cases, a hybrid approach combining both UV and CO₂ laser marking technologies may offer the best solution. This approach allows for:

- Versatility in handling a wide range of glass types and thicknesses

- Ability to switch between high-precision and high-speed marking

- Flexibility to meet diverse customer requirements

- Optimized energy efficiency by using the most suitable laser for each task

While hybrid systems may require a higher initial investment, they can provide unparalleled flexibility and efficiency for businesses that work with a diverse range of glass marking projects.

Maintenance and Longevity Considerations

When choosing between UV and CO₂ glass laser marking machines, it's essential to consider the long-term maintenance requirements and expected lifespan of each technology:

- UV lasers typically have a longer operational lifespan due to lower heat generation

- CO₂ lasers may require more frequent maintenance of optics and cooling systems

- UV laser systems often have higher initial costs but can offer lower long-term operating expenses

- CO₂ lasers generally have lower upfront costs but may incur higher maintenance expenses over time

Consider your budget, production volume, and in-house maintenance capabilities when evaluating the total cost of ownership for each laser marking technology.

Future-Proofing Your Investment

As technology continues to evolve, it's crucial to choose a glass laser marking machine that can adapt to future needs:

- Look for systems with upgradeable software and firmware

- Consider machines with modular designs that allow for component upgrades

- Evaluate the manufacturer's track record of innovation and product support

- Assess the potential for integration with emerging Industry 4.0 technologies

By selecting a forward-thinking laser marking solution, you can ensure that your investment remains valuable and competitive in the years to come.

Environmental Impact and Sustainability

In today's eco-conscious business environment, it's important to consider the environmental impact of your glass laser marking machine:

- UV lasers generally produce less waste heat, potentially reducing cooling requirements

- CO₂ lasers may offer advantages in terms of the recyclability of consumables

- Both technologies can contribute to reducing chemical waste compared to traditional marking methods

- Consider the energy efficiency ratings and eco-friendly features of different models

Choosing an environmentally responsible laser marking solution can not only reduce your carbon footprint but also appeal to environmentally conscious customers and partners.

Conclusion

Selecting the right glass laser marking machines factory between UV and CO₂ technologies depends on a careful evaluation of your specific needs, material types, production volume, and budget constraints. While UV lasers offer unparalleled precision and are ideal for delicate applications, CO₂ lasers provide versatility and efficiency for larger-scale projects.

By considering factors such as material compatibility, energy efficiency, application-specific advantages, and long-term sustainability, you can make an informed decision that aligns with your business goals and customer requirements.

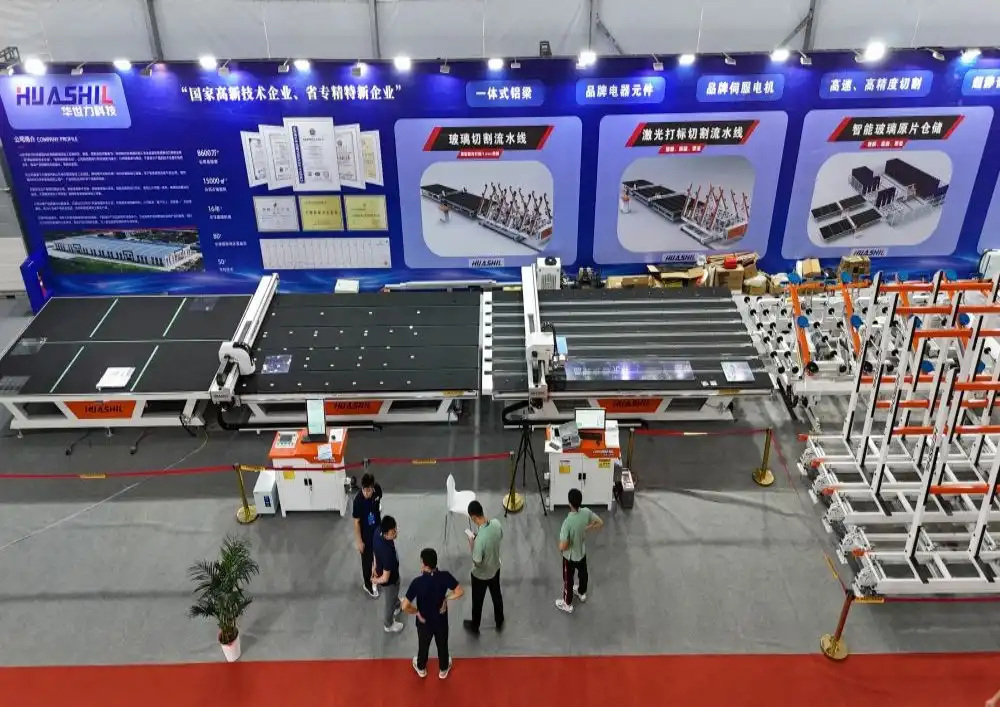

Ready to elevate your glass marking capabilities? At Shandong Huashil Automation Technology Co., LTD, we offer cutting-edge glass laser marking solutions tailored to your unique needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, our team is committed to providing advanced technology, stable quality, and excellent service to customers worldwide. Contact us today to explore how our expertise can transform your glass marking processes and drive your business forward.

FAQ

1. What is the main difference between UV and CO₂ laser marking on glass?

UV lasers use ultraviolet light for precise, high-contrast markings with minimal heat, ideal for delicate glass. CO₂ lasers employ infrared light, generating more heat suitable for deeper engravings and frosted effects on various glass thicknesses.

2. Which laser type is better for marking medical glass devices?

UV lasers are generally preferred for medical glass devices due to their ability to create microscopic, high-precision markings without compromising the material's integrity or sterilization compatibility.

3. Can CO₂ lasers mark all types of glass effectively?

While CO₂ lasers are versatile, they may not be optimal for all glass types. They excel with soda-lime and borosilicate glass but may have limitations with certain specialized or ultra-thin glass materials.

4. How do maintenance requirements differ between UV and CO₂ laser marking machines?

UV lasers typically require less frequent maintenance due to lower heat generation. CO₂ lasers may need more regular servicing of optics and cooling systems, but often have lower initial costs.

Glass Laser Marking Machines: Precision Engineering for Your Marking Needs | HUASHIL

Experience the pinnacle of glass marking technology with Shandong Huashil Automation Technology Co., LTD. Our state-of-the-art glass laser marking machines combine precision engineering with user-friendly design, ensuring optimal results for your unique applications. Whether you're in need of UV or CO₂ laser technology, our expert team is ready to guide you towards the perfect solution for your business. Don't settle for anything less than excellence in glass marking – contact us at salescathy@sdhuashil.com to discuss your requirements and discover how our advanced laser marking solutions can elevate your production capabilities.

References

1. Johnson, A. (2022). "Advancements in Glass Laser Marking: UV vs CO₂ Technologies". Journal of Laser Applications, 34(2), 022037.

2. Smith, R. et al. (2021). "Comparative Analysis of Energy Efficiency in Industrial Laser Marking Systems". Applied Energy, 288, 116618.

3. Zhang, L. and Liu, X. (2023). "Material Compatibility and Surface Quality in UV and CO₂ Laser Glass Marking". Optics and Lasers in Engineering, 158, 107008.

4. Brown, K. (2022). "Emerging Trends in Glass Laser Marking for Industry 4.0". Procedia Manufacturing, 54, 116-121.