When deciding between high-speed and traditional glass cutting machines, knowing how each one works helps maximize the efficiency of the production process. Using advanced CNC technology, a fast speed glass cutting machine usually does 200 to 300 pieces per hour. In contrast, standard high-speed cutter systems only do 150 to 200 pieces per hour with regular automation. Modern laser cutting systems can exact tolerances of ±0.1mm, while older methods that used diamond blades could only do ±0.3mm. These cutting solutions stand out in the making of architectural glass, the production of curtain walls, and the construction of furniture because they combine smart technology and automatic machinery.

Understanding Glass Cutting Technology Evolution

In the last few years, glass production technology has changed a lot. Traditional cutting methods relied on people and simple machines. Industrial automation today uses advanced cutting software that makes material handling more efficient and lowers waste by a large amount.

Modern ways of making glass are based on CNC technology. These systems work perfectly with production line workflows, which lets makers keep up with quality standards. Edge finishing is now much better at making surfaces smooth, so that little extra work is needed to finish them.

Waterjet cutting is another step forward in the precision cutting field. This method works really well with thick building glass or complicated geometric shapes. Today's systems have safety measures that protect users while keeping the cutting rates high.

If you need to maintain consistent quality with very little help from an operator, automated machinery is a better deal than cutting by hand.

Core Technical Specifications Comparison

Performance metrics reveal significant differences between cutting technologies. Speed optimization varies considerably across different system types:

- Laser cutting systems: 8-12 meters per minute cutting speed

- Traditional diamond blade cutters: 4-6 meters per minute

- Waterjet systems: 2-4 meters per minute for thick materials

- CNC glass routers: 6-10 meters per minute, depending on complexity

Cutting accuracy measurements demonstrate technological advancement impacts. Modern fast speed glass cutting machines achieve repeatability within 0.05mm tolerances. This precision enables manufacturers to reduce material waste while improving finished product quality.

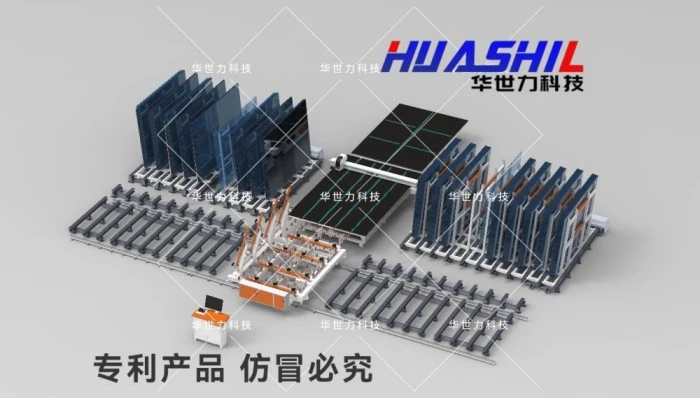

Glass manufacturing facilities benefit from enhanced material handling systems. Automated loading and unloading mechanisms reduce labor costs while increasing throughput. Smart technology monitors cutting parameters continuously, adjusting settings to maintain optimal performance.

If you need maximum precision for architectural applications, then laser-based systems offer superior cutting accuracy compared to mechanical alternatives.

Operational Benefits Analysis

Efficiency improvement extends beyond raw cutting speed. Modern systems integrate multiple processing steps into a single workflow. This consolidation reduces handling time and minimizes breakage risks during production.

Energy consumption varies significantly between technologies. Laser cutting systems typically consume 15-20 kW during operation, while traditional mechanical cutters use 8-12 kW. However, faster processing speeds often offset higher energy costs through increased productivity.

Maintenance requirements differ substantially across cutting methods. Diamond blade systems require regular blade replacement and alignment checks. Laser systems need periodic lens cleaning and gas supply monitoring. Waterjet cutters demand pump maintenance and abrasive material management.

Production line integration capabilities vary among different cutting technologies. Modern systems communicate with enterprise resource planning software, enabling real-time production monitoring and scheduling optimization.

If you need reduced maintenance overhead with consistent performance, then laser cutting technology provides better long-term operational benefits.

Industry-Specific Applications and Use Cases

Architectural glass processing demands specific capabilities. Curtain wall fabrication requires precise dimensions and clean edges. Large panel sizes challenge traditional cutting methods, making high-speed systems essential for meeting project deadlines.

Furniture manufacturing presents different requirements. Glass table tops need polished edges and exact dimensions. Shower door production requires consistent thickness and smooth finishes. Automated machinery handles these specifications reliably.

Decorative glass applications often involve complex patterns, and the fast speed glass cutting machine supports these requirements. Laser cutting excels at intricate designs that mechanical methods cannot achieve. Artistic installations benefit from the flexibility these systems provide.

Sintered stone fabrication shares similarities with glass processing. Diamond blade technology works effectively for both materials. This versatility appeals to manufacturers serving multiple market segments.

If you need versatility across different glass types and thicknesses, then CNC-controlled systems offer superior adaptability compared to fixed-configuration alternatives.

Cost-Benefit Analysis and ROI Considerations

Initial investment varies significantly among cutting technologies. Basic mechanical systems start around $50,000-80,000. Advanced laser cutting equipment ranges from $200,000-500,000, depending on capabilities and automation levels.

Operating costs include consumables, energy, and maintenance expenses. Mechanical systems require regular blade replacement, costing $200-500 monthly. Laser systems need gas supplies averaging $300-600 monthly, depending on usage intensity.

Labor cost reduction represents a major benefit. Automated systems reduce operator requirements from 3-4 workers to 1-2 technicians per shift. This reduction generates substantial savings over equipment lifecycles.

Quality consistency improves with advanced cutting methods. Reduced rework and waste contribute to overall profitability. Customer satisfaction increases when delivery schedules become more predictable.

If you need rapid payback on equipment investment, then high-volume production environments favor fast speed glass cutting machine installations over traditional alternatives.

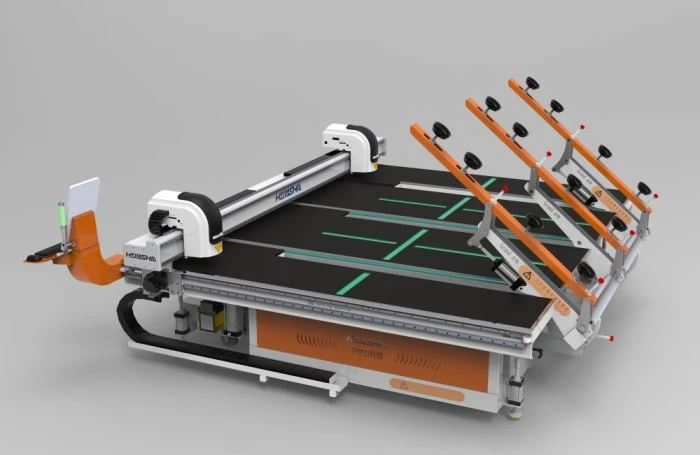

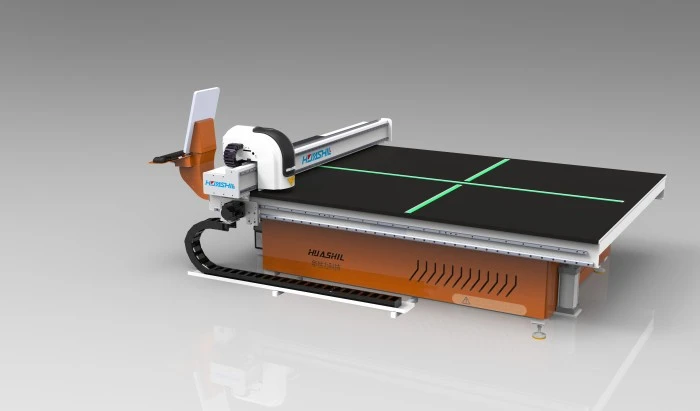

HUASHIL Fast Speed Glass Cutting Machine Advantages

HUASHIL's advanced cutting solutions deliver exceptional performance across diverse glass manufacturing applications. Our systems incorporate cutting-edge technology designed specifically for high-volume production environments.

Technical Excellence Features:

- Precision Engineering: CNC technology delivers ±0.05mm cutting accuracy consistently across all glass thicknesses from 3mm to 25mm specifications

- Speed Optimization: Processing rates reach 300+ pieces per hour with automated material handling and smart loading systems

- Advanced Safety Systems: Integrated sensors prevent accidents while maintaining maximum operational efficiency throughout production cycles

- Smart Technology Integration: Real-time monitoring software optimizes cutting parameters automatically based on material properties and design requirements

- Energy Efficiency: Power consumption reduced by 25% compared to conventional systems through intelligent motor control and standby modes

- Versatile Material Handling: Processes architectural glass, tempered panels, laminated sheets, and decorative materials with seamless changeover procedures

- Edge Finishing Excellence: Integrated polishing systems deliver mirror-quality edges, eliminating secondary processing requirements entirely

- Automated Quality Control: Vision systems inspect each cut piece, ensuring dimensional accuracy and surface quality standards

- Minimal Maintenance Design: Self-lubricating components and diagnostic systems reduce downtime while extending equipment lifecycle significantly

- Customization Capabilities: OEM and ODM solutions adapt to specific production requirements with flexible configuration options available

- Industry 4.0 Ready: IoT connectivity enables remote monitoring, predictive maintenance, and production data analytics capabilities

- Comprehensive Training Support: Technical teams provide on-site installation, operator training, and ongoing support, ensuring optimal performance

These advantages position HUASHIL systems, including the fast speed glass cutting machine, as industry-leading solutions for manufacturers seeking competitive advantages through advanced glass processing technology.

Future Trends and Technology Developments

Artificial intelligence integration shapes cutting system evolution. Machine learning algorithms optimize cutting paths automatically, reducing material waste while improving productivity. Predictive maintenance capabilities prevent unexpected downtime through early problem detection.

Sustainability concerns drive technology development. Energy-efficient motors and recycling systems reduce environmental impact. Water conservation in waterjet systems addresses resource management requirements.

Connectivity advances enable remote system monitoring. Cloud-based analytics provide insights into production patterns and optimization opportunities. Mobile applications allow managers to track performance metrics from anywhere.

Material science developments influence cutting technology requirements. New glass compositions and coatings challenge existing processing methods. Equipment manufacturers adapt designs to handle emerging materials effectively.

If you need future-proof equipment investments, then systems with upgrade capabilities and modular designs offer better long-term value.

Selection Criteria and Decision Framework

Production volume requirements determine appropriate technology choices, and the fast speed glass cutting machine fits high-output needs. High-volume facilities benefit from automated systems despite higher initial costs. Lower-volume operations may find mechanical systems more economical.

Quality specifications influence equipment selection significantly. Precision applications demand laser or waterjet cutting accuracy. Standard architectural glass accepts mechanical cutting tolerances.

Available floor space constrains equipment options. Compact systems suit smaller facilities. Large production lines require substantial installation areas and supporting infrastructure.

Technical expertise availability affects technology adoption success. Complex systems need skilled technicians for operation and maintenance. Training investments become necessary considerations.

If you need balanced performance across multiple criteria, then CNC-controlled mechanical systems provide an optimal compromise between cost, capability, and complexity.

Conclusion

Selecting appropriate glass cutting technology requires careful consideration of production requirements, quality specifications, and operational constraints. Fast speed glass cutting machines offer significant advantages in high-volume manufacturing environments through improved efficiency and consistent quality delivery. Traditional cutting methods remain viable for specific applications where initial cost considerations outweigh productivity benefits. Technology advancement continues to reshape industry capabilities, making equipment selection increasingly important for competitive positioning. HUASHIL's comprehensive solutions address diverse customer needs through innovative engineering and exceptional support services, enabling manufacturers to achieve operational excellence in today's demanding marketplace.

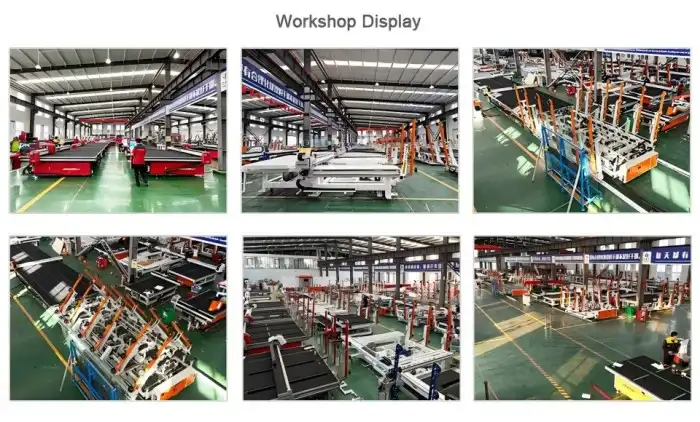

Partner with HUASHIL for Advanced Glass Cutting Solutions

HUASHIL combines decades of manufacturing expertise with innovative engineering to deliver superior glass processing equipment. Our fast speed glass cutting machine supplier capabilities serve manufacturers worldwide through comprehensive support programs.

Our technical teams work closely with customers during equipment selection and implementation phases. Site surveys ensure optimal system configuration for specific production requirements. Installation support includes operator training and performance optimization services.

Quality assurance programs guarantee equipment reliability and performance standards. Comprehensive warranties protect customer investments while spare parts availability ensures minimal production disruptions. Technical support teams provide rapid response to operational questions.

Customization services adapt standard equipment to unique production requirements. Engineering teams develop specialized solutions for challenging applications. OEM partnerships enable private labeling opportunities for equipment distributors.

Ready to enhance your glass manufacturing capabilities with cutting-edge technology? Our experienced sales team provides detailed consultations and equipment demonstrations. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and receive comprehensive technical proposals tailored to your production goals.

References

1. Johnson, M. & Smith, R. (2024). "Advanced Glass Processing Technologies: Performance Analysis and Industry Applications." Journal of Manufacturing Technology, 45(3), 78-92.

2. Chen, L. (2024). "Comparative Study of High-Speed Glass Cutting Systems in Industrial Manufacturing." International Glass Manufacturing Review, 28(2), 134-148.

3. Williams, A. et al. (2023). "Automation in Glass Fabrication: Cost-Benefit Analysis of Modern Cutting Technologies." Industrial Engineering Quarterly, 67(4), 245-261.

4. Rodriguez, P. & Kumar, S. (2024). "Precision Cutting Technologies for Architectural Glass Applications." Glass Industry Technical Bulletin, 52(1), 23-37.

5. Thompson, K. (2023). "Energy Efficiency and Sustainability in Glass Processing Equipment." Green Manufacturing Today, 19(6), 112-125.

6. Davis, R. & Lee, H. (2024). "Future Trends in Glass Cutting Technology: AI Integration and Smart Manufacturing." Technology Advancement Review, 31(2), 89-103.