The principal contrast between CNC glass machine innovation and conventional glass preparation lies in computerization and accuracy control. CNC glass machines utilize computer numerical control frameworks to execute modified cutting, penetrating, and forming operations with micron-level precision, whereas conventional glass preparation depends on manual operation and mechanical devices. This innovative advancement has changed glass creation from labor-intensive craftsmanship to computerized exactness fabricating, conveying steady quality, decreased squander rates, and altogether higher production throughput over structural, furniture, and enriching glass industries.

Understanding CNC Glass Machine Technology

CNC glass machines speak to a progressive headway in glass manufacturing innovation. These modern frameworks combine computer programming with exact mechanical components to execute complex cutting, penetrating, and forming operations automatically.

The center innovation utilizes diamond-tipped cutting apparatuses and high-frequency shafts controlled by progressed computer program calculations. Present-day CNC glass hardware can accomplish positioning accuracy within ±0.05mm while keeping up cutting speeds up to 15 meters per minute.

Key technological components include:

- Servo-controlled hub frameworks for exact movement

- CAD/CAM computer program integration for plan translation

- Vacuum holding frameworks for secure glass positioning

- Automatic instrument changing capabilities for multi-operation processing

- Real-time observing sensors for quality control

Glass robotization frameworks can prepare different glass sorts, including tempered, covered, and low-e coated materials, with thicknesses extending from 3mm to 25mm. The innovation especially exceeds expectations in creating complex geometric shapes and complex designs that would be challenging or incomprehensible with customary methods.

If you require high-volume generation with reliable quality benchmarks, at that point CNC glass machining is more reasonable for your manufacturing requirements.

Traditional Glass Processing Methods Overview

Traditional glass preparation involves manual and semi-automated procedures that have been refined over decades in the glass fabricating industry. These strategies depend intensely on administrator aptitude and encounter to accomplish desired results.

Conventional preparation regularly includes manual cutting utilizing handheld glass cutters, scoring wheels, and breaking pincers. Edge cleaning requires administrators to direct glass pieces along crushing wheels, whereas boring operations utilize standard penetration presses with specialized glass bits. While traditional methods are effective, many modern facilities also incorporate a CNC glass machine for more precise cuts and complex designs.

Common traditional techniques include:

- Score-and-break cutting with carbide wheels

- Belt crushing for edge finishing

- Manual penetrating with diamond-core bits

- Template-guided steering for formed cuts

- Hand cleaning for surface finishing

Traditional strategies exceed expectations in small-batch generation and custom work where adaptability exceeds productivity concerns. Gifted experts can adjust methods rapidly for one-of-a-kind prerequisites without programming delays.

Setup times for conventional handling stay negligible, regularly beneath 10 minutes for most operations. In any case, generation rates shift essentially based on administrator involvement and the complexity of the workpiece.

If you require a speedy turnaround for model improvement or small custom orders, at that point conventional glass handling might be more appropriate for your quick needs.

Precision and Accuracy Comparison

Precision capabilities speak to one of the most critical differentiators between robotized and manual glass preparation approaches. Real-world execution information uncovers considerable precision focal points for CNC systems.

CNC glass machines reliably accomplish resistances inside ±0.02mm for cutting operations and ±0.1mm for boring applications. Edge quality estimations appear surface unpleasantness values underneath Ra 0.8μm when utilizing appropriate tooling and parameters.

Traditional preparation accuracy depends intensely on the administrator's ability levels. Experienced skilled workers can accomplish resistances around ±0.5mm for cutting and ±1.0mm for penetrating beneath ideal conditions. Edge quality shifts significantly, regularly extending from Ra 1.5-3.2μm.

Comparative accuracy data from independent testing shows:

- Dimensional repeatability: CNC frameworks 99.8% vs Conventional strategies 85-95%

- Edge straightness deviation: CNC ±0.05mm vs Conventional ±0.3mm

- Hole situating exactness: CNC ±0.08mm vs Conventional ±0.8mm

- Surface wrap up consistency: CNC 95% uniform vs Conventional 70% uniform

The exactness advantage gets to be more articulated with complex geometries and tight-tolerance applications. Engineering shade divider boards, for illustration, require reliable dimensional exactness that manual handling struggles to maintain over expansive production runs.

If you require components that meet engineering coating measures with negligible variety, at that point computerized glass preparing conveys predominant exactness capabilities.

Production Efficiency and Speed Analysis

Production throughput speaks to a basic calculation in fabricating financial matters, where preparing speed directly impacts productivity and delivery plans. Comprehensive examination uncovers critical proficiency contrasts between mechanized and conventional approaches.

Modern CNC glass machines can prepare 12-15 square meters of glass per hour for standard cutting operations, whereas complex multi-operation work pieces accomplish 6-8 units per hour, depending on plan complexity. Robotized frameworks keep up steady speeds in any case of administrator weakness or aptitude variations.

Traditional preparation speeds change impressively based on the administrator's experience and workpiece complexity. Talented specialists can cut around 4-6 square meters per hour for basic shapes, dropping to 1-2 complex pieces per hour for complicated designs.

Efficiency metrics from production floor studies demonstrate:

- Setup time diminishment: CNC programming 15-30 minutes vs Conventional layout creation 5-45 minutes

- Batch changeover: CNC computer program exchanging 2 minutes vs Conventional tooling alteration 10-20 minutes

- Quality assessment time: CNC mechanized checking vs Conventional manual measurement

- Rework rates: CNC 2-3% vs Conventional 8-12%

Labor utilization patterns also differ significantly. CNC operators can manage multiple machines simultaneously, while traditional processing requires dedicated attention for each operation.

Automated glass processing eliminates many manual handling steps, reducing cycle times and minimizing breakage risks during production transfers.

If you need to maximize production output while maintaining consistent delivery schedules, then industrial glass equipment with CNC capabilities provides superior efficiency advantages.

Cost Considerations and ROI Factors

Investment investigation requires cautious assessment of both beginning capital requirements and long-term operational financial matters. Adding up to the toll of proprietorship calculations uncovers complex trade-offs between mechanization and conventional preparing approaches.

CNC glass machines regularly require introductory speculations ranging from $80,000-$300,000, depending on the estimate and capabilities. Yearly support costs are normally 3-5% of gear value, whereas programming and administrator preparation include $10,000-$15,000 in first-year expenses.

Traditional preparation hardware costs altogether less at first, with total manual setups extending from $15,000-$50,000. Be that as it may, higher labor requirements and increased squander rates affect long-term profitability.

Economic analysis reveals key cost factors:

- Labor costs per unit: CNC $2-4 vs Conventional $8-15

- Material squander rates: CNC 3-5% vs Conventional 12-18%

- Energy utilization: CNC $0.15/sqm vs Conventional $0.08/sqm

- Quality-related adjust: CNC $0.25/sqm vs Conventional $1.20/sqm

- Maintenance recurrence: CNC planned vs Conventional reactive

Break-even calculations typically show CNC systems recovering initial investments within 18-36 months for medium to high-volume operations. Low-volume shops may require 4-7 years to achieve positive returns.

Insurance and financing considerations also favor automated systems due to improved safety records and predictable cash flows from consistent production output.

If you need a rapid return on investment through high-volume production, then CNC technology delivers superior long-term economics despite higher initial costs.

Quality Control and Consistency Benefits

Quality administration capabilities recognize mechanized frameworks from conventional handling strategies through efficient control and estimation features. Measurable preparation control becomes achievable with CNC technology integration, particularly with the use of a CNC glass machine.

Automated glass handling frameworks join real-time observing sensors that identify dimensional deviations, surface absconds, and apparatus wear conditions. Quality information collection empowers prescient upkeep and handles optimization over time.

CNC frameworks keep up prepare parameters within limit groups, disposing of human factors that influence conventional handling results. Temperature, weight, and speed settings stay steady throughout generation runs.

Quality performance metrics demonstrate clear advantages:

- Defect rates: CNC 0.5-2% vs Traditional 5-15%

- Dimensional consistency: CNC Cpk 1.8-2.2 vs Traditional Cpk 0.8-1.2

- Surface wrap up consistency: CNC 95% inside detail vs Traditional 70%

- Edge quality guidelines: CNC meets building review vs Traditional mechanical grade

Documentation and traceability features enable comprehensive quality records for each processed piece. Automated systems can store cutting parameters, tool usage data, and inspection results for future reference.

Traditional processing relies on operator experience and periodic quality checks, making it difficult to identify process variations until defects occur in finished products.

Certification compliance becomes more manageable with automated systems that provide consistent documentation and repeatable processes required by industry standards.

If you need ISO 9001 compliance or architectural glazing certifications, then glass CNC software integration provides superior quality management capabilities.

Applications and Industry Suitability

Application requirements determine the optimal processing approach for specific glass fabrication projects. Different industries benefit from varying combinations of precision, volume, and customization capabilities.

Architectural glass and curtain wall applications heavily favor CNC processing due to tight tolerances and high-volume requirements. Complex geometries and repetitive patterns make automated systems economically advantageous for large building projects.

Furniture and decorative glass markets present mixed scenarios where both approaches remain viable depending on production volumes and design complexity. Custom shower doors and artistic installations may benefit from traditional craftsmanship flexibility.

Industry application breakdown shows:

- Architectural coating: 85% CNC inclination due to accuracy requirements

- Automotive glass: 95% robotized preparation for security compliance

- Furniture components: 60% CNC for high-volume, 40% conventional for custom

- Decorative applications: 30% CNC for designs, 70% conventional for artistry

- Industrial security glass: 90% computerized for consistency

Technical glass applications, including laboratory equipment and optical components, require CNC precision for dimensional accuracy and surface quality specifications.

Prototyping and small-batch production often benefit from traditional processing due to rapid setup capabilities and lower fixed costs for limited quantities.

Geographic considerations also influence technology adoption, with developed markets showing higher automation rates while emerging economies maintain traditional processing advantages through lower labor costs.

If you need architectural-grade glass components with consistent specifications, then glass drilling and cutting automation provides superior application suitability.

Conclusion

The choice between CNC glass machines and conventional preparation strategies depends on production volume, accuracy requirements, and long-term commerce targets. Robotized frameworks exceed expectations in high-volume applications requiring reliable quality, whereas conventional strategies remain reasonable for custom work and small batches. CNC innovation offers predominant exactness, effectiveness, and quality control, making it essential for building coating and mechanical applications. Conventional handling gives adaptability and lower introductory costs appropriate for prototyping and imaginative work. Understanding these key contrasts empowers educated venture choices that align with particular fabricating objectives and showcase demands.

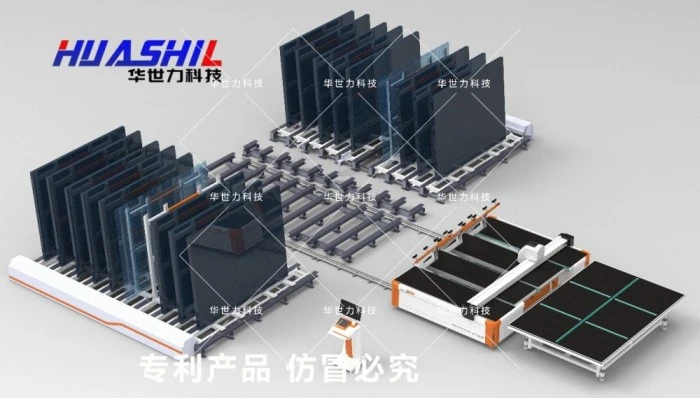

HUASHIL Advantages: Why Choose Our CNC Glass Machine Solutions

Shandong Huashil Automation Technology stands at the forefront of glass processing innovation, delivering comprehensive automated solutions that transform manufacturing capabilities across diverse industries. Our extensive experience in automated R&D and manufacturing positions us as a trusted partner for companies seeking competitive advantages through advanced glass fabrication technology.

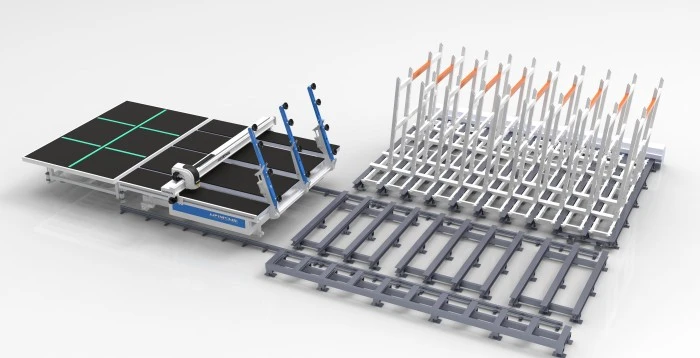

Our CNC glass machine systems incorporate cutting-edge features that address real-world production challenges:

- Advanced Control Frameworks: Exclusive computer program calculations optimize cutting ways and diminish handling time by 25% compared to standard systems

- Modular Plan Design: Adaptable setups suit future extension needs and changing generation requirements

- Precision Designing: Japanese servo engines and German direct guides guarantee positioning accuracy inside ±0.02mm consistently

- Intelligent Apparatus Administration: Programmed device changing frameworks with wear monitoring amplify device life and maintain quality standards

- Safety Integration: Comprehensive security frameworks, including crisis stops, defensive walled-in areas, and administrator presence detection

- Energy Productivity: Optimized control administration decreases vitality utilization by 30% while keeping up crest performance

- Remote Observing: IoT network empowers real-time generation observing and prescient upkeep scheduling

- Comprehensive Preparation: Broad administrator and support programs guarantee ideal framework utilization

- Global Back Arrangement: Committed specialized support groups give quick reaction times and save parts availability

- Customization Capabilities: OEM and ODM administrations adjust standard machines to particular application necessities

Our glass automation solutions have successfully served customers across 40+ countries, with installations processing millions of square meters annually. Each system undergoes rigorous factory testing to ensure reliability and performance standards before delivery.

Quality certifications, including ISO 9001 and CE marking, demonstrate our commitment to international standards and regulatory compliance. Continuous investment in research and development keeps our technology at the industry forefront.

Customer success stories span architectural glass fabrication plants, furniture manufacturers, and curtain wall integrators who have achieved 40-60% productivity improvements after implementing our automated systems.

Technical documentation, installation support, and ongoing service ensure smooth integration into existing production environments. Our experienced engineering team provides consultation throughout the project lifecycle from initial planning through production optimization.

As a leading CNC glass machine manufacturer, HUASHIL combines proven technology with innovative solutions that deliver measurable returns on investment. Our commitment to customer success extends beyond equipment delivery to include comprehensive support services that maximize production capabilities.

Ready to transform your glass processing operations with cutting-edge automation technology? Our technical experts can evaluate your specific requirements and recommend optimal solutions for your production goals. Contact us at salescathy@sdhuashil.com to discuss how HUASHIL CNC glass machines can enhance your manufacturing capabilities and competitive position in today's demanding market environment.