Today’s glass manufacturing business needs a level of precision, efficiency, and reliability that only modern automated systems can provide. The CNC glass machine is the most advanced example of computer numerical control technology used in glass processing. It gives makers the ability to cut, drill, polish, and shape glass with amazing precision. When CAD code, high-speed spindles, and precision guides are used together, these advanced systems can take unrefined glass and shape it into difficult building parts, car parts, and decorative pieces. Knowing about CNC glass cutting tools' specs, applications, and ways to buy them can have a big effect on your production and profits.

Understanding CNC Glass Machine Technology

Before computer numerical control (CNC) was invented, making glass was a very imprecise process that relied on people to do most of the work. CNC has now perfected the process by removing inconsistencies and mistakes that come from doing it by hand. When digital designs are sent to these automatic glass processing systems, they use high-tech software to figure out how to cut the glass exactly as needed. With diamond-tipped cutting tools and high-frequency spindle motors, this technology makes clean cuts through glass of different sizes without chipping or cracking.

Servo motors for exact positioning, linear guides for smooth movement, and complex control systems that handle tool pressure, feed rate, and cutting speed are all key parts of the CNC glass machine system. With modern CNC technology, makers can work with flat glass, curved surfaces, and even complicated 3D shapes with the same quality every time they make a run.

Advanced models include vacuum holding systems to keep glass in place while it's being worked on, tool changes that do it automatically for different operations, and built-in cooling systems to stop thermal stress. Using computer-aided design makes it easy for people to go from an idea to a finished product. This technology speeds up the process and helps people avoid wasting materials.

Key Specifications and Features

When performance is measured, a lot of important details must be taken into account in CNC glass machine specs. The size of the working area usually falls somewhere between a small 1500x1000mm table used for making furniture and a big 6000x3000mm system used for processing building glass. The power of the spindle ranges from 3kW for decorative work to 15kW for very tough commercial uses.

Cutting speed is another important feature. Modern systems can cut accurately at traverse rates of up to 60 meters per minute. The Z-axis motion depth affects how thick the material you can work with is. Industrial models can handle glass sheets that are up to 50 mm thick. The accuracy of the resolution, which is measured in micrometers, affects the finest details that can be achieved in glass engraving and etching processes.

The complexity of the control system changes a lot from one type to the next. Basic systems use standard G-code programming, but advanced ones come with private software that can automatically nest parts, recognize collisions, and predict when maintenance is needed. The amount of work that can be done with each tool and the ability to automatically change between tools affect how quickly and efficiently work can be done, especially when there are a lot of steps involved in a project.

Aspects that make this safe are safety covers, systems that stop the machine in an emergency, and dust removers that collect glass particles while cutting is taking place. These standards have a direct effect on the safety of people who work in manufacturing plants and on the plants' ability to meet environmental rules.

Primary Applications Across Industries

The most common use for CNC glass cutting devices is in architectural glass. The complicated mounting holes and edge profiles on these big panels mean that accurate cutting is needed when making curtain walls. For making sure that frames fit right and channels for weatherproofing are made, window and door makers use these tools. The technology lets builders bring their most creative ideas to life by adding complex geometric patterns and custom shapes that could not be done by hand.

For safety reasons, the making of automotive glass needs to be done with great care. For windshield manufacturing, the curvature has to be cut and the mounting points drilled with great precision using a CNC glass machine. For side window production, shapes that are complex and fit the vehicle's aerodynamics have to be made. Automotive quality standards are higher than those in most other fields, so CNC precision is needed to get governmental approval.

Precision cutting is very important for interactive display inclusion in smart mirror technology. These uses need precise cutouts for cameras, sensors, lights, and other parts that don't affect how the eye sees them. Glass machining is used by the furniture industry to make table tops, shelving units, and decorative panels with beveled edges and pretty designs.

CNC technology can be used to make art, which is what decorative glass shows. Architectural features made just for you, artistic sculptures, and displays with your brand on them all benefit from being able to make complex patterns that are always made the same way every time. The technology lets glass fabricators make unique products while still being able to mass-produce goods.

Essential Buying Considerations

The amount of production that needs to be done affects the choice of tools. Automated loading systems and the ability to run continuously are helpful for manufacturers that work with a lot of materials using a CNC glass machine. On the other hand, smaller businesses might value flexibility and the ability to work with different types of materials. Figure out whether you need to start producing more right now or wait until you're ready to expand, since CNC systems are expensive and last for 15 to 20 years.

Material suitability goes beyond just simple kinds of glass. Think about whether you work with tempered glass, laminated materials, or unique surfaces like ceramic or stone. There are some tasks that require the processing of several materials at the same time, which means that the tooling systems and cutting parameters must be able to change.

Facility needs include more than just floor space. When the power needs of a big machine go over 50 kW, they need to improve the way that they get power. Coolant circulation, dust extraction, compressed air systems, and other things make up the utility needs. Floor loading ability becomes very important for heavy-duty machines that can weigh several tons when they are fully loaded.

Software compatibility has an impact on how well the workflow can be used with design tools that are already in place. Check if the control system can read your favorite CAD file types and if the difficulty of the code is in line with what your staff can do. Training needs a lot of different makers. This affects how productive people are right away and how well the business runs in the long term.

Quality and Performance Factors

The dependability of machines is directly linked to how often they can be used to make products and the company's profits. Rate the quality of the mechanical design, the details about the parts, and the tolerances in the production process. Premium systems come with precision-ground linear guides, high-quality servo motors, and strong structure frames that keep accuracy even after years of use.

Spindle runout, machine rigidity, software tuning, and other things affect the quality of the cut on a CNC glass machine. Ask for trial cuts in your specific materials to check the quality of the edges, the accuracy of the dimensions, and the smoothness of the surface. Pay attention to how well the machine can keep cutting envelope quality and corner radius capability.

Cutting speed, setup time, and material utilization all play a role in production productivity. Advanced nesting software can greatly increase material output by finding the best way to arrange parts and cutting down on waste. Features for automatic tool measurement and adjustment keep accuracy when changing tools and lower the time needed for setup.

Long-term prices must take maintenance into account. Check how easy it is to get to the parts that wear out, how easy it is to get new parts, and how often people say you should do maintenance. Predictive repair lets people know about possible problems before they get in the way of making things.

Cost Analysis and ROI Planning

The first cost of equipment changes a lot depending on its size, features, and amount of automation. The most basic methods that can be used for making furniture cost at least $50,000. On the other hand, complete production lines for glass used in architecture can cost over $500,000. When you plan how much money you can spend on new equipment, you need to think about the cost of installing it, teaching people to use it, and buying the tools needed for it.

Tools that are used up, utilities, and repair contracts are part of the operating costs. Depending on the details, diamond cutting tools usually cost between $200 and $800 each, and how often they need to be replaced depends on the materials being worked on. Using a lot of energy can mean high monthly costs for large systems, especially where power is expensive.

ROI calculations should take into account savings on labor, higher quality, and more possibilities with a CNC glass machine. CNC automation usually cuts down on the amount of work that needs to be done by 50% to 70% while also making things more consistent and cutting down on waste. Being able to take difficult special orders can make high prices reasonable and open up more market possibilities.

You can pay for it with a standard equipment loan, a lease, or a financing program from the manufacturer. A lot of suppliers give payment plans that are in line with customers' cash flow needs, especially for manufacturers with good credit.

After-Sales Support and Service

The quality of technical support has a big effect on the success of a business, especially when it is first set up. Check out the manufacturer's support system for the CNC glass machine, which includes local service centers, the ability to diagnose problems remotely, and promised reaction times. Premium brands usually provide help hotlines that are available 24/7 and guaranteed response times for important problems.

The ability to get spare parts quickly is very important for reducing downtime. Ask about how delivery times, price stability, and parts inventory rules work. Some makers ship from overseas warehouses with longer lead times, while others keep parts warehouses in the US.

Operation and simple maintenance should be part of every training program. Operator mistakes are less common, and equipment lasts longer when people get full training. Advanced training in programming and optimization can greatly increase output and make more use of the capability.

Warranty terms are very different between makers and price ranges. Standard guarantees usually last for one year for mechanical parts and six months for electrical ones. Longer warranty choices might be a cheap way to protect important production equipment.

Conclusion

Choosing the right CNC glass machine means looking closely at technical specs, how the machine will be used, and the long-term goals of the business. The purchase of modern glass processing technology pays off in a big way by making more products, improving quality, and opening up new markets. Success depends on making sure that the equipment can do what it needs to do and that there is enough help for the system to keep working. To get the most out of your investment and make sure your business runs smoothly, work with manufacturers who have a lot of experience, a history of success, and can offer you a lot of different kinds of help.

Choose HUASHIL for Your CNC Glass Machine Requirements

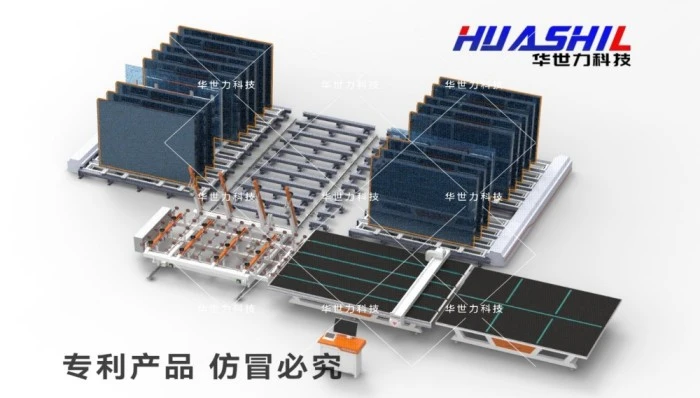

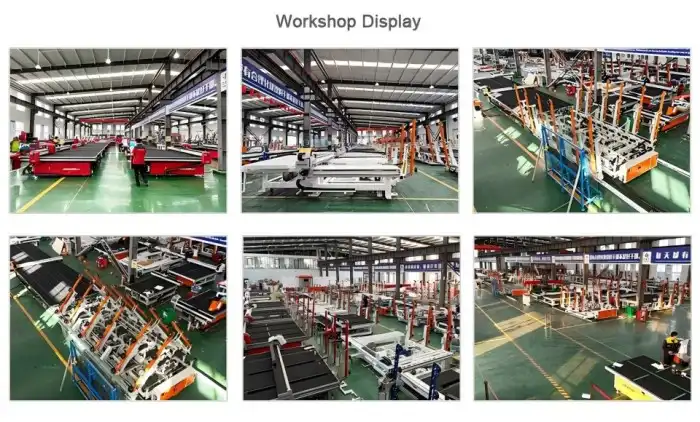

Architectural glass makers, curtain wall builders, and furniture makers around the world have been relying on HUASHIL's CNC glass machines for decades. From small workshop systems to full automatic production lines, our wide range of products meets a variety of production needs. The engineering team at HUASHIL uses cutting-edge automation technology and its own deep understanding of the industry to make sure that productivity and quality are both maximized.

Our CNC glass cutting systems come with our own control software that is fine-tuned for glass processing tasks, as well as accurate mechanical parts made to aerospace standards. Plus, you get full support after you buy, which keeps your production going smoothly. Before shipping, each system is tested in a variety of ways. Our skilled installation teams make sure that everything is set up correctly and that the operators are trained.

HUASHIL's commitment to customer success extends beyond equipment delivery. We provide ongoing technical support, productivity optimization consulting, and flexible financing options that align with your business objectives. Ready to transform your glass processing capabilities? Contact our technical specialists to discuss your specific requirements and explore how our solutions can drive your business forward. Reach out to our team today and contact us at salescathy@sdhuashil.com to schedule a consultation and receive a customized proposal for your glass machining needs.

References

1. Glass Manufacturing Industry Council. "Advanced CNC Technologies in Glass Processing: Industry Standards and Best Practices." International Glass Review, 2023.

2. Smith, Robert J. "Computer Numerical Control Applications in Architectural Glass Fabrication." Journal of Manufacturing Technology, Volume 45, Issue 3, 2023.

3. International Association of Glass Processors. "CNC Glass Cutting Equipment Specification Guidelines." Technical Publication Series, 2023.

4. Chen, Wei, and Johnson, Mark. "Automation in Glass Manufacturing: ROI Analysis and Implementation Strategies." Industrial Automation Quarterly, 2023.

5. European Glass Technology Institute. "Safety Standards for CNC Glass Processing Equipment." Technical Standards Document, 2023.

6. Martinez, Elena. "Precision Glass Cutting: Technologies and Applications in Modern Manufacturing." Advanced Materials Processing, Volume 78, 2023.