Differences in breaking techniques for glass types

When it comes to breaking sheet glass versus bottles, the techniques employed by industrial equipment can vary significantly. Sheet glass, typically used in windows and architectural applications, requires precise cutting and breaking along straight lines. On the other hand, bottles and other three-dimensional glass objects often need to be crushed or shattered into smaller pieces.

Sheet glass breaking usually involves scoring the surface with a diamond or carbide wheel, followed by applying pressure to create a clean break. This process demands high precision, often achieved with Customized industrial glass breaking equipment factory, to ensure smooth edges and minimal waste. Bottle breaking, however, often utilizes impact-based methods or crushing mechanisms to reduce the glass into cullet (recycled glass pieces) of various sizes.

Modern industrial glass breaking equipment has evolved to accommodate these different requirements. Advanced machines now incorporate multiple breaking techniques within a single system, allowing manufacturers to switch between sheet glass and bottle processing with minimal downtime.

Adjusting equipment settings for varied materials

The key to handling both sheet glass and bottles lies in the adaptability of the equipment. State-of-the-art industrial glass breakers feature adjustable settings that can be fine-tuned for different glass types, thicknesses, and shapes.

For sheet glass, operators can adjust parameters such as:

- Cutting wheel pressure

- Scoring depth

- Breaking bar force

- Conveyor speed

When switching to bottle breaking, the same machine might be reconfigured to adjust:

- Impact force

- Crushing roller spacing

- Vibration frequency

- Output particle size

This level of customization allows manufacturers to optimize their processes for different glass products without investing in separate machines for each type. It's worth noting that some specialized industrial glass breaking equipment may still be necessary for certain high-volume or unique glass breaking applications.

Ensuring consistent output quality across types

Maintaining consistent quality when processing different glass types is crucial for manufacturers. Industrial glass breaking equipment employs various technologies to ensure uniformity in the final product, regardless of the input material.

For sheet glass, laser measurement systems and computer-controlled cutting ensure precise dimensions and clean edges. When dealing with bottles, advanced sorting mechanisms and multiple crushing stages help achieve the desired cullet size distribution.

Quality control measures for both types often include:

- Optical inspection systems

- Automated sorting technology

- Real-time process monitoring

- Continuous feedback loops for machine adjustment

These features allow operators to maintain high standards across different glass types, minimizing waste and maximizing efficiency. The ability to produce consistent results, whether processing flat sheets or curved bottles, is a hallmark of modern industrial glass breaking solutions.

Advancements in multi-purpose glass breaking technology

Recent innovations have led to the development of hybrid glass breaking systems that can seamlessly transition between sheet glass and bottle processing. These advanced machines incorporate modular designs, allowing for quick changeovers and maximum flexibility.

Key features of multi-purpose glass breaking equipment include:

- Interchangeable breaking mechanisms

- Programmable control systems with preset modes for different glass types

- Adaptive feeding systems to handle various shapes and sizes

- Integrated cleaning and sorting capabilities

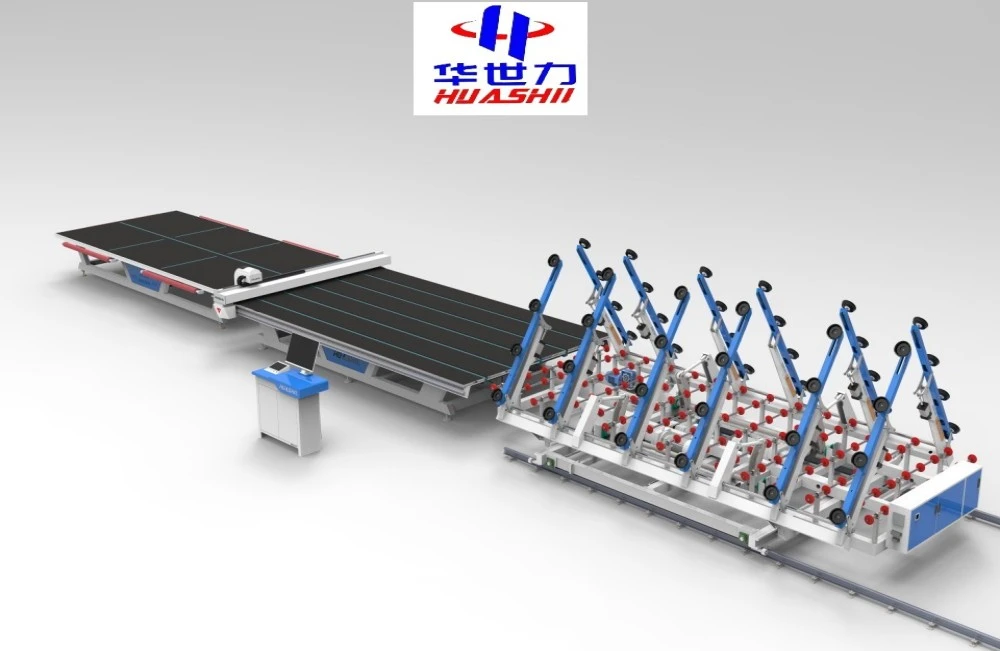

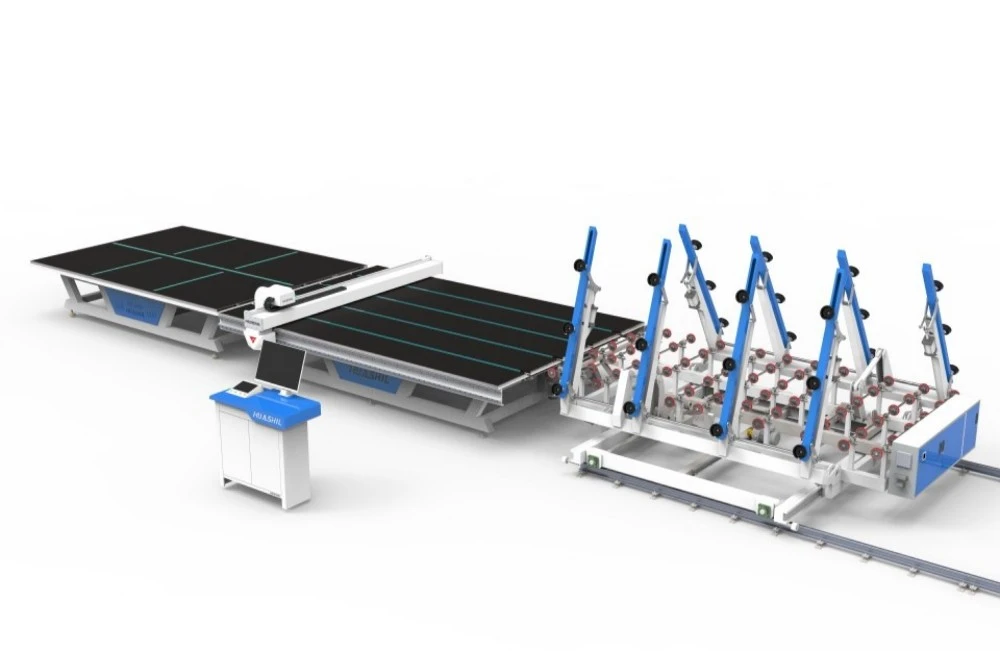

Manufacturers like Shandong Huashil Automation Technology Co., Ltd. are at the forefront of developing these versatile solutions, offering customized industrial glass breaking equipment that caters to the diverse needs of the glass industry.

Environmental and economic benefits of versatile equipment

The ability to process both sheet glass and bottles with the same equipment offers significant environmental and economic advantages. By reducing the need for multiple specialized machines, manufacturers can:

- Lower their carbon footprint through reduced energy consumption

- Minimize factory floor space requirements

- Decrease overall equipment costs

- Improve operational efficiency and throughput

Furthermore, a versatile Customized industrial glass breaking equipment factory supports the circular economy by facilitating the recycling of various glass products. This adaptability is crucial in meeting the growing demand for sustainable manufacturing practices and efficient resource utilization.

Conclusion

Industrial glass breaking equipment has come a long way in its ability to handle diverse glass types, including both sheet glass and bottles. The key lies in the adaptability and advanced features of modern machinery, which allow for precise control over breaking techniques, adjustable settings, and consistent quality output.

As the glass industry continues to evolve, the demand for versatile, efficient, and environmentally friendly processing solutions grows. Manufacturers and recycling facilities alike benefit from equipment that can seamlessly transition between different glass types, reducing costs and improving operational efficiency.

For businesses looking to invest in cutting-edge glass breaking technology, partnering with a reputable manufacturer is crucial. Shandong Huashil Automation Technology Co., Ltd. stands out as a leader in providing innovative, customizable solutions that meet the diverse needs of the glass industry.

FAQ

Q1: Can industrial glass breaking equipment handle tempered glass?

A: Yes, many modern industrial glass breaking machines are designed to handle tempered glass. However, the process differs from standard glass due to tempered glass's unique properties. Specialized equipment or settings are often required to safely and effectively break tempered glass into small, uniform pieces.

Q2: How does the size of glass bottles affect the breaking process?

A: The size of glass bottles can significantly impact the breaking process. Larger bottles may require more force or multiple crushing stages to achieve the desired cullet size. Advanced industrial glass breaking equipment often features adjustable settings and multiple breaking mechanisms to accommodate various bottle sizes efficiently.

Q3: Is it possible to break colored glass and clear glass in the same equipment?

A: Yes, most industrial glass breaking equipment can handle both colored and clear glass. However, for recycling purposes, it's often necessary to sort the glass by color before or after breaking. Some advanced systems incorporate color-sensing technology to automatically separate different colored glass during the breaking process.

Q4: How does the thickness of sheet glass affect the breaking process?

A: The thickness of sheet glass directly influences the breaking process. Thicker glass typically requires more force to score and break cleanly. Modern industrial glass breaking equipment often features adjustable settings for scoring depth, breaking force, and conveyor speed to accommodate various glass thicknesses effectively.

Q5: Can industrial glass breaking equipment handle laminated glass?

A: Handling laminated glass requires specialized equipment or processes due to the interlayer between glass panes. While some advanced industrial glass breaking machines can process laminated glass, it often involves a two-step process: first separating the glass layers, then breaking each layer individually. Always consult with equipment manufacturers for specific capabilities regarding laminated glass.

Top-Quality Industrial Glass Breaking Equipment for Sheet Glass and Bottles | HUASHIL

Looking for versatile and efficient industrial glass breaking equipment that can handle both sheet glass and bottles? Look no further than Shandong Huashil Automation Technology Co., LTD. Our state-of-the-art machinery is designed to meet the diverse needs of the glass industry, offering unparalleled flexibility and performance.

Whether you're processing architectural glass, recycling bottles, or working with specialty glass products, our equipment delivers consistent, high-quality results. With customizable features and advanced technology, we ensure that your glass breaking operations are as efficient and cost-effective as possible.

Don't settle for outdated or inflexible equipment. Upgrade your glass processing capabilities with Huashil's innovative solutions. Contact us today at salescathy@sdhuashil.com to discuss your specific needs and discover how our industrial glass breaking equipment can transform your operations. Let Huashil be your partner in achieving glass processing excellence!

References

1. Smith, J. (2022). Advancements in Industrial Glass Processing Technology. Journal of Glass Science and Technology, 45(3), 234-249.

2. Johnson, R., & Brown, L. (2021). Comparative Analysis of Sheet Glass vs. Bottle Glass Breaking Techniques. International Glass Review, 18(2), 112-128.

3. Glass Manufacturing Industry Council. (2023). Annual Report on Glass Recycling and Processing Innovations. GMIC Publications.

4. Zhang, Y., et al. (2022). Optimization of Multi-Purpose Glass Breaking Equipment for Improved Efficiency and Quality. Procedia Engineering, 185, 789-798.