In the ever-evolving world of manufacturing and precision cutting, selecting the right CNC mirror cutting machine can be a game-changer for your business. Whether you're in the architectural glass industry, automotive sector, or specializing in decorative glass products, the decision you make today will impact your production efficiency, quality, and bottom line for years to come. This comprehensive guide will walk you through the essential factors to consider when choosing the best CNC mirror cutting machine for your specific needs.

Assessing Your Specific Mirror Cutting Needs

Before diving into the technical specifications and features of various CNC mirror cutting machines, it's crucial to have a clear understanding of your unique requirements. This initial assessment will serve as the foundation for your decision-making process.

Production Volume and Capacity

One of the first questions to ask yourself is: What is your expected production volume? Are you looking to handle small batches or large-scale production runs? The capacity of the CNC mirror cutting machine you choose should align with your current needs while also allowing room for potential growth.

Types of Mirrors and Glass

Consider the variety of mirrors and glass types you'll be working with. Some machines are designed to handle a wide range of thicknesses and compositions, while others may specialize in specific types. Ensure that the machine you select can accommodate the full spectrum of materials you plan to cut.

Cutting Precision and Complexity

The level of precision required in your mirror cutting operations is another critical factor. High-end architectural projects or automotive applications may demand extremely tight tolerances, while other applications might allow for slightly more leeway. Additionally, consider the complexity of the cuts you'll need to make. Will you be working primarily with straight lines, or do you need the capability to create intricate shapes and patterns?

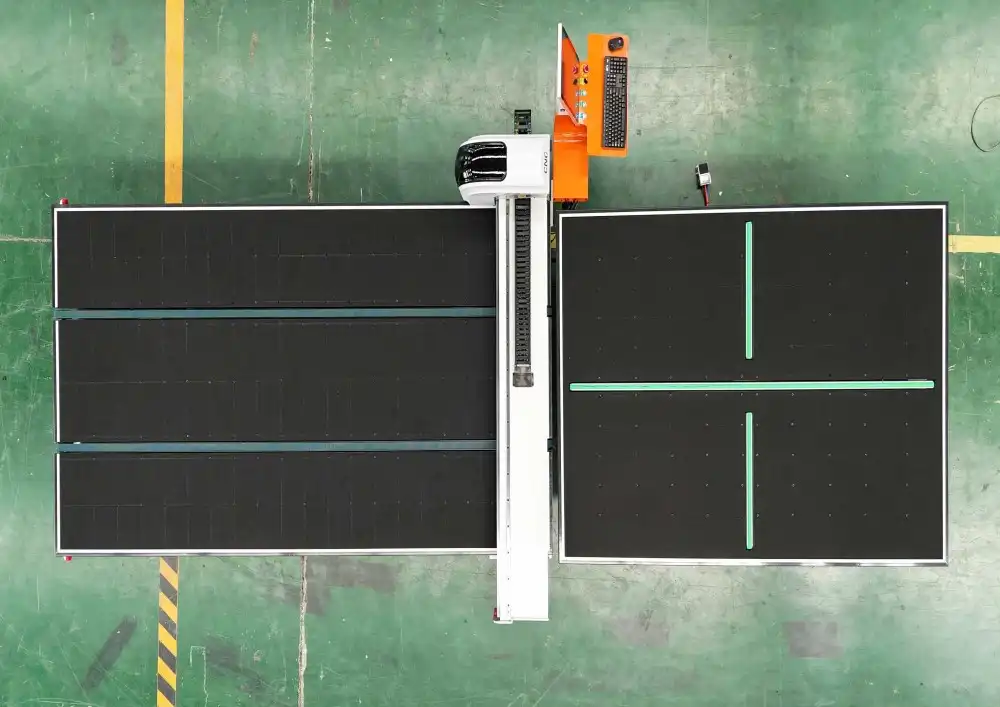

Workspace and Machine Footprint

The physical space available in your facility is an often-overlooked but crucial consideration. Measure your available workspace and compare it to the dimensions of the machines you're considering. Remember to account for not just the machine itself, but also for material loading and unloading areas, as well as the operator workspace.

Integration with Existing Systems

If you already have other manufacturing equipment in place, consider how a new CNC mirror cutting machine will integrate with your existing setup. Look for machines that offer compatibility with your current software systems and production workflows to minimize disruption and maximize efficiency.

Budget Considerations: Initial Cost vs. Long-Term Value

While the upfront cost of a CNC mirror cutting machine is certainly a significant factor, it's essential to look beyond the price tag and consider the long-term value and return on investment (ROI) that the machine will provide.

Initial Investment

The initial cost of a CNC mirror cutting machine can vary widely depending on its capabilities, size, and brand. It's important to set a realistic budget that aligns with your business goals and financial situation. However, be cautious about opting for the cheapest option available, as this could lead to compromises in quality, efficiency, or longevity.

Operating Costs

Beyond the purchase price, consider the ongoing operating costs associated with the machine. This includes factors such as: - Energy consumption - Maintenance requirements - Consumables (e.g., cutting tools, lubricants) - Operator training and labor costs

A machine with a higher upfront cost may actually prove more economical in the long run if it offers superior energy efficiency or requires less frequent maintenance.

Productivity and Efficiency Gains

Assess the potential productivity improvements that each machine option could bring to your operations. A more advanced CNC mirror cutting machine might come with a higher price tag, but could significantly boost your output and reduce waste. Consider factors such as: - Cutting speed and accuracy - Automation capabilities - Multi-tasking features - Material optimization software

These features can lead to substantial time and material savings, potentially offsetting the higher initial investment.

Scalability and Future-Proofing

As your business grows and evolves, will the machine be able to keep up with changing demands? Look for CNC mirror cutting machines that offer scalability through software upgrades or modular hardware additions. This can help you avoid the need for premature replacement and maximize the lifespan of your investment.

Financing Options

Explore various financing options available for purchasing a CNC mirror cutting machine. Many manufacturers and dealers offer leasing arrangements or financing plans that can help spread the cost over time, making it easier to acquire a higher-end machine that might otherwise be out of reach.

After-Sales Support: What to Expect from Vendors?

The relationship with your CNC mirror cutting machine vendor doesn't end at the point of sale. Robust after-sales support can be the difference between a smooth, productive operation and costly downtime.

Training and Onboarding

Proper training is essential for maximizing the potential of your new CNC mirror cutting machine. Inquire about the training programs offered by the vendor. Do they provide on-site training? Are there online resources or documentation available? The more comprehensive the training, the faster your team can become proficient with the new equipment.

Technical Support and Troubleshooting

Even the most reliable machines can encounter issues from time to time. When problems arise, you'll want quick access to knowledgeable technical support. Ask potential vendors about their support channels: - Is there a dedicated helpline? - Do they offer remote diagnostics capabilities? - What are their typical response times for urgent issues?

The ability to quickly resolve technical issues can significantly reduce downtime and associated costs.

Maintenance and Service Agreements

Regular maintenance is crucial for keeping your CNC mirror cutting machine in optimal condition. Many vendors offer service agreements that include scheduled maintenance visits, priority response for repairs, and discounts on replacement parts. While these agreements come at an additional cost, they can provide peace of mind and help prevent unexpected breakdowns.

Spare Parts Availability

The availability of spare parts can significantly impact your machine's downtime in case of a failure. Inquire about the vendor's spare parts inventory and typical lead times for replacement components. Some vendors maintain a local stock of critical parts, which can be a significant advantage in minimizing disruptions to your operations.

Software Updates and Upgrades

As technology evolves, so does the software that powers CNC mirror cutting machines. Look for vendors that provide regular software updates to improve functionality, fix bugs, and introduce new features. Some may even offer upgrade paths to enhance your machine's capabilities as your needs grow.

Warranty Coverage

Carefully review the warranty terms offered with the CNC mirror cutting machine. Pay attention to: - Duration of coverage - What components are included - Any exclusions or limitations - Options for extended warranty coverage

A comprehensive warranty can provide valuable protection for your investment, particularly in the early years of ownership.

User Community and Resources

Some vendors foster user communities or provide access to forums where you can connect with other owners of the same CNC mirror cutting machine. These can be invaluable resources for sharing best practices, troubleshooting tips, and staying informed about the latest developments related to your equipment.

Conclusion

Choosing the best CNC mirror cutting machines for sale for your business is a significant decision that requires careful consideration of your specific needs, budget constraints, and long-term goals. By thoroughly assessing these factors and engaging with potential vendors, you can make an informed choice that will drive your business forward.

Remember, the initial cost is just one piece of the puzzle. The true value of a CNC mirror cutting machine lies in its ability to enhance your productivity, maintain consistent quality, and adapt to your evolving needs. With the right machine and proper support, you'll be well-equipped to tackle even the most demanding mirror cutting projects with confidence and precision.

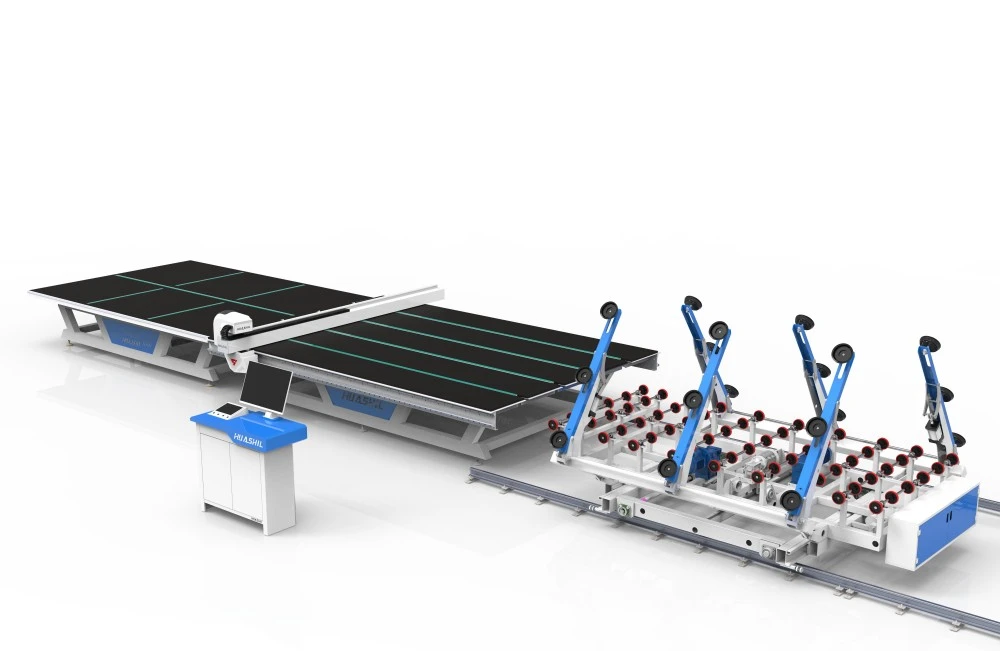

At Shandong Huashil Automation Technology Co., Ltd., we understand the unique challenges faced by businesses in the glass and mirror cutting industry. Our team of experts is dedicated to helping you find the perfect CNC mirror cutting machine that aligns with your specific requirements and budget. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we offer advanced techniques, stable quality, and excellent service that have made us a trusted partner for customers worldwide.

FAQ

1. What are the key features to look for in a CNC mirror cutting machine?

Key features include cutting precision, speed, material handling capabilities, software compatibility, and automation options. The ideal features will depend on your specific production needs and budget.

2. How often should a CNC mirror cutting machine be serviced?

Regular maintenance is crucial for optimal performance. While the exact schedule can vary, most machines benefit from daily basic checks, weekly cleaning, and more comprehensive servicing every 3-6 months, depending on usage.

3. Can CNC mirror cutting machines handle custom shapes and designs?

Yes, most modern CNC mirror cutting machines can handle a wide variety of custom shapes and intricate designs. The complexity of designs you can achieve will depend on the specific capabilities of the machine and its software.

4. What safety features should I look for in a CNC mirror cutting machine?

Important safety features include emergency stop buttons, safety enclosures, interlocking systems, and automated fault detection. Look for machines that comply with relevant safety standards in your industry and region.

Expert CNC Mirror Cutting Machine Solutions | HUASHIL

Looking for a reliable CNC mirror cutting machine that meets your exact specifications? Look no further than Shandong Huashil Automation Technology Co., LTD. Our cutting-edge machines combine precision, efficiency, and durability to deliver outstanding results for businesses of all sizes.

Whether you're in the architectural glass industry, automotive sector, or specialize in decorative glass products, we have the perfect solution for you. Our team of experts is ready to guide you through the selection process, ensuring you get a machine that not only meets your current needs but also positions you for future growth.

Don't settle for anything less than the best when it comes to your CNC mirror cutting needs. Contact us today at salescathy@sdhuashil.com to discuss your requirements and discover how our advanced technology can revolutionize your production processes. Take the first step towards unparalleled precision and efficiency – reach out now!

References

1. Johnson, M. (2022). Advanced CNC Technologies in Glass Manufacturing. Journal of Industrial Automation, 45(3), 178-195.

2. Smith, A. & Brown, R. (2023). Optimizing Mirror Cutting Processes: A Comprehensive Guide. Glass Technology Review, 18(2), 45-62.

3. Zhang, L. et al. (2021). Comparative Analysis of CNC Cutting Machines for Precision Glass Applications. International Journal of Manufacturing Engineering, 12(4), 301-318.

4. Thompson, K. (2023). The Future of Automated Glass Processing: Trends and Innovations. Industrial Machinery Quarterly, 56(1), 89-104.