Product Category

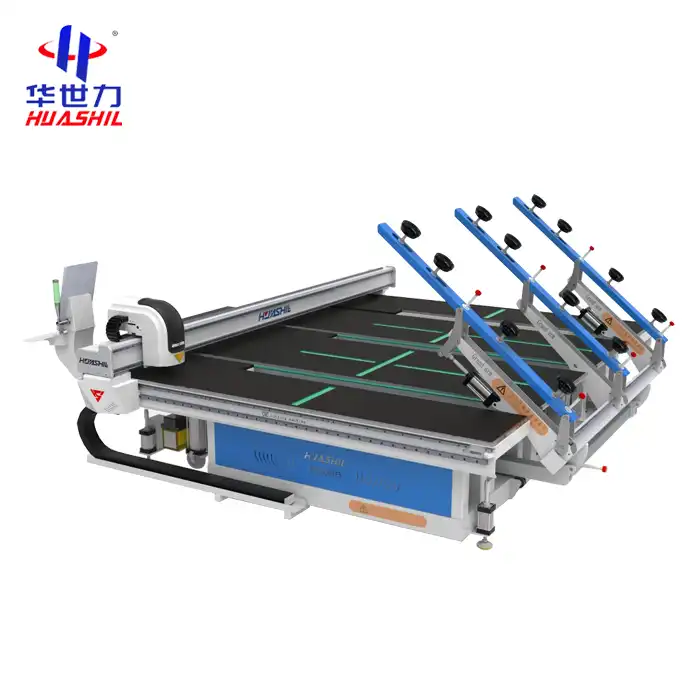

Automatic Glass Cutting Assembly Line Factory

Increase Factory Efficiency with Automated Glass

Cutting Shandong Huashil Automation Technology Co. , Ltd.

provides sophisticated Automatic Glass Cutting Assembly Line solutions for contemporary companies to improve precision and production.

These technologies automate glass processing to reduce manual mistakes and provide consistent output in high-volume factories.

The **Automatic Glass Cutting Assembly Line** reduces waste and operational expenses with millimeter-level material utilisation optimisation.

Custom setups accommodate various glass thicknesses and complicated forms in specific industrial layouts.

Real-time monitoring and AI-driven modifications ensure smooth automotive, construction, and solar panel production operations.

Shandong Huashil has 20 years of experience in strong engineering and adaptable factory-ready solutions.

Their technologies help firms expand sustainably with 24/7 technical assistance.

The Automatic Glass Cutting Assembly Line revolutionises glass manufacturing worldwide for firms that value automation and ROI.

Related Products

-

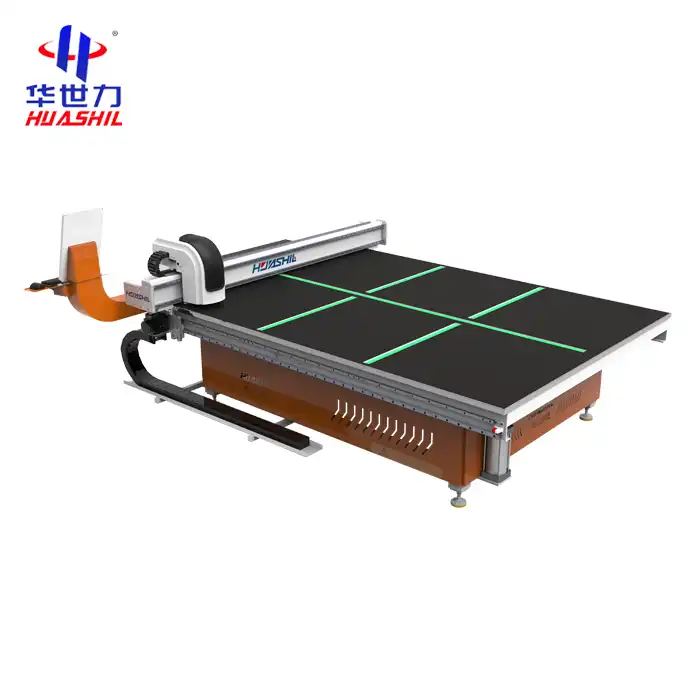

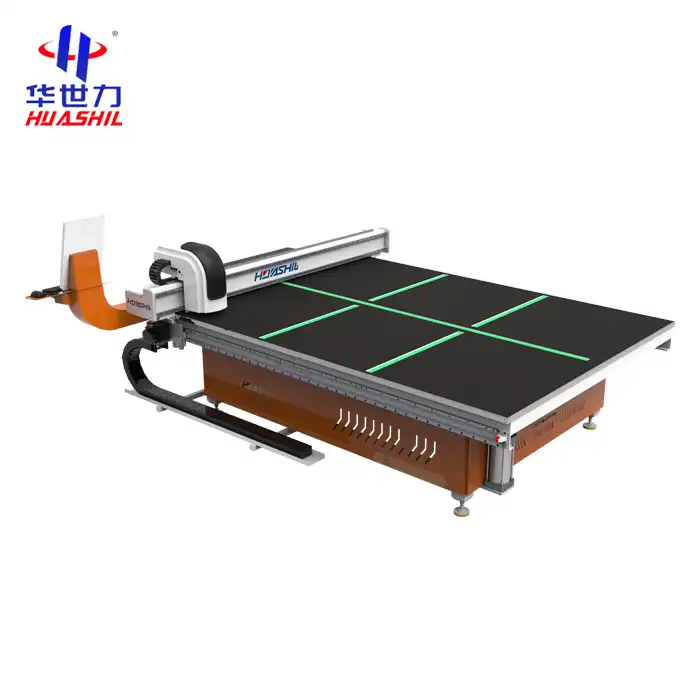

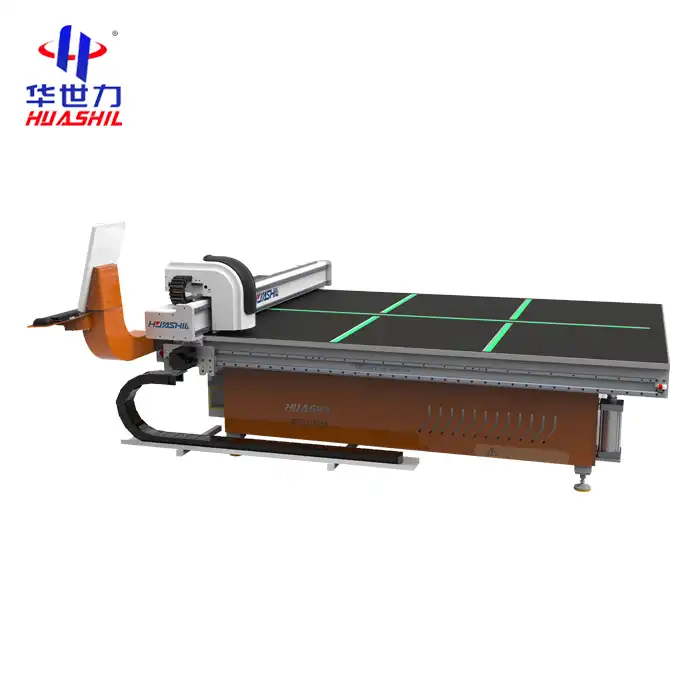

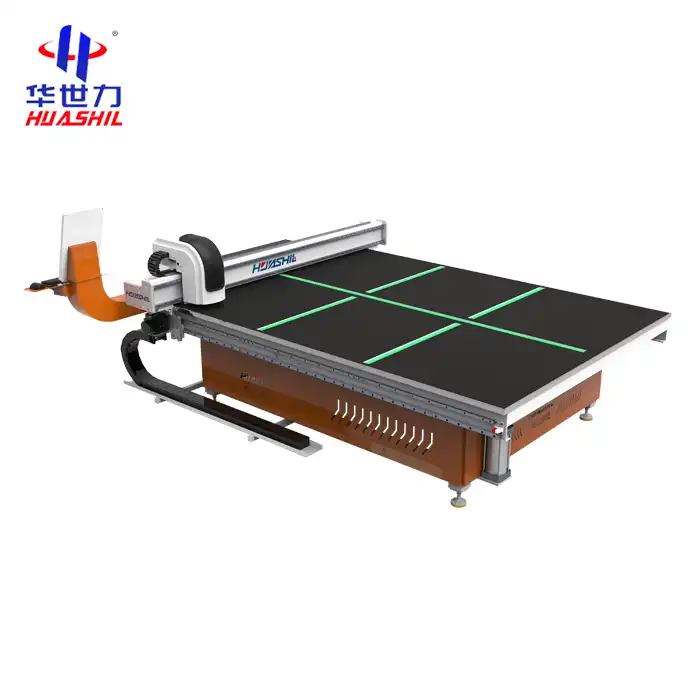

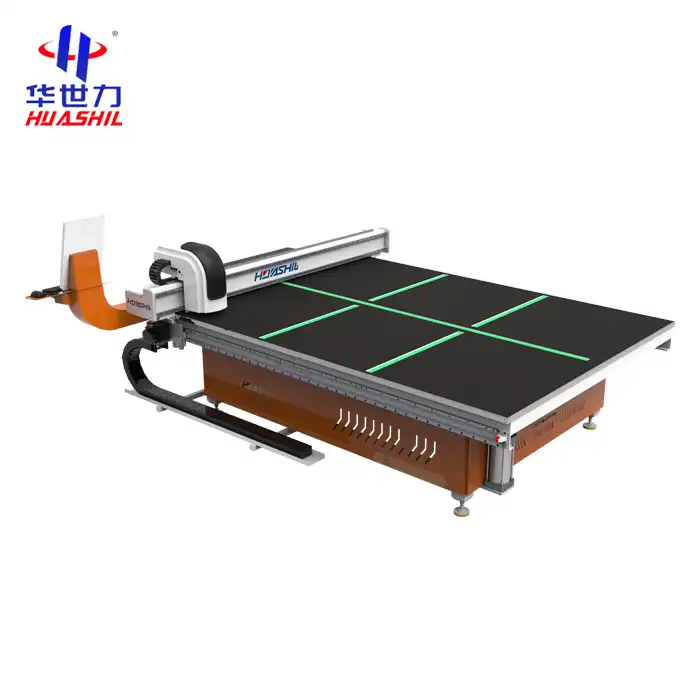

small cnc glass cutting machine

1.Model:HSL-CNC2721

2.Max glass size:2700*2100mm

3.Glass cutting thickness:2-19mm

4.Dimension:3660*3185mm

5.Optimization software:Optima

6.Function: automatic pressure control,automatic edge finding,air flotation system, 360 degree remote control walking

7.Certificate:CE, ISO9001 -

CNC glass cutting machine

-

CNC3826 glass cutting machine

-

flat glass cutting machine

-

Automatic shaped glass cutting machine

Improve Factory Efficiency with Automated Glass

Cutting Shandong Huashil Automation Technology Co. , Ltd.

offers advanced Automatic Glass Cutting Assembly Line solutions for modern organisations to boost precision and output.

These technologies automate glass production in high-volume manufacturers to decrease errors and ensure consistency.

The **Automatic Glass Cutting Assembly Line** optimises millimeter-level material use to save waste and costs.

Custom configurations allow complex shapes and glass thicknesses in industrial design.

Automotive, construction, and solar panel manufacturing run smoothly with real-time monitoring and AI-driven changes.

Shandong Huashil offers 20 years of engineering and factory-ready solutions expertise.

With 24/7 technical support, their tools enable organisations grow sustainably.

The Automatic Glass Cutting Assembly Line revolutionises glass manufacturing worldwide for automated and ROI-focused enterprises.

Improve Factory Efficiency with Automated Glass

Cutting Shandong Huashil Automation Technology Co. , Ltd.

provides sophisticated Automatic Glass Cutting Assembly Line solutions for contemporary companies to improve precision and production.

Automating glass manufacturing in high-volume producers reduces mistakes and ensures uniformity.

The **Automatic Glass Cutting Assembly Line** optimises millimeter-level material consumption to save waste and expenses.

Industrial design uses custom arrangements for complicated forms and glass thicknesses.

Real-time monitoring and AI-driven modifications streamline automotive, construction, and solar panel manufacture.

Shandong Huashil has 20 years of engineering and factory-ready solutions experience.

Their products help companies develop sustainably with 24/7 technical assistance.

Glass manufacturing globally is transformed by the Automatic Glass Cutting Assembly Line for automated and ROI-focused businesses.

FAQs

1. What technological characteristics do your automatic glass cutting assembly lines have?

Our assembly lines cut 0.1mm accurately, cycle 15-20 times per minute, and work with 2mm to 19mm glass. A reputable Automatic Glass Cutting Assembly Line Factory, Shandong Huashil Automation uses innovative servo systems and user-friendly interfaces for smooth operation.

2. Can equipment be customised for specific manufacturing needs?

Absolutely! Our Automatic Glass Cutting Assembly Line Factory customises solutions for your business, including custom dimensions, software, and sorting conveyors. We work closely with clients to meet all their needs.

3. How does your manufacturer guarantee product quality?

Each line is tested with 48-hour trial runs and ISO-certified inspections. We use quality components and real-time assembly monitoring. As a top Automatic Glass Cutting Assembly Line Factory, we prioritise machine durability and uniformity.

4. What after-sales assistance do you offer?

24/7 remote troubleshooting, 72-hour on-site professional dispatch, and yearly maintenance plans. Globally supplied spares provide speedy repairs. To reduce machine downtime, our factory-trained personnel is accessible throughout its lifespan.

5. How long is installation and training?

Most systems start up 5-7 days after birth. Operators and managers receive hands-on instruction in safety, everyday operations, and basic maintenance. Continuous reference is provided by documentation and video tutorials.

Best Selling Products

-

CNC glass cutting machine

-

CNC3826 glass cutting machine

-

3829 glass cutting machine

-

glass auto cutting machine

-

furniture cabinet glass cutting machine

-

manual glass loading machine

Related Blogs

- How Do You Maintain a CNC Mirror Cutting Machine?

- What is a Mobile Glass Cutting Machine?

- How Accurate is a CNC Glass Cutting Assembly Line?

- How is a Glass Deep Cutting Machine Different from a Standard Cutting Machine?

- How Do I Choose the Right Glass Processing Equipment for My Business?

- Can Glass Manufacturing Equipment Be Customized for Different Production Needs?

Related Search

- cnc Glass Cutting Assembly Line Manufacturer

- Jumbo glass cutting machine Manufacturer

- glass breaking table Manufacturer

- CNC glass cutting machine Manufacturer

- CNC3826 glass cutting machine Manufacturer

- 3829 glass cutting machine Manufacturer

- glass auto cutting machine Manufacturer

- furniture cabinet glass cutting machine Manufacturer

- manual glass loading machine Manufacturer

- mobile glass cutter machine Manufacturer

- industrial glass cutting and laminating systems Manufacturer

- automatic double glass processing machine Manufacturer

- glass transport table line Manufacturer

- glass cut outs machine Manufacturer

- high quality mirror processing machine Manufacturer

- mobile glass cutter Manufacturer

- cutting laminated glass machine Manufacturer

- automatic glass cutter Manufacturer

- air flotation table Manufacturer

- furniture cutting equipment Manufacturer

- Float Glass Double Machinery Manufacturer

- Special Shape Sintered Stone Cutting Machines Manufacturer

- Automatic Cnc Glass Loading Machine Manufacturer

- High-Performance Glass Processing Equipment Manufacturer

- Glass Measure Table Machine Manufacturer

- Industrial Glass Cutting Table Manufacturer

- Glass Industry Air Flotation Machine Manufacturer

- Gtm Glass Loading Machine Manufacturer

- Glass Sheet Loader Manufacturer

- Reasonable Price Glass Loading Table Manufacturer

- Automated Glass Processing Manufacturer

- Automated Glass Processing Systems Manufacturer

- Glass Cnc Cut Out Machine Manufacturer

- Furniture Glass Machine Manufacturer

- Glass Loader Manufacturer

- Glass Loading Table With Arm Manufacturer

- Glass Cutting Line Manufacturer

- Glass Sheet Storage Cutting Line Manufacturer

- Electric Glass Sheet Storage Rack Manufacturer

- Glass Cutting Line Machine Manufacturer

- 2721 Glass Cutting Line Manufacturer

- Cnc Glass Cutting Line Manufacturer

- Auto Glass Cutting Line Machine Manufacturer

- Automatic Glass Cutting Line Manufacturer

- Glass Cutting Assembly Line Manufacturer

- Float Glass Cutting Machine Manufacturer

- Automatic Glass Cutting Assembly Line Manufacturer

- Glass Processing Equipment Manufacturer

- Glass Manufacturing Equipment Manufacturer

- Glass Cutting Loading Machine Manufacturer

- 5133 Glass Cutting Line Manufacturer

- Low E Glass Edge Deletion Machine Manufacturer

- Automatic Glass Cutting Line For Low-E Glass Manufacturer

- Industrial Glass Cutting Machine Manufacturer

- Professional Glass Cutting Machine Manufacturer

- Industrial Glass Breaking Equipment Manufacturer

- Custom Glass Loading Machine Manufacturer

- Automatic Glass Loading Machine Manufacturer

- Air Float Glass Loading Table Manufacturer

- All In One Glass Cutting Machine Manufacturer

- Glass Grinding Equipment Manufacturer

- Automatic Glass Grinding Machine Manufacturer

- Flat Glass Cutting Machine Manufacturer

- Round Glass Grinding Machine Manufacturer

- Automatic Shaped Glass Cutting Machine Manufacturer

- Glass Double Edging Machine Manufacturer

- Glass Cutting Equipment Manufacturer

- Glass Edge Grinding Machine Manufacturer

- Glass Double Edger Machine Manufacturer

- Double Edger Machine Manufacturer

- Glass Bilateral Edging Machine Manufacturer

- Mirror Loading And Cutting Machine Manufacturer

- Cnc Mirror Cutting Machine Manufacturer

- Cnc Glass Loading Cutting Breaking Machine Manufacturer

- Window Glass Cutting Machine Manufacturer

- Float Glass Cutting Equipment Manufacturer

- Cnc Glass Cutting Equipment Manufacturer

- Cnc Shaped Glass Cutting Machine Manufacturer

- Cnc Glass Machine Manufacturer

- Fast Speed Glass Cutting Machine Manufacturer

- Commercial Glass Cutting Machine Manufacturer

- 3826 Glass Cutting Machine Manufacturer

- Cutting Machine For Stained Glass Windows Manufacturer

- Mobile Glass Cutting Machine Manufacturer

- Glass Deep Cutting Machine Manufacturer

- Integrated Glass Cutting Machine Manufacturer

- Glass Cutting Table Manufacturer

- Small Glass Cutting Machine Manufacturer

- Glass Cutting Table Machine Manufacturer

- Automatic Glass Breaking Machine Manufacturer

- Small Cnc Glass Cutting Machine Manufacturer

- Cnc Stone Cutting Machine Manufacturer

- Portable Tile Cutting Machine Manufacturer

- Large Tile Cutting Machine Manufacturer

- Automatic Stone Cutting Machine Manufacturer

- Sintered Stone Cutting Machine Manufacturer

- Best Stone Cutting Machine Manufacturer

- Special Shape Sintered Stone Cutting Machine Manufacturer

- Cnc Sintered Stone Cutting Machine Manufacturer

- Glass Storage Racks Manufacturer

- Glass Loading Table Manufacturer

- Shuttle Car Manufacturer

- Intelligent Manufacturing Mes System Manufacturer

- Intelligent Glass Storage System Manufacturer

- Mini Glass Cutting Machine Manufacturer

- Small Glass Cutting Machinery Manufacturer

- Cnc Glass Machinery Manufacturer

- Cnc Glass Processing Machine Manufacturer

- Glass Cnc Cutting Machine Manufacturer

- Glass Processing Machine Manufacturer

- Window Cutting Machine Manufacturer

- Cnc Glass Equipment Manufacturer

- Laser Marking Machine Manufacturer

- Laser Marking And Cutting Machine Manufacturer

- Double Side Glass Cutting Line Manufacturer

- Double Turn Loading Glass Cutting Line Manufacturer

- Cnc Control Glass Cutting Line Manufacturer

- Glass Production Line Manufacturer

- Glass Air Float Loading Table Manufacturer

- Semi Automatic Glass Loading Machine Manufacturer

- Cnc Glass Cutting Assembly Line Factory

- Jumbo Glass Cutting Machine Factory

- Glass Breaking Table Factory

- Cnc Glass Cutting Machine Factory

- Cnc3826 Glass Cutting Machine Factory

- 3829 Glass Cutting Machine Factory

- Glass Auto Cutting Machine Factory

- Furniture Cabinet Glass Cutting Machine Factory

- Manual Glass Loading Machine Factory

- Industrial Glass Cutting And Laminating Systems Factory

- Automatic Double Glass Processing Machine Factory

- Glass Transport Table Line Factory

- Glass Cut Outs Machine Factory

- High Quality Mirror Processing Machine Factory

- Mobile Glass Cutter Factory

- Cutting Laminated Glass Machine Factory

- Automatic Glass Cutter Factory

- Air Flotation Table Factory

- Furniture Cutting Equipment Factory

- All In One Glass Cutting Machine Factory

- Float Glass Double Machinery Factory

- Special Shape Sintered Stone Cutting Machines Factory

- Automatic Cnc Glass Loading Machine Factory

- High-Performance Glass Processing Equipment Factory

- Glass Measure Table Machine Factory

- Industrial Glass Cutting Table Factory

- Glass Industry Air Flotation Machine Factory

- Gtm Glass Loading Machine Factory

- Glass Sheet Loader Factory

- Reasonable Price Glass Loading Table Factory

- Automated Glass Processing Factory

- Automated Glass Processing Systems Factory

- Glass Loader Factory

- Glass Loading Table With Arm Factory

- Glass Cutting Line Factory

- Glass Sheet Storage Cutting Line Factory

- Electric Glass Sheet Storage Rack Factory

- Glass Cutting Line Machine Factory

- 2721 Glass Cutting Line Factory

- Cnc Glass Cutting Line Factory

- Auto Glass Cutting Line Machine Factory

- Automatic Glass Cutting Line Factory

- Glass Cutting Assembly Line Factory

- Float Glass Cutting Machine Factory

- Automatic Glass Cutting Assembly Line Factory

- Glass Processing Equipment Factory

- Glass Cutting Loading Machine Factory

- 5133 Glass Cutting Line Factory

- Low E Glass Edge Deletion Machine Factory

- Professional Glass Cutting Machine Factory

- Industrial Glass Breaking Equipment Factory

- Custom Glass Loading Machine Factory

- Automatic Glass Loading Machine Factory

- Glass Grinding Equipment Factory

- Automatic Glass Grinding Machine Factory

- Flat Glass Cutting Machine Factory

- Round Glass Grinding Machine Factory

- Glass Double Edging Machine Factory

- Glass Cutting Equipment Factory

- Glass Edge Grinding Machine Factory

- Glass Double Edger Machine Factory

- Double Edger Machine Factory

- Glass Bilateral Edging Machine Factory

- Mirror Loading And Cutting Machine Factory

- Cnc Mirror Cutting Machine Factory

- Cnc Glass Loading Cutting Breaking Machine Factory

- Door Glass Cutting Machine Factory

- Float Glass Cutting Equipment Factory

- Cnc Shaped Glass Cutting Machine Factory

- Cnc Glass Machine Factory

- Fast Speed Glass Cutting Machine Factory

- Commercial Glass Cutting Machine Factory

- 3826 Glass Cutting Machine Factory

- Cutting Machine For Stained Glass Windows Factory

- Mobile Glass Cutting Machine Factory

- Glass Deep Cutting Machine Factory

- Integrated Glass Cutting Machine Factory

- Stained Glass Cutting Machine Factory

- Glass Cutting Table Factory

- Glass Cutting Table Machine Factory

- Automatic Glass Breaking Machine Factory

- Small Cnc Glass Cutting Machine Factory

- Cnc Stone Cutting Machine Factory

- Glass Laser Marking Machine Factory

- Portable Tile Cutting Machine Factory

- Large Tile Cutting Machine Factory

- Automatic Stone Cutting Machine Factory

- Sintered Stone Cutting Machine Factory

- Best Stone Cutting Machine Factory

- Special Shape Sintered Stone Cutting Machine Factory

- Cnc Sintered Stone Cutting Machine Factory

- Glass Storage Racks Factory

- Glass Loading Table Factory

- Shuttle Car Factory

- Intelligent Manufacturing Mes System Factory

- Intelligent Glass Storage System Factory

- Small Glass Cutting Machinery Factory

- Cnc Glass Machinery Factory

- Cnc Glass Processing Machine Factory

- Glass Cnc Cutting Machine Factory

- Glass Processing Machine Factory

- Window Cutting Machine Factory

- Cnc Glass Equipment Factory

- Laser Marking Machine Factory

- Laser Marking And Cutting Machine Factory

- Glass Loading Machine Factory

- Double Side Glass Cutting Line Factory

- Auto Glass Cutting Line Factory

- Double Turn Loading Glass Cutting Line Factory

- Cnc Control Glass Cutting Line Factory

- Glass Production Line Factory

- Glass Air Float Loading Table Factory

- Semi Automatic Glass Loading Machine Factory

- Cnc Glass Cutting Assembly Line Supplier

- Jumbo Glass Cutting Machine Supplier

- Cnc Glass Cutting Machine Supplier

- Cnc3826 Glass Cutting Machine Supplier

- 3829 Glass Cutting Machine Supplier

- Furniture Cabinet Glass Cutting Machine Supplier

- Manual Glass Loading Machine Supplier

- Mobile Glass Cutter Machine Supplier

- Industrial Glass Cutting And Laminating Systems Supplier

- Automatic Double Glass Processing Machine Supplier

- Glass Cut Outs Machine Supplier

- High Quality Mirror Processing Machine Supplier

- Mobile Glass Cutter Supplier

- Cutting Laminated Glass Machine Supplier

- Automatic Glass Cutter Supplier

- Air Flotation Table Supplier

- All In One Glass Cutting Machine Supplier

- Float Glass Double Machinery Supplier

- Special Shape Sintered Stone Cutting Machines Supplier

- Automatic Cnc Glass Loading Machine Supplier

- High-Performance Glass Processing Equipment Supplier

- Glass Measure Table Machine Supplier

- Industrial Glass Cutting Table Supplier

- Glass Industry Air Flotation Machine Supplier

- Gtm Glass Loading Machine Supplier

- Reasonable Price Glass Loading Table Supplier

- Automated Glass Processing Supplier

- Automated Glass Processing Systems Supplier

- Glass Cnc Cut Out Machine Supplier

- Furniture Glass Machine Supplier

- Glass Loader Supplier

- Glass Loading Table With Arm Supplier

- Glass Sheet Storage Cutting Line Supplier

- Electric Glass Sheet Storage Rack Supplier

- Glass Cutting Line Machine Supplier

- 2721 Glass Cutting Line Supplier

- Cnc Glass Cutting Line Supplier

- Auto Glass Cutting Line Machine Supplier

- Automatic Glass Cutting Line Supplier

- Glass Cutting Assembly Line Supplier

- Float Glass Cutting Machine Supplier

- Automatic Glass Cutting Assembly Line Supplier

- Glass Processing Equipment Supplier

- Glass Manufacturing Equipment Supplier

- Glass Cutting Loading Machine Supplier

- 5133 Glass Cutting Line Supplier