Meeting stringent building standards: Precision matters

When it comes to architectural glass, precision isn't just a luxury—it's a necessity. Modern building codes and standards demand exacting specifications for glass installations, particularly in large-scale projects where even minor deviations can lead to significant issues.

Ultra-precise float glass cutting equipment ensures that every panel meets these rigorous standards. Here's why this level of precision is critical:

- Structural integrity: Precisely cut glass panels distribute stress evenly, reducing the risk of cracks or breaks under pressure.

- Energy efficiency: Exact cuts mean tighter fits, minimizing heat loss and improving overall building energy performance.

- Safety compliance: Many building codes require specific dimensions for safety glass installations, which can only be consistently achieved with high-precision cutting.

- Aesthetic perfection: In modern architecture, where glass often plays a prominent role, even slight imperfections can mar the overall visual impact of a building.

By utilizing float glass cutting equipment made in China and state-of-the-art cutting technology, architects and builders can ensure that every piece of glass not only meets but exceeds industry standards. This level of precision contributes to the longevity, safety, and aesthetic appeal of the finished structure.

Customization capabilities: Unique architectural designs

The true beauty of modern architecture often lies in its ability to push boundaries and create unique, eye-catching designs. Ultra-precise float glass cutting equipment plays a pivotal role in bringing these innovative visions to life.

Here's how advanced cutting technology enables customization:

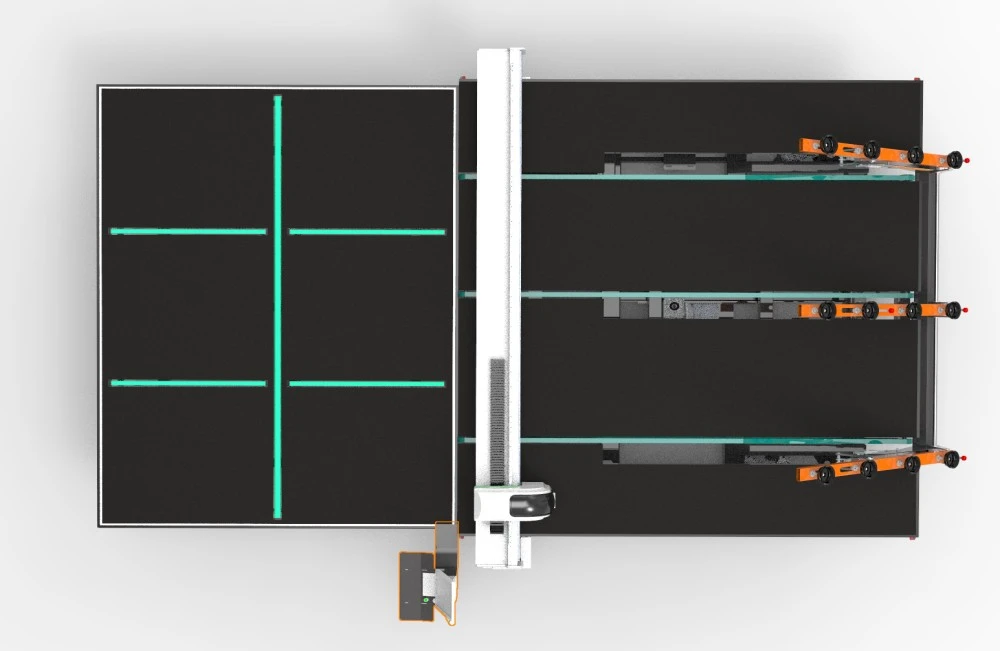

- Complex shapes: From curved panels to intricate geometric designs, precision cutting equipment can handle a wide array of custom shapes.

- Varied sizes: Whether it's a small decorative piece or a massive curtain wall panel, high-precision cutters can accommodate diverse size requirements.

- Multi-layered designs: For projects requiring laminated or insulated glass units, precise cutting ensures perfect alignment of multiple layers.

- Edge finishing: Many modern designs call for exposed glass edges, which must be cut and finished with extreme precision for both safety and aesthetics.

The ability to customize glass elements opens up a world of possibilities for architects. It allows for the creation of signature buildings that stand out in the urban landscape, from twisting skyscrapers to organically shaped cultural centers.

Moreover, this customization with float glass cutting equipment extends beyond mere aesthetics. Precision-cut glass can be tailored to meet specific functional requirements, such as enhanced acoustic properties for concert halls or optimized light transmission for greenhouses and solar installations.

Cost-efficiency: Reducing waste in high-value glass

In the realm of architectural glass, waste isn't just an environmental concern—it's a significant financial consideration. High-quality architectural glass is a premium material, and any waste directly impacts project costs. This is where the economic advantages of ultra-precise float glass cutting equipment become evident.

Let's break down the cost-saving benefits:

- Minimized material waste: Precision cutting reduces off-cuts and scraps, maximizing the use of each glass sheet.

- Fewer errors: High-precision equipment minimizes human error, reducing the need for costly replacements due to mis-cuts.

- Optimized cutting patterns: Advanced software in modern cutting equipment can calculate the most efficient cutting patterns, further reducing waste.

- Reduced labor costs: Automated, precise cutting is faster and requires less manual intervention, streamlining the production process.

- Lower energy consumption: Efficient cutting processes often translate to reduced energy usage in the overall manufacturing process.

The cost savings achieved through precision cutting can be substantial, especially in large-scale projects where the volume of glass used is significant. This efficiency not only benefits the bottom line but also contributes to more sustainable building practices by minimizing resource consumption and waste.

Furthermore, the precision offered by float glass cutting equipment made in China often results in higher-quality end products. This can lead to reduced maintenance and replacement costs over the lifespan of the building, providing long-term economic benefits to property owners and managers.

Conclusion

The selection of ultra-precise float glass cutting equipment for sale for architectural glass is not just a choice—it's a necessity in today's demanding construction landscape. From meeting stringent building standards and enabling unique architectural visions to significantly reducing costs and waste, the benefits of this technology are clear and multifaceted.

As we continue to push the boundaries of architectural design, the role of precision glass cutting will only grow in importance. It's a technology that not only meets current needs but also paves the way for future innovations in building design and construction.

For architects, builders, and property developers looking to create truly remarkable structures, investing in projects that utilize ultra-precise float glass cutting equipment is a decision that pays dividends in quality, efficiency, and architectural excellence.

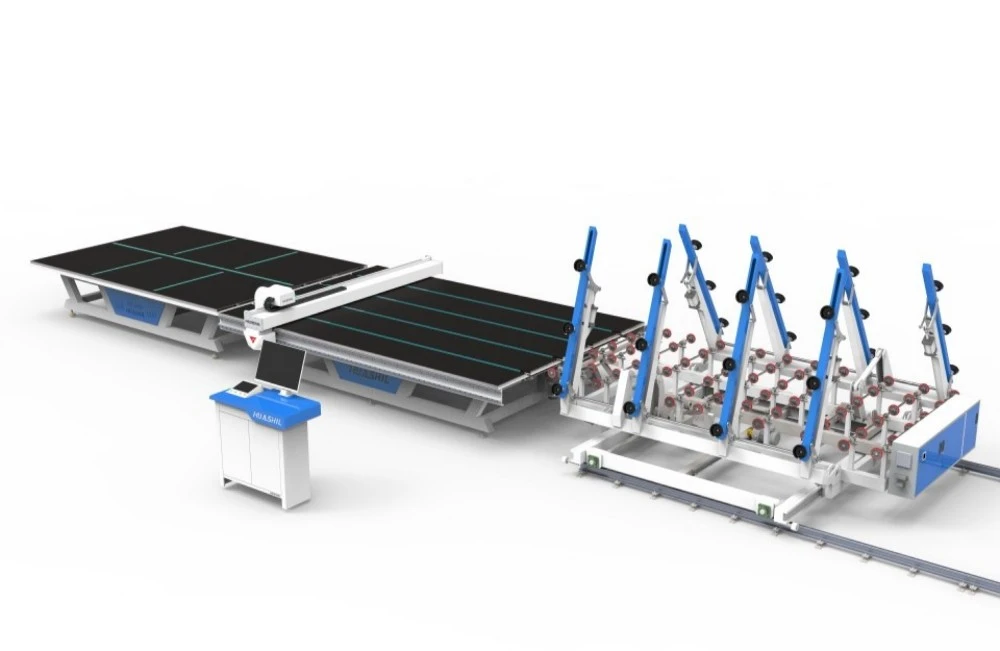

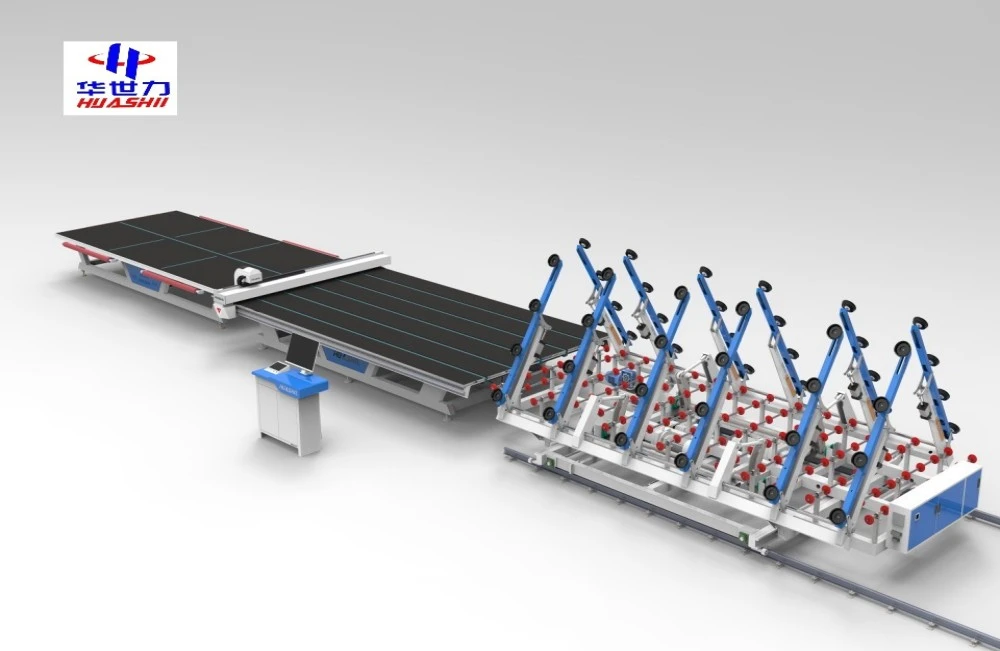

Are you ready to elevate your architectural glass projects to new heights of precision and innovation? At Shandong Huashil Automation Technology Co., LTD, we specialize in providing cutting-edge float glass cutting equipment that meets the exacting standards of modern architecture. With years of experience in automated R&D, manufacturing, and sales, our advanced techniques and commitment to quality have made us a trusted partner for customers worldwide.

Don't let imprecision hold back your architectural vision. Contact us today to learn how our ultra-precise float glass cutting equipment can transform your projects, reduce costs, and help you create truly stunning buildings. Our team of experts is ready to provide you with personalized solutions tailored to your specific needs.

FAQ

Q1: What types of glass can be cut with ultra-precise float glass cutting equipment?

A: Ultra-precise float glass cutting equipment is versatile and can handle various types of glass, including: - Standard float glass - Tempered glass - Laminated glass - Low-E glass - Patterned and textured glass - Tinted and reflective glas.The equipment's precision allows for accurate cutting of these different glass types, ensuring they meet specific architectural requirements.

Q2: How does ultra-precise float glass cutting equipment contribute to sustainable building practices?

A: Ultra-precise float glass cutting equipment significantly contributes to sustainable building practices in several ways: 1. Reduced material waste: Precision cutting minimizes off-cuts and scraps, maximizing the use of each glass sheet. 2. Energy efficiency: Precisely cut glass panels fit more tightly, improving a building's overall energy performance. 3. Longevity: Accurately cut glass is less prone to stress-related failures, reducing the need for replacements over time. 4. Optimized production: Efficient cutting processes often require less energy, reducing the carbon footprint of glass manufacturing. 5. Support for innovative designs: Precision cutting enables the creation of complex glass structures that can enhance a building's environmental performance, such as advanced solar control facades.

Q3: Can ultra-precise float glass cutting equipment handle custom shapes and sizes for unique architectural designs?

A: Yes, ultra-precise float glass cutting equipment is specifically designed to handle custom shapes and sizes, making it ideal for unique architectural designs. These advanced machines can: - Cut complex curved shapes with high accuracy - Produce intricate geometric patterns - Handle a wide range of glass sizes, from small decorative pieces to large curtain wall panels - Create precise openings and cutouts within glass panels - Ensure consistent edge quality for exposed glass applications This flexibility allows architects to push the boundaries of design, creating signature buildings with distinctive glass features.

High-Precision Float Glass Cutting Equipment for Architectural Marvels | HUASHIL

Transform your architectural glass projects with HUASHIL's state-of-the-art float glass cutting equipment. Our precision technology ensures unparalleled accuracy, minimizes waste, and brings your most ambitious designs to life. Whether you're working on a sleek skyscraper or a cutting-edge cultural center, our equipment delivers the quality and efficiency you need.

Ready to elevate your architectural glass production? Contact us at salescathy@sdhuashil.com for a personalized consultation. Let HUASHIL be your partner in creating the buildings of tomorrow, today.

References

1. Smith, J. (2023). "Advancements in Architectural Glass Cutting Technologies". Journal of Modern Construction, 45(3), 212-228.

2. Chen, L., et al. (2022). "Impact of Precision Glass Cutting on Building Energy Efficiency". Energy and Buildings, 256, 111672.

3. García-Santos, A., & Neila-González, F. J. (2021). "Innovative Glass Solutions in Contemporary Architecture". Architectural Science Review, 64(4-5), 281-294.

4. Thompson, R. (2023). "Cost-Benefit Analysis of High-Precision Glass Cutting in Large-Scale Construction Projects". Construction Management and Economics, 41(2), 145-160.