Today's production environment needs machines that are precise, efficient, and reliable, and they also have to meet very high quality standards. Modern glass processing plants use high-tech glass manufacturing equipment like automated cutting lines and advanced tempering stations. With these new technologies, manufacturers can make anything from architectural glass to precise optical parts. Whether you're in charge of a curtain wall fabrication plant or make decorative glass furniture, you need to know what the newest glass manufacturing equipment can do to stay ahead of the competition in a market that is always changing.

How modern glass processing technology has changed over time?

Over the past ten years, the speed at which glass automation technology has changed has been very fast. Smart sensors, AI-driven optimization software, and predictive maintenance systems are now all built into the production processes of factories. With these improvements, operators can see real-time performance metrics that help them cut down on waste and boost throughput.

Modern machines for cutting glass have laser guidance systems and positioning systems that are controlled by a computer. These features make sure that the measurements are always correct for large glass sheets up to 5100x3300mm. Modern breaking tables and loading systems work together to make production sequences that run smoothly and require less manual handling.

Energy-saving technologies have been added to float glass production lines, which means they use a lot less power. Better thermal management systems are now built into glass annealing ovens, and precise application methods that reduce material waste are used in glass coating machines. Automated inspection protocols built into quality control systems can find flaws that humans can't see.

Important Types of Equipment for Glass Manufacturers

Most production facilities are held together by glass melting furnaces, which are the basis for all operations that follow. Regenerative heating systems and new refractory materials are used in modern furnace designs to make them last longer and use less energy.

Another important type of component is a glass-forming machine. These systems shape molten glass into basic shapes that can be used for further processing. Glass molding presses are used for specific tasks that need precise control of dimensions, like in optical and automotive applications.

Through controlled heating and quick cooling cycles, glass tempering equipment makes finished products stronger. This process improves safety features while keeping the clarity of the image. Protective coatings that make things last longer and work better are put on glass surfaces by surface treatment systems.

Automated glass handling systems change the way things move around in factories. These mechanisms lower the number of breaks while also making workers safer. Protective materials and safe containment methods are used by glass packaging machinery to make sure that products get to customers in perfect condition. All of these types of equipment are essential parts of the overall glass manufacturing equipment that drives modern glass production.

Automation Solutions on the Cutting Edge

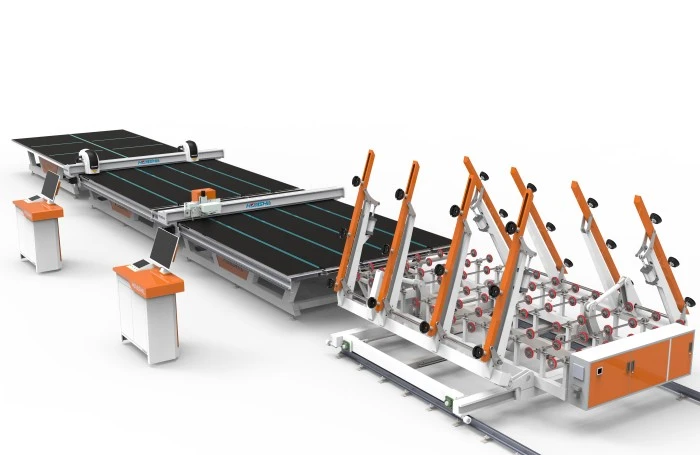

The HUASHIL HSL-LSX5133 is an example of cutting glass technology of the future. It has three built-in tables that are used for loading, cutting, and breaking glass. This setup makes production as efficient as possible while keeping quality standards high. The system can handle glass panels up to 5100x3300mm, which means it can be used for big architectural projects.

Intelligent material utilization is driven by Optima optimization software, which figures out the best cutting patterns that produce the least amount of waste. The software looks at the size of the glass and the output that is needed to make cutting sequences that get the most out of each sheet.

Both above-ground and underground rail systems can be set up in a variety of ways to fit different facility layouts. The 2+2 station arrangement lets multiple glass sheets be processed at the same time, which greatly increases the throughput capacity. On each side, there are five specialized arms that make positioning the glass very accurate.

Low-E deletion lets you get rid of certain parts of energy-efficient coatings when needed for certain tasks. In the production of architectural glass, this feature comes in very handy when electrical connections or areas with poor visibility need coatings to be removed.

Systems for inspecting and controlling quality

High-resolution cameras and advanced image processing algorithms are used in glass inspection systems to find flaws on the surface, differences in size, and optical distortions. These systems work at production speeds and have detection accuracy that is better than what can be done by hand.

During production runs, automated measurement stations check the quality of the edges, stress patterns, and uniformity of the thickness. Real-time data collection lets process changes be made right away, which stops quality problems from spreading to whole batches.

Statistical process control and machine learning algorithms are both used in glass quality control protocols. These systems can predict possible quality problems in finished products before they happen by learning from past production data, making them an important extension of advanced glass manufacturing equipment.

Optical testing tools check how well colors are spread across glass surfaces by measuring how much light passes through them and how much it reflects back. These tests make sure that products meet certain performance standards for the jobs they are meant to do.

Thoughts on Going Green and Saving Energy

Heat recovery systems take thermal energy from different stages of production and use it in glass equipment that uses less energy. Equipment for recycling glass is used to process cullet materials. This reduces the amount of raw materials needed and lowers the melting point.

These days' furnaces use a lot less fuel because they are better insulated and have better controls for burning fuel. Exhaust heat is used by waste heat recovery systems to warm up new materials or make steam that heats the building.

Reusing water systems are better for the environment and cost less to run. Closed-loop cooling systems keep water from going to waste and stop heat pollution. Water that has been recycled goes through chemical treatment to make sure it meets quality standards so it can be used again.

When solar integration opportunities come up, facilities can get the power they need from renewable sources. Battery storage systems keep power running even when the power goes out or when there is a lot of demand.

Industries that use it and specific needs

You need tools that can accurately handle large sheets of glass in order to make architectural glass. Curtain wall systems need consistent edge quality and accurate measurements to seal well and keep the structure strong.

To quickly shape the containers into bottles, special tools are used to shape the glass. Mold cooling systems keep the temperature stable, which changes how even the walls are and how clear the image is. For making auto glass, you need tools that can bend glass into complicated shapes while still making sure it meets optical standards. Parts that are used for lighting and decoration are made by machines that blow glass.

Glass needs to be polished so that it looks like a mirror for people who make furniture. Edge polishing machines make edges that are smooth, safe, and nice to look at and handle.

Infrastructure for Support and Maintenance

Predictive maintenance systems keep an eye on the performance parameters of equipment to plan service visits before they break down. Vibration analysis, thermal imaging, and oil analysis can all show problems before they get too bad.

Having spare parts on hand becomes very important for keeping production schedules. Comprehensive inventory management systems keep important parts close at hand while keeping storage costs as low as possible.

Technical training programs make sure that operators know what their glass manufacturing equipment can and can't do. New features and optimization techniques that boost productivity are taught in regular skill development sessions.

Manufacturers of equipment can offer real-time support and troubleshooting help by monitoring it from afar. Diagnostic systems send information about how well something is working so that proactive maintenance suggestions can be made.

Trends and advances in technology for the future

Integration of artificial intelligence (AI) has the potential to change the way glass is made by improving the quality control process and making it smarter. Machine learning algorithms look at very large datasets to find ways to improve things that humans can't see.

Robots can be used for more than just moving things around. They can also be used for complex assembly tasks and quality inspections. Human operators and collaborative robots work together to increase productivity while keeping safety standards high.

Connectivity to the Internet of Things allows for full monitoring of production and remote management of equipment. Real-time data analytics give you information about how to make production more efficient and how to use equipment in the best way.

Advanced materials science keeps coming up with new ways to make glass that has better properties. The machines used in manufacturing need to change in order to work with these new materials while still keeping production rates high.

Conclusion

Equipment used to make glass combines old-fashioned skills with cutting-edge automation technologies. Picking systems that balance performance, dependability, and long-term value is key to success. Modern facilities need tools that can change with the needs of the market while still meeting quality standards. When making an investment decision, you should think about the total cost of ownership, the availability of technical support, and the ability to make changes. The glass industry keeps moving forward by coming up with new ways to make equipment that is more productive and less harmful to the environment.

Work with HUASHIL to get advanced solutions for making glass

As a top provider of equipment for making glass, HUASHIL comes up with new ways to automate production that make it more efficient. Our wide range of glass manufacturing equipment meets the needs of many different industries, from those that need architectural glazing to those that need specialized glass components. The HSL-LSX5133 cutting system shows that we are dedicated to precise engineering and high-quality operations.

Our skilled engineers work with clients to create custom solutions that make production processes run more smoothly. Technical support lasts for the entire lifecycle of the equipment, making sure that it works at its best and is reliable. Training programs give operators the skills they need to use the whole system while still following safety rules.

Email us at salescathy@sdhuashil.com to talk about your specific needs and find out how our glass processing equipment can help your business.

References

1. The International Association for the Manufacturing of Glass. "An Industry Report on Advanced Automation in Glass Processing for 2025." The 47th issue of Glass Technology Quarterly comes out in 2024.

2. Chen, Wei-Ming, and Mitchell, Sarah. "Innovations in Modern Glass Manufacturing Equipment That Save Energy." The 2024 Journal of Industrial Glass Technology.

3. European Companies That Make Glass Processing Equipment. "Quality Control Systems for Glass Production Lines That Are Automated." Technical Standards Report, 2024.

4. That's Maria Elena Rodriguez. "Environmental Friendly Methods in Modern Glass Making: Improving Tools and Methods." The 2024 Environmental Glass Technology Review.

5. Institute for Glass Manufacturing Technology. "Predictive Maintenance Strategies for Equipment Used in Glass Processing." Journal of Industrial Equipment Reliability, Volume 15, 2024.

6. Thompson, David R., and Zhang, Lin. "Integration of AI and IoT Technologies in Glass Manufacturing Systems." Smart Manufacturing Quarterly, Issue 2, 2024.