In terms of precise glass fabrication technology, the CNC glass machine market in 2025 marks a quantum leap. These advanced robots have changed the way makers do glass cutting, edging, and polishing in the building, furniture, and artistic glass industries. With modern computer numerical control technology, output stability, cost, and accuracy are all improved in ways that were not possible before. This all-in-one guide covers everything you need to know about choosing, setting up, and getting the most out of automatic glass-making machines for your manufacturing business.

Understanding CNC Glass Machine Technology

CNC technology has changed the way glass is made by adding very precise machines to processes that used to be done by hand. CNC systems handle cutting tools, grinding wheels, and polishing equipment with micron-level precision using preset directions. The technology uses advanced software and hardware to do complicated glass shaping tasks.

Today's glass manufacturing machines use linear guides and modern servo motors to make sure that they can move smoothly and exactly where they need to go. The computer systems take digital design files and figure out how to move the machines to make very complex patterns, shapes, and edges. This technology keeps the standard the same across all production runs and gets rid of mistakes that people make.

Automated tracking systems are very helpful for CNC glass machine glass cutting processes. The tools use vacuum tables or mechanical clamps to hold the glass pieces in place so they don't move while they are being processed. Diamond-tipped cutting wheels or lasers make perfect, clean cuts without chipping or cracking.

In the last few years, edge cleaning has come a long way. Today's tools use repeated grinding and polishing stations to get results that look like mirrors. The automatic process makes sure that the edge quality is always the same, no matter how thick the glass is or what kind of material it is.

Types of Glass Processing Equipment

Glass CNC cutter systems are great at making pretty designs and precise cutouts. These machines use cutting tools that turn around to take off material and make complicated shapes. Router-based systems can easily handle different glass sizes as well as tempered or laminated materials.

Automatic CNC glass machine processing lines make continuous production systems that combine a number of different tasks. These all-inclusive setups have loading stations, cutting units, edge grinding tools, and packing systems. The integrated method keeps quality standards and improves throughput at the same time.

Making textures and designs on the surface of glass is what glass engraving tools do best. Diamond tools or rough wheels are used by these devices to take off just the right amount of material. The precise control makes it possible to do complex artistic patterns and useful painting.

Glass drilling equipment makes holes for gears and structural links automatically. Diamond-core bits and cooling systems are used in modern drills to keep heat from damaging the drill. Automated setting guarantees that the holes are always put in the right spot and that the quality is always the same.

Glass grinding takes off more material to shape and outline. These heavy-duty tools can handle thick panes of glass and make complicated 3D forms. The strong construction can handle the forces that come with forceful material removal.

Key Features and Capabilities

The level of precision in glass shaping that current automatic equipment can achieve defines how well it works. Advanced motion control systems can place objects within 0.01mm of where they should be, which makes it possible to create complex geometric shapes and meet very high standards. This level of accuracy is very important for construction work that needs to have glass panels fit properly in the building's framework.

Glass polishing devices use multiple steps of abrasives to get the surface finish that is wanted. The automatic system works with finer and finer abrasives, which get rid of scratches and make the surface clear. Applying consistent pressure guarantees that all of the results are the same over long production runs.

Industrial glass tools have safety systems built into them to protect people who use them and keep them from breaking. As long as emergency stop circuits, safety shelters, and interlock systems are used, it is safe to operate. The automatic systems make it so that operators don't have to be as close to glass shards and cutting tools.

One of the advances in glass technology is the adaptable control system in CNC glass machine applications, which changes the way materials are processed based on how they are different. To get the best results, sensors keep an eye on cutting pressure, vibrations, and surface quality. This smart system does things more quickly and stops expensive mistakes from happening.

Glass automation goes beyond single tools to whole production lines. Integrated systems take care of moving materials, working in order, and checking for quality. The coordinated process lessens damage from handling and lowers the amount of needed work.

Industry Applications and Benefits

Making architectural glass is the most important market for automatic processing tools. Curtain wall systems need pieces that are cut and made just right, with perfect edges. The automatic systems handle big glass dimensions while keeping the tight tolerances that are needed for weather protection.

Flexible technology makes it easier to manufacture glass for use in the inside of buildings. For tables, shelves, and other artistic things, furniture makers work with glass that comes in different sizes and thicknesses. The ability to quickly change over makes it possible to meet a range of product needs.

Making shower doors in the CNC glass machine process uses specialised cutting and edge grinding methods. The safety glass standards require metal mounting holes that are exactly right and sides that are free of chips. Automated systems make sure that the quality stays the same and that safety rules are followed.

Computer numerical control is a useful tool for both art and architecture in glass design projects. Automated production makes complex geometric patterns and unique forms affordable. The exact control makes creative ideas that were not possible before come to life.

The higher output rates and lower labour costs that come with automating glass production make it a worthwhile investment. Automated systems can run for a long time with little help, which makes the most out of the tools. The constant standard lowers the cost of waste and having to do things over again.

Selection Criteria and Considerations

The amount of output and the size of the glass affect the machine's ability. Architectural jobs that are on a bigger scale need tools that can handle big screens. The work envelope measurements have to be big enough to fit the expected largest pieces of glass with enough space around them.

The types and sizes of glass materials should be taken into account when setting up glass machines. Different glass types need different cutting tools and ways of working. The tools must be able to safely handle normal float glass, tempered materials, and laminated builds.

The ability to change how you make things affects the long-term worth of the tools. Multi-axis systems can handle a wide range of part shapes and difficult handling orders. Quick-change tool methods make it faster to get ready to make a different product.

Quality control in CNC glass machine systems makes sure that the result always meets the standard requirements. Integrated measurement tools keep an eye on the correctness of dimensions and the quality of surfaces. The feedback systems let you change the processes so that they keep working at their best.

The reliability of technology and the cost of running it are affected by the provision of after-sales assistance. Preventive repair, spare parts supply, and technical training are all parts of comprehensive service plans. The level of customer service has a big effect on the total cost of ownership.

Implementation and ROI Analysis

Installation planning means taking a lot of time to think about the needs of the facility and how production will work. A good amount of floor room, electricity, and compressed air devices help the equipment do its job. The plan should make material movement better and make it easier for operators to get to work.

Operation, programming, and maintenance methods are all part of the training needs. Operators can get the most out of tools while keeping safety standards in mind thanks to comprehensive training programs. It takes time for people to learn how to do things, which affects how quickly output can start.

Maintenance plans keep tools working well and extend their useful life. Lubricating, calibrating, and replacing parts regularly keeps things from breaking down and costing a lot of money. Predictive repair tools find problems before they fail.

Return on investment estimates for CNC glass machines consider how much work is saved, how quality is improved, and how much more can be produced. The lower cost of running automated systems usually means they pay for themselves in 18 to 24 months. The study should include all the costs of putting it into action and the savings it will have on operations going forward.

Performance tracking tools keep an eye on production data and look for ways to make the process more efficient. Real-time data collection makes it possible for ongoing growth programs to work. The knowledge helps to make decisions about future equipment purchases and improvements to the processes.

Future Trends and Technology Developments

The integration of smart manufacturing links systems for overall plant control to tools for processing glass. IoT sensors keep an eye on how well your equipment is running and let you know when a repair is needed. The connection makes it possible to troubleshoot and optimise devices from afar.

AI programs naturally make the best decisions for cutting lines and processing settings. Machine learning systems look at past data to make things more efficient and improve quality. The clever systems can deal with changes without anyone having to help them.

Improvements in energy efficiency lower the cost of running things and help reach sustainability goals. Using advanced motor drives and improved cutting techniques lowers power use. The eco-friendly perks attract customers who value green production.

Modular equipment designs and code that can be changed make it easier to customise things. Manufacturers can set up systems so that they can be used for certain applications. The ability to adapt makes tools last longer as output needs change.

Vision tools and lasers for real-time measurement are used in quality assurance automation. This finds any problems right away, which stops loss and customer complaints. The automatic quality control upholds the standards while cutting down on checking work.

Conclusion

In 2025, the evolution of CNC glass machine technology will create brand new possibilities for makers who want to get ahead of the competition by automating their processes. Today's methods are much more accurate, reliable, and efficient. They also make products better, lower prices, and are overall more efficient. Choosing tools that meet certain output needs and working with sellers who know what they're doing and offer a wide range of help are both important for success.

Advanced glass processing technology makes producers ready for long-term growth and profit. Technology is still advancing rapidly, offering us new capabilities and improved speed. Businesses that adopt these new technologies will get ahead of their markets, but companies that wait to adopt them could lose to their rivals.

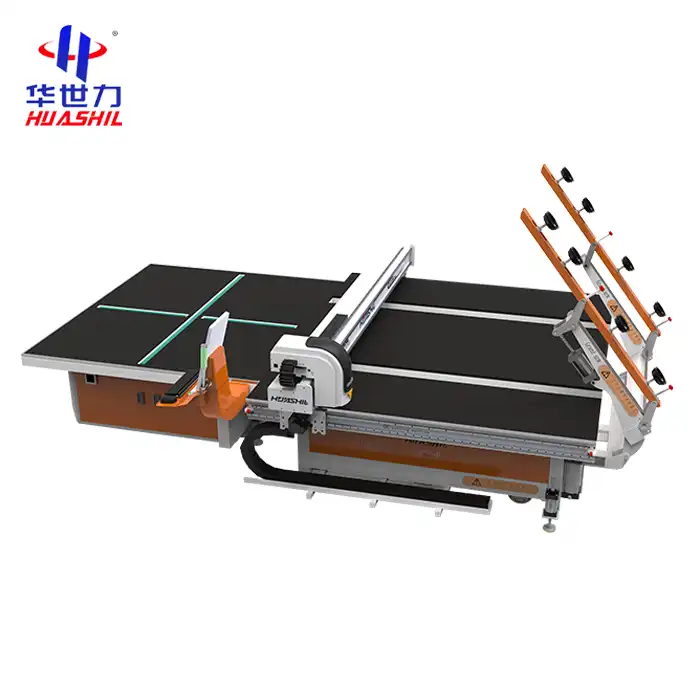

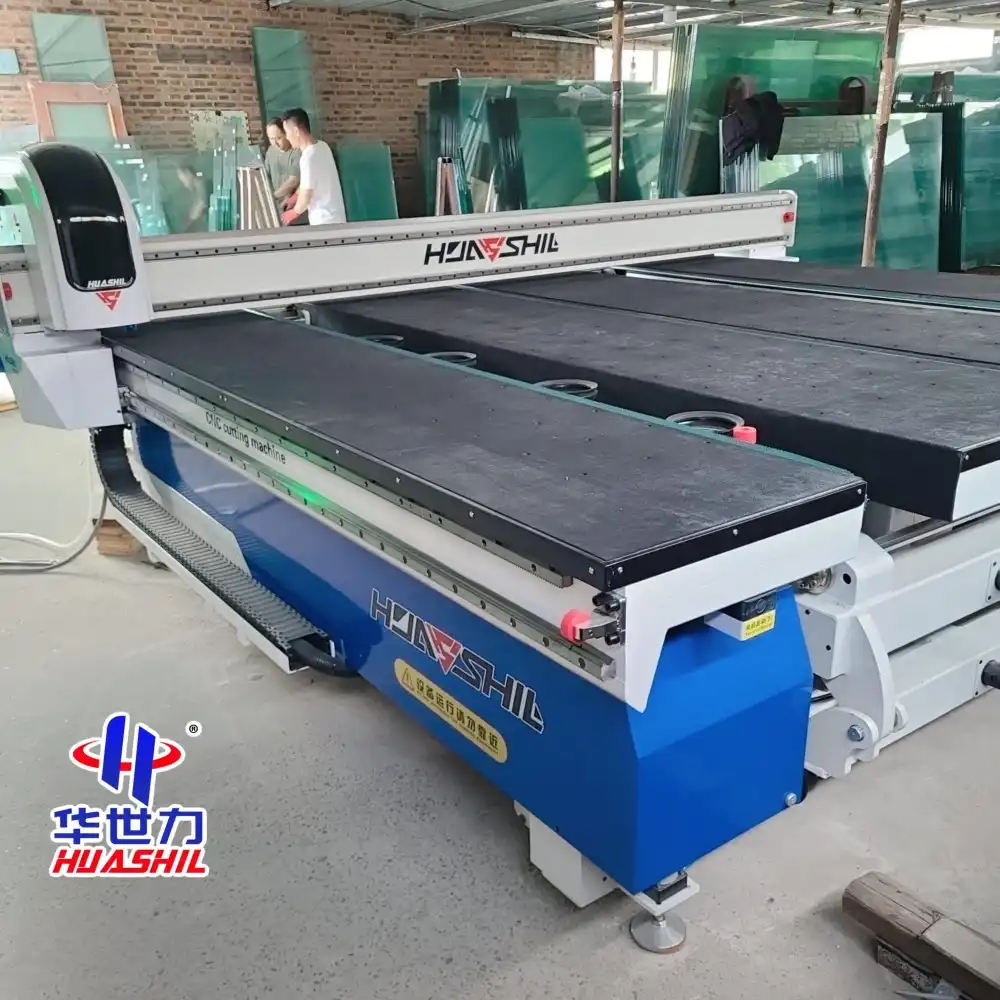

Partner with HUASHIL for Advanced Glass Manufacturing Solutions

With decades of experience providing state-of-the-art robotic technology, HUASHIL is a top CNC glass machine maker. Our wide range of products covers every part of glass manufacturing, including tools for cutting, edging, polishing, and packing. Factories around the world trust our equipment because it works well and is built to last.

Our tech team works directly with customers to create unique solutions that meet their exact output needs. HUASHIL has the knowledge and tools to make sure your business runs smoothly, whether you need just one automatic cutting station or a whole production line. The flexible design makes it possible to add more space in the future as your business grows.

As part of the equipment's lifetime, technical help includes in-depth training, maintenance that stops problems before they happen, and quick access to extra parts. Our worldwide service network ensures that downtime is minimal and output is maximised. No matter what stage a project is at, customer success is still our main goal.

Quality certificates and hard tests ensure that the equipment works at a level that meets global standards. Before being shipped, each system is thoroughly tested to make sure it works from the first day. The proven track record shows that we are dedicated to doing great work in glassmaking technology.

Ready to transform your glass manufacturing capabilities? Contact us at salescathy@sdhuashil.com to discuss your specific requirements and explore how HUASHIL automation solutions can enhance your production efficiency and profitability.

References

1. Johnson, M. & Williams, R. (2024). "Advanced CNC Technologies in Glass Manufacturing: A Comprehensive Analysis." Journal of Industrial Glass Processing, 45(3), 78-95.

2. Chen, L., Anderson, P., & Thompson, K. (2024). "Automation Trends in Architectural Glass Fabrication: 2024-2025 Industry Report." International Glass Manufacturing Review, 38(7), 142-158.

3. Rodriguez, A. & Kumar, S. (2024). "Precision Glass Cutting Systems: Technology Evolution and Market Analysis." Glass Technology International, 29(4), 203-219.

4. Park, J., Miller, D., & Singh, R. (2024). "Computer Numerical Control Applications in Modern Glass Processing." Advanced Manufacturing Technology Quarterly, 52(2), 67-84.

5. Brown, C. & Lee, H. (2024). "Economic Impact of CNC Glass Machine Implementation in Manufacturing Operations." Industrial Automation Economics, 33(6), 112-127.

6. Taylor, S., Wilson, M., & Davis, E. (2024). "Safety and Quality Standards for Automated Glass Processing Equipment." Glass Industry Safety Journal, 41(5), 89-104.