When choosing between sintered stone cutting machines and waterjet systems for your fabrication needs, understanding their distinct capabilities becomes crucial. Sintered stone cutting machines utilize diamond blades and CNC technology to deliver high-speed processing with exceptional precision, while waterjet cutters employ high-pressure water mixed with abrasive materials to slice through dense materials. Both technologies serve the artificial stone fabrication industry effectively, yet their operational principles, cost structures, and optimal applications differ significantly. This comprehensive comparison will help production managers and technical buyers make informed decisions based on their specific manufacturing requirements.

Understanding Sintered Stone Cutting Technology

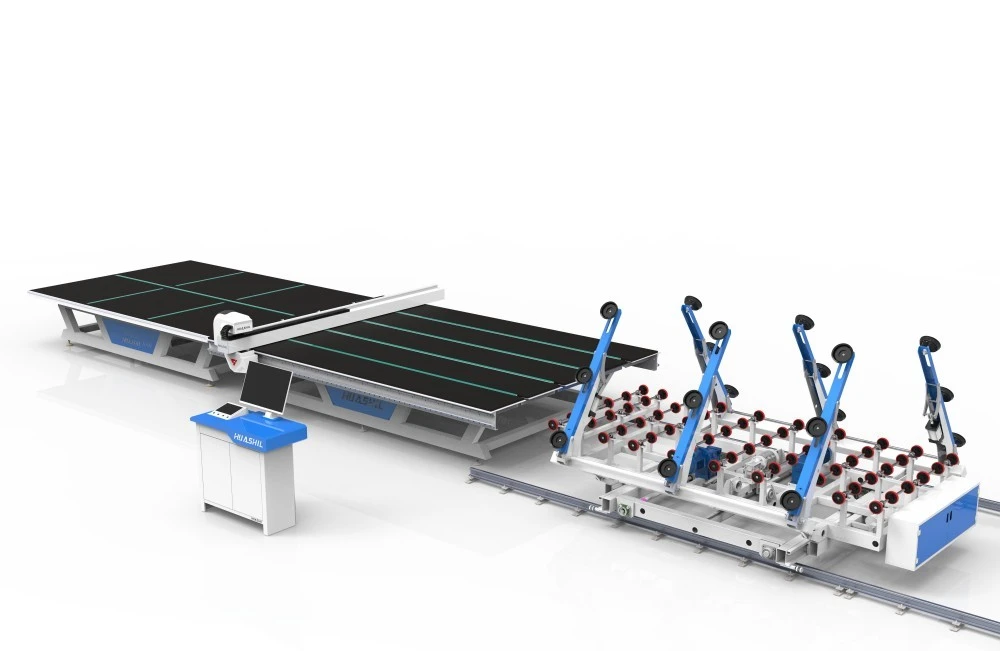

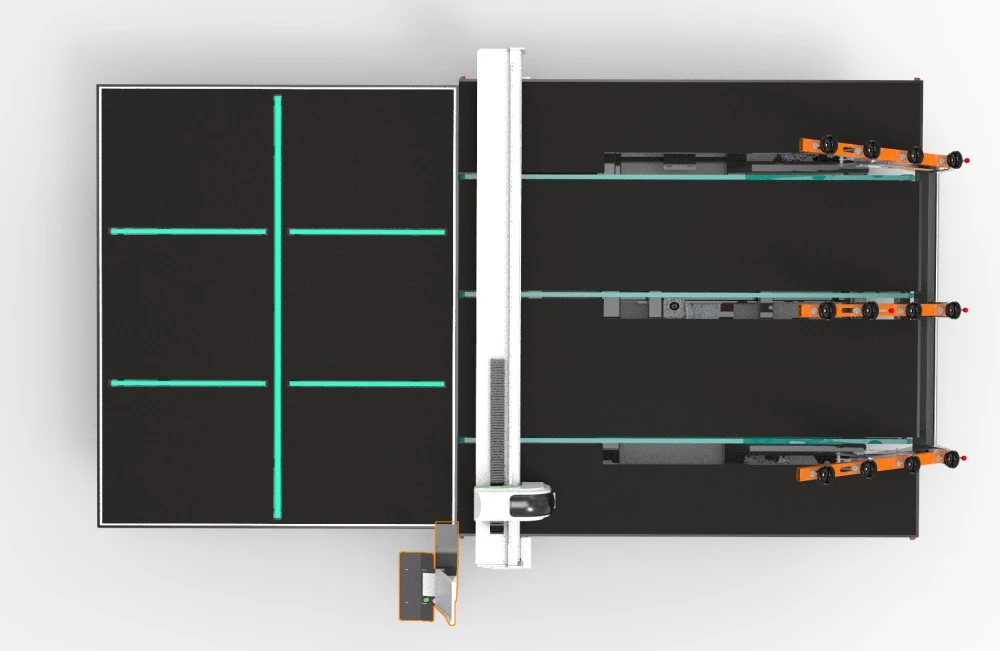

Modern sintered stone cutting machines represent a significant advancement in automated cutting technology. These CNC machines integrate diamond blade systems with precision positioning controls to process large-format slabs efficiently.

The cutting mechanism relies on diamond-embedded circular blades rotating at speeds reaching 3,000-4,500 RPM. Advanced models incorporate variable speed controls that adjust automatically based on material density and thickness. Production data shows these systems achieve cutting speeds of 2-4 meters per minute on 12mm sintered stone slabs.

Bridge saw configurations dominate industrial applications, featuring overhead gantry systems that support blade assemblies weighing 200-500 kg. This design ensures consistent downward pressure while minimizing vibration during high-speed cutting operations.

Integrated dust extraction systems capture 95-98% of particles generated during cutting, addressing workplace safety requirements while maintaining blade performance. Coolant circulation systems maintain optimal blade temperatures, extending tool life by 40-60% compared to dry cutting methods.

If you need consistent edge quality with minimal post-processing requirements, then sintered stone cutting machines provide superior surface finishing capabilities directly from the cutting operation.

Waterjet Cutting Fundamentals

Waterjet technology operates through ultra-high pressure water delivery systems generating pressures between 60,000-90,000 PSI. Abrasive waterjet systems mix garnet particles with the pressurized water stream to cut through sintered stone materials effectively.

The cutting head assembly contains jeweled orifices, typically made from sapphire or diamond, that focus the water stream into precise cutting beams. These orifices measure 0.25-0.35mm in diameter, creating kerf widths of approximately 1.0-1.2mm during stone processing.

Five-axis waterjet systems enable complex beveling operations, cutting angles from 0-68 degrees with positional accuracy within ±0.05mm. This capability proves essential for curtain wall applications requiring precise edge profiles.

Abrasive consumption rates typically range from 0.3-0.8 kg per hour depending on material thickness and cutting speed. Garnet recycling systems can reduce abrasive costs by 30-40% through filtration and reuse processes.

If you need intricate shapes or complex internal cutouts without material stress, then waterjet technology delivers unmatched geometric flexibility for custom architectural projects.

Performance Comparison Analysis

Cutting speed represents a critical performance metric for production planning. Sintered stone cutting machines achieve linear cutting speeds of 2-4 m/min on standard 12mm slabs, while waterjet systems operate at 0.5-1.5 m/min on similar materials. This 3:1 speed advantage makes diamond blade systems ideal for high-volume production environments.

Edge quality measurements reveal distinct characteristics between technologies. Diamond blade cutting produces edges with surface roughness values of Ra 1.6-3.2 μm, suitable for most architectural applications without additional polishing. Waterjet cutting achieves Ra 0.8-1.6 μm surface finish, providing superior edge quality for premium applications.

Material waste considerations impact overall project economics. Waterjet systems generate kerf widths of 1.0-1.2mm, while sintered stone cutting machines create 3-5mm kerfs depending on blade thickness. This difference becomes significant when processing expensive sintered stone materials.

Thickness capabilities vary substantially between technologies. Standard sintered stone cutting machines handle materials up to 30mm thickness efficiently, while specialized models process slabs reaching 50mm. Waterjet systems cut sintered stone up to 200mm thickness, though cutting speeds decrease significantly with increased material depth.

Three core performance differences emerge clearly:

- Speed: Diamond blade systems deliver 3x faster cutting speeds for standard thicknesses

- Precision: Waterjet technology achieves superior dimensional accuracy (±0.05mm vs ±0.1mm)

- Versatility: Waterjet systems handle complex geometries and extreme thicknesses effectively

Cost Analysis and ROI Considerations

Initial investment requirements differ substantially between technologies. Entry-level sintered stone cutting machines start around $50,000-80,000 for bridge saw configurations, while waterjet systems begin at $200,000-350,000 for comparable cutting areas.

Operating cost structures reveal ongoing expense patterns. Diamond blade replacement costs average $800-1,500 per blade with typical lifespans of 40-80 hours depending on material hardness. Waterjet systems consume abrasives costing $2-4 per hour plus high-pressure pump maintenance averaging $15,000-25,000 annually.

Energy consumption impacts operational budgets significantly. Sintered stone cutting machines typically consume 15-25 kW during operation, while waterjet systems require 45-75 kW for pump operation plus additional power for auxiliary systems.

Labor efficiency metrics show automation advantages. Modern CNC sintered stone cutting machines enable one operator to manage 2-3 cutting stations simultaneously. Waterjet systems typically require dedicated operator attention due to complex programming and material handling requirements.

Total cost of ownership calculations over five years show sintered stone cutting machines delivering 15-25% lower costs for standard rectangular cutting applications. Complex shapes requiring multiple operations favor waterjet technology despite higher initial investment.

If you need rapid payback on equipment investment with straightforward cutting applications, then sintered stone cutting machines offer superior financial returns for most fabrication operations.

Application-Specific Recommendations

Architectural glass and curtain wall projects demand precise dimensional control for panel fitting. Waterjet technology excels in these applications through superior edge quality and geometric accuracy. Complex notching requirements around structural connections benefit from waterjet's ability to create internal features without material stress.

Furniture and interior decoration manufacturing prioritizes production speed and surface quality. Sintered stone cutting machines deliver optimal results for table tops, countertops, and decorative panels where straight cuts dominate production requirements.

Large-format slab processing for construction applications benefits from the high-speed capabilities of diamond blade systems. Production volumes exceeding 100 m² per day favor sintered stone cutting machines due to their superior material throughput rates.

Custom artistic installations requiring intricate patterns and complex internal cutouts demand waterjet precision. The technology's ability to follow complex tool paths without tool changes enables creative designs impossible with conventional cutting methods.

Automated cutting lines integrate more easily with sintered stone cutting machines due to their predictable cycle times and simplified material handling requirements. Full production line automation projects typically specify diamond blade technology for consistency and reliability.

If you need maximum production flexibility for diverse customer requirements, then hybrid facilities incorporating both technologies provide comprehensive capabilities for any project specification.

HUASHIL Sintered Stone Cutting Machine Advantages

Shandong Huashil Automation Technology Co., LTD delivers advanced sintered stone cutting solutions designed specifically for high-volume production environments. Our engineering expertise spans over two decades in automated cutting technology development.

- Precision CNC Control Systems: Proprietary motion controllers achieve positional accuracy within ±0.05mm through advanced servo motor integration and real-time feedback systems

- High-Speed Diamond Blade Technology: Custom blade assemblies operate at optimized speeds up to 4,500 RPM with automatic speed adjustment based on material density detection

- Integrated Dust Collection: Advanced filtration systems capture 98% of cutting particles while maintaining consistent airflow across the cutting zone

- Automated Material Handling: Pneumatic clamping systems and conveyor integration enable lights-out operation for extended production runs

- Coolant Circulation Systems: Closed-loop cooling maintains optimal blade temperatures while recycling cutting fluids to minimize operational costs

- Customizable Cutting Configurations: Modular designs accommodate various slab sizes from 1200x600mm to 3200x1600mm with quick changeover capabilities

- Real-Time Production Monitoring: Integrated sensors track cutting performance, blade wear, and maintenance requirements through user-friendly interface systems

- Energy-Efficient Operation: Optimized motor controls reduce power consumption by 20-30% compared to conventional cutting systems

- Comprehensive Safety Systems: Emergency stops, blade guards, and operator protection systems exceed international safety standards

- OEM/ODM Customization: Flexible engineering services adapt standard machines to specific production requirements with rapid prototype development

- Global Service Network: 24/7 technical support with spare parts availability and on-site training programs for optimal equipment utilization

- Quality Assurance: ISO certification and rigorous testing protocols ensure consistent performance and long-term reliability

Conclusion

The choice between sintered stone cutting machines and waterjet technology depends primarily on your production requirements, quality specifications, and economic objectives. Diamond blade systems excel in high-volume applications requiring rapid processing speeds and consistent edge quality. Waterjet technology dominates complex cutting applications demanding superior precision and geometric flexibility.

Production managers must evaluate cutting speed requirements, material thickness ranges, and geometric complexity when selecting optimal technology. Cost analysis should include initial investment, operational expenses, and long-term maintenance requirements to determine true total cost of ownership.

HUASHIL's comprehensive range of sintered stone cutting machines addresses diverse fabrication needs through advanced automation technology, reliable performance, and comprehensive support services. Our commitment to continuous innovation ensures your investment delivers sustained competitive advantages in evolving market conditions.

Contact HUASHIL for Your Sintered Stone Cutting Solution

Selecting the right cutting technology requires careful consideration of your specific production requirements, budget constraints, and long-term growth plans. HUASHIL's experienced engineering team provides comprehensive consultation services to help you choose the optimal sintered stone cutting machine configuration for your manufacturing needs.

As a leading sintered stone cutting machine manufacturer, we understand the unique challenges facing artificial stone fabricators, curtain wall integrators, and furniture manufacturers. Our automated cutting solutions deliver proven results across diverse applications while maintaining the reliability and performance standards demanded by industrial production environments.

Whether you need single-machine installations or complete production line integration, our technical specialists work closely with plant managers and engineering teams to develop customized solutions. OEM and ODM services enable system integrators to incorporate our cutting technology into larger automated manufacturing systems.

Ready to enhance your sintered stone processing capabilities? Our application engineers provide detailed technical consultations, including production capacity analysis, ROI calculations, and implementation timelines tailored to your specific requirements. Contact us at salescathy@sdhuashil.com to discuss how HUASHIL's advanced cutting technology can optimize your fabrication operations and drive sustainable growth in your competitive market.