Another specialized tool to consider is glass cutting equipment and a glass engraving machine. While not strictly a cutting tool, engraving equipment can add another dimension to your architectural glass designs, allowing for the creation of frosted patterns, logos, or decorative elements directly on the glass surface.

Selecting the right glass cutting equipment for architectural glass projects is crucial for achieving precision, efficiency, and quality in your designs. Whether you're working on large-scale commercial buildings or custom residential projects, the right tools can make all the difference. In this comprehensive guide, we'll explore the key factors to consider when choosing glass cutting equipment for architectural applications, helping you make an informed decision that will elevate your projects to new heights.

Factors to consider: Size and thickness capabilities

When it comes to architectural glass, size and thickness are two critical factors that will influence your choice of cutting equipment. The diversity of architectural designs demands versatility in your tools, as you may need to work with glass panels of varying dimensions and thicknesses.

First, consider the maximum size of glass sheets you'll be working with. Large-format architectural glass is becoming increasingly popular, so ensure your cutting equipment can accommodate these expansive panels. Look for machines with ample cutting beds that can handle oversized sheets without compromising on precision or safety.

Thickness is another crucial aspect to consider. Architectural glass can range from thin decorative panels to thick, load-bearing structural glass. Your cutting equipment should be capable of handling this spectrum of thicknesses with equal precision. Some advanced glass cutting equipment offers adjustable cutting pressure, allowing you to fine-tune the tool for different glass thicknesses, ensuring clean, accurate cuts every time.

Additionally, consider the types of glass you'll be working with most frequently. While float glass is common in many architectural applications, you may also encounter tempered glass, laminated glass, or even specialty glasses with unique properties. Ensure your cutting equipment is compatible with these various glass types to maximize its versatility and utility in your projects.

It's also worth noting that some cutting equipment may offer multi-functional capabilities. For instance, some machines can not only cut but also score and break glass in a single process, streamlining your workflow and potentially reducing the need for multiple pieces of equipment.

Specialized tools for custom architectural designs

Architectural glass often requires more than just straight cuts. Custom designs, intricate patterns, and unique shapes are hallmarks of modern architecture, and your cutting equipment should be able to meet these demanding requirements.

CNC (Computer Numerical Control) glass cutting machines are invaluable for creating complex shapes and patterns. These advanced tools offer unparalleled precision and repeatability, making them ideal for large-scale projects that require consistent, high-quality cuts. CNC machines can execute intricate designs with ease, from curved edges to internal cutouts, opening up a world of possibilities for your architectural glass projects.

For more specialized applications, consider equipment with capabilities like waterjet cutting. This technology uses a high-pressure jet of water mixed with abrasive particles to cut through glass with exceptional precision. Waterjet cutting is particularly useful for creating intricate designs or working with extremely thick glass panels.

When evaluating specialized tools, consider the software that comes with the equipment. User-friendly design interfaces and compatibility with common CAD (Computer-Aided Design) formats can significantly streamline your workflow, allowing for seamless translation of designs from concept to finished product.

It's also worth considering the adaptability of your cutting equipment. Some machines offer modular designs or interchangeable cutting heads, allowing you to switch between different cutting techniques or add new capabilities as your needs evolve. This flexibility can be a valuable asset in the ever-changing world of architectural design.

Balancing precision and speed in large-scale projects

In the realm of architectural glass, large-scale projects often come with tight deadlines and high-volume requirements. Balancing precision with speed becomes crucial in these scenarios, and your choice of cutting equipment can significantly impact your ability to meet project demands.

High-speed cutting tables are designed to maximize productivity without sacrificing accuracy. These machines often feature multiple cutting heads that can work simultaneously, dramatically reducing processing times. When evaluating high-speed options, pay attention to factors like acceleration rates and maximum cutting speeds, as these will directly influence your overall productivity.

However, speed should never come at the expense of precision. Look for cutting equipment that maintains tight tolerances even at high speeds. Advanced motion control systems and robust machine frames help ensure that rapid movements don't result in vibrations or misalignments that could compromise cut quality.

Automation features can also play a significant role in balancing precision and speed. Automatic glass loading and unloading systems, for instance, can keep your cutting equipment running continuously, minimizing downtime between cuts. Similarly, automated optimization software can calculate the most efficient cutting patterns, maximizing material utilization and reducing waste.

Consider the ease of maintenance and durability of the glass cutting equipment as well. In high-volume production environments, unexpected downtime can be costly. Look for machines with robust construction, easily replaceable wear parts, and comprehensive warranty coverage to ensure your operations can run smoothly and consistently.

It's also worth considering the integration capabilities of your cutting equipment. Machines that can seamlessly connect with your existing production management systems can provide valuable data insights, helping you identify bottlenecks, optimize workflows, and further improve efficiency.

Lastly, don't overlook the importance of operator training and support. Even the most advanced cutting equipment requires skilled operators to achieve its full potential. Look for manufacturers that offer comprehensive training programs and responsive technical support to ensure your team can make the most of your investment.

Conclusion

Choosing the right glass cutting equipment manufacturer for architectural glass projects is a decision that requires careful consideration of various factors. From size and thickness capabilities to specialized tools for custom designs and the balance between precision and speed, each aspect plays a crucial role in determining the success of your projects.

By carefully evaluating your specific needs and the capabilities of different cutting equipment options, you can make an informed decision that will enhance your productivity, expand your design possibilities, and ultimately contribute to the creation of stunning architectural glass installations.

Remember, the right equipment is an investment in your business's future, enabling you to take on more challenging projects, improve efficiency, and stay competitive in the ever-evolving world of architectural glass design.

FAQ

1. What are the key features to look for in glass cutting equipment for architectural applications?

Key features include precision cutting capabilities, adaptability to various glass thicknesses, ability to handle large formats, and compatibility with different glass types. Advanced features like CNC control, automated optimization, and multi-functional capabilities (cutting, scoring, and breaking) are also valuable for architectural glass projects.

2. How does CNC glass cutting equipment benefit architectural glass production?

CNC glass cutting equipment offers superior precision, repeatability, and the ability to execute complex designs. It enables the creation of intricate patterns, curved edges, and internal cutouts with ease, expanding the possibilities for architectural glass designs while ensuring consistent quality across large-scale projects.

3. What role does automation play in glass cutting for architectural projects?

Automation in glass cutting equipment can significantly enhance productivity and efficiency. Features like automatic glass loading/unloading, optimized cutting patterns, and integration with production management systems can reduce downtime, minimize waste, and provide valuable data insights for process improvement.

4. How important is after-sales support when choosing glass cutting equipment?

After-sales support is crucial when selecting glass cutting equipment. Comprehensive training programs, responsive technical support, and reliable maintenance services ensure that you can maximize the potential of your equipment, minimize downtime, and quickly resolve any issues that may arise during operation.

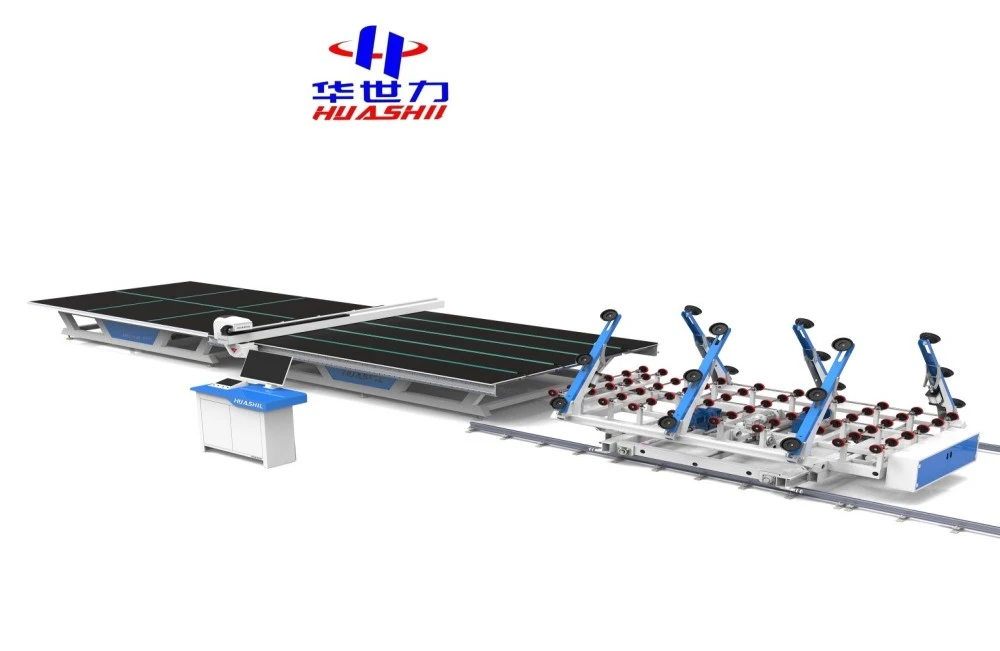

Quality Glass Cutting Equipment for Architectural Applications | HUASHIL

Looking for top-tier glass cutting equipment for your architectural glass projects? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art solutions designed to meet the exacting demands of the architectural glass industry. Our cutting-edge machines combine precision, speed, and versatility to help you tackle even the most challenging projects with confidence. Whether you're working on large-scale commercial buildings or custom residential designs, our equipment can help you achieve outstanding results efficiently and consistently. Don't settle for less when it comes to your glass cutting needs. Reach out to us at salescathy@sdhuashil.com to learn more about our product range and how we can tailor our solutions to your specific requirements. Let HUASHIL be your partner in elevating the quality and efficiency of your architectural glass production.

References

1. Smith, J. (2022). Architectural Glass Cutting: Advancements in Technology and Techniques. Journal of Architectural Engineering, 45(3), 112-128.

2. Brown, A. & Johnson, L. (2021). Precision and Efficiency in Large-Scale Architectural Glass Projects. Glass Technology International, 18(2), 45-59.

3. García, M. et al. (2023). CNC Technology in Architectural Glass Fabrication: A Comprehensive Review. International Journal of Architectural Glass and Metal Work, 7(1), 23-40.

4. Wilson, R. (2022). Balancing Speed and Accuracy in Modern Glass Cutting Equipment for Architecture. Architectural Glass Quarterly, 29(4), 78-92.