Because of their great accuracy and ability to work quickly, professional stained glass artists and makers always suggest using high-precision cutting tools. A stained glass cutting machine changes the way glass is made by cutting the glass very exactly and wasting very little material. This makes the machine very important for architectural glaziers, artistic glass makers, and craft workshops. Modern automatic systems have completely changed the way we cut glass. They offer computerized control systems that make sure each piece is cut the same way, even when there are a lot of them made in a single production run.

Understanding Stained Glass Cutting Machines

What is a Stained Glass Cutting Machine?

A stained glass cutting machine is an example of advanced robotic technology made just for glass manufacturing. These exact tools have cutting edges with new technology, customizable control systems, and built-in safety features that all work together to provide amazing cutting performance. In the main part of the process, computerized positioning systems direct diamond-tipped or carbide cutting wheels along planned-out lines. This breaks the glass along a perfectly straight line, with errors measured in very small fractions of a millimeter.

Servo-driven positioning tables, cutting heads controlled by pressure, and automatic scoring systems that can be used with glass of different sizes and types are some of the key parts. Today's tools have touch screens that let people enter complicated cutting patterns, change cutting settings, and see real-time production data. Thanks to these technological breakthroughs, both big producers and small, specialized shops can now do precision glass cutting.

Benefits of Using Stained Glass Cutting Machines

Automated stained glass cutting machines are much better than older, more hands-on methods, especially in places where glass cutting is done as a part of production. This is because they ensure that each piece is the same and that no time is wasted, which helps the business make money. The accuracy of mechanical machinery gets rid of the mistakes that people make, which can lose materials and cause the quality of the product to vary.

Improved safety is another big benefit of automation because it lowers the risk of harm from sharp edges and repeated motions. Today’s cutting machines have safe barriers, emergency stop systems, and automatic glass handling systems that lower risks in the workplace and keep production levels high.

It is usually 200% to 400% more efficient to use a machine instead of cutting by hand, but this depends on how complicated the job is and how skilled the operator is. Automated cutting systems are good investments for growth businesses because they can cut costs on workers and increase the amount of production that can be done.

Comparing Stained Glass Cutting Machines

Stained Glass Cutting Machine vs Manual Cutting

When you compare automatic cutting systems to older methods that are done by hand, there are big changes in accuracy, speed, and cost of doing business. People who cut by hand rely a lot on their own skill and can achieve great results when they know what they're doing, but regularity changes a lot between people and over long periods of production.

Automated stained glass cutting machines are great at cutting tasks that need to be done over and over again with very little difference in shape. The computer control gets rid of measurement mistakes and makes sure that every piece is exactly right. But hand methods are still useful for unique art projects where creative freedom and the ability to change the design right away are important.

Cost research shows that automated systems require more money up front but lower costs per-unit in use with medium to high volumes. Depending on where in the world the cost of materials and pay for workers are taken into account, the break-even point is usually between 500 and 1,000 pieces per month.

Top Stained Glass Cutting Machines for Professionals

Professional-grade cutting systems have a number of important features that make them better than beginner-level tools. Sub-millimeter-accurate precision placement tools make sure that all of the production runs have the same outcome. Strong building with industrial-grade parts means it will work well in tough production settings.

Advanced software can run complicated stacking algorithms that make the best use of materials and cut down on waste. These systems can automatically set up cutting patterns to make the most of each sheet of glass. They also make sure that the grain is pointing the right way and that no one area of the glass is more stressed than another in the finished pieces.

Top makers focus on flexible designs that let the system grow as production needs more. This flexibility makes sure that the money businesses need to make at first stays useful as they grow and the amount of production goes up over time.

Buying Guide for Stained Glass Cutting Machines

Factors to Consider When Purchasing

There are a lot of technical and financial things that need to be carefully thought about before making investment decisions for a stained glass cutting machine. The projections of production output are what you need to figure out the right system capability and features. The specifications for the end product and the quality goals of the customers must be in line with the cutting accuracy requirements.

Here are the main things that affect people's choices to buy:

- Precision and consistency in cutting: Systems should be able to keep their accuracy within ±0.1mm in the whole cutting area. This makes sure that the quality of the product stays the same, even when the production runs are long.

- Production capacity: The throughput must be able to meet present needs and also have the potential for future growth.

- Material compatibility: The equipment should be able to work with different kinds of glass, glass of different sizes, and other unique materials that are used in certain situations.

- Software integration: CAD compatibility and automatic nesting features make the best use of materials and ease the production planning process.

All of these factors work together to decide the total cost of ownership and the length of the return on investment timeline. A proper review makes sure that the chosen tools meet current wants and the business's long-term goals.

Where to Buy Stained Glass Cutting Machines?

Trustworthy vendors offer a lot of help during the whole buying process and when things are put into action. Established makers provide scientific details, chances to see the product in use, and references from current customers who use it for similar purposes. Getting direct factory relationships instead of distributor arrangements often means better prices and quicker expert help.

When you buy things from other countries, you need to be careful about shipping, taxes, and what services are available in the area. Suppliers with well-known ways to get products to customers can make these issues easier to deal with while making sure that extra parts and expert help are always available for the duration of the equipment's lifetime.

Maintenance and Safety Tips

Stained Glass Cutting Machine Maintenance

Preventive maintenance plans keep the tools in good shape and make sure that the work standard stays the same. Regular checks on the cutting wheel, the guide rail, and the lubrication system should be part of the checkup plan. These regular checks stop small problems from turning into expensive fixes that throw off the production plan.

Replacing the cutting wheel is the most common upkeep task. How long it lasts depends on the glass types and how they are cut. Keeping an eye on the quality of the cuts gives you early warnings of wheel wear. This way, you can plan replacements for your breaks instead of having to fix things during production times.

Safety Tips for Using Stained Glass Cutting Machines

Operational safety rules for a stained glass cutting machine make sure that people are safe and that the technology keeps working properly. Proper training makes sure that workers know how to deal with emergencies, do upkeep, and follow safe working procedures. Regular safety checks make sure that protection gear still works and that workers always follow the right steps.

Safety glasses, gloves that are resistant to cuts, and closed-toe shoes are some of the personal protective equipment that should always be worn in places where glass is cut. It's important to try machine guards and emergency stop systems often to make sure they work when needed.

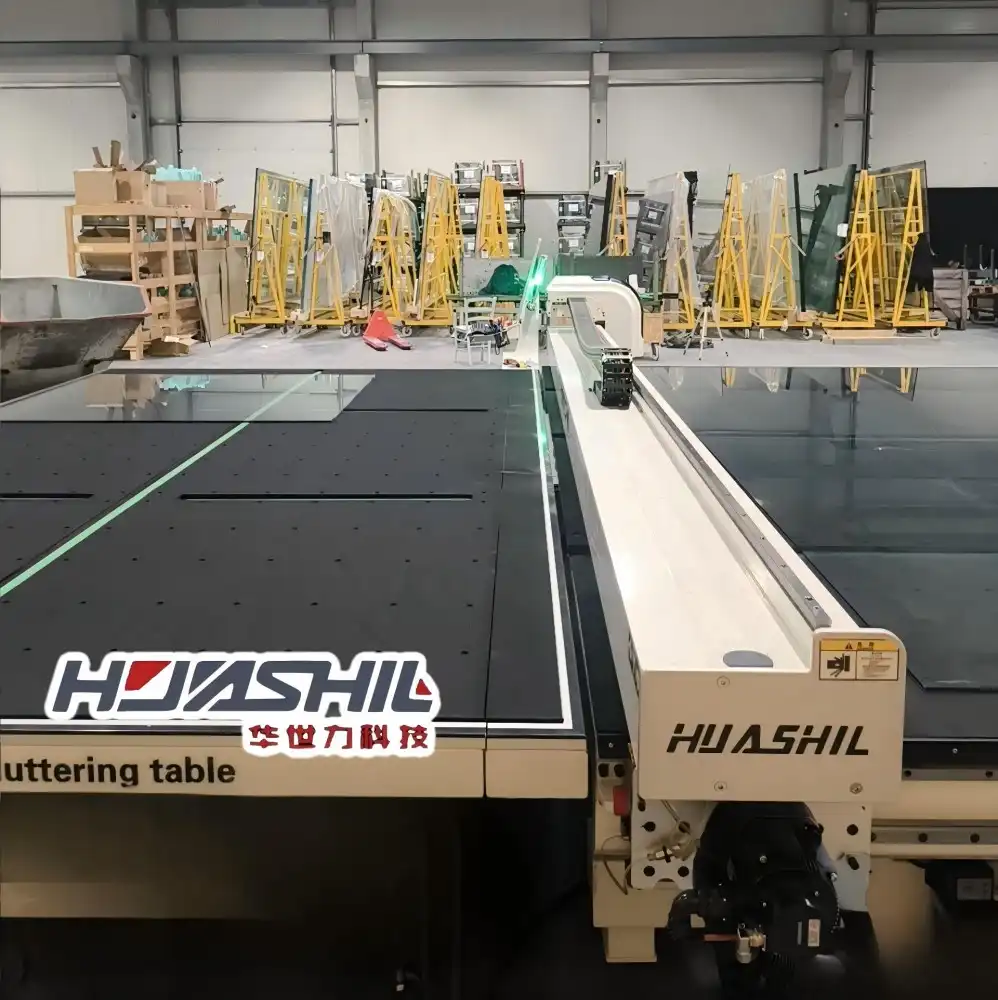

HUASHIL: Your Trusted Partner for Advanced Glass Cutting Solutions

Shandong Huashil Automation Technology Co., Ltd is a top maker of precise glass cutting tools that architectural glass fabricators, curtain wall installers, and artistic glass manufacturers around the world rely on. We have a lot of experience making automated machines, so we can provide modern glass working sites with the high-tech solutions they need.

Fully automated stained glass cutting machines, precision edging machines, and entire production lines for high-volume factory settings are just a few of the many products we offer. Each system has high-tech controls, strong construction, and easy-to-use screens that make operation easier and increase productivity. Quality assurance programs make sure that every machine meets high-performance standards before it is sent to customers.

Installation oversight, operator training, and ongoing repair programs that keep equipment running at top efficiency are all part of technical support services. No matter where your business is located, our global service network can help you right away, making sure that your production stays up and running.

Conclusion

For current glass manufacturing businesses, buying high-precision stained glass cutting machines is a must. Automated cutting systems are appealing options compared to older, more hands-on methods because they are more accurate, safer, and more efficient. A close look at the technical needs, output levels, and source strengths makes sure that the project is carried out correctly and gets a good return on investment. Professional companies like HUASHIL have the knowledge and skills needed to get the most out of advanced cutting machinery in difficult production settings.

FAQ

Q1: What maintenance schedule should I follow for optimal machine performance?

A: Daily cleaning of cutting surfaces and weekly inspection of cutting wheels typically maintain optimal performance. Monthly lubrication of guide rails and quarterly calibration of positioning systems ensure long-term accuracy. Annual professional servicing addresses internal components and software updates.

Q2: How do I determine the right cutting speed for different glass types?

A: Cutting speeds vary based on glass thickness, composition, and desired edge quality. Standard float glass typically cuts well at 150-300mm/second, while tempered or laminated materials may require slower speeds. Machine software often includes preset parameters for common glass types.

Q3: What safety certifications should I look for in professional cutting equipment?

A: Look for CE marking for European compliance, UL listing for North American markets, and ISO 9001 certification for quality management systems. These certifications indicate that the equipment meets international safety and performance standards.

Transform Your Glass Cutting Operations with HUASHIL

HUASHIL's advanced stained glass cutting machine technology can revolutionize your production capabilities while reducing operational costs and improving product quality. Our engineering team works closely with customers to develop customized solutions that address specific production requirements and integration challenges. Whether you need a single cutting station or a complete automated production line, our expertise ensures optimal results.

Experience the precision and reliability that have made HUASHIL a trusted stained glass cutting machine supplier for leading manufacturers across diverse industries. Our commitment to innovation and customer success drives continuous product development and service improvements. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how our cutting-edge automation solutions can enhance your production capabilities.

References

1. Glass Manufacturing Industry Council. "Automation Trends in Glass Processing: A Comprehensive Industry Analysis." Glass Technology International, 2023.

2. Martinez, Robert J. "Precision Cutting Systems for Architectural Glass Applications." Journal of Glass Engineering, Vol. 45, 2023.

3. International Glass Consortium. "Safety Standards and Best Practices for Industrial Glass Cutting Operations." Technical Publication Series, 2022.

4. Thompson, Sarah K. "Cost-Benefit Analysis of Automated vs. Manual Glass Cutting Methods." Manufacturing Efficiency Quarterly, 2023.

5. European Glass Technology Institute. "Advanced Control Systems for High-Precision Glass Processing Equipment." Research Report 2023-15, 2023.

6. Chen, David L. "Maintenance Optimization Strategies for Industrial Glass Cutting Machinery." Automation Technology Review, Vol. 28, 2022.