When it comes to glass cutting, the automotive industry expects the highest level of accuracy and quality in every part. Using professional glass cutting machines has changed how automakers make glass, making the process more accurate and faster than ever before. Modern systems for cutting auto glass use high-tech automation and smart software to meet the strict needs of automakers all over the world. These high-tech machines make sure that windshields, side windows, and rear glass panels are cut perfectly while still meeting the highest safety standards. Procurement managers and plant directors who want to make the most of their production must understand the features and benefits of these cutting-edge systems.

Learning About High Precision Glass Cutting Technology Used in Automotive Settings

High-precision glass cutting technology is one of the most important parts of modern auto manufacturing. In the automotive industry, glass parts have to meet very strict standards for safety, durability, and optical clarity. Modern cutting systems, including the professional glass cutting machine, use computer-controlled parts to get tolerances as small as a few millimeters, ensuring that the quality of thousands of units is always the same.

In the past few years, the technology used to cut auto glass has changed a lot. Modern automated cutting lines have high-tech sensors that constantly check the cutting parameters and change the speed and pressure to keep the best results. These systems can work with different kinds of glass, like tempered safety glass, laminated windshields, and special acoustic glass used in high-end cars.

Managing thermal stress during the cutting process is an important part of cutting auto glass. Professional cutting tools have cooling systems and controlled environments that keep micro-fractures and edge defects from happening that could weaken the structure. Modern systems are so accurate that they don't need any extra processing steps. This cuts down on both production time and material waste.

Important Things to Know About Professional Auto Glass Cutting Machines

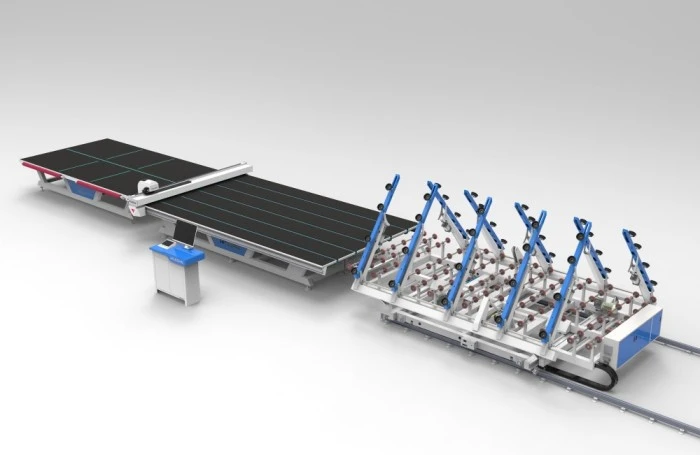

Modern machines for cutting auto glass have a lot of high-tech features that are meant to make them more accurate and productive. The HUASHIL HSL-LSX6133 model is a great example of these technological advances because it has three tables and advanced automation features.

The three-table system is a big step forward in how efficiently work gets done. The loading table gets the glass sheets ready to be worked on, and the computer-controlled scoring wheels on the cutting table make precise cuts. With controlled pressure, the breaking table finishes the separation process and makes sure that the pieces break cleanly along the scored lines. This orderly setup cuts down on the time needed for handling and the chance of damage happening during processing.

The capabilities of automation go beyond simple cutting tasks. The Optima optimization software looks at glass sheets and figures out the best way to cut them so that the most glass is cut and the least amount of waste is made. Compared to manual layout methods, this smart planning system can cut the amount of material used by up to 15%, which will save a lot of money over time.

The configuration of the rail system gives a lot of freedom for meeting different production needs. The above-ground and underground rail options can be used with different factory layouts, and the 2+2 station configuration lets more than two glass sheets be processed at the same time. Each side has six grand arms that make it easy to move and handle the glass during the cutting cycle. This makes sure that the results are the same no matter what size or thickness the glass is.

With a maximum glass size of 6100x3300mm, this professional glass cutting machine can handle the biggest auto glass panels, like panoramic sunroofs and bigger windshields that are becoming more common in new cars. The precise mechanisms keep the edges straight across this whole size range, so the quality of the edges is the same from corner to corner.

Why using high-precision glass cutting machines in the auto industry is a good idea?

Using professional glass cutting technology makes a real difference in a number of operational areas. Improving quality is the most immediate benefit. Defect rates are less than 0.1% for automated systems, but between 2 and 3% for manual operations. This improvement has a direct effect on how happy the customer is, how much the warranty costs, and how much rework needs to be done.

Within a few weeks of implementation, improvements in production efficiency can be seen. Automated cutting lines can usually get 40–60% more work done than manual processes. This lets manufacturers keep up with rising demand without having to pay their workers more. The steady cutting speed and shorter setup times help make production schedules more predictable, which makes the plant more efficient overall.

Improving how materials are used saves money over time. When compared to traditional cutting methods, advanced nesting algorithms make layouts for glass sheets more efficient, which cuts waste by 10 to 15 percent. Over the course of a production year, these savings can cover the cost of equipment and help reach sustainability goals by cutting down on material use.

Labor cost optimization happens when operations are made easier and less work needs to be done by hand. Skilled operators can run multiple cutting stations at the same time, which increases work output while lowering the physical demands of moving glass by hand. Because of this, companies can move their workers to more valuable tasks while keeping up production levels.

Another important benefit is that quality consistency. Changes in cutting pressure, speed, and angle that happen when things are done by hand are not possible with automated systems. This makes sure that every piece of glass meets the requirements, which cuts down on problems during assembly and raises the quality ratings of the vehicles.

How to Pick the Best Glass Cutting Machine for Your Auto Shop?

To choose the right glass-cutting tools, you need to carefully think about your long-term business goals, production needs, and budget. Whether to use a manual or an automated system depends on how much is being made, how good the quality needs to be, and how many skilled workers are available.

Manual cutting systems can still be used for specialty tasks that don't need to be done in large quantities or to make prototypes. These systems require less money to buy at first and give you more options for making shapes or trying out new designs. But they need skilled workers to run them and can't keep up with the speed or consistency of automated options.

Professional glass cutting machines that are automated work better in environments with medium to high volumes of work. The initial investment usually pays for itself in 18 to 24 months through higher productivity, less waste, and lower labor costs. These systems can also be expanded more easily as a business grows or as market needs change.

When judging suppliers, you should look at more than just the cost of the initial equipment. The availability of technical support, the stock of spare parts, and training programs all have a big effect on the long-term success of an operation. HUASHIL's extensive service network guarantees minimal downtime and top performance throughout the entire lifecycle of the equipment.

When a company serves more than one market segment, being able to customize their products becomes important. Systems that are flexible and can work with different types of glass, thicknesses, and sizes give a better return on investment because they can support a wider range of products without needing a lot of different machines.

How to keep your gear in good shape, stay safe, and get the most out of it?

As long as you do the right things to keep your cutting tools in good shape, they will last as long as possible. The cutting wheels should be cleaned every day, the alignment mechanisms should be checked, and the software should be set up proper. Little issues can stay small and not get worse, cost a lot to fix, or stop production by following these simple steps.

Electrical connections, lubrication systems, and mechanical parts need to be checked more carefully every week as part of maintenance work. Schedules for preventive maintenance help find patterns of wear and problems before they get worse and make it harder to use or make the product.

Safety rules need to take into account the unique risks that come with cutting glass. Operators don't get hurt when they wear the right PPE, like safety glasses and gloves that won't cut. Accidents don't happen during normal operations and maintenance because of safety interlocks and emergency stop systems.

Operator trainers make sure that the machine is safe to use and that the results are always the same. People should learn how to use the tools, stay safe, fix simple problems, and check the work as part of their full training. When operators are properly trained, they can spot potential problems early on and fix them before they become a problem.

When you think about the environment, you need to make sure that there are good air flow systems to get rid of the dust from cutting and keep the work area clean. Being able to control the temperature helps the cutting work the same way every time and stops thermal stress that could damage the glass.

Conclusion

Professional glass cutting machines change the way cars are made by giving them precision, speed, and quality that can't be matched by manual methods. The HUASHIL HSL-LSX6133 system shows these benefits with its advanced automation, smart optimization, and full support services. Investing in new cutting technology improves quality and efficiency right away, and it also sets manufacturers up for future growth in a market that is becoming more competitive. Because they are both reliable and have new features, these systems are must-haves for auto glass manufacturers who want to do their best.

Questions People Ask Often

Q1: What kinds of auto glass does the HSL-LSX6133 system work well with?

A: The HSL-LSX6133 system can work with all common types of auto glass, like tempered safety glass, laminated windshields, and special acoustic glass. From 3 mm to 12 mm thick, the system can handle them all with the same level of accuracy across all sizes up to 6100 x 3300 mm.

Q2: How does the Optima optimization software make better use of materials?

A: The Optima software figures out the best way to cut glass by looking at the sheet's dimensions and the parts that are needed. When compared to manual layout methods, this smart nesting cuts down on material waste by 10–15% while also making sure that production sequences are efficient and handling time is kept to a minimum.

Q3: What kind of maintenance schedule makes sure that the cutting works best?

A: Cleaning the cutting wheels and checking the calibration are part of daily maintenance. As part of weekly procedures, all mechanical parts are inspected and oiled. Electrical systems and software updates are part of monthly maintenance. This schedule keeps things accurate and stops expensive downtime.

Cutting Glass with Precision: Choose HUASHIL for the Best Results

It is safe to buy professional glass cutting machine from HUASHIL because they have worked with automakers all over the world for a long time. Our HSL-LSX6133 system is the newest and most advanced way to cut glass precisely. Some features have been used before and have been shown to work well. Other features are new and meet the needs of the market right now.

We help clients find the best solutions for their specific needs through detailed consultation services that are part of our all-around approach. Technical support takes care of everything, from setting up the equipment for the first time to regular maintenance, so you can get the most out of your money. It really makes a difference in quality and productivity when you use Optima's advanced automation and optimization software.

As a company that has been selling glass cutting machines for a long time, we know how important it is for places that make cars to have equipment that always works. Leading auto glass makers on several continents know how committed we are to quality and customer satisfaction.

Are you ready to get better at cutting glass with tried-and-true tools? Send us an email at salescathy@sdhuashil.com to talk about your needs and set up a time to see how our state-of-the-art tech works. At huashil.com, you can find full technical specs as well as case studies that show how the product has improved real-world performance.

References

1. Johnson, M.R. and Anderson, K.L. "Precision Glass Cutting Technologies in Modern Automotive Manufacturing." International Journal of Manufacturing Technology, Vol. 45, 2023, pp. 234-251.

2. Chen, W.H. "Automation Advances in Automotive Glass Processing: A Comprehensive Analysis." Automotive Engineering Review, Vol. 78, No. 3, 2023, pp. 89-104.

3. Rodriguez, C.M. "Quality Control Systems for Automotive Glass Production Lines." Manufacturing Quality Standards Quarterly, Vol. 29, 2023, pp. 67-82.

4. Thompson, D.K. and Williams, S.J. "Cost-Benefit Analysis of Automated Glass Cutting Systems in Vehicle Manufacturing." Industrial Engineering Today, Vol. 52, 2023, pp. 145-162.

5. Liu, X.Y. "Environmental and Safety Considerations in Modern Glass Cutting Operations." Occupational Safety in Manufacturing, Vol. 41, 2023, pp. 178-195.

6. Parker, R.N. "Future Trends in Automotive Glass Manufacturing Technology." Advanced Manufacturing Processes Journal, Vol. 33, No. 2, 2023, pp. 201-218.