For modern architecture, making glass needs to be very precise and quick. For this reason, high-precision CNC glass cutting machines are essential for modern architectural projects. These high-tech automated systems change the way architects and fabricators work on complicated glass installations. They provide unmatched accuracy while cutting down on production time and waste. As architectural glass designs get more complicated, CNC glass machines have become necessary tools for professionals who need to meet strict quality standards and tight project deadlines in today's competitive construction industry.

How to Understand CNC Glass Machines?

What is a CNC glass machine?

Cutting glass with CNC glass machines, which use computer numerical control systems to make cutting very precise, is the cutting edge of technology in the glass fabrication industry. Combining advanced software with mechanical parts, these machines can cut in complex patterns more consistently than traditional methods done by hand. Fabricators can use this technology to work with different kinds of glass, from regular float glass to special materials for architectural glazing.

Using automated glass cutting technology has benefits that go far beyond just making things more precise. Because these machines work continuously with little human input, production efficiency goes up by a lot. This is because labor costs go down while quality standards stay high. Because of precise cutting calculations and optimized glass layout patterns, a lot less material is wasted, which saves money and is better for the environment.

This is how the CNC glass machine works

Computer-controlled systems for cutting glass depend on CAD software and precise mechanical work working together in a very complex way. Engineers give the control system very specific instructions on how to cut things, and it turns these into precise mechanical movements. The cutting head follows predetermined paths with accuracy down to the micron level, making sure that every cut meets the exact requirements of the architecture.

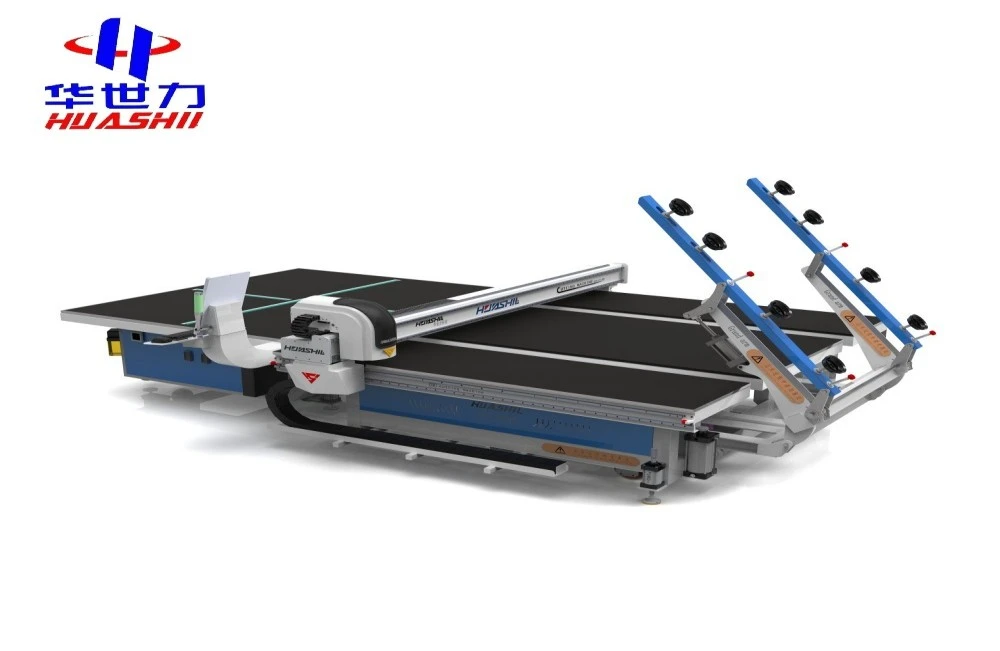

High-resolution servo motors, precision cutting wheels, and advanced positioning systems are some of the most important parts of these automated systems. The control panel shows real-time cutting progress and system diagnostics and is the link between the operator and the machine. During operation, structural frames keep the machine stable, reducing vibrations that could affect the accuracy of the cut.

CNC Glass Machine Types

Different kinds are available

The market for glass cutting equipment has a wide range of machine configurations that are made to fit the needs of different architectural projects. Knowing about these differences helps technical directors and procurement managers choose the best solutions for their factories. In the larger architectural glass industry, each type of machine is used for a specific task.

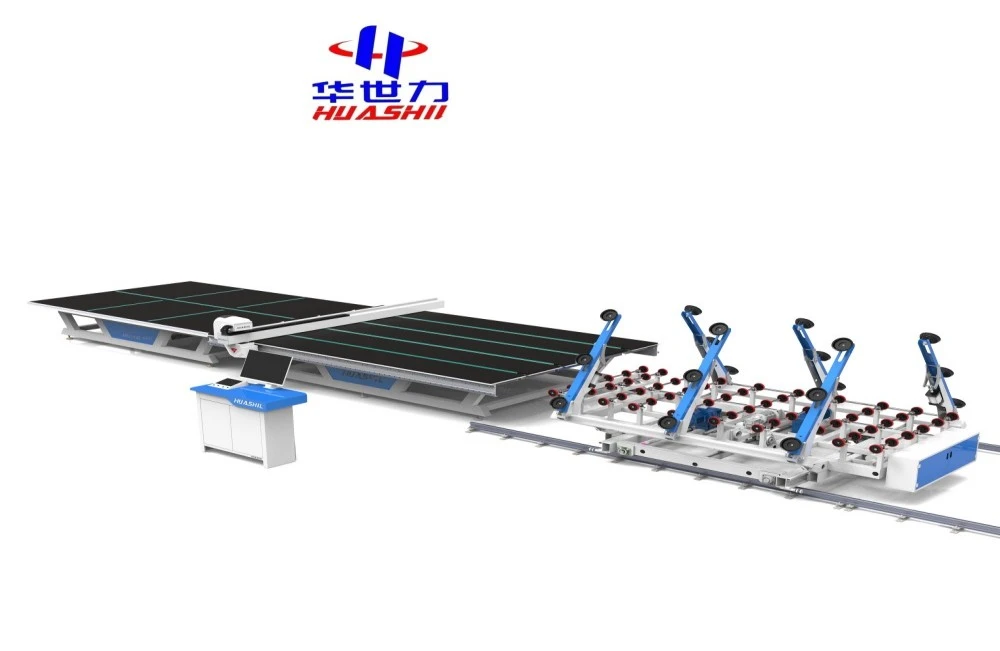

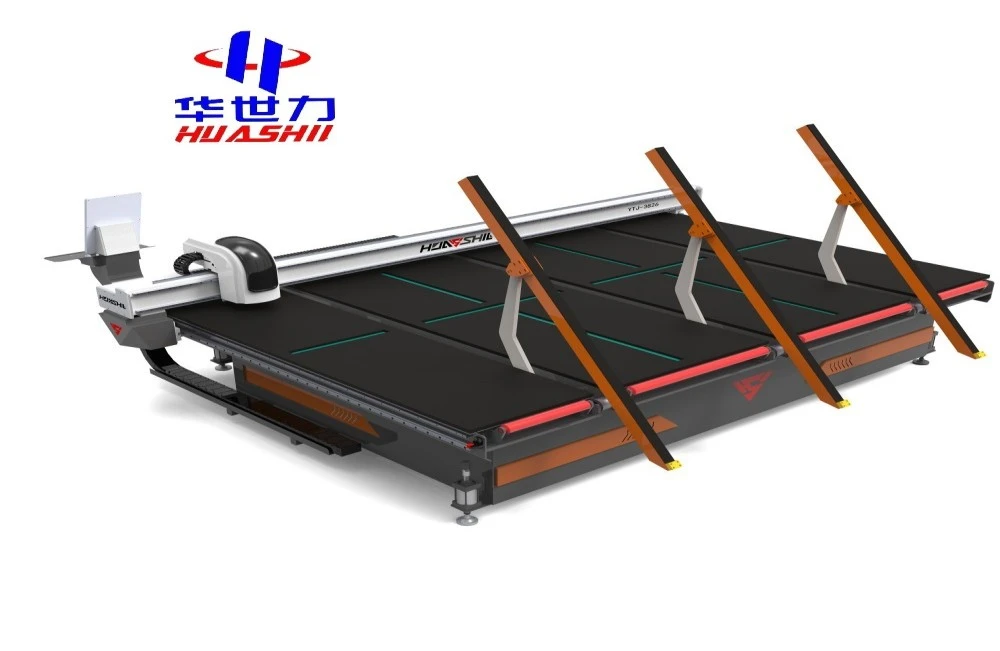

Architectural glass processors can usually pick from a few main types of automated cutting tools. Bridge-type machines are great for cutting large glass sheets like those used in curtain walls because they have large cutting areas and are built to last. Table-type systems are very stable and allow for precise work on smaller panels, which makes them perfect for use in furniture and interior design.

Waterjet cutting systems work perfectly with glass processing lines, making it possible to cut glass into shapes and patterns that are too complicated for other cutting methods. These machines are especially useful for building parts that need decorative elements or shapes that aren't typical. Laser cutting technology makes it possible to get very precise edges for specific uses where a high-quality finish is very important.

Compare the Features of CNC Glass Machines

To choose the right glass cutting automation, you need to carefully look at its technical specs and how it works. When comparing different systems, plant managers need to think about how fast they cut, how accurate they are, and how well they work with other software. These things have a direct effect on how well the product is made and how good it is in the end.

Cutting speeds that range from normal production rates to high-speed operations for mass production are important performance metrics. Positioning accuracy is usually measured within ±0.1mm tolerances by accuracy specifications. This makes sure that architectural glass meets strict building standards. As workflow processes become more streamlined by integrating with existing CAD systems, software compatibility becomes more important.

When making an investment, you should think about how much the equipment will cost to buy, how much it will cost to maintain, and the total cost of ownership. Ratings for energy efficiency have an effect on operational costs, while machine reliability has a direct effect on production uptime. Warranty coverage and access to technical support are very important for protecting large investments. CNC glass machines play a vital role in making sure all these factors are optimized.

Guidelines for keeping CNC glass in good shape

Looking after a CNC glass machine is important.

Even when they're not being used, maintenance plans keep things in good shape so they last for years. Regular maintenance plans make sure that there isn't too much unplanned downtime and that the cutting is accurate. Because you did it right, warranties stay valid and hardware stays valuable.

You should clean the glass chips and cutting residue every day. You should grease moving parts once a week and check the calibration of positioning systems once a month. If you cut a lot of different types of glass, you should check the cutting wheel often and get a new one every so often. Since it was updated, it now works better with new CAD systems and can still connect to older ones.

They need to be fixed by someone who knows what the problems are and why they happen. Too worn-out cutting wheels or systems that don't work right can cause this. If parts of the drive are worn out or not in the right place, the calibration might not be right. Standardized diagnostic steps make it easier for maintenance teams to quickly find and fix technical problems.

How to keep your CNC glass machine safe?

Auto-cut glass tools have rules in place to keep people and the tools safe. All of them should be followed. It is the job of safety people to make sure that operators know what to do and how to do it in real life. When you work, you need to protect yourself by wearing safety glasses, gloves that won't cut, and the right shoes.

To keep people safe, machines are built with emergency stop systems, protective barriers, and ways to make sure they shut down automatically when safety rules are broken. Every so often, safety checks are done to make sure that OSHA rules and the best ways to do things in the field are being followed. Anyone who breaks the rules of safety at work will be held responsible, and safety will always get better if these rules are written down.

Learn how to get CNC glass machines?

How to Find a CNC Glass Machine?

You should think about your budget, your technical needs, and the skills of the service provider before you buy automation to cut glass. Managers of purchases can make smart decisions that stick to operational goals and budgets now that they know these facts. You should first carefully think about what you need and write it down in clear terms before you go shopping for gear.

It costs money to buy equipment, set it up, teach people how to use it, and keep it running. This cost needs to be included in the budget. You could rent an investment, borrow money, or work with a company that will finance you if you want to pay for it over time. You can save money when you buy a lot of machines or whole production lines, including CNC glass machines.

Before you do business with someone, you should think about how knowledgeable they are in your field, how good they are at customer service, and how steady they will be in the long run. A great way to find out how well a supplier does their job and how reliable their gear is is to talk to current and past customers. They can help you with technical issues and get spare parts to you faster if they are close to each other.

Different ways to set up and ship

Services for setting up As soon as you set up the gear correctly, it will work better. It is usually up to the installation team to set up the software, put the hardware together, and do the first calibrations. Trainee programs help people learn how to use new tools quickly, even while they are still being set up.

Planned shipping is important to make sure that expensive equipment stays safe while it's being moved. Unique handling and insurance make sure that freight is safe while it's being shipped. So that they don't get behind schedule, delivery times should match up with when the teams can set up and prepare the space.

Introducing Our Company and Our Products

About Our Business

Shandong HUASHIL Automation Technology Co., Ltd. is a leader in automating the cutting of glass. They bring decades of engineering experience to the architectural glass industry. Because we know a lot about the problems that come up in production, we can come up with solutions that meet real-world manufacturing needs while also going above and beyond quality expectations.

Our dedication to excellence goes beyond just making equipment; it also includes full customer support for the entire lifecycle of the equipment. We can help you choose the right equipment, make your processes more efficient, and make your production more effective thanks to our technical knowledge gained through years of experience in the field. Customer success stories show that we can make a real difference in increasing productivity and profits.

Information on Products and Services

Offering a wide range of services helps customers succeed from the first meeting to many years of successful operation. Warranty coverage protects against defects and makes sure that the product, including CNC glass machines, works reliably during key production times. Through strategic inventory management and fast delivery, parts availability guarantees lower the risk of downtime.

Technical support services include remote diagnostics, service visits to the customer's location, and programs for training operators on how to get the most out of their equipment. Advanced glass cutting technology is available to businesses of all sizes thanks to payment plans and discounts for buying in bulk. Customization options make sure that the configurations of equipment meet the needs of production and the limitations of the facility.

Conclusion

Working with architectural glass is now easier, faster, and more flexible than ever thanks to CNC glass cutting machines. Builders and architects can use these high-tech tools to create complicated designs that still meet strict quality standards and tight deadlines for production. It takes longer to make things, costs less, and makes things better when you buy high-tech tools to cut glass. We still need CNC glass cutting technology to finish projects and help businesses grow, even though building plans are getting trickier and need to be more accurate.

Questions People Ask Often

1. What is the most accurate cutting that modern CNC glass machines can do?

It is common for modern CNC glass cutting systems to achieve positioning accuracy within ±0.1mm. For more precise tasks that need even higher accuracy, high-end models can reach ±0.05mm.

2. What are some ways that CNC glass machines work with different thicknesses of glass?

Cutting thicknesses of glass ranging from 2 mm to 25 mm can be handled by advanced CNC systems that have cutting parameters that can be changed and tooling configurations that are designed to work best with each material.

3. What kind of training do people who work with CNC glass machines need?

Most operator training takes three to five days of full instruction that covers how to use the machine, follow safety rules, do basic maintenance, and find your way around software for daily use.

Partner with HUASHIL for Advanced Glass Cutting Solutions

Architectural glass fabricators seeking competitive advantages through precision automation will find exceptional value in HUASHIL's advanced CNC glass machine technology. Our engineering team understands the unique challenges facing modern glass processors and develops solutions that deliver measurable improvements in productivity, quality, and profitability. As a trusted cnc glass machine supplier, we provide comprehensive support from initial consultation through years of reliable operation.

Investment in cutting-edge glass processing technology positions your operation for sustained growth and competitive advantage in demanding architectural markets. Our proven track record of successful installations demonstrates our commitment to customer success and operational excellence. Technical expertise combined with responsive service ensures maximum return on equipment investment.

Discover how HUASHIL's precision glass cutting automation can transform your production capabilities and accelerate business growth. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and explore customized solutions designed for your operational objectives. Visit our website at huashil.com to learn more about our comprehensive product offerings and service capabilities.

References

1. Glass Manufacturing Industry Council. "Advanced Manufacturing Technologies in Architectural Glass Production." Industrial Glass Technology Review, Vol. 45, 2023.

2. Johnson, Michael R. "Precision Automation in Modern Glass Fabrication: A Comprehensive Analysis." Journal of Manufacturing Technology, Vol. 31, No. 4, 2023.

3. International Association of Glass Manufacturers. "CNC Technology Applications in Architectural Glass Processing." Annual Manufacturing Technology Report, 2023.

4. Chen, Wei-Ming. "Computer-Controlled Glass Cutting Systems: Performance and Applications in Construction Industry." Advanced Materials Processing, Vol. 178, 2023.

5. European Glass Technology Institute. "Safety and Efficiency Standards for Automated Glass Processing Equipment." Technical Standards Publication, Edition 7, 2023.

6. Rodriguez, Carlos A. "Economic Impact of Automation in Architectural Glass Manufacturing." Manufacturing Economics Quarterly, Vol. 29, No. 2, 2023.