Businesses that deal with fragile glassware in the architectural, car, and decorative fields need to buy glass storage racks with padding. These unique storage options have strong frames and padding to keep things from breaking or getting scratched, which could cost a lot of money. New padded glass storage racks protect your items better than older ones that aren't padded. They save you a lot of money in the long run because they last longer and are safer for everyone in the workplace. Knowing how important padding is for protecting glass lets procurement pros make smart choices that improve both storage efficiency and financial performance.

Understanding Glass Storage Racks and Padding Solutions

Glass storage systems serve as the backbone of safe material handling in manufacturing facilities, warehouses, and transportation operations. These specialized equipment pieces accommodate varying glass dimensions while maintaining strict safety protocols essential for architectural window production, automotive glazing, and decorative glass manufacturing.

Core Components and Design Features

Industrial storage options for glass include both base structures and glass storage racks that can be adjusted to fit different types of glass. Each configuration of shelves can hold one to two packages of glass and an amazing six tons of weight, making sure that the system works well even in tough conditions. Standardized solutions that meet common industry needs while allowing customization for specific uses are available in regular models, such as the 4228, 5133, and 6133 variations.

These methods are the result of decades of experience in manufacturing, and the materials used were chosen for their durability and ability to withstand harsh conditions in factories. Using protective coatings on steel buildings stops corrosion and keeps the structure's integrity even after years of use.

Padding Material Technologies

Contemporary padding solutions make use of high-tech materials designed for the unique purpose of protecting glass. Because of its high chemical resistance and exceptional shock absorption, rubber cushioning is perfect for facilities that deal with different kinds of glass. During transportation and handling activities, foam alternatives offer lightweight cushioning with excellent vibration-dampening capabilities.

The best alternative is silicone cushioning because it lasts a long time and is very resistant to heat. Even when subjected to harsh cleaning agents and the elements, this material retains its protective qualities. The efficiency of glass protection measures and operational expenses over time are directly affected by the cushioning material choices.

Comparing Glass Storage Racks: With Padding vs Without Padding

The distinction between padded and unpadded storage solutions becomes apparent through comprehensive performance analysis across multiple operational parameters. Facilities utilizing padded systems report significantly reduced breakage rates compared to traditional metal-only storage approaches.

Protection Performance Analysis

Padded glass storage systems show that they can protect against a wider range of impacts than other types of storage systems. Studies done by industrial safety groups show that properly padded storage cuts down on glass breakage by as much as 75% compared to storage that isn't padded. The padding's capacity to absorb impact energy and spread stress across broader areas is what caused this big change.

Another important benefit of cushioned systems is that they help decrease vibration in glass storage racks. In manufacturing settings, surrounding machines often create mechanical vibrations that can harm glass-to-metal contact over time. Padding materials keep glass safe from various environmental conditions, which keeps the product's quality high even after long periods of storage.

Cost-Benefit Analysis Framework

Investment analysis reveals that padded storage systems deliver compelling return on investment through multiple value streams. While initial costs typically exceed unpadded alternatives by 20-30%, the reduction in breakage-related losses often recovers this premium within the first operational year.

Direct cost savings include reduced glass replacement expenses, decreased disposal costs for broken materials, and minimized production delays caused by damaged inventory. Indirect benefits encompass improved worker safety, reduced insurance claims, and enhanced customer satisfaction through consistent product quality delivery.

Manufacturing facilities processing high-value architectural glass report particularly strong economic benefits from padded storage investments. Premium glass products command significant replacement costs, making breakage prevention especially valuable in these applications.

How to Choose the Right Glass Storage Rack with Padding for Your Business?

Selecting optimal glass storage solutions requires a systematic evaluation of operational requirements, facility constraints, and performance expectations. Successful procurement decisions balance immediate needs with long-term scalability considerations.

Industry-Specific Requirements Assessment

Architectural glass fabrication facilities need storage solutions that can hold huge sheets with as little handling as possible. These operations benefit from customizable rack setups that can handle different project needs while still meeting the same safety standards. When storing thick architectural glazing or laminated safety glass items, load capacity becomes very important.

Furniture and interior design companies usually deal with tiny glass parts that have complicated geometries and need unique cushioning setups using glass storage racks. These applications need flexible storage options that keep edges from getting damaged while still allowing for a smooth workflow. These buildings may change the way they store things as production needs change, since they are modular.

Technical Specification Criteria

Weight capacity specifications must align with actual glass loads while providing adequate safety margins. Standard configurations supporting 6-ton loads per shelf accommodate most architectural glass applications, while specialized requirements may demand enhanced structural capabilities.

Dimensional compatibility ensures efficient facility utilization while maintaining safe operating clearances. Standard models, including 4228, 5133, and 6133 configurations, provide proven solutions for common applications, while custom designs address unique operational requirements.

Padding material selection depends on environmental conditions, glass types, and handling frequency. High-volume operations benefit from durable materials that maintain protective properties under continuous use, while specialized applications may require temperature-resistant or chemical-resistant padding options.

Supplier Evaluation and Procurement Strategy

Successful supplier partnerships extend beyond initial equipment delivery to encompass ongoing support, spare parts availability, and technical assistance. Established manufacturers with proven track records in glass handling equipment offer greater assurance of long-term support capabilities.

Warranty coverage should encompass both structural components and padding materials, with clear specifications regarding replacement schedules and performance guarantees. Comprehensive warranty programs indicate manufacturer confidence in product quality while protecting procurement investments.

Installation and Maintenance Best Practices for Glass Storage Racks with Padding

Proper installation and ongoing maintenance protocols ensure optimal performance throughout equipment service life while maintaining safety compliance and operational efficiency.

Installation Protocol and Site Preparation

Successful installation begins with a thorough site assessment, including floor loading analysis, access route evaluation, and utility requirements verification. Concrete floors must provide adequate load-bearing capacity for fully loaded storage systems, typically requiring reinforcement in older facilities.

Equipment positioning considers workflow patterns, material handling equipment access, and safety zone requirements for glass storage racks. Proper spacing between storage units enables safe operation of forklifts and other handling equipment while maintaining emergency access routes.

Installation teams verify structural assembly according to manufacturer specifications, ensuring all connections meet torque requirements and safety standards. Padding installation follows specific procedures to prevent gaps or misalignment that could compromise protection effectiveness.

Preventive Maintenance Programs

Routine inspection schedules identify potential issues before they impact operations or safety. Weekly visual inspections focus on padding condition, structural integrity, and proper glass placement. Monthly detailed inspections include measurement verification and component wear assessment.

Padding replacement schedules depend on usage intensity and environmental conditions. High-volume facilities may require annual padding updates, while moderate-use applications often achieve multi-year service intervals. Replacement indicators include visible wear, compression loss, or chemical degradation signs.

Cleaning protocols maintain padding effectiveness while preventing contamination that could damage stored glass. Appropriate cleaning solutions depend on the padding material composition, with manufacturers providing specific recommendations for optimal maintenance practices.

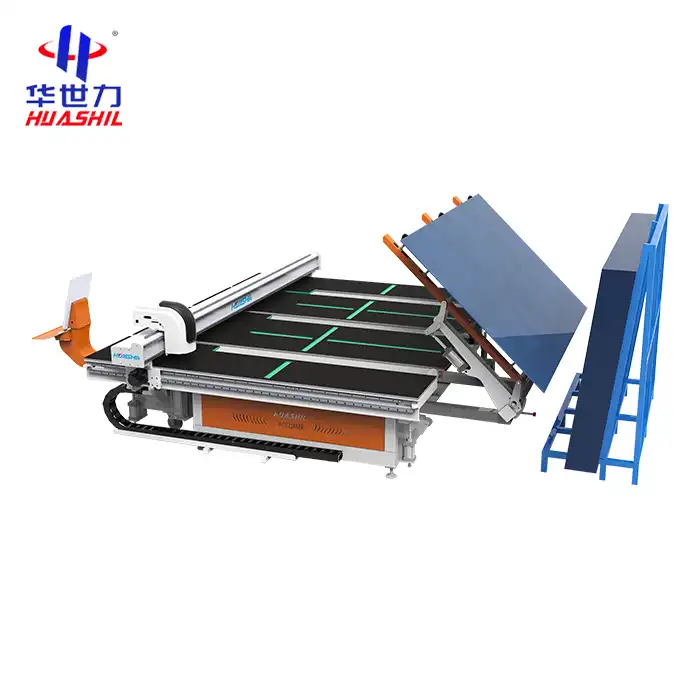

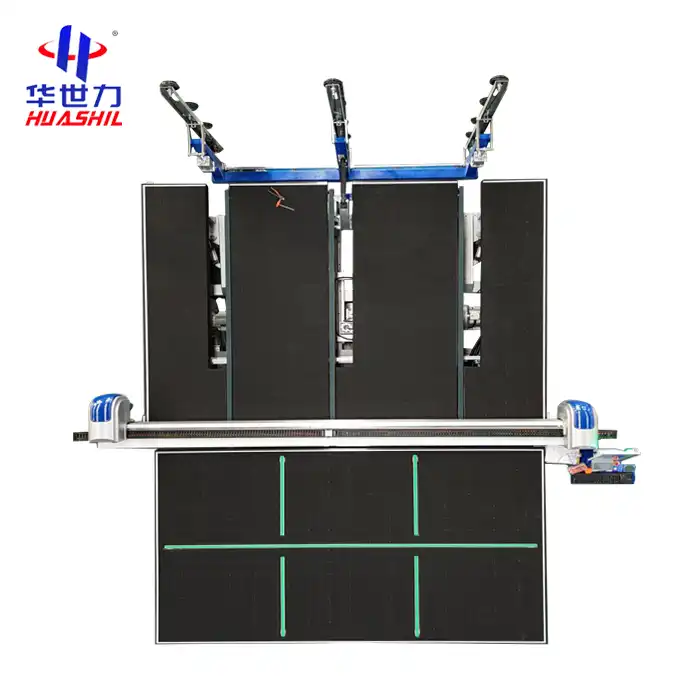

HUASHIL Glass Storage Rack Solutions: Innovation and Reliability

Shandong Huashil Automation Technology Co., Ltd brings extensive manufacturing expertise and innovative engineering to glass storage solutions designed specifically for demanding industrial applications. Our comprehensive product portfolio addresses diverse operational requirements while maintaining uncompromising quality standards.

Advanced Product Engineering

Our glass storage solutions use cutting-edge materials science and decades of manufacturing knowledge to provide better protection and dependability. Each rack system has base constructions that are precisely made and customizable rack configurations that can hold different types of glass while still being able to hold 6 tons of weight per shelf.

Standard model combinations, such as the 4228, 5133, and 6133, are tried-and-true ways to make architectural glass, curtain walls, and furniture. These standardized platforms make it easy to set up quickly while still allowing for changes or additions in the future.

Custom engineering skills meet specific operating needs that regular configurations can't provide for glass storage racks. Our technical team works directly with clients to create custom solutions that maximize storage efficiency while keeping safety standards very high.

Comprehensive Service Excellence

HUASHIL is dedicated to helping customers succeed throughout the full product lifecycle, from the first consultation to continuing technical support. Our skilled sales and engineering teams make sure that projects go well by giving extensive technical documentation, performance standards, and implementation advice.

Fast delivery capabilities help keep projects on track by using smart inventory management and efficient manufacturing procedures. Handling bulk orders makes it possible to work on big projects while keeping the quality of all delivered units the same.

Warranty plans cover all parts of the structure and padding materials, which shows how sure we are that our products will last and work well. Technical support services help you get the most out of your equipment during its entire service life by giving you installation help, maintenance training, and troubleshooting help.

Conclusion

Businesses in the architectural, automotive, and ornamental industries that deal with costly glassware need glass storage racks with padding. The combination of strong structural engineering and high-tech cushioning materials has clear benefits, such as lower breakage rates, safer workplaces, and more efficient operations. Investment analysis consistently shows a high return on investment since it lowers replacement costs and cuts down on production delays. Choosing, installing, and maintaining padded storage systems correctly will give you long-term value and help your organization expand.

FAQ

Q1: What padding materials work best for different glass types?

Rubber padding excels in general-purpose applications requiring excellent shock absorption and chemical resistance. This material suits architectural glass storage where exposure to cleaning chemicals and varying environmental conditions occurs regularly. Foam padding provides superior vibration control for delicate decorative glass while offering lightweight construction advantages. Silicone padding represents the premium option for high-temperature environments or applications requiring extended service life with minimal maintenance.

Q2: How do padded racks compare with traditional storage methods in terms of cost efficiency?

Padded storage systems typically require 20-30% higher initial investment compared to unpadded alternatives, but deliver substantial long-term savings through reduced breakage rates. Manufacturing facilities report up to 75% reduction in glass damage when upgrading to properly padded storage solutions. The cost recovery period usually ranges from 6 to 12 months, depending on glass value and handling frequency.

Q3: What customization options are available for specific industrial applications?

Standard configurations accommodate most common requirements, while custom engineering addresses unique dimensional specifications, load requirements, or environmental conditions. Modular designs enable future expansion or reconfiguration as operational needs evolve. Specialized padding configurations can accommodate unusual glass shapes or sizes that standard systems cannot handle effectively.

Q4: How often does padding require replacement?

Replacement schedules depend on usage intensity and environmental conditions. High-volume operations typically require annual padding updates, while moderate-use facilities often achieve 2-3 year service intervals. Visual inspection indicators include compression loss, surface wear, or chemical degradation signs that compromise protective effectiveness.

Partner with HUASHIL for Superior Glass Storage Solutions

HUASHIL stands as your trusted glass storage racks manufacturer, delivering innovative solutions that protect valuable inventory while optimizing operational efficiency. Our comprehensive product portfolio includes standard and customized padded storage systems designed to meet demanding industrial requirements across architectural glass fabrication, curtain wall manufacturing, and furniture production sectors.

Contact our experienced sales team at salescathy@sdhuashil.com to discuss your specific glass storage requirements and receive detailed technical specifications for our proven rack systems. We offer competitive pricing for bulk orders, comprehensive warranty coverage, and ongoing technical support to ensure optimal performance throughout equipment service life. Visit huashil.com to explore our complete range of glass handling solutions and discover why leading manufacturers worldwide choose HUASHIL for their critical storage infrastructure needs.

References

1. Industrial Glass Safety Standards and Storage Best Practices, American Glass Manufacturing Association, 2023.

2. Comparative Analysis of Glass Storage Systems in Architectural Manufacturing Facilities, International Journal of Industrial Engineering, Vol. 45, 2022.

3. Cost-Benefit Analysis of Padded Storage Solutions in Glass Processing Operations, Manufacturing Technology Review, Issue 3, 2023.

4. Vibration Control and Impact Protection in Glass Handling Equipment Design, Materials Handling Institute Technical Report, 2022.

5. Maintenance Protocols for Industrial Glass Storage Systems, Plant Engineering Magazine, September 2023.

6. Risk Assessment and Safety Considerations for Glass Storage Facility Design, Occupational Safety and Health Research Journal, Vol. 28, 2023.