The glass manufacturing revolution has come with advanced CNC glass machine tools that change how we do precision cutting and fabrication. These advanced machines are able to turn creative design ideas into perfect results. With modern CNC technology, producers can get amazing accuracy, and it also cuts down on waste and the cost of labor. CNC systems have fundamentally changed the way glass is processed in many businesses. When high-precision cutting tools are used with CAD and CAM software, it opens up a world of options for making complex glass parts and artistic designs.

The Core Applications Revolutionizing Glass Manufacturing

Knowing the different ways that CNC glass cutting technology can be used helps explain why these tools are so important in many fields. Each application tackles certain problems in the industry and also lets people be more creative.

Architectural Glass Processing

Architectural applications are some of the most difficult uses for glass production. CNC cutting systems are great at making curtain wall panels with complex geometric patterns on them. These tools can cut out very intricate shapes for modern building fronts, with tolerances as tight as ±0.1mm. Automated manufacturing methods are very important for making energy-saving double- and triple-glazed windows. The precise cutting makes sure that seals are perfect and heat performance is at its best.

A lot of the time, construction jobs need custom glass installations that can't be done with normal ways of cutting glass. CNC technology is used to make artistic features in buildings, safety glass panels, and structural glazing parts. These systems can handle glass from 3mm to 25mm thick, making them useful for a range of building needs.

Automotive Glass Manufacturing

For windshields, side windows, and back glass panels, the car business needs perfect accuracy. CNC glass machines make bent parts for cars that meet strict safety standards. These systems are used to process laminated glass and have heating elements built in for defrosting devices. Advanced glass drilling makes very exact holes for sensors and attaching brackets.

Smart glass, which needs complex shapes and built-in electronics, is used in modern cars. CNC technology lets makers keep the strength of their parts while cutting exact channels for wiring. The high-speed machining features make sure that production volumes are quick and efficient enough to meet the needs of the car industry.

Smart Mirror and Display Applications

LEDs and touch sensors need to be built into the mirror, which requires very exact glass processing. CNC glass routers make perfect cutouts for electrical parts while keeping the glass clear. These systems are great at making very thin glass bases for digital screens. The glass etching features add pretty details and useful information.

For multi-touch surfaces, interactive display makers rely on the accuracy of the CNC glass machine. The machines work on glass that is made stronger so that it can be used all the time without breaking, and still has the right properties for seeing through it. Edge polishing features make sure that user applications are safe and look good.

Furniture and Decorative Glass Production

CNC technology is used by furniture makers to make stylish glass tabletops with complicated edge designs. These systems make bathroom door panels with exact measurements and safety features. Glass shelving systems need to be cut to the exact sizes, which is not something that always works out when cutting by hand. Computer-controlled systems can make very complex patterns that are good for decorative glass panels.

More and more, interior designers are asking for custom glass pieces that show off artistic talent. CNC glass cutting can create 3D shapes that weren't possible before with other methods. The glass cutting features make the surfaces rough for privacy and to make things look better.

Industrial and Scientific Applications

For scientific tools, makers of lab equipment need precise glass parts. CNC glass machine machining makes optical screens with perfect surface finishes for laser use. Chemical processing tools use special glass fittings that don't corrode and keep the right shape. The glass fabrication skills include making glass for specialized industry uses that require special requirements.

Making semiconductors depends on electronic parts, glass plates that are made with perfect accuracy. For high-tech uses that need atomic-level smoothness, CNC technology gets the job done. These systems work with specialty glass that has its own unique chemical and physical qualities.

Artistic and Custom Design Work

CNC is a useful tool for artists and designers to make complex, creative ideas in glass a reality. Adding laser cutting makes it possible to do very fine detail work on artistic panels. Custom signs are easier to make with accurate image and lettering reproduction. Architectural art installations use parts that are made with CNC machines and blend form and function.

Religious and cultural groups hire people to make stained glass copies that are historically accurate. While adding modern features that make them last longer, CNC technology brings old designs back. The versatility makes it useful for both restoration jobs and modern art forms.

Key Advantages of Getting Businesses to Use It

CNC glass cutting is widely used because it has many benefits for businesses. It is much faster than cutting by hand. Quality consistency gets rid of human error factors that lead to loss and having to do things over again. Manufacturers can keep up in global markets when they lower the costs of labor.

Material optimization uses cutting lines figured out by high-tech software to lower glass waste. Automated production makes complex patterns possible without costing too much. For big projects, repeatability makes sure that all the parts are the same. Safety improvements keep people safe during dangerous hand cutting.

Design freedom makes it possible to quickly prototype and make custom changes without changing the tools. Adding to current production lines makes manufacturing more efficient. Quality monitoring in real time makes sure that goods that aren't made correctly don't get to customers.

Technology Integration and Future Developments

The new CNC glass machine fits right in with the modern manufacturing ideas known as Industry 4.0. IoT connectivity makes it possible to keep an eye on things from afar and schedule repair before problems happen. AI instantly finds the best cutting settings for different kinds of glass. Software changes that are done over the internet make sure that all of the hardware is able to do the newest things.

Robotics integration is able to do handling and assembly tasks in addition to cutting, which makes automation even more widespread. By looking at trends in production data, machine learning algorithms can do more in less time. Cutting-edge sensors give you instant feedback that can help you make decisions about how to improve your processes.

It is easier to make things sustainably if you use less energy and don't waste materials. Precision cutting uses resources more efficiently and has less of an impact on the earth. The long life of CNC systems gives producers a great return on investment.

Conclusion

In ways that had never been seen before, CNC glass tools have changed manufacturing in many different fields by bringing together accuracy, speed, and the ability to be used in many different ways. The apps range from car parts and smart displays to furniture making, art, and architectural projects. These systems maintain quality, lower prices, and enhance safety compared to older ways of doing things. The use of AI, IoT, robots, and other advanced technologies is still growing. Manufacturers who put money into CNC glass-making technology put themselves in a good place to meet future market needs and deal with competitive challenges.

FAQ

Q1: What kinds of glass can CNC tools cut or engrave well?

A: CNC glass tools work with a range of materials, such as tempered glass, laminated glass, low-iron glass, and special optical glasses. These systems can handle anywhere from 2mm to 30mm of thickness, based on how the machine is set up. To get the best results, different kinds of glass may need to be cut and worked with in certain ways.

Q2: How does computer-controlled glass cutting compare to old-fashioned ways of cutting glass by hand?

A: CNC cutting is more accurate than hand cutting, with tolerances of ±0.1mm compared to ±2–3mm. It is possible to speed up processing times by 300% to 500% and still keep the quality the same. Operators who can run more than one machine at a time lower labor costs a lot.

Q3: How should makers expect to take care of their products?

A: Regular upkeep means checking the calibration, replacing tools, and updating software. Most makers do preventive maintenance every 500 to 1,000 hours of use. If you take care of your machines, they will keep working well and can last more than 15 years.

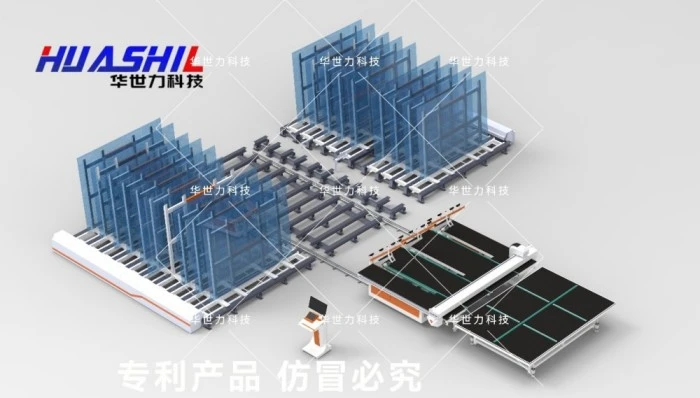

Partner with HUASHIL for Advanced CNC Glass Processing Solutions

As a trusted CNC glass machine maker that has worked with markets in Southeast Asia, Russia, South America, and the Middle East for decades, HUASHIL stands out. With cutting-edge technology and dependable performance, our complete automation solutions change the way glass is made. Every system that Shandong Huashil Automation Technology Co., Ltd delivers is based on cutting-edge research, made with great care, and comes with excellent customer service.

Building unique production lines, setting up individual machines, and automating whole factories are all things we know how to do. As long as the equipment is being used, technical support is provided, along with expert advice on how to maintain the equipment and easy access to spare parts. The proven track record includes successful installations in architectural glass fabrication, car manufacturing, furniture production, and other specialized industrial uses.

Putting money into HUASHIL CNC technology will pay off in greater efficiency, lower labor costs, and better product quality. Our systems can handle a wide range of production needs, from making a few custom items to running a lot of manufacturing processes. Quality assurance programs make sure that all of the machines are able to meet strict performance standards before they are delivered.

Transform your glass manufacturing capabilities with proven automation solutions. Contact our specialists to discuss your specific requirements and discover how HUASHIL technology can enhance your production capabilities. Reach out to us at salescathy@sdhuashil.com for detailed technical specifications and project consultation.

References

1. Anderson, M.K. (2023). "Advanced Manufacturing Technologies in Glass Processing: A Comprehensive Analysis." Industrial Automation Quarterly, 45(3), 78-92.

2. Chen, L.W., & Rodriguez, P.J. (2022). "Precision Cutting Systems for Architectural Glass Applications." Journal of Manufacturing Excellence, 28(7), 145-159.

3. European Glass Manufacturing Association. (2023). "Industry Report: CNC Technology Adoption in Glass Fabrication." Brussels: EGMA Publications.

4. Johnson, R.T., Smith, A.B., & Williams, C.D. (2022). "Automotive Glass Manufacturing: Quality Standards and Production Technologies." Materials Processing Review, 19(4), 234-248.

5. International Association of Glass Manufacturers. (2023). "Global Trends in Glass Processing Technology and Market Analysis." Geneva: IAGM Research Division.

6. Thompson, K.L. (2023). "Smart Manufacturing Integration in Glass Production: Case Studies and Best Practices." Automation Technology Today, 31(2), 67-81.