The glass industry has witnessed a remarkable transformation in recent decades, particularly in the realm of float glass cutting equipment. From humble beginnings with manual cutting tables to today's state-of-the-art fully automated lines, the journey has been nothing short of revolutionary. This evolution has not only enhanced productivity and precision but has also redefined safety standards in glass manufacturing. Let's explore this fascinating progression and its implications for the future of the industry.

Historical Perspective: Milestones in Glass Cutting

The history of glass cutting is as old as glassmaking itself. However, the modern era of float glass cutting began in the mid-20th century with the invention of the float glass process by Sir Alastair Pilkington. This innovation paved the way for the development of specialized cutting equipment.

In the early days, glass cutting was primarily a manual process. Skilled craftsmen used hand-held tools to score and break glass sheets. While this method allowed for customization, it was time-consuming and often resulted in inconsistent quality.

The introduction of manual cutting tables in the 1960s marked the first significant leap forward. These tables provided a flat surface for glass sheets and incorporated measuring tools, making the process more accurate and efficient. However, the cutting itself was still performed manually.

The 1970s and 1980s saw the emergence of semi-automated cutting systems. These machines featured motorized cutting heads that moved along tracks, guided by operators. This development increased cutting speed and improved precision, but still required significant human intervention.

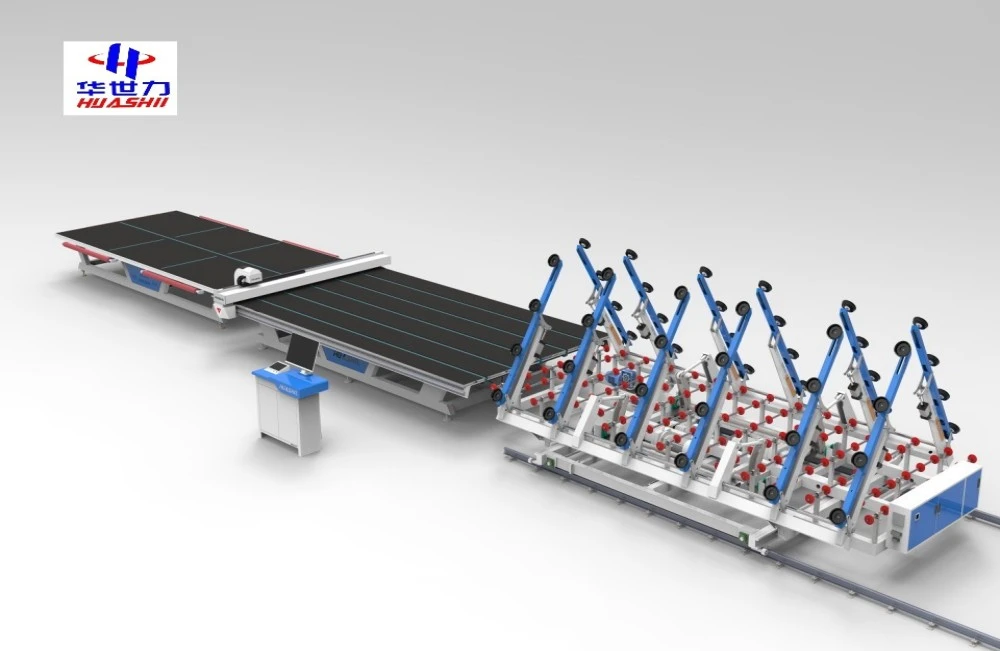

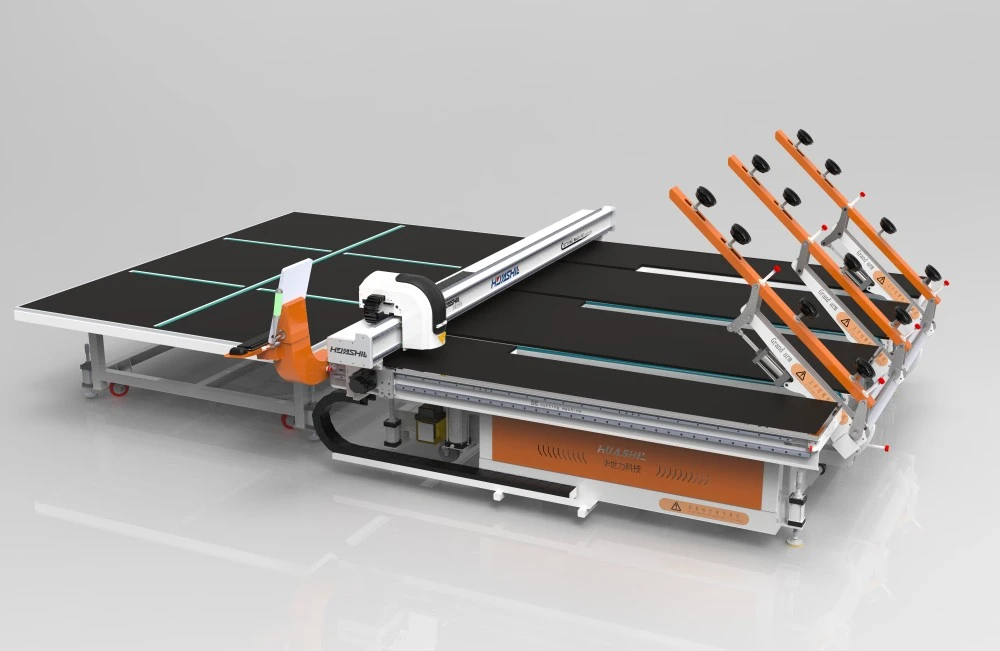

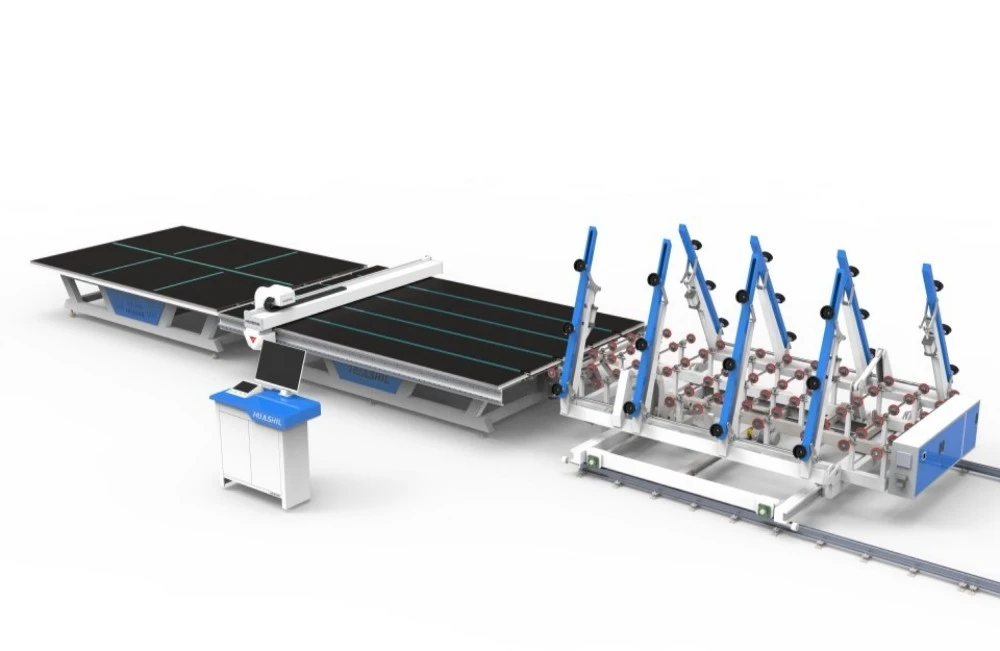

The real game-changer came in the 1990s with the introduction of fully automated float glass cutting equipment by China float glass cutting equipment factory. These systems integrated computer controls, allowing for programmed cutting patterns and minimal human input. This advancement not only boosted productivity but also dramatically improved cutting accuracy and consistency.

Automation Benefits: Increased Productivity and Safety

The shift towards automation in float glass cutting has brought numerous benefits to the industry:

- Enhanced Precision: Automated systems can achieve cutting tolerances as low as ±0.2mm, ensuring exceptional quality and reducing waste.

- Improved Productivity: Modern cutting lines can process hundreds of square meters of glass per hour, significantly outpacing manual methods.

- Reduced Labor Costs: While skilled operators are still needed, automated systems require fewer personnel to achieve higher output.

- Increased Safety: Automation minimizes direct human contact with sharp glass edges and heavy sheets, reducing workplace accidents.

- Optimized Material Usage: Advanced software can calculate the most efficient cutting patterns, maximizing yield from each glass sheet.

- Consistency: Automated systems ensure uniform quality across large production runs, crucial for industries like automotive and construction.

These advantages have made automated float glass cutting equipment indispensable in modern glass manufacturing facilities. Companies like Shandong Huashil Automation Technology Co., Ltd. have been at the forefront of this technological revolution, providing cutting-edge solutions to meet the evolving needs of the industry.

Future Trends: AI and Machine Learning Integration

As we look to the future, the evolution of float glass cutting equipment shows no signs of slowing down. The integration of artificial intelligence (AI) and machine learning (ML) is set to usher in a new era of smart manufacturing in the glass industry.

Some emerging trends include:

- Predictive Maintenance: AI algorithms can analyze equipment performance data to predict potential failures before they occur, minimizing downtime and maintenance costs.

- Adaptive Cutting Patterns: Machine learning models can optimize cutting patterns in real-time based on glass quality, reducing waste and improving yield.

- Quality Control: Advanced vision systems powered by AI can detect defects and imperfections at unprecedented levels of accuracy.

- Energy Efficiency: Smart systems can optimize energy consumption by adjusting equipment parameters based on production demands and environmental conditions.

- Collaborative Robots: The integration of cobots (collaborative robots) in glass cutting lines can further enhance safety and flexibility in manufacturing processes.

These advancements are not just theoretical; they're already being implemented by forward-thinking manufacturers. For instance, Shandong Huashil Automation Technology Co., Ltd. is actively researching and developing AI-enhanced float glass cutting equipment to stay ahead of industry trends and meet the evolving needs of its global clientele.

The journey from manual tables to fully automated lines has been remarkable, but it's clear that the evolution of float glass cutting equipment is far from over. As we move further into the 21st century, we can expect to see even more innovative solutions that will continue to reshape the glass manufacturing landscape.

For glass manufacturers looking to stay competitive in this rapidly evolving industry, investing in state-of-the-art cutting equipment from a China float glass cutting equipment factory is no longer optional—it's a necessity. The benefits in terms of productivity, quality, and safety far outweigh the initial investment costs.

Conclusion

The evolution of float glass cutting equipment from manual tables to fully automated lines represents a significant leap forward in glass manufacturing technology. This progression has not only enhanced productivity and precision but has also improved safety standards and opened up new possibilities in glass design and production.

As we look to the future, the integration of AI and machine learning promises to take float glass cutting to even greater heights. For businesses in the glass industry, staying abreast of these technological advancements is crucial for maintaining competitiveness and meeting the ever-increasing demands of the market.

Shandong Huashil Automation Technology Co., LTD stands at the forefront of this technological revolution, offering cutting-edge float glass cutting solutions that embody the latest advancements in the field. With years of experience in R&D, manufacturing, and export, Huashil has established itself as a trusted partner for businesses seeking to upgrade their glass cutting capabilities.

Are you ready to take your glass cutting operations to the next level? Don't let outdated equipment hold you back. Contact Shandong Huashil Automation Technology Co., LTD today to explore how our advanced float glass cutting equipment can transform your production line. Our team of experts is ready to provide personalized solutions tailored to your specific needs.

FAQ

Q1: What are the main advantages of automated float glass cutting equipment over manual methods?

A: Automated float glass cutting equipment offers several significant advantages over manual methods:

- Higher precision and consistency in cuts

- Increased productivity and output

- Improved safety for workers

- Reduced material waste through optimized cutting patterns

- Lower labor costs

- Ability to handle larger glass sheets and more complex cutting patterns

Q2: How has the evolution of float glass cutting equipment impacted the quality of glass products?

A: The evolution of float glass cutting equipment has significantly improved the quality of glass products in several ways:

- Enhanced cutting precision, resulting in more accurate dimensions

- Reduced edge defects and chipping

- Improved consistency across large production runs

- Ability to create more complex shapes and patterns

- Decreased likelihood of human error in the cutting process

- Better optimization of glass sheets, leading to a higher quality yield

Q3: What maintenance considerations are there for modern float glass cutting equipment?

A: Modern float glass cutting equipment requires regular maintenance to ensure optimal performance:

- Regular cleaning of cutting surfaces and components

- Lubrication of moving parts as per manufacturer guidelines

- Periodic calibration of cutting heads and measurement systems

- Replacement of cutting wheels or tools as they wear

- Software updates to ensure the latest features and optimizations

- Inspection and maintenance of electrical and pneumatic systems

- Regular checks on safety features and emergency stop mechanisms

Advanced Float Glass Cutting Equipment Solutions | HUASHIL

Looking for state-of-the-art float glass cutting equipment? Shandong Huashil Automation Technology Co., Ltd. is your trusted partner in glass manufacturing innovation. Our advanced cutting solutions combine precision, efficiency, and reliability to meet the demands of modern glass production.

Experience the Huashil difference: - Cutting-edge technology for superior accuracy - Customizable solutions to fit your production needs - Expert support and maintenance services - Competitive pricing without compromising on quality

Ready to elevate your glass cutting operations? Contact us today at salescathy@sdhuashil.com for a personalized consultation. Let Huashil help you stay ahead in the competitive world of glass manufacturing!

References

1. Smith, J. (2022). "The Technological Evolution of Float Glass Manufacturing". Journal of Glass Science and Technology, 45(2), 112-128.

2. Johnson, A. & Brown, L. (2021). "Automation in the Glass Industry: A Comprehensive Review". International Glass Review, 18(3), 67-85.

3. Zhang, W. et al. (2023). "AI and Machine Learning Applications in Modern Glass Cutting Processes". Advanced Manufacturing Technology, 12(4), 345-360.

4. Pilkington, D. (2020). "From Manual to Automated: A Historical Perspective on Glass Cutting Techniques". Glass Processing Quarterly, 33(1), 22-36.