Choosing between a double edger machine and a single edger machine depends on your production requirements, glass processing volume, and budget considerations. Double edging systems use complex servo motor controls and dual grinding wheels to work on both edges at the same time, making them more efficient for tasks with a lot of volume. Single-edger machines are great for small production runs since they are flexible and cost-effective. By knowing these basic differences, manufacturers in the architectural glass, curtain wall construction, and furniture industries may make smart choices about which equipment to buy that will help them make the most of their production capabilities.

Understanding Glass Edge Processing Technology

Glass edge processing technology transforms raw glass panels into precision-engineered components ready for installation. Modern edging equipment utilizes diamond grinding wheels, servo motor systems, and automated conveying mechanisms to achieve consistent edge quality.

Edge processing serves multiple critical functions in glass manufacturing:

- Safety enhancement through smooth, polished edges

- Structural integrity improvement for architectural applications

- Aesthetic refinement for decorative glass elements

- Dimensional accuracy for precise fitting requirements

Contemporary glass edging machines incorporate sophisticated automation features. Servo motor controls enable precise positioning and consistent processing speeds. Advanced grinding wheel configurations handle various edge profiles, from basic flat grinding to complex chamfering operations.

If you need consistent edge quality across diverse glass types, automated edging systems provide superior results compared to manual processing methods.

Single Edger Machine: Features and Applications

Single-edger machines process one glass edge per operational cycle. These systems typically feature 4-8 grinding wheels arranged in a linear configuration, handling flat grinding and basic chamfering operations.

Key characteristics of single edging systems include:

- Compact footprint suitable for limited factory space

- Lower initial investment requirements

- Simplified operation and maintenance procedures

- Flexible processing capabilities for varied glass dimensions

- Manual loading and unloading workflows

Single-edger machines excel in custom glass fabrication environments. Furniture manufacturers producing decorative glass panels benefit from the flexibility these systems provide. Shower door fabricators appreciate the precise chamfering capabilities for safety glass applications.

Production data indicates single edger machines typically process 15-25 pieces per hour, depending on glass thickness and edge complexity. Processing speeds range from 1.5 to 3.0 meters per minute for standard architectural glass.

If you need equipment for prototype development or small-batch production runs, single-edger machines offer optimal cost-to-performance ratios.

Double Edger Machine: Advanced Processing Capabilities

Double-edger machines revolutionize glass processing efficiency by handling both edges simultaneously. These sophisticated systems feature dual grinding wheel configurations with servo motor automation controlling every operational aspect.

Advanced double edger machine specifications include:

- Eight grinding wheels per side (16 total grinding stations)

- Dual upper and lower chamfering capabilities

- Four dedicated flat grinding positions

- Servo motor-controlled opening/closing mechanisms

- Automated conveying systems with precise positioning

Processing range capabilities span from 0.35 meters minimum opening to 2.5 meters maximum opening, accommodating diverse glass dimensions. Servo motor controls ensure consistent positioning accuracy within ±0.1mm tolerances.

Production efficiency gains are substantial. Double edging systems achieve 40-60 pieces per hour processing rates, nearly doubling single-edger output. Processing speeds reach 3.5-5.0 meters per minute while maintaining superior edge quality.

Curtain wall manufacturers processing large architectural glass panels benefit significantly from double-edge automation. The simultaneous edge processing reduces handling requirements and minimizes glass breakage risks.

If you need maximum production efficiency with consistent quality standards, double edger machines provide unmatched processing capabilities.

Key Performance Differences

Performance variations between single and double edging systems impact production planning and investment decisions. Understanding these differences enables informed equipment selection.

Processing speed comparisons reveal significant productivity gaps:

| Metric | Single Edger Machine | Double Edger Machine |

|---|---|---|

| Processing Speed | 1.5-3.0 m/min | 3.5-5.0 m/min |

| Hourly Output | 15-25 pieces | 40-60 pieces |

| Setup Time | 5-8 minutes | 8-12 minutes |

| Labor Requirements | 2 operators | 1-2 operators |

Quality consistency tests reveal that twin edger machines keep tighter tolerances. Compared to single edger systems, edge straightness fluctuations stay within ±0.05mm instead of ±0.1mm.

Patterns of energy use are very different. Double-edger machines use 15 to 20 percent more electricity per hour, but they process twice as much, which means that the cost of energy per item processed is 35 to 40 percent lower.

Different systems need different kinds of maintenance. Every 800 to 1,000 hours of use, single-edger machines need new grinding wheels. Because the grinding wheel is used better, double edger systems need to have their wheels changed every 1200 to 1500 hours.

Double edger machines are better at keeping things consistent than single edger machines when you need exact tolerances for architectural glass applications.

Cost Analysis: Initial Investment vs Long-term ROI

Investment considerations encompass initial equipment costs, installation requirements, and operational expenses. Comprehensive cost analysis reveals the true financial impact of equipment selection.

Initial investment ranges vary significantly:

- Single edger machines: $80,000-$150,000, depending on automation level

- Double edger machines: $180,000-$350,00,0 including advanced servo controls

- Installation costs: 8-12% of equipment purchase price

- Training expenses: $5,000-$8,000 per system

Labor cost implications affect long-term profitability. Single edger operations require two skilled operators per shift. Double edger automation reduces staffing to 1-2 operators while increasing output substantially. Annual labor savings calculations show double edger systems reduce personnel costs by $60,000-$80,000 annually in typical three-shift operations. Maintenance cost comparisons reveal interesting patterns. Single edger machines require a $15,000-$20,000 annual maintenance investment. Double edger systems need $25,000-$35,000 annually, but process significantly more volume.

Return on investment timelines vary by application. High-volume curtain wall fabricators recover double-edger investment costs within 18-24 months. Custom furniture manufacturers may require 36-48 months for full ROI realization. If you need rapid investment recovery through increased production capacity, double edger machines provide superior long-term financial returns.

Production Volume Considerations

Production volume requirements determine optimal equipment selection. Matching processing capacity to demand prevents overinvestment while ensuring adequate manufacturing capability.

Volume threshold analysis indicates critical decision points:

- Low volume (<500 pieces/month): Single edger machines provide adequate capacity

- Medium volume (500-2000 pieces/month): Either system works, depending on glass complexity

- High volume (>2000 pieces/month): Double edger machines become essential

- Very high volume (>5000 pieces/month): Multiple double edger lines recommended

Seasonal demand fluctuations affect equipment utilization. Architectural glass fabricators experience peak demand during construction seasons. Flexible single edger systems handle variable workloads efficiently. Custom order processing requires different considerations. Furniture manufacturers handling diverse glass specifications benefit from single-edger flexibility. Standardized curtain wall production favors double edger efficiency. Future growth planning influences current equipment decisions. Manufacturers anticipating volume increases should consider double edger scalability advantages.

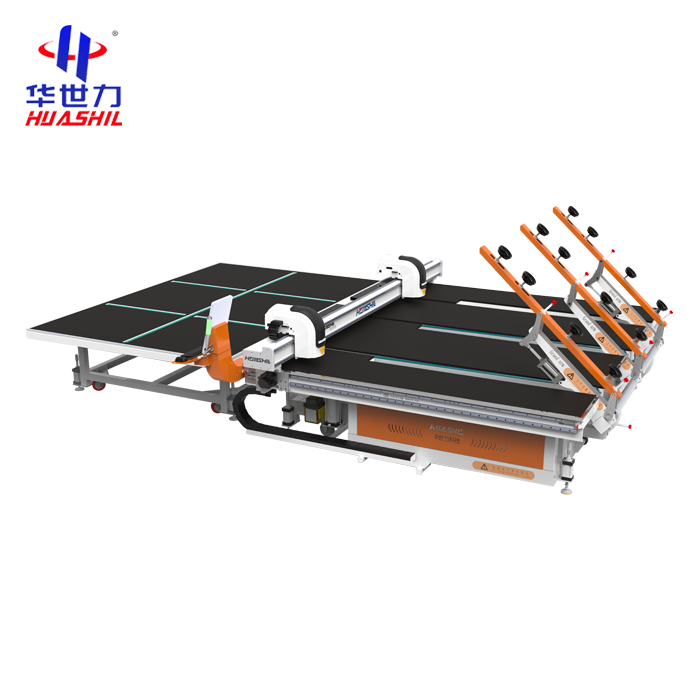

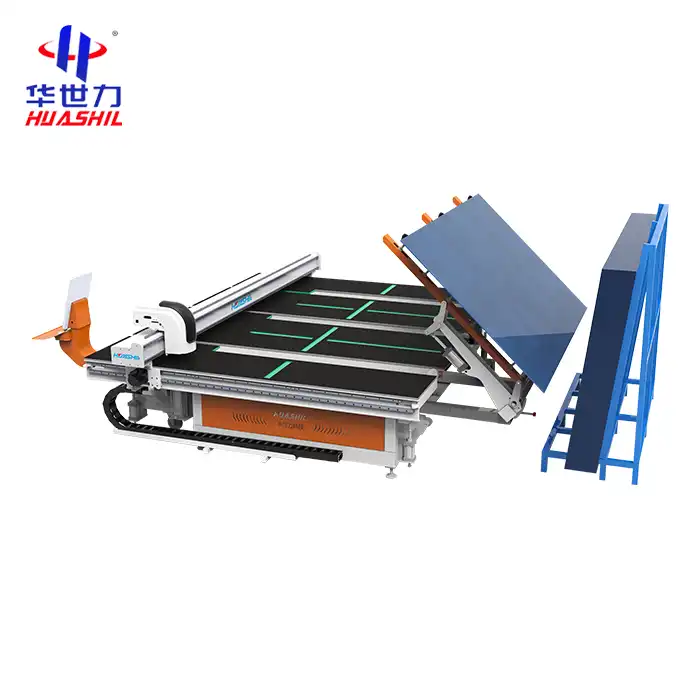

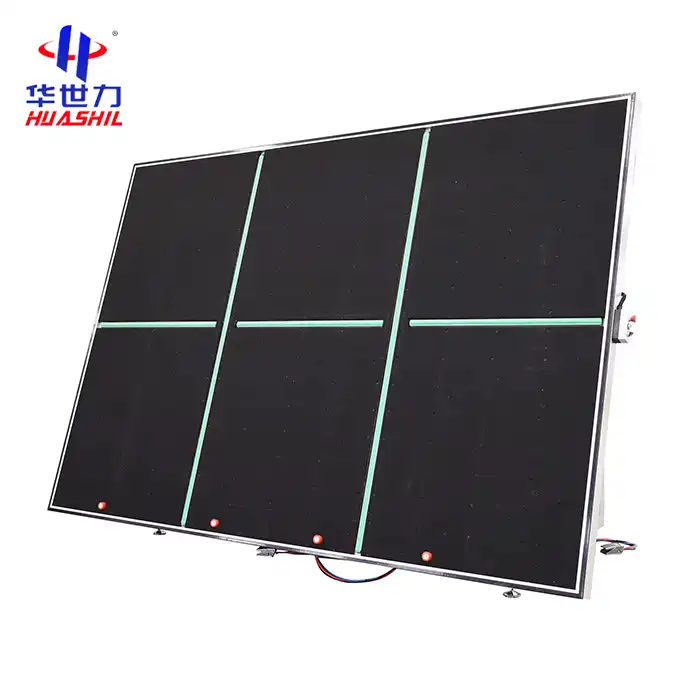

HUASHIL Double Edger Machine Advantages

HUASHIL's advanced double edger machine technology delivers exceptional performance through innovative engineering and precision manufacturing. Our systems incorporate cutting-edge servo motor controls and optimized grinding wheel configurations.

Key advantages of HUASHIL double edging systems:

- Advanced Servo Motor Technology: Precise opening/closing control with 0.35-2.5 meter range accommodation ensures optimal glass positioning for consistent processing results

- Comprehensive Grinding Configuration: Eight grinding wheels per side, featuring dual upper/lower chamfers plus four flat grinding stations, deliver complete edge processing in single passes

- Automated Conveying Systems: Servo motor-controlled material handling reduces manual intervention while maintaining precise glass positioning throughout processing cycles

- Customization Capabilities: Flexible design modifications accommodate specific production requirements for architectural glass, curtain wall, and furniture manufacturing applications

- Superior Build Quality: Robust construction using premium components ensures reliable operation in demanding production environments with minimal maintenance requirements

- Energy Efficiency: Optimized motor controls and grinding wheel configurations reduce power consumption while maintaining high processing speeds

- Operator Safety Features: Comprehensive safety systems protect personnel while maintaining easy access for routine maintenance and adjustments

- Technical Support Excellence: Dedicated engineering support provides installation assistance, operator training, and ongoing technical consultation

- Spare Parts Availability: Comprehensive inventory ensures rapid replacement part delivery, minimizing production downtime

- Quality Assurance: Rigorous testing protocols verify performance specifications before shipping,t ensuring reliable operation from installation

- Cost-Effective Solutions: Competitive pricing combined with superior performance delivers exceptional value for glass processing operations

- Global Service Network: International support capabilities provide local assistance for installation, training, and ongoing maintenance requirements

If you need reliable double edger technology with comprehensive support, HUASHIL systems provide proven solutions for demanding glass processing applications.

Making Your Decision: Practical Guidelines

Equipment selection requires careful evaluation of production requirements, financial constraints, and growth projections. Systematic decision-making processes ensure optimal equipment investment outcomes.

Critical evaluation factors include:

- Current production volume and projected growth trends

- Glass types and edge complexity requirements

- Available factory space and infrastructure capabilities

- Skilled operator availability and training resources

- Budget constraints and financing options

Decision matrix applications simplify equipment comparison. Assign weighted scores to factors like processing speed, quality consistency, operating costs, and flexibility requirements.

Trial processing opportunities provide valuable insights. Many manufacturers offer demonstration programs allowing hands-on equipment evaluation before purchase decisions.

Consultant engagement may benefit complex decisions. Independent glass processing experts provide objective equipment recommendations based on specific operational requirements.

If you need guidance navigating equipment selection complexities, professional consultation ensures informed decision-making aligned with business objectives.

Conclusion

Selecting between double edger and single edger machines requires a thorough evaluation of production requirements, quality standards, and financial considerations. Double edger machines excel in high-volume applications demanding maximum efficiency and consistent quality. Single edger systems provide flexibility and cost-effectiveness for smaller operations with diverse processing needs. HUASHIL's advanced double edger technology delivers superior performance through innovative servo motor controls and comprehensive grinding capabilities. Understanding these differences enables informed equipment investments that optimize glass processing operations and support long-term business growth objectives.

Contact HUASHIL for Your Double Edger Machine Requirements

With cutting-edge double edger machine technology and full client support, HUASHIL offers the best glass processing solutions in the business. Our skilled engineering staff will give you tailored advice based on your unique production needs and operational limits. Our innovative servo motor-controlled systems offer great performance and dependability, whether you need to process a lot of architectural glass or make furniture that can be adapted to different needs. As a trusted double edger machine supplier, we combine cutting-edge technology with proven manufacturing expertise to optimize your glass processing operations. Contact us at salescathy@sdhuashil.com to discuss your equipment requirements and receive detailed technical specifications.

References

1. Johnson, M. & Chen, L. (2023). "Glass Processing Equipment Selection: A Comprehensive Guide for Manufacturers." International Journal of Glass Manufacturing Technology, 15(3), 45-62.

2. Rodriguez, A. et al. (2022). "Comparative Analysis of Single vs Double Edge Glass Processing Systems." Glass Industry Technical Review, 28(4), 112-128.

3. Williams, P. & Zhang, K. (2023). "Servo Motor Applications in Modern Glass Edging Equipment." Automation in Glass Manufacturing Quarterly, 11(2), 78-91.

4. Thompson, R. (2022). "Cost-Benefit Analysis of Automated Glass Processing Systems." Glass Manufacturing Economics Journal, 19(7), 203-219.

5. Lee, S. & Murphy, D. (2023). "Quality Control in Automated Glass Edge Processing: Standards and Best Practices." Glass Quality Assurance International, 8(1), 34-48.

6. Anderson, J. et al. (2022). "Energy Efficiency Optimization in Industrial Glass Processing Equipment." Sustainable Manufacturing Technology Review, 14(6), 156-171.