When choosing the right glass processing equipment for your business, you need to think carefully about how it can be automated, how it can be customized, and how reliable it will be in the long term. To make glass today, you need precise tools that can do a lot of different jobs, from building glazing to decorative panels. The right equipment partner will combine cutting-edge technology with adaptable production options to make sure your production line can meet the needs of both current and future growth. When standard machinery can't meet your specific operational needs or market positioning strategies, it's important to understand how OEM and ODM partnerships work.

How OEM/ODM Solutions Work in Glass Processing?

Partnerships between Original Equipment Manufacturing (OEM) and Original Design Manufacturing (ODM) change how glass fabrication plants buy equipment. OEM agreements let you put your company's name on designs for already-made machines, while ODM services make completely new machines that are made to your exact specifications.

The glass cutting machine business has changed a lot over the years. Now, manufacturers offer a lot more customization options than just basic branding. Modern machines for edging glass can be changed to work with different thicknesses of material, different processing speeds, and different needs for integration. This adaptability is very important for curtain wall manufacturers who need to keep exact measurements and edge quality consistent.

Processing tempered glass comes with its own problems that can't always be solved with regular tools. Architectural glass fabricators can meet all the requirements set by building codes and aesthetic standards with the help of custom automation solutions. The success of a project often depends on how well the machine can be changed to fit the needs of the job.

What Makes HUASHIL a Good OEM/ODM Company?

It has been decades since Shandong Huashil Automation Technology Co., LTD has made automated glass-making machines. Our engineering team knows how hard it is to work with flat glass and how precise it needs to be for modern building uses.

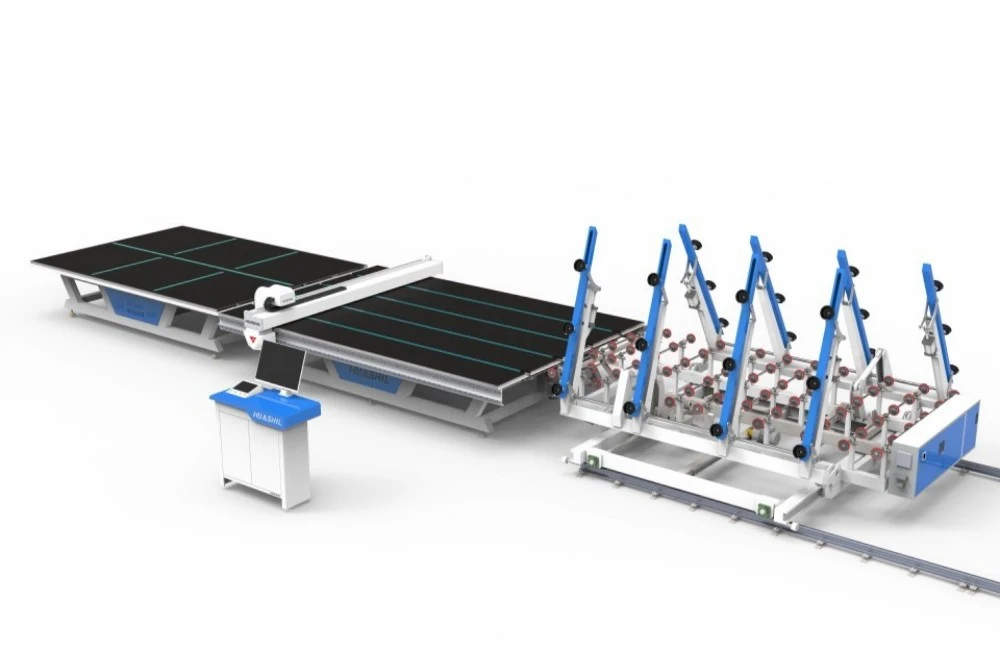

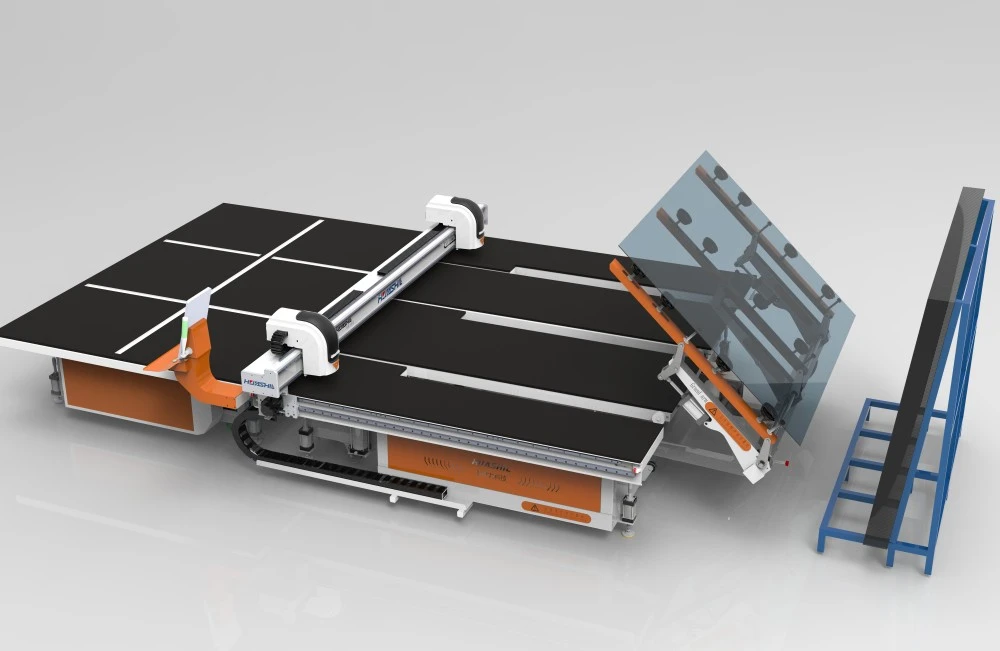

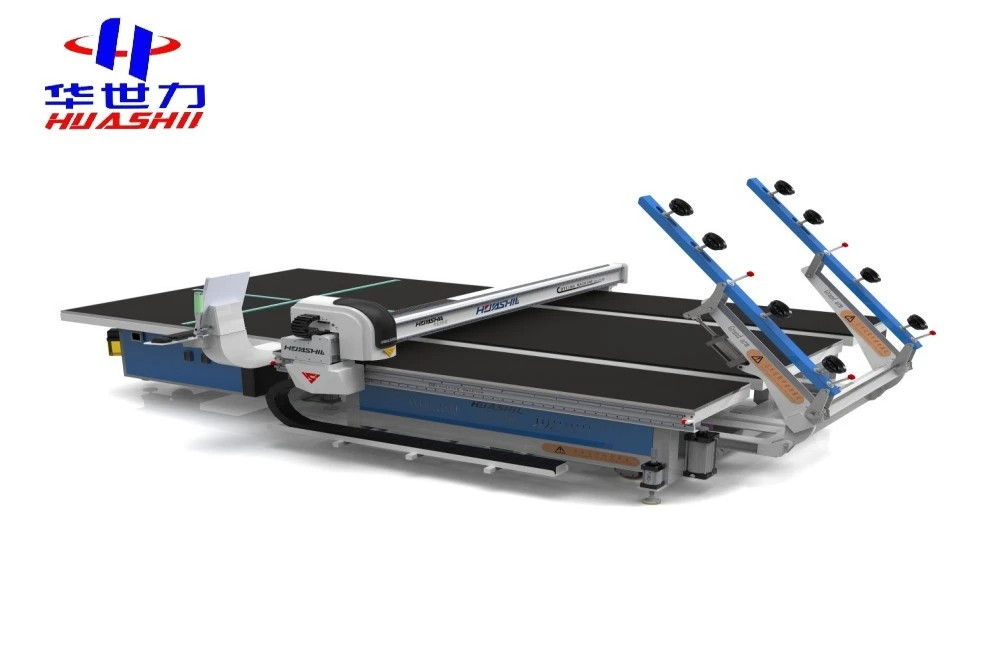

Standard glass polishing equipment isn't the only thing we can make. We design full production lines that work with the way things are done now. The HSL-LSX5133 model shows how committed we are to new ideas because it has three specialized tables that work together perfectly: a loading table, a cutting table, and a breaking table.

Quality control is still the most important part of how we make things. Before it is sent out, every CNC glass cutting system goes through a lot of tests. Our quality assurance protocols make sure that the product works the same way in all kinds of conditions and with all kinds of materials.

With our knowledge of the supply chain, we can find high-quality parts at prices that are competitive. Because we work with top automation suppliers, we can make prototypes quickly and efficiently scale up production. When making custom glass washing machines or specialized glass inspection systems, this network is very helpful.

Using the latest technology

Our Optima optimization software is a big step forward in how efficiently glass processing equipment is used. This smart system figures out the best way to cut things, so less material is wasted and more work gets done. The software automatically changes to fit different types of glass and thickness needs.

Both above-ground and underground rail systems can be set up in a number of different ways. Our 2+2 station setup lets us work on multiple glass sheets at the same time. There are five large arms on each side that make sure the material is handled safely throughout the processing cycle.

The largest size of glass that can be used is 5100x3300mm, which can fit large architectural panels and extra-large decorative elements. Because of this, our equipment can be used for high-value commercial projects that can't use standard machinery because of their size.

Lots of options for customization

Specific space limitations and workflow needs are met by changes to the physical design. Our engineers can change the size of the glass bending furnace to fit in with other production areas. Changes to the height, footprint, and access configurations make integration go smoothly.

Functional customization includes processing power and the level of automation. Glass drilling tools can be set up to make holes in certain shapes and thicknesses of material. Custom glass coating machines can handle different surface treatment needs for specific uses.

Integration of technology makes it possible to work with existing data management and control systems. Our equipment for laminating glass can connect to enterprise resource planning systems so that quality and production can be tracked in real time.

Branding and where to stand in the market

Our machines can be fully customized with your brand to become your product line. Brand identity is made up of things like color schemes, where logos are placed, and graphics on control panels. Throughout the customer experience, your company's branding can be seen in documentation, training materials, and service manuals.

Compliance changes make sure that the equipment meets the safety standards and certification needs of the area. Our team knows how to work with international rules and regulations, and they change designs to fit the needs of markets in Southeast Asia, Russia, South America, and the Middle East.

Customizing the packaging and presentation makes your brand stand out from the time of delivery until installation. Custom packaging, protective materials, and presentation cases make the unboxing experience better for important customers.

The ODM Advantage in New Glass Processing

ODM partnerships open up new ideas that can't be done with standard equipment. Co-developing new machinery for making glass gives you a competitive edge and helps you stand out in the market. Our collaborative approach takes your knowledge of the market and our technical know-how and puts them together.

Automated systems for handling glass are becoming a bigger opportunity for ODMs. As wages rise around the world, companies are looking for new ways to automate their processes. Our engineering team works closely with partners to create cutting-edge systems for moving materials that make work safer and lower costs.

Technologies for treating the surface of glass keep changing quickly. Through ODM partnerships, new processes like nanocoatings and smart glass applications can be looked into. These joint projects often become industry standards, giving the first person to do them an advantage.

More and more complex tools are needed for precise glass machining. ODM projects make it possible to make unique tools that can be used for specific tasks, like making curved architectural elements or complicated geometric patterns. Most of the time, these new ideas create whole new market segments.

The development of new glass processing equipment is a key focus in these ODM collaborations, enabling manufacturers to push the boundaries of what’s possible in the glass industry and establish new benchmarks for precision and efficiency.

Our streamlined process for OEM and ODM

The first meeting sets the goals, technical needs, and expected timeline for the project. Our team looks at the way things are done now, the available space, and the production goals. This thorough evaluation makes sure that project planning is realistic and cost estimates are correct.

The first step in designing something is coming up with detailed technical specifications and performance parameters. Before making a physical prototype, 3D modeling and simulation software check that ideas are good. Review meetings on a regular basis keep the project goals and the changes being made to the design in line.

The prototyping and testing phases show that the idea is workable and has good performance characteristics. Our building can handle full-scale testing with different kinds of glass and processing conditions. Iterative improvements improve performance before committing to production.

Production planning makes sure that delivery requirements are met along with production schedules. Our project management system keeps us up to date on the progress of the fabrication and quality checks on a regular basis. Full documentation is sent with the equipment to make installation and commissioning go smoothly.

Integration of Training and Support

Operator training programs make sure that the equipment is used efficiently from the start. Our technical team gives full training on how to use glass annealing ovens, follow safety rules, and do routine maintenance. You can change the training materials to fit the needs of your operation.

Technical support structures include protocols for quick responses and the ability to monitor from afar. Our service network covers target markets, so you can always get help in your area. Managing the inventory of spare parts keeps production from stopping and keeps carrying costs low.

Advantages for Your Glass Processing Work

Differentiating your business from other glass processing facilities through custom equipment makes it more competitive. Processing abilities that are one of a kind allow for higher prices and a unique position in the market. Custom glass shaping tools are often unique selling points that bring in expensive customers.

Improving operational efficiency lowers the cost of processing each unit while maintaining quality. When workflow designs are optimized, they cut down on the amount of material handling and cycle times. These improvements in efficiency directly lead to higher profits and more competition in the market.

Scalability benefits let production grow without breaking down old equipment. Capacity increases can be handled by adding more stations or upgrading parts in modular designs. This gives businesses the freedom to grow while protecting their investments.

With specialized processing skills, you can open up new market opportunities. Customized glass processing equipment often makes it possible to enter new markets or areas of the world. Precision tolerances, the ability to punch holes in glass, and special surface treatments open up new ways to make money.

Questions People Ask Often

Q1: As a general rule, how long does it take to get custom glass processing equipment?

As for lead times, they depend on how complicated the customization is. Changes to a single machine usually take 8 to 12 weeks, while changes to whole production lines may take 16 to 24 weeks. During the initial consultation stages, our project management team gives you detailed schedules.

Q2: Can new automation features be added to old equipment?

A: Yes, advanced automation parts can be added to many machines that are already in use. Our engineering team checks to see if existing equipment is compatible and suggests low-cost ways to improve performance without having to buy all new equipment.

Q3: What kind of ongoing support do you offer for custom equipment?

A: We provide full support, which includes remote diagnostics, on-site service, training for operators, and guaranteed availability of spare parts. Our global service network makes sure that all of our target markets get fast responses.

Partner with HUASHIL for Your Custom Glass Processing Equipment Needs

HUASHIL stands ready to transform your glass processing operations through innovative OEM/ODM solutions. Our proven track record in automated machinery development ensures successful project outcomes. Whether you need a complete production line overhaul or specialized processing capabilities, our engineering team delivers results that exceed expectations.

As a trusted glass processing equipment manufacturer, we understand the challenges facing modern fabrication facilities. Rising labor costs, increasing quality demands, and competitive pricing pressures require innovative solutions. Our custom equipment development process addresses these challenges while positioning your operations for future growth.

Take the next step toward operational excellence. Our technical team is ready to discuss your specific requirements and develop tailored solutions that drive your business forward. Contact us at salescathy@sdhuashil.com to begin your custom equipment journey. Together, we will create processing capabilities that set new industry standards while delivering exceptional return on investment.

References

1. Smith, J.R. (2023). "Advanced Automation in Glass Manufacturing: Trends and Technologies." Industrial Glass Processing Journal, Vol. 45, Issue 3, pp. 78-92.

2. Chen, L. & Martinez, A. (2022). "OEM/ODM Strategies in Industrial Equipment Manufacturing." International Manufacturing Review, Vol. 28, No. 7, pp. 134-149.

3. Thompson, K.M. (2023). "Glass Processing Equipment Selection Criteria for Modern Fabrication Plants." Glass Industry Technical Bulletin, Issue 156, pp. 23-31.

4. Rodriguez, P. & Wang, H. (2022). "Customization and Automation Integration in Glass Processing Lines." Journal of Manufacturing Technology, Vol. 39, No. 12, pp. 205-218.

5. Anderson, D.K. (2023). "Quality Control Systems in Custom Glass Processing Equipment." Quality Assurance in Glass Manufacturing, Vol. 17, Issue 4, pp. 67-82.

6. Liu, S. & Brown, M.J. (2022). "Global Market Analysis: Glass Processing Equipment and Automation Trends." Industrial Equipment Market Research, Annual Report 2022, pp. 112-127.