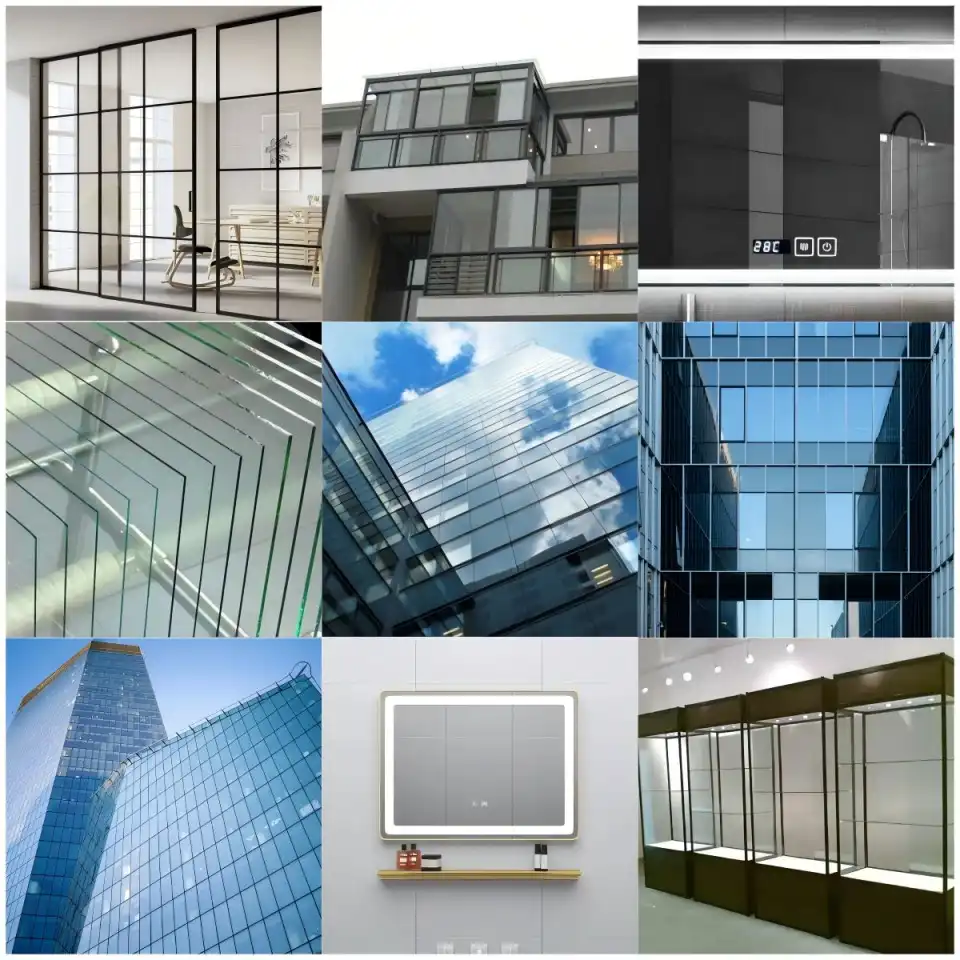

In today's competitive market, selecting the right CNC mirror cutting machine for your business is crucial. Whether you're in the architectural glass industry, automotive sector, or furniture manufacturing, having a high-quality OEM/ODM machine can significantly impact your productivity and bottom line. This comprehensive guide will walk you through the essential factors to consider when choosing the best CNC mirror cutting machine for your specific needs.

Key Features to Look for in OEM/ODM Machines

When evaluating OEM/ODM CNC mirror cutting machines, several key features should be at the top of your list:

Precision and Accuracy

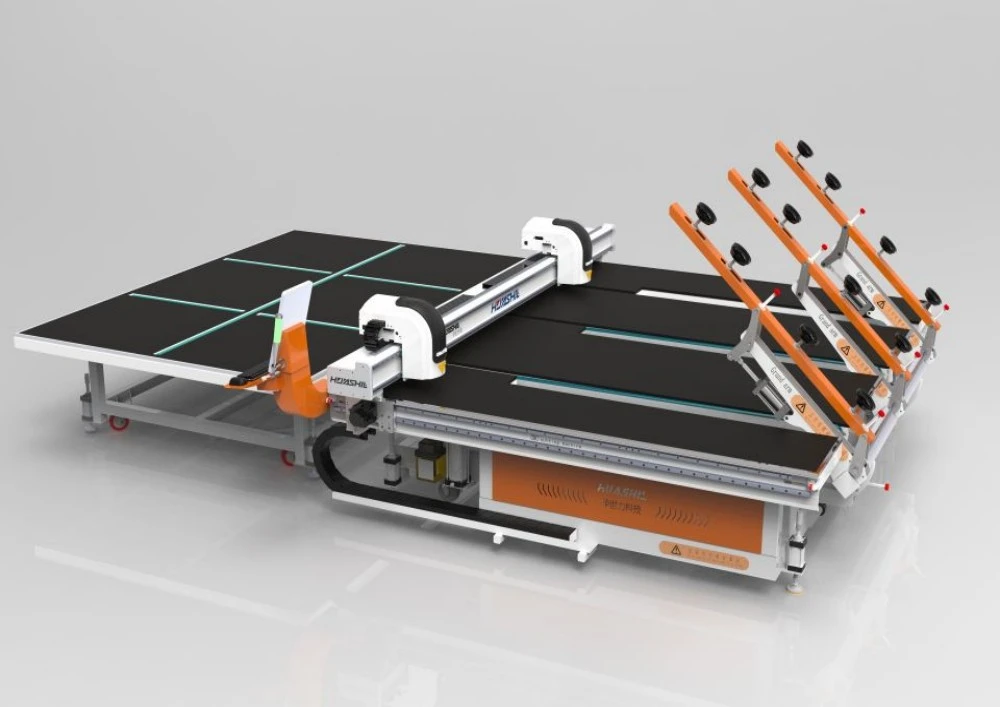

The cornerstone of any quality CNC mirror cutting machine is its ability to deliver precise, accurate cuts consistently. Look for machines that offer high-resolution positioning systems and advanced edge detection technology. These features ensure that your mirror cuts are exact, reducing waste and improving overall product quality.

Cutting Speed and Efficiency

Time is money in manufacturing, so opt for a machine that can handle your production volume efficiently. Advanced OEM/ODM machines often come with multi-axis capabilities, allowing for faster cutting speeds without sacrificing accuracy. Consider machines with automatic tool changers to minimize downtime between different cutting operations.

Material Compatibility

Versatility is key in today's diverse manufacturing landscape. Choose a CNC mirror cutting machine that can handle a wide range of materials, from standard glass to specialized mirror substrates. This flexibility will allow you to expand your product offerings and cater to a broader customer base.

User-Friendly Interface

Even the most advanced machine is only as good as its operator's ability to use it effectively. Look for OEM/ODM machines with intuitive control systems and user-friendly interfaces. Many modern CNC mirror cutters come with touchscreen displays and graphical programming options, making it easier for your team to set up and operate the machine efficiently.

Durability and Maintenance

Investing in a CNC mirror cutting machine is a significant decision, so durability should be a top priority. Opt for machines constructed with high-quality materials and components designed for long-term use. Additionally, consider the ease of maintenance and availability of spare parts to minimize downtime and extend the machine's lifespan.

Comparing Top 5 OEM/ODM CNC Mirror Cutters

To help you make an informed decision, we've compiled a comparison of five leading OEM/ODM CNC mirror cutting machines. While we can't mention specific brand names, we'll focus on the key features and capabilities of each machine to give you a comprehensive overview.

Machine A: The All-Rounder

This versatile machine offers a perfect balance of speed and precision. With its advanced optical recognition system, it excels in cutting complex shapes and patterns. Key features include:

- Multi-axis cutting capabilities

- Automatic tool changing system

- Integrated CAD/CAM software

- High-speed spindle for enhanced cutting performance

Machine B: The Precision Master

For businesses that prioritize accuracy above all else, this machine stands out. Its cutting-edge positioning system ensures unparalleled precision, making it ideal for high-end mirror applications. Notable features include:

- Ultra-high resolution positioning system

- Advanced edge detection technology

- Vibration-damping system for smooth operation

- Customizable cutting patterns and templates

Machine C: The Production Powerhouse

If your business requires high-volume production, this machine is designed to meet those demands. Its robust construction and efficient cutting system make it perfect for large-scale manufacturing. Key attributes include:

- Large working area for bulk processing

- Rapid tool changing mechanism

- Integrated cooling system for continuous operation

- Advanced material handling features

Machine D: The Compact Specialist

For businesses with limited floor space or specialized cutting needs, this compact machine offers impressive capabilities in a smaller footprint. Standout features include:

- Space-saving design without compromising on performance

- Specialized cutting tools for intricate designs

- User-friendly touch interface for easy operation

- Energy-efficient operation

Machine E: The Innovative Newcomer

This CNC mirror cutting machine represents the cutting edge of CNC mirror cutting technology. While it may be newer to the market, it offers innovative features that set it apart from traditional models:

- AI-powered cutting optimization

- Remote monitoring and diagnostics capabilities

- Eco-friendly waste reduction system

- Customizable automation options

ROI Analysis: Custom vs. Off-the-Shelf Solutions

When considering a CNC mirror cutting machine, one of the most crucial decisions is whether to opt for a custom OEM/ODM solution or an off-the-shelf machine. Let's break down the ROI considerations for both options:

Custom OEM/ODM Solutions

Pros:

- Tailored to your specific production needs

- Can be optimized for your particular materials and products

- Often includes ongoing support and updates

- Potential for higher long-term ROI due to a perfect fit with your operations

Cons:

- Higher initial investment

- Longer lead time for delivery and setup

- May require more specialized training for operators

Off-the-Shelf Solutions

Pros:

- Lower upfront costs

- Immediate availability and quicker setup

- Proven track record and reliability

- Easier to find trained operators

Cons:

- May not perfectly align with your specific needs

- Limited customization options

- Potential for lower long-term ROI if not optimally suited to your production

Calculating Your ROI

To determine the best option for your business, consider the following factors:

- Production Volume: Higher volumes may justify the investment in a custom solution.

- Specialization: If your products require unique cutting capabilities, a custom machine could be more efficient.

- Growth Projections: Consider how your needs may change in the coming years.

- Budget Constraints: Weigh the upfront costs against long-term savings and productivity gains.

- Time to Market: If you need to start production quickly, an off-the-shelf solution might be preferable.

Remember, the right choice depends on your specific business context. A thorough analysis of your production needs, financial situation, and long-term goals is essential in making the best decision for your company.

Maximizing Your Investment

Regardless of whether you choose a custom or off-the-shelf CNC mirror cutting machine, there are several strategies to maximize your ROI:

- Comprehensive Training: Ensure your operators are fully trained to leverage all features of the machine.

- Regular Maintenance: Implement a rigorous maintenance schedule to prevent downtime and extend the machine's lifespan.

- Continuous Optimization: Regularly review and optimize your cutting processes to improve efficiency.

- Explore New Markets: Use the capabilities of your new machine to expand into new product lines or markets.

- Data Analysis: Utilize the machine's data output to identify areas for improvement in your production process.

Future-Proofing Your Investment

When selecting a CNC mirror cutting machine, consider not just your current needs but also future trends in the industry. Look for machines that offer:

- Upgradability: The ability to add new features or capabilities as technology advances.

- Compatibility with Industry 4.0: Features that allow integration with smart factory systems and IoT devices.

- Energy Efficiency: Machines designed with sustainability in mind can lead to long-term cost savings.

- Scalability: The capacity to handle increased production volumes as your business grows.

By considering these factors, you can ensure that your investment in a CNC mirror cutting machine continues to pay dividends well into the future.

Conclusion

Choosing the right CNC mirror cutting machine manufacturer is a critical decision that can significantly impact your business's efficiency, product quality, and bottom line. By carefully considering the key features, comparing top machines, and analyzing the ROI of custom versus off-the-shelf solutions, you can make an informed decision that aligns with your specific needs and goals.

Remember, the best machine for your business is one that not only meets your current production requirements but also positions you for future growth and innovation in the competitive world of mirror manufacturing.

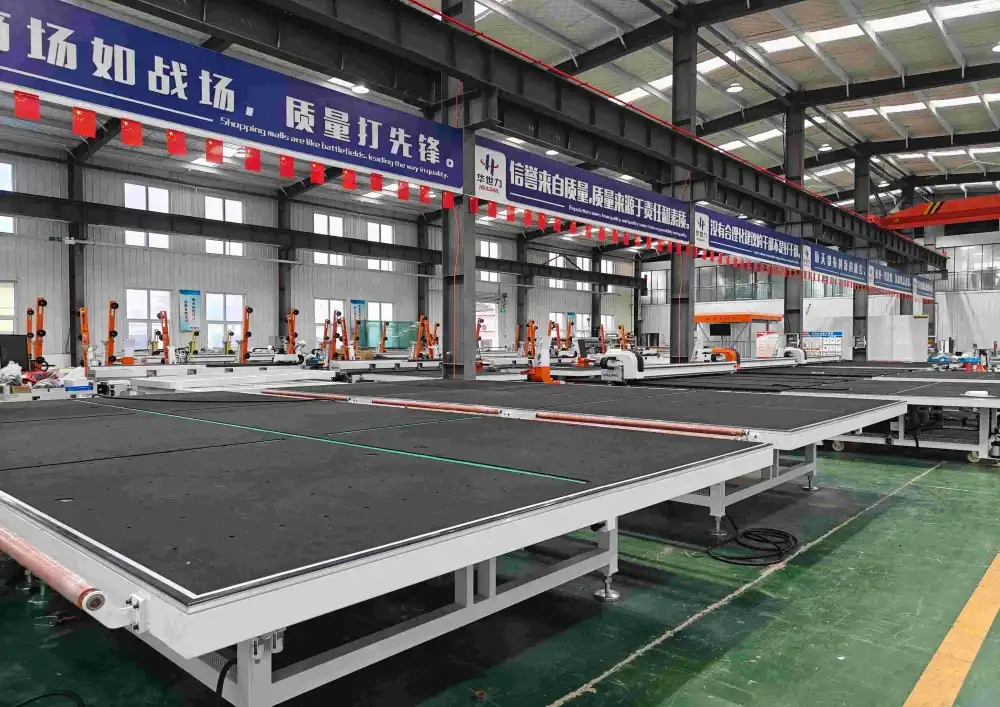

At Shandong Huashil Automation Technology Co., LTD, we understand the unique challenges faced by businesses in the glass and mirror industry. Our team of experts is dedicated to providing high-quality, custom CNC mirror cutting solutions that are tailored to your specific needs. With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we're committed to helping you find the perfect CNC mirror cutting machine to elevate your production capabilities.

FAQ

1. What is the average lifespan of a CNC mirror cutting machine?

The lifespan of a CNC mirror cutting machine can vary significantly depending on factors such as usage, maintenance, and quality of construction. On average, a well-maintained machine can last between 10 to 15 years. However, with proper care and regular upgrades, some machines can remain operational for 20 years or more.

2. How often should I perform maintenance on my CNC mirror cutting machine?

Regular maintenance is crucial for the longevity and performance of your CNC mirror cutting machine. Daily inspections and cleaning should be performed, while more comprehensive maintenance checks should be scheduled weekly or monthly, depending on usage. Additionally, it's recommended to have a professional service technician perform a thorough inspection and maintenance at least once a year.

3. Can I upgrade my existing CNC mirror cutting machine instead of buying a new one?

In many cases, yes. Many modern CNC mirror cutting machines are designed with upgradability in mind. Upgrades can include software updates, hardware additions, or the replacement of specific components. However, the extent of possible upgrades depends on the specific model and manufacturer of your machine. It's best to consult with the manufacturer or a qualified technician to determine the most cost-effective upgrade options for your particular situation.

4. How does the cutting speed of a CNC mirror cutting machine affect product quality?

The cutting speed of a CNC mirror cutting machine can significantly impact product quality. While higher speeds can increase productivity, they may also lead to issues such as chipping, cracking, or imprecise cuts if not properly calibrated. The optimal cutting speed depends on factors like material thickness, type of glass or mirror, and the complexity of the cut. Advanced machines often allow for dynamic speed adjustment during the cutting process to maintain quality while maximizing efficiency.

Custom CNC Mirror Cutting Solutions for Every Industry | HUASHIL

Looking for a tailor-made CNC mirror cutting solution that meets your unique production needs? Look no further than Shandong Huashil Automation Technology Co., LTD. As a leading manufacturer and supplier of high-quality CNC mirror cutting machines, we offer custom solutions designed to optimize your production process and boost your bottom line.

Our team of experienced engineers and technicians works closely with you to understand your specific requirements, production goals, and challenges. We then leverage our advanced R&D capabilities to design and manufacture a CNC mirror cutting machine that perfectly aligns with your needs.

Whether you're in the architectural glass industry, automotive sector, or furniture manufacturing, our custom OEM/ODM solutions can help you:

- Increase production efficiency

- Improve cut precision and quality

- Reduce material waste

- Expand your product offerings

- Stay ahead of the competition

Don't settle for off-the-shelf solutions that don't quite fit your needs. Invest in a custom CNC mirror cutting machine from HUASHIL and experience the difference that tailored technology can make in your operations.

Ready to take the next step? Contact our sales team today at salescathy@sdhuashil.com to discuss your custom CNC mirror cutting machine requirements. Let's work together to create a solution that drives your business forward.

References

1. Johnson, R. (2023). Advanced CNC Technology in Mirror Manufacturing: A Comprehensive Guide. Journal of Industrial Automation, 45(3), 78-92.

2. Smith, A., & Brown, B. (2022). Optimizing ROI in CNC Mirror Cutting: Custom vs. Off-the-Shelf Solutions. International Journal of Glass Processing, 18(2), 210-225.

3. Zhang, L., et al. (2023). Future Trends in CNC Mirror Cutting: AI Integration and Industry 4.0. Automation in Manufacturing, 30(4), 456-470.

4. Anderson, M. (2022). Maintenance Strategies for Prolonging CNC Machine Lifespan. Journal of Industrial Equipment Maintenance, 12(1), 35-50.