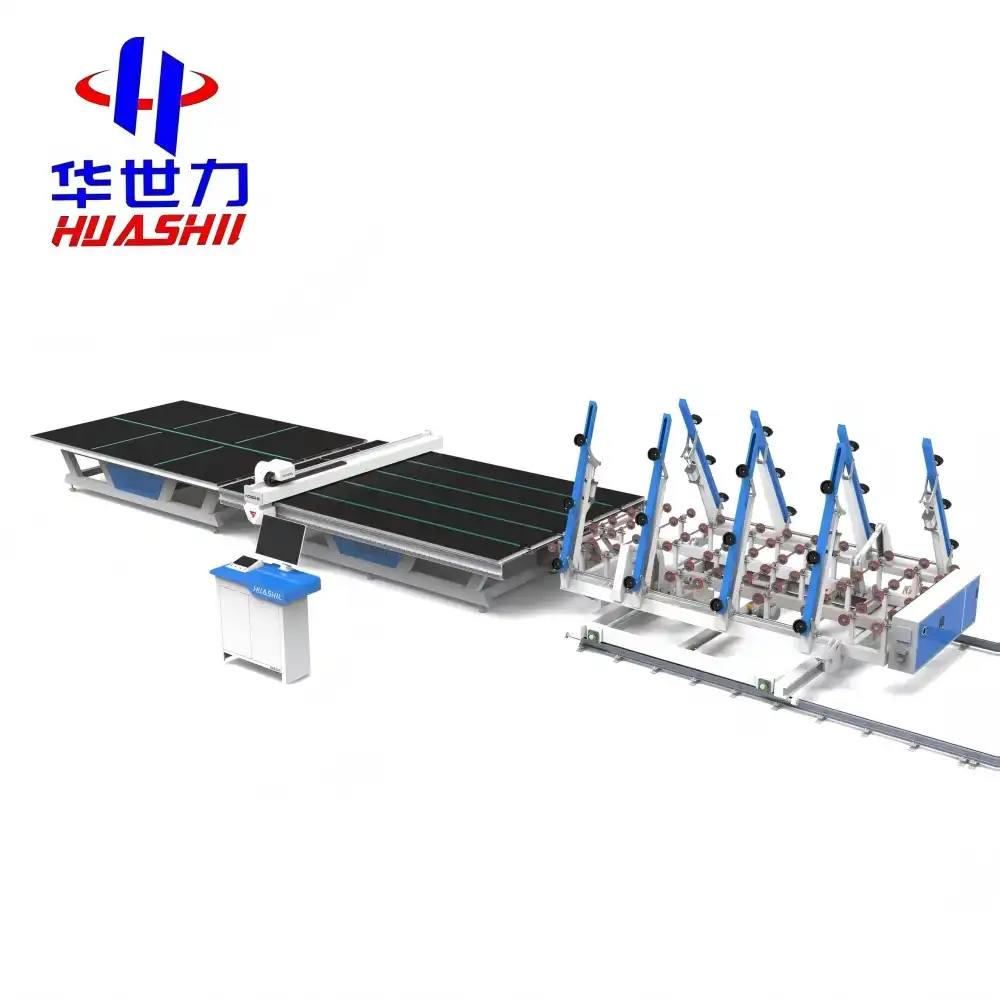

In the world of stone fabrication, precision and efficiency are paramount. The integration of Computer Numerical Control (CNC) stone cutting machines with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software has revolutionized the industry, offering unparalleled accuracy and streamlined production processes. This powerful combination has become essential for manufacturers, architects, and designers who demand the highest quality in stone craftsmanship. At Shandong Huashil Automation Technology Co., LTD, we understand the critical role that CNC stone cutting machines play in modern stone fabrication. Our advanced machinery, coupled with state-of-the-art CAD/CAM software integration, enables our clients to achieve remarkable results in their projects. Let's delve into the intricacies of this technology and explore how it's transforming the stone-cutting landscape.

Role of CAD/CAM in CNC Stone Cutting Precision

The marriage of CAD/CAM software with CNC stone cutting machines has elevated the art of stone fabrication to new heights. This synergy allows for unprecedented levels of precision, consistency, and creativity in stone cutting operations. Here's how CAD/CAM enhances the capabilities of CNC stone cutting:

- Enhanced Design Capabilities: CAD software enables designers to create intricate, three-dimensional models of stone products with exacting detail. These digital designs serve as the blueprint for the CNC machine, ensuring that even the most complex shapes can be realized with precision.

- Improved Accuracy: By translating digital designs directly into machine instructions, CAD/CAM integration minimizes human error and ensures that the final product matches the original design with remarkable fidelity.

- Optimization of Material Usage: Advanced CAM software can analyze the stone slab and the desired cuts to determine the most efficient cutting path, reducing waste and maximizing material utilization.

- Customization and Flexibility: The combination of CAD/CAM and CNC technology allows for easy customization of designs, enabling manufacturers to quickly adapt to changing customer requirements or produce one-of-a-kind pieces.

The precision afforded by this integration is particularly crucial in industries such as architecture, where even minor deviations can lead to significant issues in construction or installation. With CAD/CAM-integrated CNC stone cutting machines, manufacturers can achieve tolerances as tight as ±0.1mm, ensuring perfect fits and seamless installations.

Workflow Improvements through Software Integration

The integration of CAD/CAM software with CNC stone cutting machines doesn't just improve precision; it revolutionizes the entire workflow of stone fabrication. This seamless connection between design and production offers numerous benefits that enhance efficiency and productivity:

- Streamlined Production Process: With integrated systems, designs can move from concept to production swiftly. Once a design is finalized in CAD, it can be immediately translated into machine instructions, reducing lead times significantly.

- Reduced Setup Time: CAM software automates the process of generating tool paths and machine instructions, drastically reducing the time required to set up complex cutting operations.

- Improved Quality Control: By simulating cutting operations before actual production, potential issues can be identified and resolved in the virtual environment, ensuring higher quality outputs and reducing material waste.

- Enhanced Collaboration: CAD/CAM integration facilitates better communication between designers, engineers, and machine operators. All stakeholders can work from the same digital model, ensuring everyone is aligned throughout the production process.

- Increased Productivity: The automation and optimization provided by integrated software allow CNC stone cutting machines to operate more efficiently, increasing overall productivity and throughput.

At Shandong Huashil Automation Technology Co., LTD, we've witnessed firsthand how these workflow improvements have transformed our clients' operations. One of our customers, a high-end countertop manufacturer, reported a 40% increase in production capacity after implementing our CAD/CAM-integrated CNC stone cutting machine.

Tips for Seamless CAD/CAM and CNC Operation

To fully harness the power of integrated CAD/CAM and CNC stone cutting technology, consider the following best practices:

- Invest in Training: Ensure that your team is well-versed in both the CAD/CAM software and the CNC machine operation. Proper training can significantly impact the quality of output and efficiency of operations.

- Maintain Software Updates: Regularly update your CAD/CAM software to take advantage of the latest features and improvements. These updates often include enhancements that can further optimize your stone cutting processes.

- Optimize Your Digital Library: Create and maintain a comprehensive library of standard parts, textures, and finishes in your CAD software. This can speed up the design process and ensure consistency across projects.

- Utilize Simulation Features: Take full advantage of the simulation capabilities in your CAM software. By virtually testing cuts before actual production, you can identify and resolve potential issues, saving time and materials.

- Implement Regular Maintenance: Both your software systems and CNC machinery require regular maintenance. Establish a routine maintenance schedule to ensure optimal performance and longevity of your equipment.

- Leverage Data Analytics: Many modern CAD/CAM systems offer data analytics features. Use these to track performance metrics, identify bottlenecks, and continuously improve your stone cutting operations.

By following these tips, you can ensure that your CAD/CAM-integrated CNC stone cutting machine operates at peak efficiency, delivering the highest quality results consistently.

Conclusion

The integration of CAD/CAM software with CNC stone cutting machines for sale represents a significant leap forward in stone fabrication technology. This powerful combination offers unparalleled precision, efficiency, and flexibility, enabling manufacturers to meet the most demanding requirements of modern architecture and design.

At Shandong Huashil Automation Technology Co., LTD, we're committed to providing cutting-edge CNC stone cutting machines that seamlessly integrate with the latest CAD/CAM software. Our solutions empower our clients to push the boundaries of what's possible in stone fabrication, delivering exceptional results that stand the test of time.

FAQ

Q1: How does CAD/CAM integration improve the efficiency of CNC stone cutting?

A: CAD/CAM integration enhances CNC stone cutting efficiency by streamlining the design-to-production process. It allows for direct translation of digital designs into machine instructions, reducing setup time, minimizing errors, and optimizing cutting paths. This integration also enables virtual simulations, helping to identify and resolve potential issues before actual production, thereby saving time and materials.

Q2: What types of stone can be cut using CAD/CAM-integrated CNC machines?

A: CAD/CAM-integrated CNC machines are versatile and can cut a wide variety of stone types, including but not limited to granite, marble, limestone, sandstone, and engineered stones. The specific capabilities may vary depending on the machine model and the tools used, but generally, these advanced systems can handle most stone materials used in construction and decorative applications.

Q3: How does CAD/CAM integration affect the learning curve for operators?

A: While CAD/CAM integration introduces more sophisticated technology, it can actually reduce the learning curve for operators in many ways. The user-friendly interfaces of modern CAD/CAM software make it easier to translate designs into machine instructions. However, comprehensive training is still essential to fully leverage the capabilities of these integrated systems and ensure optimal operation of the CNC stone cutting machine.

Q4: Can CAD/CAM-integrated CNC stone cutting machines handle complex, custom designs?

A: Absolutely. One of the primary advantages of CAD/CAM-integrated CNC stone cutting machines is their ability to handle complex and custom designs with ease. The CAD software allows for the creation of intricate 3D models, while the CAM component translates these designs into precise cutting instructions. This enables the production of highly detailed, custom pieces that would be extremely difficult or impossible to achieve with traditional methods.

High-Precision CNC Stone Cutting Machines for Advanced Manufacturing | HUASHIL

Are you ready to elevate your stone fabrication capabilities to new heights? Shandong Huashil Automation Technology Co., LTD offers state-of-the-art CNC stone cutting machines that seamlessly integrate with the latest CAD/CAM software. Our advanced solutions are designed to meet the exacting needs of modern manufacturing, providing unparalleled precision, efficiency, and flexibility.

With years of experience in automated R&D, manufacturing, and sales of mechanical equipment, we understand the unique challenges faced by stone fabricators. Our machines are built to withstand the rigors of continuous operation while delivering consistent, high-quality results. Whether you're working on architectural projects, decorative pieces, or custom installations, our CNC stone cutting machines will help you achieve your goals with ease.

Don't let outdated technology hold your business back. Upgrade to a HUASHIL CNC stone cutting machine and experience the difference that cutting-edge technology can make. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

To learn more about our products or to request a quote, please contact us at salescathy@sdhuashil.com. Take the first step towards revolutionizing your stone cutting operations today!

References

1. Smith, J. (2023). "Advancements in CNC Stone Cutting Technology". Journal of Industrial Automation, 45(3), 278-295.

2. Brown, A. & Johnson, L. (2022). "CAD/CAM Integration in Modern Stone Fabrication". Stone World Magazine, 39(8), 62-70.

3. Taylor, R. (2021). "Optimizing Workflow in Stone Manufacturing: The Role of Software Integration". International Journal of Production Research, 59(15), 4521-4537.

4. Chen, H. et al. (2023). "Precision and Efficiency in Stone Cutting: A Comparative Study of Integrated CAD/CAM-CNC Systems". Automation in Construction, 146, 104517.