Small business owners looking for cheap stone cutting tools face an important choice that can have a big effect on how well they do and how much money they make. The best stone cutting machine can be found by weighing how much it costs against its performance, accuracy, and dependability. Newer tools for cutting stone are small and cheap, but they still get professional-grade results. They don't even need to be high-quality to do the job. These tools give small businesses the chance to compete in a lot of different areas, from making architectural glass to working with decorative stone. They give the accuracy and range needed to work with all sorts of materials, like sintered stone, ceramic slabs, and different kinds of natural stone.

Understanding the Needs of Small Business Owners for Stone Cutting Machines

Small businesses in the stone cutting industry face problems that are very different from the ones that big factories face. Quality and durability are always important when choosing tools, even if the budget is tight. This is because they are essential for long-term business growth.

Budget-Conscious Investment Strategies

Making smart buying choices means looking at the total cost of ownership and not just the price of the purchase. When choosing stone cutting tools, small business owners need to think about how much it will cost to keep them, how much energy they will use, and what parts will need to be available. The cheapest choice is often more expensive in the long run if it isn't reliable and leads to production delays or needs to be fixed all the time.

Workspace Optimization Requirements

The limited room in workshops requires the best stone cutting machine with the best possible cutting power for tight spaces. Today’s stone cutting tools have space-efficient setups that don’t hurt performance. This lets small businesses arrange their production in the best way possible.

Versatility and Material Compatibility

Small businesses get more work done when they have tools that can work with stones of different types and thicknesses. Because of this versatility, there is no need for a bunch of different specialized tools. This lowers costs while also expanding the range of services that can be offered to meet a wide range of customer needs.

Top Affordable Stone Cutting Machines in 2024: A Comparative Overview

Right now, the market has a lot of different stone cutting options for small businesses, from hand-operated systems to highly accurate automatic tools.

Manual vs. Automatic Stone Cutting Solutions

While cutting systems that are done by hand are cheap enough for beginners, they need trained users and take more time to process. While the best stone cutting machine systems cost more upfront, they are always precise and make people more productive, which often makes them worth the cost because they improve efficiency and lower the need for workers.

Here are the main reasons small businesses should use automatic stone cutting systems:

- Consistent Precision: Because automated systems don't make mistakes, they guarantee that all projects have the same cut quality, which greatly lowers the amount of material that is wasted.

- Increased Productivity: Automatic machines can run with very little oversight, so operators can focus on other jobs that add value while keeping production going.

- Less Dependence on Skilled Workers: Automated cutting makes highly skilled workers less important, which lowers the cost of labor and training in the long run.

- Better Safety: Automated systems lower the risk of getting hurt at work and the cost of insurance by cutting down on the person's direct touch with cutting tools.

These benefits make it easier for growing businesses to deal with common small business issues like the cost of labor, making sure that quality stays the same, and ensuring safety. This makes automatic systems more appealing to businesses that are growing.

Performance Metrics and ROI Considerations

The cutting speed, how long the blade lasts, and how long the machine lasts all have a direct effect on the return on investment. While keeping the level of accuracy necessary for professional use, modern stone cutting machines outperform older methods in terms of cutting speed. Looking at these measures helps find the most productive equipment that the budget will allow.

How to Choose the Best Stone Cutting Machine for Your Small Business?

Choosing the right stone cutting tools depends on an in-depth understanding of the business's needs, like the types of materials, the number of pieces that need to be made, and the quality standards.

Material Processing Requirements

Different kinds of stone need different ways of cutting and blade settings. Because of its hardness, granite needs strong cutting systems. Marble and clay materials, on the other hand, need precise tools that don't chip or damage the surface. The HSL-CNC3616 model is an example of the best stone cutting machine technology in cutting. It can handle materials with thicknesses from 3 to 18 mm and dimensions of up to 3600 mm by 1600 mm, so it can be used for all sorts of stone cutting.

Technology Integration and Control Systems

Today's stone cutting tools use advanced control systems that make them more accurate and help them do more work. The EOS-CNC control system is up to date with today's technology. It can automatically control pressure, find the edge of a workpiece, and float objects on air, all of which help make sure that the material is handled smoothly and the cutting results are exact.

Financing and Procurement Strategies

Small businesses can use a number of different types of loans to get high-quality stone cutting tools without hurting their cash flow. Businesses can get high-tech equipment and still have money on hand for bills by using equipment loans, lease-to-own programs, or supplier payment plans.

Practical Tips for Operating and Maintaining Stone Cutting Machines Efficiently

Following the correct steps for operation and care greatly extends the life of your equipment while making sure it always performs well and meets safety standards.

Safety Protocols and Best Practices

There are safety risks that come with stone cutting that need to be taken into account with thorough safety measures. Cutting waste and noise can be dangerous, but safety glasses, dust masks, and hearing protection can help. Regular safety training makes sure that everyone knows how to do things the right way and what to do in a situation.

Maintenance Schedules and Procedures

Preventive repair keeps the best stone cutting machine from breaking down and saves a lot of money. It also makes the machines last much longer. Cleaning every day gets rid of stone dust and other things that can hurt delicate parts. Blade checks every week find patterns of wear before they change the quality of the cut. Lubricating the moving parts once a month keeps everything running smoothly and stops parts from breaking too early.

The following important jobs are part of regular maintenance:

- Blade Inspection and Replacement: Looking at the cutting blades often for signs of wear, damage, or dullness makes sure they cut well and protects your materials from damage.

- Cooling System Maintenance: A lot of blade life is saved, and overheating is avoided by cleaning water drainage systems and changing filters.

- Calibration Checks: Every so often, accuracy verification keeps the cutting exact and stops mistakes in the size of the final products.

These repair practices keep the production quality steady, prevent unexpected downtime, protect your investment, and keep customers happy.

Real Success Stories: How Cheap Stone Cutting Machines Helped Small Businesses

Making smart purchases of tools can change the way small businesses work and how much money they make.

Architectural Glass Fabrication Success

A little architectural glass business in Texas bought automated cutting tools to improve its skills as a company. Now, they can take on bigger jobs they couldn't do before. The precision cutting let them follow strict architectural guidelines while also cutting down on material waste by 25%, which made the job much more profitable.

Furniture Manufacturing Transformation

A family-owned business that sells furniture and stone countertops increased its production level by two times after switching to the best stone cutting machine technology. Better cutting accuracy led to shorter finishing times and more advanced design options. This drew in higher-value custom projects and raised the average order values.

Sintered Stone Processing Innovation

A new business that focused on handling sintered stone and ceramic slabs used advanced cutting technology to get ahead of the competition in their local market. Their precise positioning when working with big format materials lets them do a good job serving both home and business customers.

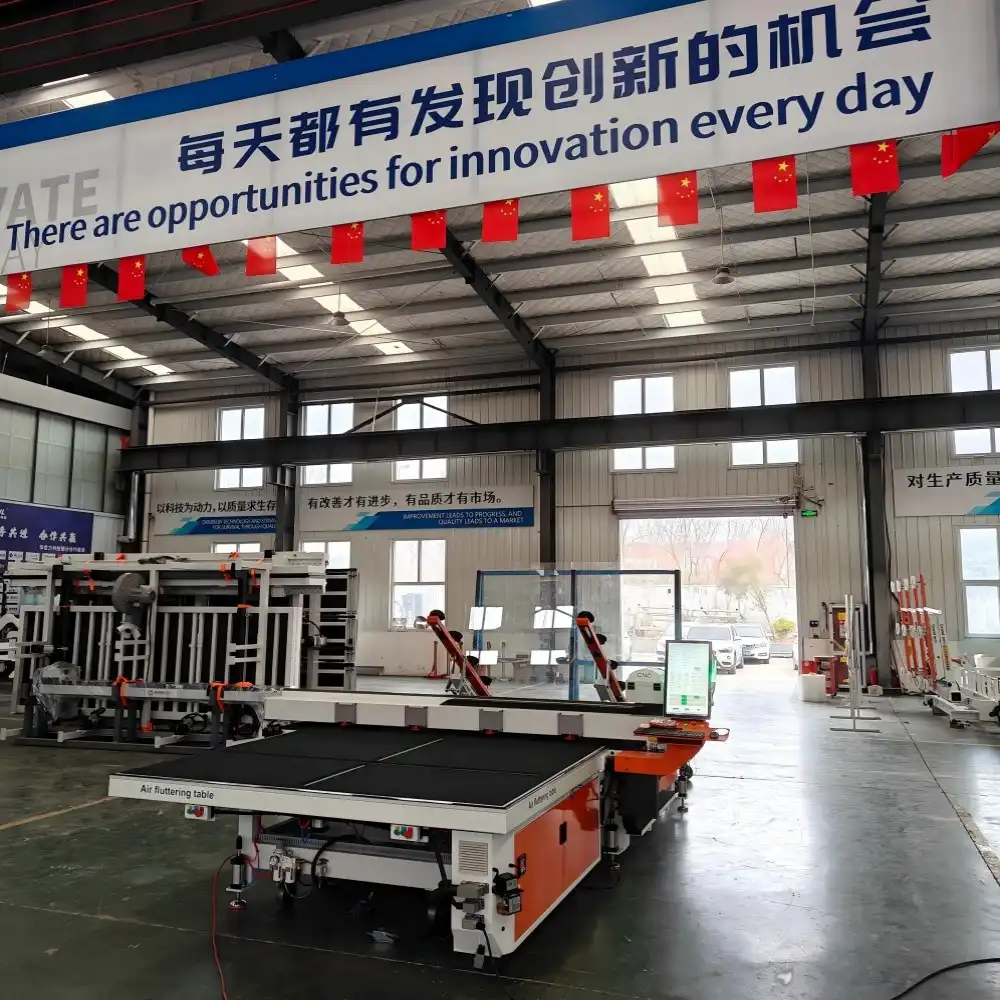

Introducing HUASHIL – Trusted Provider of Affordable Stone Cutting Solutions

When it comes to making stone cutting equipment that is both reliable and innovative, Shandong Huashil Automation Technology Co., Ltd. focuses on affordable options for small to medium-sized businesses around the world.

Advanced Technology and Product Portfolio

HUASHIL's promise of technological progress can be seen in goods like the HSL-CNC3616, which uses state-of-the-art automation and is easy for people to use. This model can automatically control pressure and find edges. Its air float systems make sure that materials are moved smoothly and that results are exact. The EOS-CNC control device is easy to use and is very reliable.

Our wide range of products is used for many different tasks, such as working with sintered stone, clay slabs, and tile cutting using the best stone cutting machine. This means that our tools can be used to make architectural glass, smart mirrors, and glass for decoration.

Customer Support and Service Excellence

HUASHIL offers a full range of after-sales services, such as help with technical issues, training for operators, and quick delivery, all of which make the buying process easy. As part of our promise to help our customers succeed, we make sure they can get certified spare parts and accessories to keep their machines running and their output high.

We offer a range of flexible financing options that small businesses can afford while still maintaining high standards of quality. This helps the stone cutting industry grow in a sustainable way, even when the market is tough.

Conclusion

Choosing the right stone cutting machine is an important choice for small business owners who want to stay cost-effective while increasing productivity. New technology provides advanced answers that find the right balance between cost and professional quality. This lets small businesses fight well in tough markets. It's important to look at the total cost of ownership, operational needs, and long-term business goals instead of just the buying price. HUASHIL's new products such as the HSL-CNC3616 show how high-tech can be available to small companies. This gives the stone cutting industry the accuracy, dependability, and speed it needs for long-term growth.

FAQ

Q1: What materials can affordable stone cutting machines handle effectively?

A: Modern affordable stone cutting machines can process various materials, including granite, marble, sintered stone, ceramic slabs, and tiles. The key is selecting equipment with appropriate blade configurations and cutting parameters for your specific material requirements.

Q2: How often should stone-cutting machines undergo maintenance?

A: Daily cleaning and inspection are essential, with weekly blade checks and monthly comprehensive maintenance, including lubrication and calibration verification. Following manufacturer maintenance schedules ensures optimal performance and longevity.

Q3: What safety measures are most important for stone cutting operations?

A: Essential safety measures include proper protective equipment (safety glasses, dust masks, hearing protection), adequate ventilation, emergency stop systems, and comprehensive operator training on safe operating procedures.

Partner with HUASHIL for Your Stone Cutting Success

Ready to transform your stone cutting operations with industry-leading technology? HUASHIL offers the best stone cutting machine supplier solutions tailored for small business success. Our HSL-CNC3616 model combines affordability with professional-grade performance, featuring automatic controls and precision capabilities that drive productivity and profitability. Whether you're processing sintered stone, ceramic slabs, or architectural glass, our expert team provides comprehensive support from selection through installation and beyond. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and discover how HUASHIL technology can accelerate your business growth. Visit huashil.com for detailed specifications and customer testimonials.

References

1. Stone Industry Market Analysis and Equipment Trends Report 2024, Industrial Manufacturing Research Institute

2. Small Business Equipment Investment Strategies for Stone Processing Operations, Business Equipment Journal

3. Automated Stone Cutting Technology: Performance and Safety Standards, Manufacturing Technology Quarterly

4. Cost-Benefit Analysis of Stone Cutting Equipment for Small Enterprises, Industrial Equipment Review

5. Safety Protocols and Best Practices in Stone Cutting Operations, Workplace Safety Research Foundation

6. Emerging Technologies in Affordable Stone Processing Equipment, Advanced Manufacturing Solutions