People who want to work in building glass, curtain wall construction, or decorative glass really need to learn about glass-cutting tools. The move from scoring wheels that are used by hand to complex automated cutting systems has changed the way things are made in all types of industrial settings. Businesses that want to improve their production skills can now cut glass with modern tools, like the high-tech stained glass cutting machine, which does the job with never-before-seen speed and accuracy. These are improvements in technology that help manufacturers meet strict quality standards, improve dimensional accuracy, and lower the cost of doing work. The move from old-fashioned hand tools to digital cutting systems is a big change in the way that glass fabrication shops do their work.

Understanding Stained Glass Cutting Machines

What is a Stained Glass Cutting Machine?

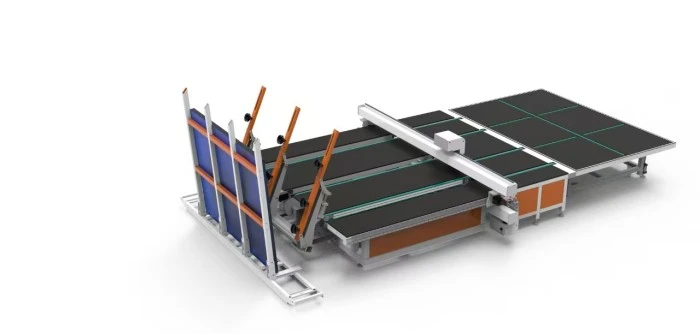

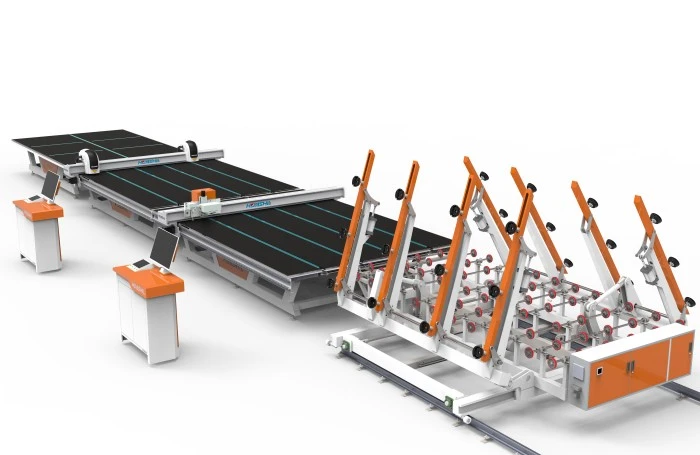

A stained glass cutting machine is an example of specialized gear designed to cut glass precisely and consistently. These machines use sophisticated control systems, highly accurate cutting wheels, and automatic positioning systems to achieve dimensional tolerances that are beyond the capabilities of hands-on methods. Servo-driven cutting heads, digital control panels, vacuum work surfaces, and built-in glass handling systems are some of the most important parts.

Today’s cutting machines have many different cutting wheel choices so that people can work with glass of different thicknesses and types. Integrated control systems allow you to design cutting patterns. This lowers the time needed to get everything ready and makes sure that every production run gets the same result. Because of these reasons, automated glass cutting is necessary for architectural glass manufacturing plants and curtain wall system builders who need to always get the same high-quality results.

History and Evolution of Stained Glass Cutting Machines

The start of automatic stained glass cutting machine technology happened in the 1950s and 1960s when makers realized that cutting glass by hand had problems. In the past, simple cam-driven devices were used to move cutting wheels along set paths. Primitive robots could cut more consistently than doing it by hand, but they couldn't adapt needed changes for complex patterns.

In the 1980s, computer numerical control (CNC) technology was invented, which completely changed what was possible in glass cutting. With CNC control, they were able to cut out complex designs very exactly, with a margin of error of only 0.1 mm in every dimension. Today’s machines have modern features like automatic tool change, multi-head cutting setups, and built-in systems for quality control. These new ideas have made advanced glass cutting available to artistic glass makers and furniture makers who used to do it all by hand.

Benefits of Using Stained Glass Cutting Machines

Efficiency and Precision

Automated stained glass cutting machine systems make a big difference in output compared to older ways of doing it by hand. Factories that use automatic machinery have reported production going up by 300–500% while also keeping quality high. The accuracy of current cutting machines eliminates the need for manual cutting, which usually wastes a lot of material.

Here's a list of the main efficiency benefits these tools offer:

- Dimensional Accuracy: CNC-controlled systems keep cutting errors within ±0.05 mm, which means that the quality of each part made in different production runs is the same.

- Automated systems can process sheets of glass faster than 20 meters per minute, which cuts down on the time needed to complete a loop.

- Material Optimization: Advanced nesting software uses glass more efficiently, cutting material waste by as much as 15%.

- Can it be done again? Using programmed cutting patterns guarantees the same outcome, no matter how skilled the person who does the work.

Automated cutting systems are necessary for competitive manufacturing because these gains in efficiency mean that less money needs to be spent on workers, and more goods can be produced.

Safety and Maintenance

Using a stained glass cutting machine safely and correctly must be done with a lot of safety measures in mind to protect people and ensure the machines keep working. Today's machines have many safety features, such as systems that can quickly stop the machine, protective barriers, and automatic glass handling devices that make sure the person operating the machine doesn't get as close to sharp edges.

Routine repair keeps equipment in good shape and makes sure it works well. Cleaning the cutting wheels and places where you work every day stops glass from building up and changing how well you cut. Lubricating the guide rails and moving parts every week keeps the system running smoothly and protects it from early wear. Once a month, a calibration check makes sure that the cutting and positioning are correct, which guarantees that the tools will always work the same way.

Choosing the Right Stained Glass Cutting Machine

Factors to Consider

Carefully considering operational limitations, material needs, and output requirements helps you choose the right glass cutting tools. To find methods that help them meet their manufacturing goals, plant managers and engineering teams must look at a lot of different technical factors.

Table size, maximum glass thickness, and production speed needs are important factors in the decision-making process. The way that the machine's control system is designed affects how well it can do complicated cutting patterns and work with the way that production is already set up to work. When making a budget, you need to think about more than just the cost of the equipment. You also need to think about the cost of installing it, teaching people to use it, and maintaining it over time.

It is very important to consider production volume needs when choosing a stained glass cutting machine. Multi-head cutting systems that work on a lot of glass pieces at the same time are helpful for high-volume architectural glass fabrication businesses. Single-head machines may have enough capacity for smaller furniture makers while also cutting down on costs.

Top Brands and Manufacturers

Finding good glass cutting tools makers lets you get good tech and a lot of help. When it comes to technical documentation, training programs, and spare parts availability, established makers typically offer more than smaller suppliers can.

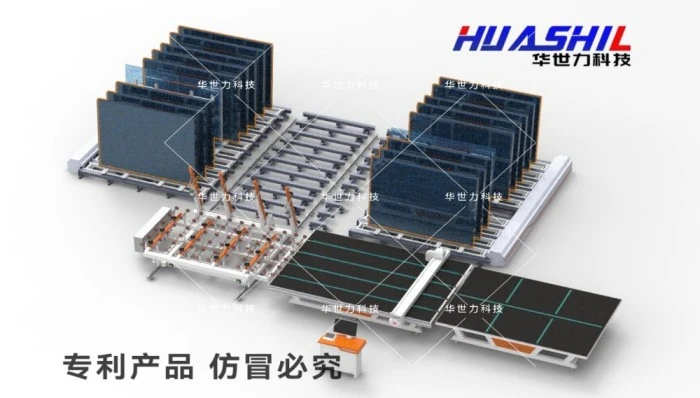

HUASHIL is one of the most well-known companies in automatic glass cutting technology, offering a full range of services to help make architectural glass, build curtain walls, and make decorative glass. Our gear uses cutting-edge ways to control and cut that are meant to meet the high standards of the glassmaking industry.

When judging possible suppliers, much technical assistance, spare parts, and installation services they offer should be taken into account. When technical problems happen, manufacturers with established service networks can quickly help fix them. This keeps production going and avoids downtime.

How to Use a Stained Glass Cutting Machine?

Step-by-Step Tutorial

Using automated glass cutting tools requires a consistent method to make sure the job is done right and the tools last a long time. The right setup helps cutting activities run smoothly and lowers the risk of damaging equipment or having safety incidents.

The first step is to make sure that the work area is clean and that the vacuum system is working properly. The glass sheets have to be put in the right place on the cutting table of the stained glass cutting machine and have to be supported properly so they don't bend while being cut. The control system needs to be programmed with the right cutting factors, such as wheel pressure, cutting speed, and tool paths.

Before cutting processes, system calibration is done to make sure that the dimensions are correct. Before cutting production materials, test cuts on samples to make sure that wheel pressure and cutting speed settings are correct. If you keep an eye on the cutting process the whole time, you can be sure of consistent quality and make quick changes if the cutting parameters drift outside of acceptable ranges.

Troubleshooting Common Issues

To fix well, you need to know about common ways that things go wrong and what causes them. Cutting wheels that are worn down, wrong pressure settings, or dirty work areas usually cause poor cutting quality. Regularly checking these important parts keeps the work quality high and the production rate up.

In tracking systems, problems with dimensional accuracy on a stained glass cutting machine often mean that either calibration has drifted or the machinery has worn down. Before they have an impact on the quality of production, systematic checking of reference points and measurement verification can find problems with calibration. Mechanical issues like too much backlash or mistakes in setting need to be fixed by a professional right away, or else they will get worse.

When complicated problems come up, it's important to be able to get technical help. Broad troubleshooting tools and the ability to talk directly with the manufacturer's technical teams help fix problems quickly and keep production on track.

Conclusion

The move from hand-operated glass cutting tools to complex automatic systems has greatly changed the way glass is made. Newer tools offer amazing accuracy, speed, and safety. They also help makers meet the rising quality standards. Understanding the technologies that are out there and what they can do helps people choose the right tools for long-term success in manufacturing. HUASHIL's dedication to new ideas and helping customers makes us a great partner for any facility that wants to improve how they cut glass with the help of new automated technology.

FAQ

Q1: How do I keep my stained glass cutting machine in good shape so it runs smoothly?

A: Regular upkeep means that work areas and cutting wheels are cleaned every day, moving parts are oiled once a week, and calibration is checked once a month. Following the manufacturer's maintenance plan ensures the equipment keeps working and extends its lifespan.

Q2: If my machine isn't cutting right, what should I do?

A: Make sure the cutting wheel is in good shape, the pressure settings are correct, and the work area is clean. If problems don't go away, look at the debugging guide or call tech support for help.

Q3: Can I use the machine to cut other kinds of glass?

A: If you change the right settings, a lot of automatic cutting systems can cut different kinds of glass that are different thicknesses. For information on what your equipment can do, look at the specs and advice from the maker.

Partner with HUASHIL for Advanced Glass Cutting Solutions

HUASHIL's automated glass cutting technology provides the accuracy, speed, and dependability that are needed for competitive production. Our wide range of tools helps architectural glass fabrication plants, curtain wall system installers, and furniture makers who want to improve their production.

We are a well-known stained glass cutting machine maker that designs equipment, installs it, trains users, and offers ongoing technical support. HUASHIL is a popular partner for glass production plants around the world because we are dedicated to quality and new ideas.

Discover how HUASHIL's advanced automation technology can transform your glass cutting operations. Contact us at salescathy@sdhuashil.com to discuss your specific requirements and learn about our comprehensive product offerings. Visit huashil.com for detailed technical specifications and application examples that demonstrate our equipment's capabilities.

References

1. Smith, Robert J. "Advanced Glass Processing Technologies in Modern Manufacturing." Journal of Industrial Glass Engineering, Vol. 42, No. 3, 2023, pp. 145-162.

2. Chen, Maria L. "Automation in Architectural Glass Fabrication: Efficiency and Quality Improvements." Glass Industry Technical Review, Vol. 28, No. 7, 2023, pp. 89-104.

3. Thompson, David K. "Safety Protocols for Automated Glass Cutting Equipment." Industrial Safety Quarterly, Vol. 15, No. 2, 2023, pp. 67-81.

4. Williams, Sarah M. "Economic Analysis of Glass Cutting Automation in Small to Medium Manufacturing." Manufacturing Technology Today, Vol. 31, No. 4, 2023, pp. 112-128.

5. Lopez, Carlos R. "Precision Control Systems for Glass Processing Equipment." Automation Engineering Review, Vol. 19, No. 6, 2023, pp. 203-219.

6. Johnson, Patricia A. "Maintenance Strategies for Industrial Glass Cutting Machinery." Equipment Reliability Journal, Vol. 24, No. 1, 2023, pp. 45-58.